Professional Documents

Culture Documents

04 Sisprod - Line Balancing

04 Sisprod - Line Balancing

Uploaded by

Eko Adhitya WarmanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

04 Sisprod - Line Balancing

04 Sisprod - Line Balancing

Uploaded by

Eko Adhitya WarmanCopyright:

Available Formats

04 04

KESEIMBANGAN KESEIMBANGAN LINTASAN LINTASAN

Presentasi Kuliah

TKI-313 Sistem Produksi

Jurusan Teknik Universitas Muhammadiyah Surakarta

Dosen : Much Djunaidi

Manual Assembly Lines

Sections:

1. Fundamentals of Manual Assembly

Lines

2. Analysis of Single Model Assembly

Lines

Chapter 4

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Lines

3. Line Balancing Algorithms

4. Other Considerations in Assembly

Line Design

5. Alternative Assembly Systems

Manual Assembly Lines

Work systems consisting of multiple workers organized to

produce a single product or a limited range of products

Assembly workers perform tasks at workstations located

along the line-of-flow of the product

Usually a powered conveyor is used

Some of the workstations may be equipped with portable

powered tools.

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

powered tools.

Factors favoring the use of assembly lines:

High or medium demand for product

Products are similar or identical

Total work content can be divided into work elements

To automate assembly tasks is impossible

Why Assembly Lines are Productive

Specialization of labor

When a large job is divided into small tasks and each

task is assigned to one worker, the worker becomes

highly proficient at performing the single task

(Learning curve)

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Interchangeable parts

Each component is manufactured to sufficiently close

tolerances that any part of a certain type can be

selected at random for assembly with its mating

component.

Thanks to interchangeable parts, assemblies do not

need fitting of mating components

Some Definitions

Work flow

Each work unit should move steadily along the line

Line pacing

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Workers must complete their tasks within a certain

cycle time, which will be the pace of the whole line

Manual Assembly Line

A production line that consists of a sequence of

workstations where assembly tasks are

performed by human workers

Products are assembled as they move along

the line

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

the line

At each station a portion of the total work content is

performed on each unit

Base parts are launched onto the beginning of

the line at regular intervals (cycle time)

Workers add components to progressively build the

product

Manual Assembly Line

Configuration of an n-workstation manual assembly line

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

The production rate of an assembly line is determined by

its slowest station.

Assembly workstation: A designated location along the

work flow path at which one or more work elements are

performed by one or more workers

Two assembly

operators working

on an engine

assembly line

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

assembly line

(photo courtesy of

Ford Motor

Company)

Manning level

There may be more than one worker per

station.

Utility workers: are not assigned to

specific workstations.

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

specific workstations.

They are responsible for

(1) helping workers who fall behind,

(2) relieving for workers for personal breaks,

(3) maintenance and repair

Manning level

Average manning level:

where

n

w w

M

n

i

i u

=

+

=

1

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

where

M=average manning level of the line,

w

u

=number of utility workers assigned to the system,

n=number of workstations,

w

i

=number of workers assigned specifically to station

i for i=1,,n

Work Transport Systems-Manual Methods

Manual methods

Work units are moved between stations by the

workers (by hand) without powered conveyor

Problems:

Starving of stations

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

The assembly operator has completed the assigned

task on the current work unit, but the next unit has not

yet arrived at the station

Blocking of stations

The operator has completed the assigned task on the

current work unit but cannot pass the unit to the

downstream station because that worker is not yet

ready to receive it.

Work Transport Systems-Manual Methods

To reduce starving,

use buffers

To prevent blocking,

provide space between upstream and downstream

stations.

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

stations.

But both solutions can result in higher WIP,

which is economically undesirable.

Work Transport Systems-Mechanized

Methods

Continuously moving conveyor: operates at constant velocity

1. Work units are fixed to the conveyor

The product is large and heavy

Worker moves along with the product

2. Work units are removable from the conveyor

Work units are small and light

Workers are more flexible compared to synchronous lines, less flexible than

asynchronous lines

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Synchronous transport (intermittent transport stop-and-go

line): all work units are moved simultaneously between stations.

Problem:

Task must be completed within a certain time limit. Otherwise the line

produces incomplete units;

Excessive stress on the assembly worker.

Not common for manual lines (variability), but often ideal for automated

production lines

Asynchronous transport : a work unit leaves a given station when

the assigned task is completed.

Work units move independently, rather than synchronously (most flexible one).

Variations in worker task times

Small queues in front of each station.

Coping with Product Variety

Single model assembly line (SMAL)

Every work unit is the same

Batch model assembly line (BMAL ) multiple model

line

Two or more different products

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Products are so different that they must be made in

batches with setup between batches

Mixed model assembly line (MMAL)

Two or more different models

Differences are slight so models can be made

simultaneously with no setup time (no need for batch

production)

Coping with Product Variety

Advantages of mixed models over batch order models

No production time is lost during changeovers

High inventories due to batch ordering are avoided

Production rates of different models can be adjusted as

product demand changes.

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

product demand changes.

Disadvantages of mixed models over batch order models

Each station is equipped to perform variety of tasks (costly)

Scheduling and logistic activities are more difficult in this

type of lines.

Analysis of Single Model Lines

The formulas and the algorithms in this section are

developed for single model lines, but they can be

extended to batch and mixed models.

The assembly line must be designed to achieve a

production rate sufficient to satisfy the demand.

Demand rate production ratecycle time

Annual demand D must be reduced to an hourly

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Annual demand D

a

must be reduced to an hourly

production rate R

p

where

D

a

= annual demand

R

p

= hourly production rate

S

w

= number of shifts/week

H

sh

= number of hours/shift

sh w

a

p

H S

D

R

52

=

Determining Cycle Time

Now our aim is to convert production rate, R

p

, to cycle time,

T

c

.

One should take into account that some production time will

be lost due to

equipment failures

power outages,

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

power outages,

material unavailability,

quality problems,

labor problems.

Line efficiency (uptime proportion): only a certain proportion

of the shift time will be available.

where production rate, R

p

, is converted to a cycle time, T

c

,

accounting for line efficiency, E.

p

c

R

E

T

60

=

Number of Stations Required

Work content time (T

wc

): The total time of all work

elements that must be performed to produce one unit

of the work unit.

The theoretical minimum number of stations that will

be required to on the line to produce one unit of the

work unit, w

*

:

>

T

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

w

*

= Minimum Integer >

where

T

wc

= work content time, min;

T

c

= cycle time, min/station

If we assume one worker per station then this gives the

minimum number of workers

c

wc

T

T

Theoretical Minimum Not Possible

Repositioning losses: Some time will be lost

at each station every cycle for repositioning the

worker or the work unit; thus, the workers will

not have the entire T

c

each cycle

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Line balancing problem (imperfect

balancing): It is not possible to divide the work

content time evenly among workers, and some

workers will have an amount of work that is

less than T

c

Repositioning Losses

Repositioning losses occur on a production

line because some time is required each

cycle to reposition the worker, the work unit,

or both

On a continous transport line, time is required

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

On a continous transport line, time is required

for the worker to walk from the unit just

completed to the the upstream unit entering the

station

In conveyor systems, time is required to

remove work units from the conveyor and

position it at the station for worker to perform

his task.

Repositioning Losses

Repositioning time = time available each

cycle for the worker to position = T

r

Service time = time available each cycle for

the worker to work on the product = T

s

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Service time T

s

= Max{T

si

} T

c

T

r

where T

si

= service time for station i, i=1,2,..,n

Repositioning efficiency E

r

=

c

r c

c

s

T

T T

T

T

=

Cycle Time on an Assembly Line

Components of cycle time at several stations on

a manual assembly line

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

T

si

=service time, T

r

=repositioning time

Line Balancing Problem

Given:

The total work content consists of many distinct

work elements

The sequence in which the elements can be

performed is restricted

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

performed is restricted

The line must operate at a specified cycle time

(=service time + repositioning time)

The Problem:

To assign the individual work elements to

workstations so that all workers have an equal

amount of work to perform

Assumptions About Work Element Times

1. Element times are constant values

But in fact they are variable

2. Work element times are additive

The time to perform two/more work The time to perform two/more work

elements in sequence is the sum of the

individual element times

Additivity assumption can be violated (due

to motion economies)

Work Element Times

Total work content time T

wc

T

wc

=

where T

ek

= work element time for element k

Work elements are assigned to station i that add up to

=

e

n

k

ek

T

1

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Work elements are assigned to station i that add up to

the service time for that station

T

si

=

The station service times must add up to the total work

content time

T

wc

=

ei k

ek

T

=

n

i

si

T

1

Constraints of Line Balancing Problem

Different work elements require different times.

When elements are grouped into logical tasks and

assigned to workers, the station service times, T

si

, are

likely not to be equal.

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Simply because of the variation among work element

times, some workers will be assigned more work.

Thus, variations among work elements make it difficult to

obtain equal service times for all stations.

Precedence Constraints

Some elements must be done before the

others.

Restrictions on the order in which work

elements can be performed

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

elements can be performed

Can be represented graphically (precedence

diagram)

Example:

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Grommet : sealant like ring

Example:

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Grommet : sealant like ring

Example: A problem for line balancing

Given: The previous precedence diagram and the

standard times. Annual demand=100,000 units/year. The

line will operate 50 wk/yr, 5 shifts/wk, 7.5 hr/shift. Uptime

efficiency=96%. Repositioning time lost=0.08 min.

Determine

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Determine

(a) total work content time,

(b) required hourly production rate to achieve the annual

demand,

(c) cycle time,

(d) theoretical minimum number of workers required on

the line,

(e) service time to which the line must be balanced.

Example: Solution

(a) The total work content time is the sum of the work

element times given in the table

T

wc

=4.0 min

(b) The hourly production rate

units/hr 33 . 53

) 5 . 7 )( 5 ( 50

000 , 100

= =

p

R

=

=

e

n

k

ek wc

T T

1

sh w

a

p

H S

D

R

50

=

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

(c) The corresponding cycle time with an uptime

efficiency of 96%

(d) The minimum number of workers:

w* = (Minimum Integer > 4.0 /1.08=3.7)=4 workers

(e) The available service time

T

s

=1.08-0.08=1.00 min

min 08 . 1

33 . 53

) 96 . 0 ( 60

= =

c

T

p

c

R

E

T

60

=

c

wc

T

T

w = *

r c s

T T T =

Measures of Balance Efficiency

It is almost imposible to obtain a perfect line balance

Line balance efficiency, E

b

:

E

b

= Perfect line: E

b

= 1

s

wc

wT

T

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Balance delay, d:

d = Perfect line: d = 0

Note that E

b

+ d = 1 (they are complement of each

other)

s

s

wc s

wT

T wT

Overall Efficiency

Factors that reduce the productivity of a

manual line

Line efficiency (Availability), E,

Repositioning efficiency (repositioning), E

r

,

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Repositioning efficiency (repositioning), E

r

,

Balance efficiency (balancing), E

b

,

Overall Labor efficiency on the assembly line =

b r

E E E

c

r c

c

s

r

T

T T

T

T

E

= =

s

wc

b

wT

T

E =

p

c

R

E

T

60

=

Skip - Worker Requirements

Skip this part

The actual number of workers on the

assembly line is given by:

w = Min Int >

wc wc

wc p

T E

T

T E E

T

E EE

T R

= =

60

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

w = Min Int >

where

w=number of workers required

R

p

=hourly production rate, units/hr

T

wc

=work content time per product, min/unit

c

r c

c

s

r

T

T T

T

T

E

= =

s

wc

b

wT

T

E =

s b c b r b r

T E T E E E EE

= =

60

p

c

R

E

T

60

=

Continously moving conveyors

- Workstation considerations

Total length of the assembly line

where L=length of the assembly line, m: L

si

=length of station i, m

Constant speed conveyor: (if the base parts remain fixed during

=

=

n

i

i

s

L L

1

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

their assembly)

Feed rate

f

p

=1/T

c

where f

p

=feed rate on the line, products/min

Center-to-center spacing between base parts

s

p

=v

c

/f

p

=v

c

T

c

where s

p

= center-to-center spacing between base parts, m/part and

v

c

=velocity of the conveyor, m/min

Continously moving conveyors

- Tolerance Time

Defined as the time a work unit spends inside the

boundaries of the workstation

Provides a way to allow for product-to-product variations

in task times at a station

L

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

T

t

=

where

T

t

= tolerance time, min;

L

s

= station length, m (ft);

v

c

= conveyor speed, m/min (ft/min)

c

s

v

L

Continously moving conveyors

-Total Elapsed Time

The time a work unit spends on the assembly

line.

ET =

t

c

nT

v

L

=

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

where

ET = total elapsed time, min;

T

t

= tolerance time, min;

L = length of the assembly line, m (ft);

v

c

= conveyor speed, m/min (ft/min)

Line Balancing Objective

To distribute the total work content on the assembly line

as evenly as possible among the workers

Minimize (wT

s

T

wc

)

or

Minimize

( )

w

si s

T T

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Minimize

Subject to:

(1)

(2) all precedence requirements are obeyed

s

i k

ek

T T s

e

( )

=

i

si s

T T

1

Line Balancing Algorithms Heuristics

1. Largest candidate rule

2. Kilbridge and Wester method

3. Ranked positional weights method, also

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

3. Ranked positional weights method, also

known as the Helgeson and Birne method

In the following descriptions, assume one

worker per workstation

Largest Candidate Rule

List all work elements in descending order based on their

T

ek

values; then,

1. Start at the top of the list and selecting the first element

that satisfies precedence requirements and does not

cause the total sum of T

ek

to exceed the allowable T

s

value

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

When an element is assigned, start back at the top of the

list and repeat selection process

2. When no more elements can be assigned to the current

station, proceed to next station

3. Repeat steps 1 and 2 until all elements have been

assigned to as many stations as needed

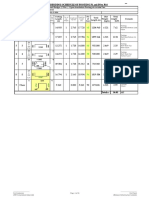

Solution for Largest Candidate Rule

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Example:

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Grommet : sealant like ring

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Solution for Largest Candidate Rule

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Solution for Largest Candidate Rule

Physical layout of workstations and assignment

of elements to stations using the largest

candidate rule

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Ranked Positional Weights Method

A ranked position weight (RPW) is calculated for each

work element

RPW for element k is calculated by summing the T

e

values for all of the elements that follow element k in the

diagram plus T

ek

itself

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

diagram plus T

ek

itself

Work elements are then organized into a list according to

their RPW values, starting with the element that has the

highest RPW value

Proceed with same steps 1, 2, and 3 as in the largest

candidate rule

Solution for Ranked Positional Weights

Method

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Example:

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Grommet : sealant like ring

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Other Considerations in Line Design

Methods analysis

To analyze methods at bottleneck or other troublesome

workstations

improved motions,

better workplace layout,

special tools to facilitate manual work elements

product design

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Utility workers

To relieve congestion at stations that are temporarily

overloaded

Preassembly of components

Prepare certain subassemblies off-line to reduce work

content time on the final assembly line

Other Considerations - continued

Storage buffers between stations

To permit continued operation of certain sections of

the line when other sections break down

To smooth production between stations with large

task time variations

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Parallel stations

To reduce time at bottleneck stations that have

unusually long task times

Worker (Labor) Shifting with crosstraining

Temporary (or periodic) relocation to expedite or to

reduce subassembly stocks

Most Follower Rule

1

4

3

8

9 10

8

5

3

5

6 10

Item i

Most Follower

1 9

2 5

3 4

4 4

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

6

5

7 2

4

9

4

6 10

6

19 19 19 19

5 4

6 4

7 3

8 3

9 2

10 1

19/19 16/19 15/19 10/19

We omit

Worker Requirements in 4.2.2

4.3.2 Kilbridge and Western Method

4.5 Alternative Assembly Systems

Work Systems and the Methods, Measurement, and Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

4.5 Alternative Assembly Systems

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- IMO Resolution 1050 - Entry Into Enclosed Spaces PDFDocument14 pagesIMO Resolution 1050 - Entry Into Enclosed Spaces PDFpgupta71No ratings yet

- Analytical Chemistry Chapter 2 by Rey CapangpanganDocument13 pagesAnalytical Chemistry Chapter 2 by Rey CapangpanganDrakeNo ratings yet

- Method 1: IB Questionbank Mathematics Higher Level 3rd Edition 1Document8 pagesMethod 1: IB Questionbank Mathematics Higher Level 3rd Edition 1Muhamad Zahwan AnwarNo ratings yet

- Jon Krohn Metis Deep Learning 2017-05-01Document107 pagesJon Krohn Metis Deep Learning 2017-05-01Arnaldo Preso De LigaNo ratings yet

- Quick Specs: HP EliteDisplay E222 21.5-Inch MonitorDocument11 pagesQuick Specs: HP EliteDisplay E222 21.5-Inch MonitorRudolph RednoseNo ratings yet

- CSJ HydraulicDocument43 pagesCSJ HydraulicВаня БойкоNo ratings yet

- Notes On Hegel's Shorter LogicDocument13 pagesNotes On Hegel's Shorter LogicShaun PoustNo ratings yet

- A Legend of The Northland StuffDocument4 pagesA Legend of The Northland StuffAngel B.No ratings yet

- JTEC Manuscript Template v5Document3 pagesJTEC Manuscript Template v5علي عدنانNo ratings yet

- Electrical Conductivity of Aqueous SolutionsDocument1 pageElectrical Conductivity of Aqueous SolutionsTing-Ting PanNo ratings yet

- VESTA-80-Technical-manual-MIU VE80 GB - 002 05 17 PDFDocument28 pagesVESTA-80-Technical-manual-MIU VE80 GB - 002 05 17 PDFFrancisco LercariNo ratings yet

- Beating The Bonk QuestionsDocument1 pageBeating The Bonk Questionst3xxaNo ratings yet

- Mercedes Actros Head FAHES - Vehicle Inspection Result 25-02-24Document1 pageMercedes Actros Head FAHES - Vehicle Inspection Result 25-02-24Sreeja LinNo ratings yet

- Conductive Polymer Based On Polyaniline-Eggshell Powder (PANI-ESP) CompositesDocument17 pagesConductive Polymer Based On Polyaniline-Eggshell Powder (PANI-ESP) CompositesSergioNo ratings yet

- Fitgurlmel's 365 Food Guide by Melissa AlcantaraDocument27 pagesFitgurlmel's 365 Food Guide by Melissa AlcantaraSinem YukselNo ratings yet

- Basics of Scientific Writing, Scientific Research, and Elementary Data AnalysisDocument12 pagesBasics of Scientific Writing, Scientific Research, and Elementary Data Analysisburhan sabirNo ratings yet

- Catabolism of HemeDocument10 pagesCatabolism of Hemermsaeed09No ratings yet

- What Is Galactic Evolution?: Milky WayDocument12 pagesWhat Is Galactic Evolution?: Milky WayPROF RAJESH DUBEYNo ratings yet

- Lecture-5 - Classification of Process Variables - Control StrategiesDocument18 pagesLecture-5 - Classification of Process Variables - Control StrategiesKshitij SoniNo ratings yet

- Tagburos FinalDocument46 pagesTagburos FinalZiedwrick Ayson DicarNo ratings yet

- LAB14Document5 pagesLAB14Aizaz HabibNo ratings yet

- BBS of All Pier Foundations of MAYARDocument16 pagesBBS of All Pier Foundations of MAYARAmanjot Singh0% (1)

- Property Inspection ChecklistDocument11 pagesProperty Inspection ChecklistVj BrillantesNo ratings yet

- Blind StickDocument2 pagesBlind Stickishanchaudhary764No ratings yet

- Comparative Study Based On Thermal Efficiency of Solar Air HeatersDocument6 pagesComparative Study Based On Thermal Efficiency of Solar Air Heatershicham El FeroualiNo ratings yet

- CB 3Document3 pagesCB 3badisa booksNo ratings yet

- Transistor-Transistor Logic (TTL or T L) : ExerciseDocument10 pagesTransistor-Transistor Logic (TTL or T L) : ExerciseHassan allaNo ratings yet

- Fluidization Laboratory of SaskatchewanDocument4 pagesFluidization Laboratory of SaskatchewanTae Vorachit UmnuaypornNo ratings yet

- ZoneID and PoreHD ServiceDocument1 pageZoneID and PoreHD ServicedownbuliaoNo ratings yet

- Assignment 1 Art HistoryDocument4 pagesAssignment 1 Art HistoryFarhanNo ratings yet