Professional Documents

Culture Documents

Inspection and Test Plan For Shell and Tube Heat Exchanger

Inspection and Test Plan For Shell and Tube Heat Exchanger

Uploaded by

tomychalilCopyright:

Available Formats

You might also like

- Aci 350-3 2020Document56 pagesAci 350-3 2020S Dutta100% (9)

- Toolroom Selection Chart 7505Document1 pageToolroom Selection Chart 7505tomychalilNo ratings yet

- ITP New Pressure VesselDocument2 pagesITP New Pressure Vesselyosafateden60% (5)

- Inspection and Test Plan - Pressure Vessel Fabrication (ITP)Document9 pagesInspection and Test Plan - Pressure Vessel Fabrication (ITP)Senthil Kumaran100% (2)

- ITP ValveDocument5 pagesITP ValveJayaram MV100% (3)

- Inspection and Test Plan For New Pressure VesselDocument2 pagesInspection and Test Plan For New Pressure VesselCak Nhass0% (1)

- Underground Piping Pressure Test RecordDocument1 pageUnderground Piping Pressure Test RecordPaulSwinbankNo ratings yet

- Contractor Quality Control Plan For Storage Tank ErectionDocument2 pagesContractor Quality Control Plan For Storage Tank ErectionHamid Alilou100% (5)

- Air Cooled Heat Exchanger Inspection and Test Plan SampleDocument4 pagesAir Cooled Heat Exchanger Inspection and Test Plan Samplemkash028No ratings yet

- ITP For Pressure Vessel PDFDocument4 pagesITP For Pressure Vessel PDFErica MartinNo ratings yet

- 5 - Tank Itp - Inspection & Test Plan For TanksDocument9 pages5 - Tank Itp - Inspection & Test Plan For Tanksmandi100% (1)

- PWHT ProcedureDocument11 pagesPWHT Proceduretbmari100% (15)

- ITP For Boiler ErectionDocument6 pagesITP For Boiler ErectionUmair Awan100% (2)

- Inspection and Test Plan For Fire Tube BoilerDocument4 pagesInspection and Test Plan For Fire Tube BoilerJayaram MV100% (1)

- Inspection and Test Plan For Pressure VesselDocument4 pagesInspection and Test Plan For Pressure VesselNurul Amirah Princesza100% (3)

- Inspection and Test Plan For Storage TankDocument7 pagesInspection and Test Plan For Storage Tankgst ajah100% (1)

- Inspection and Test Plan For Storage TankDocument6 pagesInspection and Test Plan For Storage Tankpluton1954No ratings yet

- Inspection and Test Plan For Fan and Blower PDFDocument5 pagesInspection and Test Plan For Fan and Blower PDFAulia RahmanNo ratings yet

- Pressure Vessel Itp PDFDocument4 pagesPressure Vessel Itp PDFkorbelNo ratings yet

- Inspection and Test Plan For Line Pipe PDFDocument4 pagesInspection and Test Plan For Line Pipe PDFsherviny100% (1)

- Sample ItpDocument4 pagesSample ItpWijayanto BekasiNo ratings yet

- Inspection and Test Plan For Fin Tube Heat ExchangerDocument4 pagesInspection and Test Plan For Fin Tube Heat ExchangerSenthil Kumar100% (2)

- Itp - Tanks - 01Document10 pagesItp - Tanks - 01ravigurajapuNo ratings yet

- Storage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFRadhakrishna VachaNo ratings yet

- Hydrotest ReportDocument1 pageHydrotest ReportEIWAA100% (1)

- Hydro Vs PneumaticDocument4 pagesHydro Vs PneumaticAnonymous rYZyQQot55No ratings yet

- Penumatic TestDocument10 pagesPenumatic TestahmadNo ratings yet

- Quality Control Plan (QCP) For Ammonia Pressure Vessel: Before ManufacturingDocument3 pagesQuality Control Plan (QCP) For Ammonia Pressure Vessel: Before ManufacturingFaisal Awad100% (1)

- Hydrotest ProcedureDocument12 pagesHydrotest Procedurealex_feryando42100% (1)

- Procedure For WQTDocument13 pagesProcedure For WQTwalitedisonNo ratings yet

- Bolt Tightening ReportDocument1 pageBolt Tightening ReportMahfudRido'iRonggomaniaNo ratings yet

- Inspection and Test Plan Rev.0Document3 pagesInspection and Test Plan Rev.0คุณพ่อน้อง บิ๊กบอสNo ratings yet

- ITP For Pressure Vessel - Static EquipmentDocument8 pagesITP For Pressure Vessel - Static EquipmentReduddboyNo ratings yet

- Material Traceability Inspection ReportDocument32 pagesMaterial Traceability Inspection ReportBalmiki SinghNo ratings yet

- Api 653 Report-Hydrolic Test PDFDocument12 pagesApi 653 Report-Hydrolic Test PDFnaoufel1706No ratings yet

- ITP SampleDocument6 pagesITP SampleMat RidhanNo ratings yet

- Hydrostatic Test ReportDocument1 pageHydrostatic Test ReportibicengNo ratings yet

- ITP For Field Erected Tank Rev ADocument9 pagesITP For Field Erected Tank Rev AHoang Tuan Kiet100% (1)

- Itp Existing Pressure VesselDocument3 pagesItp Existing Pressure Vesselmuhammad afrizal100% (1)

- Minimum Number of Thermocouples-Local PWHTDocument5 pagesMinimum Number of Thermocouples-Local PWHTPradip Goswami100% (1)

- j34 A Doc Ve 678138 Pmi ProcedureDocument20 pagesj34 A Doc Ve 678138 Pmi Proceduremohdbaquer_024100% (1)

- Visual Inspection of Tanks & Pressure VesselsDocument29 pagesVisual Inspection of Tanks & Pressure VesselsShahul Hameed Razik100% (5)

- Sample WPS 1Document13 pagesSample WPS 1waqas pirachaNo ratings yet

- Pmi ProcedureDocument8 pagesPmi Proceduresaurabh joshiNo ratings yet

- ITP-P-001 ITP For Above Ground Piping Rev. ADocument9 pagesITP-P-001 ITP For Above Ground Piping Rev. APhong Đỗ100% (1)

- Pickling Procedure 20 - 08Document2 pagesPickling Procedure 20 - 08Siriepathi SeetharamanNo ratings yet

- B2020-TDC-VF-009 Vessel Fabrication R0Document5 pagesB2020-TDC-VF-009 Vessel Fabrication R0Ramalingam PrabhakaranNo ratings yet

- ITP Boiler PDFDocument13 pagesITP Boiler PDFMúhámmád ÁbrorNo ratings yet

- Pressure Vessel Repair ProcedureDocument7 pagesPressure Vessel Repair ProcedureAndy UgohNo ratings yet

- WPS - Smaw - 2Document6 pagesWPS - Smaw - 2Harkesh RajputNo ratings yet

- Welcome To: Training Program On GUIDED TOUR OF ASME CodesDocument120 pagesWelcome To: Training Program On GUIDED TOUR OF ASME CodesAndri Konyoa KonyoaNo ratings yet

- ITP For PipingDocument5 pagesITP For PipingAldeline SungahidNo ratings yet

- Tube To Tube SheetDocument9 pagesTube To Tube Sheetcmpatel_00100% (2)

- Inspection and Test Plan For Pressure VesselDocument4 pagesInspection and Test Plan For Pressure Vesselbaskaran ayyapparajNo ratings yet

- Itp Vessel PDFDocument4 pagesItp Vessel PDFBUDAPESNo ratings yet

- Pressure Vessel Inspection and Test Plan SampleDocument4 pagesPressure Vessel Inspection and Test Plan SampleRanjan KumarNo ratings yet

- Pressure Vessel Inspection and Test Plan SampleDocument4 pagesPressure Vessel Inspection and Test Plan SampleTYO WIBOWONo ratings yet

- NDT Map Itp Pressure VesselDocument4 pagesNDT Map Itp Pressure VesselSYED FADZIL SYED MOHAMEDNo ratings yet

- Pressure Vessel Inspection and Test Plan SampleDocument4 pagesPressure Vessel Inspection and Test Plan SampleAndika PusbiantoNo ratings yet

- Pressure Vessel Inspection and Test Plan Sample: WWW - Inspection-For-Industry.c OmDocument4 pagesPressure Vessel Inspection and Test Plan Sample: WWW - Inspection-For-Industry.c OmMuh FarhanNo ratings yet

- Itp VesselDocument4 pagesItp VesselHakim BaihaqiNo ratings yet

- Inspection and Test Plan For Valve: Before ManufacturingDocument2 pagesInspection and Test Plan For Valve: Before ManufacturingkarthikNo ratings yet

- SOP-Attachment 3b - CNL JV-EGTL SWP 401 - Permit To Work - Dec12Document20 pagesSOP-Attachment 3b - CNL JV-EGTL SWP 401 - Permit To Work - Dec12tomychalilNo ratings yet

- Sos SystemDocument50 pagesSos SystemtomychalilNo ratings yet

- Vickers Calibration DetailsDocument1 pageVickers Calibration DetailstomychalilNo ratings yet

- Sos SystemDocument50 pagesSos SystemtomychalilNo ratings yet

- Dr2 - Spec - Non-Destructive Examination Req of PipingDocument20 pagesDr2 - Spec - Non-Destructive Examination Req of Pipingtomychalil100% (1)

- Annex C Robust Analysis: (Normative)Document1 pageAnnex C Robust Analysis: (Normative)tomychalil0% (1)

- Annex To Travellers Guidelines 28-10-2018Document25 pagesAnnex To Travellers Guidelines 28-10-2018tomychalilNo ratings yet

- CNC Table Waterjet Cutting MachineDocument9 pagesCNC Table Waterjet Cutting MachinetomychalilNo ratings yet

- Interlaboratory Comparison of FatigueDocument26 pagesInterlaboratory Comparison of FatiguetomychalilNo ratings yet

- SADCAS F 61e - Proficiency Testing Requirements ISO-IEC 17025-2005 Clause 5.9 & SADCAS Requirements (Issue 2)Document3 pagesSADCAS F 61e - Proficiency Testing Requirements ISO-IEC 17025-2005 Clause 5.9 & SADCAS Requirements (Issue 2)tomychalilNo ratings yet

- Temperature Recording SystemDocument12 pagesTemperature Recording SystemtomychalilNo ratings yet

- Admission Instruction Ug18Document2 pagesAdmission Instruction Ug18tomychalilNo ratings yet

- Surface Grinding 440 C StainlessDocument3 pagesSurface Grinding 440 C StainlesstomychalilNo ratings yet

- Heilbron PDFDocument13 pagesHeilbron PDFAilu GeraghtyNo ratings yet

- S.No Author Book No. List of Library Books/ Police Rule/Law /training Title Publish of YearDocument7 pagesS.No Author Book No. List of Library Books/ Police Rule/Law /training Title Publish of YearenergyrockfulNo ratings yet

- V Aid Ya Rat Nam ProductsDocument10 pagesV Aid Ya Rat Nam Productsdavid400No ratings yet

- Tieng Anh de Thi Chinh Thuck23ma de 414 28202323209Document4 pagesTieng Anh de Thi Chinh Thuck23ma de 414 28202323209Thư BùiNo ratings yet

- The Wonderful World of Adam Smith (Topic 2 Final)Document28 pagesThe Wonderful World of Adam Smith (Topic 2 Final)CarlosdaMaiaNo ratings yet

- Sports WritingDocument7 pagesSports Writingjeffrey catacutan flores70% (10)

- SBHS1Document5 pagesSBHS1Rahul PancholiNo ratings yet

- Programas Desinstalados No BlecauteDocument2 pagesProgramas Desinstalados No BlecauteubirajaraNo ratings yet

- Expenditure Minimization ProblemDocument5 pagesExpenditure Minimization Problemkin0013No ratings yet

- Joint Moment Generating Function of R.V.'S and Equality in DistributionDocument15 pagesJoint Moment Generating Function of R.V.'S and Equality in Distributionpankaj kumarNo ratings yet

- FIIT Thermochemistry FinalDocument41 pagesFIIT Thermochemistry FinalGoutam Pradhan0% (1)

- SPE 86863 Health Risk Assessment in Oil and Gas Exploration: Siesmic WorkDocument6 pagesSPE 86863 Health Risk Assessment in Oil and Gas Exploration: Siesmic WorkWaleed Barakat MariaNo ratings yet

- ManualDocument158 pagesManualDimitri GutiérrezNo ratings yet

- Module 6 Learning TasksDocument4 pagesModule 6 Learning TasksMarie Pearl NarioNo ratings yet

- Destructive Inspection-IDocument26 pagesDestructive Inspection-IVishal KarmakarNo ratings yet

- 190687-MR-1100-001.06 - Topographical Survey CMS-830-03-SP-10001Document13 pages190687-MR-1100-001.06 - Topographical Survey CMS-830-03-SP-10001bam494242No ratings yet

- Multiply Two 8 Bit NumbersDocument3 pagesMultiply Two 8 Bit NumbersVeda VyasNo ratings yet

- Cu AssignmentDocument3 pagesCu Assignmentharsh abrolNo ratings yet

- 10 11648 J Hss 20150301 14 PDFDocument5 pages10 11648 J Hss 20150301 14 PDFArnel VillaflorNo ratings yet

- CV 07-05Document1 pageCV 07-05ritipiti14No ratings yet

- LSMW Long Text Load by Direct Input MethodDocument21 pagesLSMW Long Text Load by Direct Input MethodAnonymous CEG1Hiu1No ratings yet

- Conceptual Metaphor in ArchitectureDocument8 pagesConceptual Metaphor in ArchitectureKent NeoNo ratings yet

- ...Document437 pages...tjohns56No ratings yet

- Civil Engineering & Construction TechnologiesDocument2 pagesCivil Engineering & Construction TechnologiesKundan PrasadNo ratings yet

- Kate Chopin and Feminism: The Significance of Water: Brittany GrovesDocument8 pagesKate Chopin and Feminism: The Significance of Water: Brittany GrovesAnne Marinelle MontegrandeNo ratings yet

- Marking Period 1 7th Grade Science Honors ProjectDocument6 pagesMarking Period 1 7th Grade Science Honors Projectapi-159185230No ratings yet

- Resume of RamaraoDocument3 pagesResume of RamaraoEl Uday KumarNo ratings yet

- (Two Vol. Set - The Pilgrimage of Reason - The Odyssey of Spirit) ) H. S. Harris-Hegel's Ladder. 1-Hackett Pub Co Inc (1997)Document232 pages(Two Vol. Set - The Pilgrimage of Reason - The Odyssey of Spirit) ) H. S. Harris-Hegel's Ladder. 1-Hackett Pub Co Inc (1997)Gon za50% (2)

Inspection and Test Plan For Shell and Tube Heat Exchanger

Inspection and Test Plan For Shell and Tube Heat Exchanger

Uploaded by

tomychalilOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection and Test Plan For Shell and Tube Heat Exchanger

Inspection and Test Plan For Shell and Tube Heat Exchanger

Uploaded by

tomychalilCopyright:

Available Formats

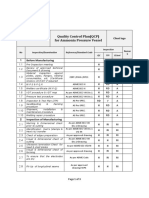

www.inspectionforindustry.

com

Remark

Manuf. TPI Client

1 PreInspectionMeeting Spec. Spec. MOM H H H

2

DWG,Design,

CalculationDocument

ASME,Spec ASME,Spec

DWG,

Calculationbook

H R A

3 WPS&PQR ASME ASMEIX WeldingBook H R A

4

WelderQualification

Certificates

ASME ASMEIX Certificates H R

5 NDTprocedure ASME ASMEV,VIII,IX Procedures H R A

6

NDEPersonnel

Certificates

ASME ASMEV Certificates H R

7

PWHTProcedure

(ifneeded)

ASME ASMEVIII Procedure H R A

8

HydroStaticTest

Procedure

ASME ASMEVIII Procedure H R A

9 PaintingProcedure ASME Spec. Procedure H R A

10 MaterialCertificates ASME ASMEII

OriginalMaterial

Certificates

H R

11

Storageofrawmaterial

andWelding

ASME ASME H W

12

Visual,Dimensionand

MarkingControl

ASMEVIII ASMEVIII Report H W

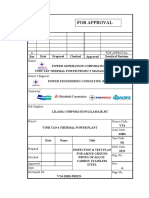

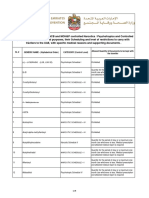

InspectionandTestPlanforShellandTubeHeatExchanger

BeforeManufacturing

Materials

DuringManufacturingShellandChannel

ActivityBy

No. InspectionandTestPlan ReferenceDocument AcceptanceCriteria VerifyingDocument

1

www.inspectionforindustry.com

13

Transferringofmarking

Material

ASMEVIII ASMEVIII Report H SW

14

Cutting&Edge

Preparation

DWG DWG H SW

15

Headformingand

DimensionCheck

DWG DWG,ASMEVIII Report H W

16

CheckofRollingfor

Shell

DWG DWG,ASMEVIII H SW

17

CheckofWeldingplan

withWPS

DWG/WPS WPS/DWG H SW

18

FitUp&welding(shell

toshell)

DWG/WPS WPS/DWG H SW

19 SecondRollingofShell DWG DWG,ASMEVIII Report H SW

20

FitUpHeadsto

Shell/Channel

DWG/WPS WPS/DWG H SW

21 DimentionCheck DWG/WPS WPS/DWG H SW

22

WeldingHeadto

Shell/Channel

DWG/WPS WPS/DWG H SW

23 VisualCheck DWG/WPS WPS/DWG H W

24 NDTTest(RT) NDTProcedure ASMEVIII Report H R

25

DimentionCheckBody

Flanges

DWG/WPS WPS/DWG H SW

26

FitUpBodyFlangesto

Shell/Channel

DWG/WPS WPS/DWG H SW

27 DimentionCheck DWG/WPS WPS/DWG H SW

28

WeldingBodyFlangesto

Shell/Channel

DWG/WPS WPS/DWG H SW

2

www.inspectionforindustry.com

29 VisualCheck DWG/WPS WPS/DWG H W

30 NDTTEST(RT) NDTProcedure ASMEVIII Report H R

31 FitUpNozzlestoFlange DWG/WPS WPS/DWG H SW

32 DimentionCheck DWG/WPS WPS/DWG H SW

33

WeldingNozzlesto

Flanges

DWG/WPS WPS/DWG H SW

34 VisualCheck DWG/WPS WPS/DWG H SW

35 NDTTest(RT) NDTProcedure ASMEVIII Report H R

36

FitUpNozzlestoShell&

Channel

DWG/WPS WPS/DWG H SW

37 DimensionCheck DWG/WPS WPS/DWG H W

38

WeldingNozzlesto

Shell/Channel

DWG/WPS WPS/DWG H SW

39 VisualCheck DWG/WPS WPS/DWG H SW

40 NDTTest(UT) DWG/WPS WPS/DWG Report H R

41

CuttingSubPeacesof

Saddle

DWG/WPS WPS/DWG H SW

42 DimensionCheck DWG/WPS WPS/DWG H W

43 WeldingSaddlePeaces DWG/WPS WPS/DWG H SW

44 VisualCheck DWG/WPS WPS/DWG H SW

3

www.inspectionforindustry.com

45

FitUpSaddletoWear

Plate

DWG/WPS WPS/DWG H SW

46 DimentionCheck DWG/WPS WPS/DWG H W

47

WeldingSaddletoWear

Plate

DWG/WPS WPS/DWG H SW

48 VisualCheck DWG/WPS WPS/DWG H SW

49 NDTTest(PT) NDTProcedure ASMEVIII Report H R

50

DIM.Checkoftubesheet,

BafflesandSupportPlates

DWG ASMEVIII H SW

51

DrillingTubesheet&

Baffles

DWG ASMEVIII H SW

52 Dimention&VisualCheck DWG ASMEVIII Report H W

53 Cuttingtubes&Spacers DWG ASMEVIII H SW

54

DimentionCheckofTubes

&TieRods&

Spacers

DWG ASMEVIII Report H R

55

FitUpTheTubeto

Tubesheet

DWG ASMEVIII H SW

56

DimensionCheckofTube

Bundle

DWG ASMEVIII H W

57 TubeExpanding DWG ASMEVIII Report H W

58

HydroStaticTest

Procedure ASMEVIII H H

FinalInspection

DuringManufacturingTubeBundle

4

www.inspectionforindustry.com

59

FinalDimentional&Visual

Check

DWG/Spec. ASMEVIII Report H H

60 PressureTest(Tube) Procedure ASMEVIII Report H H W

61

Completedraining

andDrying

Procedure ASMEVIII H SW

62

CleainingofInside

Surface

Procedure ASMEVIII H SW

63

SandBlasting

andPainting

Procedure SSPC Report H W

64

NamePlate,Tagging

andMarking

DWG Spec. Report H H

65 PreparationforShipment Spec. Spec. H SW

66 ReviewofFinalInspection

DWG/WPS/Welding

Map

ASMEVIII H H

67 IinspectionReleaseNote PackingList Spec. Report H H

Submitted

by

SW:SpotWitness=foritemswithspotwitnessmanufactureshallnotifyTPIinspectorasfulfillingthemonitoring;

ForexampleonerandomvisitforwholeUTtestsoroneortwovisitsforwholesurfacepreparationworksforpainting.

P.O:PurchaseOrder

MOM:MinuteofMeeting

Abbreviations:

H:HoldPoint=HoldontheproductiontillTPIInspectorperformsinspectionandsupervisetherequiredtest

W:WitnessPoint=ManufactureshallnotifyclientandTPIInspectorbutthereisnoholdontheproduction;

ClientcanwaivethisinspectionbasedonhisdiscretionandinformsTPIInspectoraccordingly.

R:DocumentReview=ReviewmeansReviewdocument,whichincludesofmaterialtestcertificates,WPS,PQR,NDTProceduresandetc.

A:Approval

Formoreinformationreviewfollwingarticles

5

www.inspectionforindustry.com

http://www.inspectionforindustry.com/heatexchangerinspection.html

http://www.inspectionforindustry.com/thirdpartyinspectionforshellandtubeheatexchanger.html

http://www.inspectionforindustry.com/inspectionandtestplanforshellandtubeheatexchanger.ht

6

You might also like

- Aci 350-3 2020Document56 pagesAci 350-3 2020S Dutta100% (9)

- Toolroom Selection Chart 7505Document1 pageToolroom Selection Chart 7505tomychalilNo ratings yet

- ITP New Pressure VesselDocument2 pagesITP New Pressure Vesselyosafateden60% (5)

- Inspection and Test Plan - Pressure Vessel Fabrication (ITP)Document9 pagesInspection and Test Plan - Pressure Vessel Fabrication (ITP)Senthil Kumaran100% (2)

- ITP ValveDocument5 pagesITP ValveJayaram MV100% (3)

- Inspection and Test Plan For New Pressure VesselDocument2 pagesInspection and Test Plan For New Pressure VesselCak Nhass0% (1)

- Underground Piping Pressure Test RecordDocument1 pageUnderground Piping Pressure Test RecordPaulSwinbankNo ratings yet

- Contractor Quality Control Plan For Storage Tank ErectionDocument2 pagesContractor Quality Control Plan For Storage Tank ErectionHamid Alilou100% (5)

- Air Cooled Heat Exchanger Inspection and Test Plan SampleDocument4 pagesAir Cooled Heat Exchanger Inspection and Test Plan Samplemkash028No ratings yet

- ITP For Pressure Vessel PDFDocument4 pagesITP For Pressure Vessel PDFErica MartinNo ratings yet

- 5 - Tank Itp - Inspection & Test Plan For TanksDocument9 pages5 - Tank Itp - Inspection & Test Plan For Tanksmandi100% (1)

- PWHT ProcedureDocument11 pagesPWHT Proceduretbmari100% (15)

- ITP For Boiler ErectionDocument6 pagesITP For Boiler ErectionUmair Awan100% (2)

- Inspection and Test Plan For Fire Tube BoilerDocument4 pagesInspection and Test Plan For Fire Tube BoilerJayaram MV100% (1)

- Inspection and Test Plan For Pressure VesselDocument4 pagesInspection and Test Plan For Pressure VesselNurul Amirah Princesza100% (3)

- Inspection and Test Plan For Storage TankDocument7 pagesInspection and Test Plan For Storage Tankgst ajah100% (1)

- Inspection and Test Plan For Storage TankDocument6 pagesInspection and Test Plan For Storage Tankpluton1954No ratings yet

- Inspection and Test Plan For Fan and Blower PDFDocument5 pagesInspection and Test Plan For Fan and Blower PDFAulia RahmanNo ratings yet

- Pressure Vessel Itp PDFDocument4 pagesPressure Vessel Itp PDFkorbelNo ratings yet

- Inspection and Test Plan For Line Pipe PDFDocument4 pagesInspection and Test Plan For Line Pipe PDFsherviny100% (1)

- Sample ItpDocument4 pagesSample ItpWijayanto BekasiNo ratings yet

- Inspection and Test Plan For Fin Tube Heat ExchangerDocument4 pagesInspection and Test Plan For Fin Tube Heat ExchangerSenthil Kumar100% (2)

- Itp - Tanks - 01Document10 pagesItp - Tanks - 01ravigurajapuNo ratings yet

- Storage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFRadhakrishna VachaNo ratings yet

- Hydrotest ReportDocument1 pageHydrotest ReportEIWAA100% (1)

- Hydro Vs PneumaticDocument4 pagesHydro Vs PneumaticAnonymous rYZyQQot55No ratings yet

- Penumatic TestDocument10 pagesPenumatic TestahmadNo ratings yet

- Quality Control Plan (QCP) For Ammonia Pressure Vessel: Before ManufacturingDocument3 pagesQuality Control Plan (QCP) For Ammonia Pressure Vessel: Before ManufacturingFaisal Awad100% (1)

- Hydrotest ProcedureDocument12 pagesHydrotest Procedurealex_feryando42100% (1)

- Procedure For WQTDocument13 pagesProcedure For WQTwalitedisonNo ratings yet

- Bolt Tightening ReportDocument1 pageBolt Tightening ReportMahfudRido'iRonggomaniaNo ratings yet

- Inspection and Test Plan Rev.0Document3 pagesInspection and Test Plan Rev.0คุณพ่อน้อง บิ๊กบอสNo ratings yet

- ITP For Pressure Vessel - Static EquipmentDocument8 pagesITP For Pressure Vessel - Static EquipmentReduddboyNo ratings yet

- Material Traceability Inspection ReportDocument32 pagesMaterial Traceability Inspection ReportBalmiki SinghNo ratings yet

- Api 653 Report-Hydrolic Test PDFDocument12 pagesApi 653 Report-Hydrolic Test PDFnaoufel1706No ratings yet

- ITP SampleDocument6 pagesITP SampleMat RidhanNo ratings yet

- Hydrostatic Test ReportDocument1 pageHydrostatic Test ReportibicengNo ratings yet

- ITP For Field Erected Tank Rev ADocument9 pagesITP For Field Erected Tank Rev AHoang Tuan Kiet100% (1)

- Itp Existing Pressure VesselDocument3 pagesItp Existing Pressure Vesselmuhammad afrizal100% (1)

- Minimum Number of Thermocouples-Local PWHTDocument5 pagesMinimum Number of Thermocouples-Local PWHTPradip Goswami100% (1)

- j34 A Doc Ve 678138 Pmi ProcedureDocument20 pagesj34 A Doc Ve 678138 Pmi Proceduremohdbaquer_024100% (1)

- Visual Inspection of Tanks & Pressure VesselsDocument29 pagesVisual Inspection of Tanks & Pressure VesselsShahul Hameed Razik100% (5)

- Sample WPS 1Document13 pagesSample WPS 1waqas pirachaNo ratings yet

- Pmi ProcedureDocument8 pagesPmi Proceduresaurabh joshiNo ratings yet

- ITP-P-001 ITP For Above Ground Piping Rev. ADocument9 pagesITP-P-001 ITP For Above Ground Piping Rev. APhong Đỗ100% (1)

- Pickling Procedure 20 - 08Document2 pagesPickling Procedure 20 - 08Siriepathi SeetharamanNo ratings yet

- B2020-TDC-VF-009 Vessel Fabrication R0Document5 pagesB2020-TDC-VF-009 Vessel Fabrication R0Ramalingam PrabhakaranNo ratings yet

- ITP Boiler PDFDocument13 pagesITP Boiler PDFMúhámmád ÁbrorNo ratings yet

- Pressure Vessel Repair ProcedureDocument7 pagesPressure Vessel Repair ProcedureAndy UgohNo ratings yet

- WPS - Smaw - 2Document6 pagesWPS - Smaw - 2Harkesh RajputNo ratings yet

- Welcome To: Training Program On GUIDED TOUR OF ASME CodesDocument120 pagesWelcome To: Training Program On GUIDED TOUR OF ASME CodesAndri Konyoa KonyoaNo ratings yet

- ITP For PipingDocument5 pagesITP For PipingAldeline SungahidNo ratings yet

- Tube To Tube SheetDocument9 pagesTube To Tube Sheetcmpatel_00100% (2)

- Inspection and Test Plan For Pressure VesselDocument4 pagesInspection and Test Plan For Pressure Vesselbaskaran ayyapparajNo ratings yet

- Itp Vessel PDFDocument4 pagesItp Vessel PDFBUDAPESNo ratings yet

- Pressure Vessel Inspection and Test Plan SampleDocument4 pagesPressure Vessel Inspection and Test Plan SampleRanjan KumarNo ratings yet

- Pressure Vessel Inspection and Test Plan SampleDocument4 pagesPressure Vessel Inspection and Test Plan SampleTYO WIBOWONo ratings yet

- NDT Map Itp Pressure VesselDocument4 pagesNDT Map Itp Pressure VesselSYED FADZIL SYED MOHAMEDNo ratings yet

- Pressure Vessel Inspection and Test Plan SampleDocument4 pagesPressure Vessel Inspection and Test Plan SampleAndika PusbiantoNo ratings yet

- Pressure Vessel Inspection and Test Plan Sample: WWW - Inspection-For-Industry.c OmDocument4 pagesPressure Vessel Inspection and Test Plan Sample: WWW - Inspection-For-Industry.c OmMuh FarhanNo ratings yet

- Itp VesselDocument4 pagesItp VesselHakim BaihaqiNo ratings yet

- Inspection and Test Plan For Valve: Before ManufacturingDocument2 pagesInspection and Test Plan For Valve: Before ManufacturingkarthikNo ratings yet

- SOP-Attachment 3b - CNL JV-EGTL SWP 401 - Permit To Work - Dec12Document20 pagesSOP-Attachment 3b - CNL JV-EGTL SWP 401 - Permit To Work - Dec12tomychalilNo ratings yet

- Sos SystemDocument50 pagesSos SystemtomychalilNo ratings yet

- Vickers Calibration DetailsDocument1 pageVickers Calibration DetailstomychalilNo ratings yet

- Sos SystemDocument50 pagesSos SystemtomychalilNo ratings yet

- Dr2 - Spec - Non-Destructive Examination Req of PipingDocument20 pagesDr2 - Spec - Non-Destructive Examination Req of Pipingtomychalil100% (1)

- Annex C Robust Analysis: (Normative)Document1 pageAnnex C Robust Analysis: (Normative)tomychalil0% (1)

- Annex To Travellers Guidelines 28-10-2018Document25 pagesAnnex To Travellers Guidelines 28-10-2018tomychalilNo ratings yet

- CNC Table Waterjet Cutting MachineDocument9 pagesCNC Table Waterjet Cutting MachinetomychalilNo ratings yet

- Interlaboratory Comparison of FatigueDocument26 pagesInterlaboratory Comparison of FatiguetomychalilNo ratings yet

- SADCAS F 61e - Proficiency Testing Requirements ISO-IEC 17025-2005 Clause 5.9 & SADCAS Requirements (Issue 2)Document3 pagesSADCAS F 61e - Proficiency Testing Requirements ISO-IEC 17025-2005 Clause 5.9 & SADCAS Requirements (Issue 2)tomychalilNo ratings yet

- Temperature Recording SystemDocument12 pagesTemperature Recording SystemtomychalilNo ratings yet

- Admission Instruction Ug18Document2 pagesAdmission Instruction Ug18tomychalilNo ratings yet

- Surface Grinding 440 C StainlessDocument3 pagesSurface Grinding 440 C StainlesstomychalilNo ratings yet

- Heilbron PDFDocument13 pagesHeilbron PDFAilu GeraghtyNo ratings yet

- S.No Author Book No. List of Library Books/ Police Rule/Law /training Title Publish of YearDocument7 pagesS.No Author Book No. List of Library Books/ Police Rule/Law /training Title Publish of YearenergyrockfulNo ratings yet

- V Aid Ya Rat Nam ProductsDocument10 pagesV Aid Ya Rat Nam Productsdavid400No ratings yet

- Tieng Anh de Thi Chinh Thuck23ma de 414 28202323209Document4 pagesTieng Anh de Thi Chinh Thuck23ma de 414 28202323209Thư BùiNo ratings yet

- The Wonderful World of Adam Smith (Topic 2 Final)Document28 pagesThe Wonderful World of Adam Smith (Topic 2 Final)CarlosdaMaiaNo ratings yet

- Sports WritingDocument7 pagesSports Writingjeffrey catacutan flores70% (10)

- SBHS1Document5 pagesSBHS1Rahul PancholiNo ratings yet

- Programas Desinstalados No BlecauteDocument2 pagesProgramas Desinstalados No BlecauteubirajaraNo ratings yet

- Expenditure Minimization ProblemDocument5 pagesExpenditure Minimization Problemkin0013No ratings yet

- Joint Moment Generating Function of R.V.'S and Equality in DistributionDocument15 pagesJoint Moment Generating Function of R.V.'S and Equality in Distributionpankaj kumarNo ratings yet

- FIIT Thermochemistry FinalDocument41 pagesFIIT Thermochemistry FinalGoutam Pradhan0% (1)

- SPE 86863 Health Risk Assessment in Oil and Gas Exploration: Siesmic WorkDocument6 pagesSPE 86863 Health Risk Assessment in Oil and Gas Exploration: Siesmic WorkWaleed Barakat MariaNo ratings yet

- ManualDocument158 pagesManualDimitri GutiérrezNo ratings yet

- Module 6 Learning TasksDocument4 pagesModule 6 Learning TasksMarie Pearl NarioNo ratings yet

- Destructive Inspection-IDocument26 pagesDestructive Inspection-IVishal KarmakarNo ratings yet

- 190687-MR-1100-001.06 - Topographical Survey CMS-830-03-SP-10001Document13 pages190687-MR-1100-001.06 - Topographical Survey CMS-830-03-SP-10001bam494242No ratings yet

- Multiply Two 8 Bit NumbersDocument3 pagesMultiply Two 8 Bit NumbersVeda VyasNo ratings yet

- Cu AssignmentDocument3 pagesCu Assignmentharsh abrolNo ratings yet

- 10 11648 J Hss 20150301 14 PDFDocument5 pages10 11648 J Hss 20150301 14 PDFArnel VillaflorNo ratings yet

- CV 07-05Document1 pageCV 07-05ritipiti14No ratings yet

- LSMW Long Text Load by Direct Input MethodDocument21 pagesLSMW Long Text Load by Direct Input MethodAnonymous CEG1Hiu1No ratings yet

- Conceptual Metaphor in ArchitectureDocument8 pagesConceptual Metaphor in ArchitectureKent NeoNo ratings yet

- ...Document437 pages...tjohns56No ratings yet

- Civil Engineering & Construction TechnologiesDocument2 pagesCivil Engineering & Construction TechnologiesKundan PrasadNo ratings yet

- Kate Chopin and Feminism: The Significance of Water: Brittany GrovesDocument8 pagesKate Chopin and Feminism: The Significance of Water: Brittany GrovesAnne Marinelle MontegrandeNo ratings yet

- Marking Period 1 7th Grade Science Honors ProjectDocument6 pagesMarking Period 1 7th Grade Science Honors Projectapi-159185230No ratings yet

- Resume of RamaraoDocument3 pagesResume of RamaraoEl Uday KumarNo ratings yet

- (Two Vol. Set - The Pilgrimage of Reason - The Odyssey of Spirit) ) H. S. Harris-Hegel's Ladder. 1-Hackett Pub Co Inc (1997)Document232 pages(Two Vol. Set - The Pilgrimage of Reason - The Odyssey of Spirit) ) H. S. Harris-Hegel's Ladder. 1-Hackett Pub Co Inc (1997)Gon za50% (2)