Professional Documents

Culture Documents

Condensate Line Sizing

Condensate Line Sizing

Uploaded by

rohitkush0 ratings0% found this document useful (0 votes)

31 views2 pagesThis document summarizes the analysis of flashing condensate in a 14 inch pipe with a flow rate of 120,000 kg/hr. It finds that 23,946.59 kg/hr will flash to steam, leaving 96,053.41 kg/hr of liquid condensate. The density of the flashed condensate/steam mixture is 14.88213 kg/m3. The pressure drop of the mixture in the pipe is calculated to be 0.591644 psi/100ft, and the velocity is 4437.05 ft/min, so the line size is deemed adequate.

Original Description:

ys

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document summarizes the analysis of flashing condensate in a 14 inch pipe with a flow rate of 120,000 kg/hr. It finds that 23,946.59 kg/hr will flash to steam, leaving 96,053.41 kg/hr of liquid condensate. The density of the flashed condensate/steam mixture is 14.88213 kg/m3. The pressure drop of the mixture in the pipe is calculated to be 0.591644 psi/100ft, and the velocity is 4437.05 ft/min, so the line size is deemed adequate.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

0 ratings0% found this document useful (0 votes)

31 views2 pagesCondensate Line Sizing

Condensate Line Sizing

Uploaded by

rohitkushThis document summarizes the analysis of flashing condensate in a 14 inch pipe with a flow rate of 120,000 kg/hr. It finds that 23,946.59 kg/hr will flash to steam, leaving 96,053.41 kg/hr of liquid condensate. The density of the flashed condensate/steam mixture is 14.88213 kg/m3. The pressure drop of the mixture in the pipe is calculated to be 0.591644 psi/100ft, and the velocity is 4437.05 ft/min, so the line size is deemed adequate.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

You are on page 1of 2

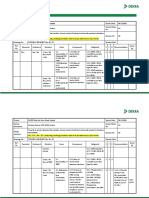

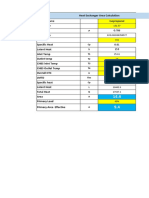

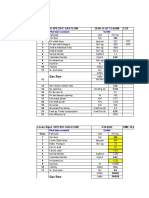

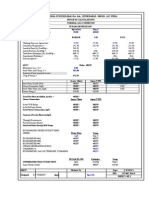

Pipe Diameter 14 Inch

Mass Flow Rate of Condensate 120000 Kg/hr 264552 lb/hr

Condensate Pressure Before Flashing 40 Kg/cm

2

G 583.143 psia

Flasher Condesate Header Pressure 5 Kg/cm

2

G 85.338 psia

Constant A 0.198495

Constant X 2.317087

Constant B 0.009815

Weight Fraction of Condensate flashed

to Vapour 0.199555

Flashed Steam Flow Rate 23946.59 Kg/hr 52792.65 lb/hr

Flashed Condensate Liquid Flow 96053.41 Kg/hr 211759.4 lb/hr

Temperature of Flashed Condensate 253.2732 C 487.8917 F

Flashed Steam Density 3.009158 kg/m

3

0.187849 lb/ft

3

Flashed Condensate Liquid Density 910.8139 kg/m

3

56.85835 lb/ft

3

Density of Mixture (Flashed

Condensate/Steam) 14.88213 kg/m

3

0.92903 lb/ft

3

For Turbulent Flow

Friction Factor 0.012571

Pressure Drop of Flashed Condensate

mixture 0.591644 psi/100ft

Velocity of Flashed Condensate

mixture 4437.05 ft/min

Line Size is adequate

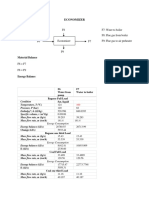

Assumptions:

1. Most of the flow patterns for steam condensate headers fall within the

annular or dispersed region on the baker map. Rarely flow pattern falls in slug

flow region.

2. Flashed steam is less than 30% by weight.

3. Vapour-liquid mixture throughout the condensate line is represented by

mixture conditions near the end of the line.

Method:

1. Amount of condensate flashed is calculated.

2. Further to above the density of the mixture (condensate+flashed steam) is

found out.

3. Using two pressure drop correlations, pressure per 100 ft. is calculated.

4. Also, the velocity of the mixture in the line of specified size is calculated. If

the velocity is lower than 5000 Foot/Min., the specified line size is said to be

adequate.

You might also like

- Sizing For Vaporiser/Flash Vessel: InputsDocument3 pagesSizing For Vaporiser/Flash Vessel: InputsSaravana ChandranNo ratings yet

- Fire Tube Boiler DesignDocument3 pagesFire Tube Boiler DesignRajendraNo ratings yet

- J1237 Asian Paints HAZOP WSDocument98 pagesJ1237 Asian Paints HAZOP WSrohitkushNo ratings yet

- Condensate Line SizingDocument2 pagesCondensate Line SizinglylyNo ratings yet

- 20 - Condensate Line SizingDocument2 pages20 - Condensate Line SizingJunaid MateenNo ratings yet

- Condensate Line SizingDocument2 pagesCondensate Line SizingAnonymous oVRvsdWzfBNo ratings yet

- Condensate Line SizingDocument2 pagesCondensate Line Sizingemmanuilmoulos6339100% (1)

- Condensate Line SizingDocument3 pagesCondensate Line Sizingadrian sotoNo ratings yet

- Condensate Line SizingDocument1 pageCondensate Line SizingShashi RaajNo ratings yet

- Condensate Line SizingDocument4 pagesCondensate Line SizingMubin Ashraf SheikhNo ratings yet

- Vessel NewDocument16 pagesVessel NewakshaybhuranNo ratings yet

- Final Ventury Working For Wet Alkaline ScrubberDocument11 pagesFinal Ventury Working For Wet Alkaline ScrubberNanasaheb JagtapNo ratings yet

- Sizing of Tank Heating CoilDocument1 pageSizing of Tank Heating Coilgeverett2765No ratings yet

- Mixer MelterDocument28 pagesMixer MelterLendy KartikiNo ratings yet

- Heat Exchanger Area & Boilup Rate CalculationDocument19 pagesHeat Exchanger Area & Boilup Rate CalculationNitin KurupNo ratings yet

- Plant InvesticationDocument3 pagesPlant InvesticationirfanNo ratings yet

- Properties by Correlation For Process SimulationDocument4 pagesProperties by Correlation For Process SimulationSuryakant RanderiNo ratings yet

- Gas Flow Rate Mass Flow Mol Flow Gas Volume FlowDocument9 pagesGas Flow Rate Mass Flow Mol Flow Gas Volume FlownivethithaNo ratings yet

- Gas Liquid Separator DesignDocument3 pagesGas Liquid Separator DesignSoheil MoradiNo ratings yet

- Steam Condensate in Return LinesDocument13 pagesSteam Condensate in Return LinesAayushi SinhaNo ratings yet

- Emma MangarooDocument17 pagesEmma MangarooCharlotte BNo ratings yet

- 1 - Calcuquick D.Ginsky 6.6.2005 EnglishDocument82 pages1 - Calcuquick D.Ginsky 6.6.2005 EnglishRahul ChandrawarNo ratings yet

- Steam Trap & InsulationDocument16 pagesSteam Trap & InsulationArindomNo ratings yet

- Desing of HEDocument25 pagesDesing of HEmeetNo ratings yet

- Desing of CoolerDocument25 pagesDesing of CoolermeetNo ratings yet

- Condenser SimulationDocument3 pagesCondenser SimulationSyed Hassan MurtazaNo ratings yet

- Perhitungan CT, Hydrant, Dan BlowerDocument13 pagesPerhitungan CT, Hydrant, Dan BlowerNicholas GeorgeNo ratings yet

- Mixer (So3 Jadi H2so4)Document6 pagesMixer (So3 Jadi H2so4)Evi SiswantoNo ratings yet

- Experiment - 7: Aim: Sizing of Pressure VesselDocument5 pagesExperiment - 7: Aim: Sizing of Pressure VesselHomesick TutorsNo ratings yet

- Question 1 (15 Marks)Document5 pagesQuestion 1 (15 Marks)Farouk BassaNo ratings yet

- Excel SizingDocument10 pagesExcel SizingJolteon JuniorNo ratings yet

- Datasheet PXL-1828-001 (MSA-100) - 2205 X 815 X 25Document4 pagesDatasheet PXL-1828-001 (MSA-100) - 2205 X 815 X 25Wilton PiresNo ratings yet

- PSV Reaction Force CalculationDocument2 pagesPSV Reaction Force CalculationSuthan100% (1)

- Methane Properties: Erty Value Unit Value Unit Value UnitDocument6 pagesMethane Properties: Erty Value Unit Value Unit Value UnitdNo ratings yet

- ProjectDocument26 pagesProjectsiddharthkharat123No ratings yet

- Gas Physical PropertiesDocument139 pagesGas Physical PropertiesYusuf RiadiNo ratings yet

- C3CYCLVDocument13 pagesC3CYCLVUok RitchieNo ratings yet

- Calculation of Flow From PinholeDocument6 pagesCalculation of Flow From PinholeSubrata MukherjeeNo ratings yet

- Design Case - A-SH1-45Document1 pageDesign Case - A-SH1-45Rufus D SNo ratings yet

- Compressor 1Document25 pagesCompressor 1Trebob GardayaNo ratings yet

- 3.1 Mass Transfer Equipment Design: H O CH Cooh CHDocument61 pages3.1 Mass Transfer Equipment Design: H O CH Cooh CHZAINOR SYAHIRA BINTI ZAINAL STUDENTNo ratings yet

- NPSH CalculationDocument3 pagesNPSH Calculationatul bansalNo ratings yet

- Double Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterDocument3 pagesDouble Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterBagusRekaNo ratings yet

- Economize R 3 TrialDocument19 pagesEconomize R 3 TrialNitish AmnerkarNo ratings yet

- Laavenya Ip FluidDocument11 pagesLaavenya Ip FluidTHARSHINIPRIYA A/P MOHAN MoeNo ratings yet

- Liq Expansion CalculationsDocument4 pagesLiq Expansion CalculationsGary JonesNo ratings yet

- Tank Volume CalculationDocument9 pagesTank Volume CalculationMangesh MandgeNo ratings yet

- GasesDocument38 pagesGaseshNo ratings yet

- Line III Heat BalanceDocument65 pagesLine III Heat Balancehmaza shakeelNo ratings yet

- Fan Flow - CementDocument5 pagesFan Flow - CementharikrushnaNo ratings yet

- CalculationDocument8 pagesCalculationmahaveenNo ratings yet

- Nitrogen Liquefaction Linde CycleDocument2 pagesNitrogen Liquefaction Linde CyclerisdiyantaNo ratings yet

- Wed Jan 07 21:43:56 2015 Case: D:/Kuliah/Semester 5/Pspk/Pak Hanif/Latihan - HSC Flowsheet: Case (Main)Document1 pageWed Jan 07 21:43:56 2015 Case: D:/Kuliah/Semester 5/Pspk/Pak Hanif/Latihan - HSC Flowsheet: Case (Main)Sebastian DjoniNo ratings yet

- Calculation of Diameter For Methanol-IPA System (Continuous) - Top Boil Up PropertiesDocument3 pagesCalculation of Diameter For Methanol-IPA System (Continuous) - Top Boil Up PropertiesBagadi AvinashNo ratings yet

- Steam Drum LevelsDocument11 pagesSteam Drum LevelsAnith kumar Reddy100% (1)

- Robin Kumar Patel B190139CH Fair Record Exp-07Document5 pagesRobin Kumar Patel B190139CH Fair Record Exp-07RobinNo ratings yet

- Anggi Bagus FixDocument23 pagesAnggi Bagus FixAbdul QodirNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Expectations For The Mi ProgramDocument3 pagesExpectations For The Mi ProgramrohitkushNo ratings yet

- Control Valve Skid ArrangementDocument1 pageControl Valve Skid ArrangementrohitkushNo ratings yet

- PSM GoalDocument2 pagesPSM GoalrohitkushNo ratings yet

- Criterion For Hazard Ranking ProcedureDocument1 pageCriterion For Hazard Ranking ProcedurerohitkushNo ratings yet

- Wind Speed (M/S) N NE E SE SDocument3 pagesWind Speed (M/S) N NE E SE SrohitkushNo ratings yet

- Line Sizing HYSYS PDFDocument1 pageLine Sizing HYSYS PDFrohitkush100% (1)

- Validated SheetDocument12 pagesValidated SheetrohitkushNo ratings yet

- Attachment-3: Relief Valve Sizing Calculation (Blocked Outlet Case-Two Phase Relief) Page 1 of 1Document1 pageAttachment-3: Relief Valve Sizing Calculation (Blocked Outlet Case-Two Phase Relief) Page 1 of 1rohitkushNo ratings yet

- Calculation For Jet MixerDocument3 pagesCalculation For Jet MixerrohitkushNo ratings yet

- Volume Calculation For BlowdownDocument6 pagesVolume Calculation For BlowdownrohitkushNo ratings yet

- Cover Sheet (West Qurna - 2 Project. Early Phase Production Stage)Document2 pagesCover Sheet (West Qurna - 2 Project. Early Phase Production Stage)rohitkushNo ratings yet

- Hydraulic Expansion (Liquid)Document1 pageHydraulic Expansion (Liquid)rohitkushNo ratings yet