Professional Documents

Culture Documents

Interruttore Tattile

Interruttore Tattile

Uploaded by

Carlos Marx Vilcapoma TaipeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Interruttore Tattile

Interruttore Tattile

Uploaded by

Carlos Marx Vilcapoma TaipeCopyright:

Available Formats

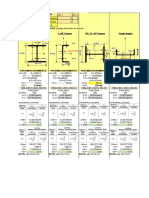

DTS(M)L-3DTSMF-3 SERIES

DIMENSIONS

DTS-3

DTSM-3

[.256.004]

6.500.10

[.051.002]

[.236]

6.0

[

.

1

3

8

]

3

.

5

3.00

[.118]

0

.

5

0

M

a

x

.

3

.

5

0

[

.

1

3

8

]

[

.

1

3

8

0

.

2

0

]

3

.

5

0

6.50

[.2560.20]

[.3110.20]

7.90

[

.

0

7

1

[

H

.

0

0

8

]

H

0

.

2

0

1

.

8

0

[.039]

1.00

2

0

.

0

[.059]

1.5

+

0

-

0

.

5

0

+

0-

.

0

2

0

0

.

5

0

0.50

[

.

0

2

0

]

]

C

L

C

L

C

L

0.50

0.25

[.010]

0

.

0

5

M

a

x

.

[

H

.

0

0

8

]

H

0

.

2

0

[.118]

3.00

L

C

[

.

0

2

0

]

3

.

5

0

[

.

1

3

8

]

0

.

5

0

M

a

x

.

[.283]

(7.20)

(

0

.

9

)

[

.

0

3

5

]

30

(

)

1.0

General Tolerance0.2mm

General Tolerance0.2mm

DTSML-3

DTSMF-3

General Tolerance0.2mm

0

.

0

5

M

a

x

.

[

H

.

0

0

8

]

H

0

.

2

0

[.118]

3.00

L

C

[

.

0

2

0

]

3

.

5

0

[

.

1

3

8

]

0

.

5

0

M

a

x

.

[.354]

9.0

DTSML-31 -V

1.0

General Tolerance0.2mm

HOW TO ORDER

DTS- - - -

Package Style:

B = Tube Package

T/R = Tape & Reel

Soldering:

V=Lead Free Solderable

Color of Stem for

Operating Force:

N = Brown, 160g

R = Red, 260gf

S = Salmon, 320gf

Y = Yellow, 520gf

Dimension H:

1 = 4.3mm

2 = 5.0mm

Prod. Size: 3 = 3.5x6mm

M = J Bend Terminal

= Through Hole Type

ML = Flat Terminal

MF = Gull Wing Terminal Only for 260gf

Tactile Switch 3.5x6mm

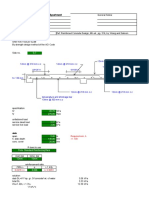

SPECIFICATION MATERIAL

MECHANICAL COVER: Stainless steel

Operation Force: 520 130gf Yellow (Y) BASE: UL94V-0 Nylon Thermoplastic

320 80gf Salmon (S)

260 50gf Red (R) STEM: UL94V-0 Nylon High-Temp. Thermoplastic

160 50gf Brown (N) Color: Brown, (160gf), Red (260gf)

Stroke: 0.25 +0.20 / - 0.1 mm Salmon (320gf), Yellow (520gf)

Operation Temperature: -25 to +70 CONTACT DISC: Stainless with silver cladding

Storage Temperature: -30 to +80 TERMINAL: Brass with silver plated

ELECTRICAL

Electrical Life: 50,000 cycles for 160gf, 320gf

30,000 cycles for 260gf, 520gf

Rating: 50mA, 12VDC

Contact Resistance: 100m max.

Insulation Resistance: 100M min. at 500VDC

Dielectric Strength: 250VAC/ 1minute

Contact Arrangement: 1 pole 1 throw

SOLDERING PROCESS

HAND SOLDERING : Use a soldering iron of 30 watts, controlled at 350 approximately max 5 seconds while

applying solder.

REFLOW SOLDERING: When applying reflow soldering, the peak temperature or the reflow oven should be set

at 260 max.

WAVE SOLDERING: Recommended solder temperature at 500 (260) max. 5 seconds for through hole type.

subject to P.C.B 1.6mm thickness.

Reflow Temperature Profile:

Part Number

Number

Per Tube

Number

Per Reel

DTS-3 135 -

DTS(M)L-31 135 1800

PACKING

DTS(M)L-32 135 1600

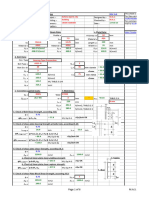

TUBE

9

.

5

0

5

.

4

5

4.30

10.0

1

.

5

5

6.80

4.40 2x0.60

4

.

5

0

5

.

6

0

18xR0.10

10xR0.60

1.5

(

)

-0.20

+0.0

0.10

-0.0

+0.20

+

0

.

0

+

0

.

2

0

-

0

.

0

0

.

1

0

-0.0

+0.20

-

0

.

2

0

C

L

0

.

0

0

3

.

7

0

4

.

2

0

7

.

6

0

1

2

.

7

0

1

0

.

7

0

0

.

0

0

1

2

.

2

0

1

2

.

7

0

3

.

2

0

7

.

1

0

7

.

2

0

0

.

2

0

3

.

3

8

.

8

4

.

3

0

Temperature

Room

150

MAX 260

60sec

120~150sec

TIME(sec)

255

230

5~10sec

General Tolerance0.2mm

REEL

General Tolerance0.1mm

You might also like

- Placa de Capat HEA160Document6 pagesPlaca de Capat HEA160Manciu Mihai-CosminNo ratings yet

- Baja BroDocument55 pagesBaja BroAdib FananiNo ratings yet

- Specifi Cations Cations: Rohs CompliantDocument6 pagesSpecifi Cations Cations: Rohs CompliantAkshay VenugopalNo ratings yet

- Castellate Beam CheckDocument19 pagesCastellate Beam Checkken koemhongNo ratings yet

- Lifting LugDocument8 pagesLifting LugEnrique BarajasNo ratings yet

- Section 07Document42 pagesSection 07christos1157No ratings yet

- Base Plate - Silo Supporting R1Document10 pagesBase Plate - Silo Supporting R1soumi bhattacharyaNo ratings yet

- STE NTC ThermistorDocument9 pagesSTE NTC ThermistorEdson RibeiroNo ratings yet

- NIC Components NSRW SeriesDocument5 pagesNIC Components NSRW SeriesNICCompNo ratings yet

- AISC360 05 LRFD Shear Plate Bolted Connection Check 17-09-2013Document8 pagesAISC360 05 LRFD Shear Plate Bolted Connection Check 17-09-2013RUBEN BARTOLOME GARCIANo ratings yet

- UB 610 X 179 - BP - PinnedDocument3 pagesUB 610 X 179 - BP - PinnedArivoli JayaramanNo ratings yet

- 5 Metros MarceloDocument2 pages5 Metros Marcelomarcelo galarzaNo ratings yet

- One-Way SlabDocument2 pagesOne-Way SlabRichelle Faye VillaverdeNo ratings yet

- BF 065Document1 pageBF 065vahid hajihasaniNo ratings yet

- Design of One-Way SlabDocument2 pagesDesign of One-Way SlabJm CampitanNo ratings yet

- Conventional-Shed IS800-2007Document369 pagesConventional-Shed IS800-2007jatinNo ratings yet

- Davit Design Calculation: L 1 D V H V H V DDocument2 pagesDavit Design Calculation: L 1 D V H V H V DSiva baalanNo ratings yet

- Splice & Knee Connection - R3 (1-3-19)Document285 pagesSplice & Knee Connection - R3 (1-3-19)rohitbhagat005No ratings yet

- Design of One Way Slab Project: Moe Title: Typical Slab PanelDocument2 pagesDesign of One Way Slab Project: Moe Title: Typical Slab PanelRal GLNo ratings yet

- ConnectionDocument68 pagesConnectionErshadNo ratings yet

- Design of One Way Slab Project: Title: Design ParametersDocument26 pagesDesign of One Way Slab Project: Title: Design Parametersjay bNo ratings yet

- Hinged Base PlateDocument2 pagesHinged Base PlateRJNo ratings yet

- Conventional ShedDocument369 pagesConventional Shedarjun100% (1)

- 3D Beam Analysis I.W.O W.B Tank HopperDocument8 pages3D Beam Analysis I.W.O W.B Tank HopperMinca AndreiNo ratings yet

- Vsmax Bwxdefx F ' CDocument10 pagesVsmax Bwxdefx F ' CFina AjjhaNo ratings yet

- Crane Beam Web Splice DesignDocument7 pagesCrane Beam Web Splice DesignCrystal JaneNo ratings yet

- Ub406-Mb300 ShearDocument2 pagesUb406-Mb300 Shearsurao.chittineniNo ratings yet

- Base Plate Design1Document24 pagesBase Plate Design1John Paul UmaliNo ratings yet

- 6952-4.T&Angle-Brace Connection (Knee Brace) (M Project) - 0618Document81 pages6952-4.T&Angle-Brace Connection (Knee Brace) (M Project) - 0618Omprakash KhodkeNo ratings yet

- BT Series CatalogDocument5 pagesBT Series CatalogShanmuga SundaramNo ratings yet

- Blind Calculation - RoarkDocument10 pagesBlind Calculation - Roarkrustamriyadi100% (2)

- Appendix A3Document6 pagesAppendix A3Thomas Stephen100% (1)

- Transverse ReinforcementDocument9 pagesTransverse ReinforcementOliver RamosNo ratings yet

- Beam Design 1Document22 pagesBeam Design 1shamen amarasekaraNo ratings yet

- Momen End Plate CS 675Document12 pagesMomen End Plate CS 675Jose royNo ratings yet

- Draft Select BeamDocument1 pageDraft Select BeamneoNo ratings yet

- Series: Metallized Polyester Film CapacitorsDocument2 pagesSeries: Metallized Polyester Film CapacitorsStuxnetNo ratings yet

- (F) (N) Hds Series: DimensionsDocument4 pages(F) (N) Hds Series: DimensionsElliot AldersonNo ratings yet

- End Plate Moment Connection (Bolt)Document72 pagesEnd Plate Moment Connection (Bolt)mengxiao74No ratings yet

- Mathcad - Primary Beam Lap Splice CalculationDocument4 pagesMathcad - Primary Beam Lap Splice Calculationmrnaeem76No ratings yet

- Design Parameter: Job Information Project Engr Job # 1 Subject Design of Footing Date 10/8/2020 SHT # 1Document3 pagesDesign Parameter: Job Information Project Engr Job # 1 Subject Design of Footing Date 10/8/2020 SHT # 1Nasroden PagayaoNo ratings yet

- End-Plate-Design BS CodeDocument15 pagesEnd-Plate-Design BS CodeRaymond SabadoNo ratings yet

- Lifting/Tailing Lug Calculation: Design DataDocument3 pagesLifting/Tailing Lug Calculation: Design DataMr IncognitoNo ratings yet

- Perhitungan Kolom Metode SRPMK SNI 2847Document6 pagesPerhitungan Kolom Metode SRPMK SNI 2847michel johnNo ratings yet

- PDF 44Document3 pagesPDF 44Eran HapNo ratings yet

- NIC Components NSRN SeriesDocument5 pagesNIC Components NSRN SeriesNICCompNo ratings yet

- Thread Turning ToolsDocument22 pagesThread Turning ToolsАндрейNo ratings yet

- Test Floor Black FinalDocument2 pagesTest Floor Black FinalHAFIZ ARSALAN ALINo ratings yet

- Typical Bolt Connection of Truss Diagonal Web MemberDocument7 pagesTypical Bolt Connection of Truss Diagonal Web Membermsh741053515No ratings yet

- UNP UPN DatasheetDocument3 pagesUNP UPN DatasheetHaytham SemaanNo ratings yet

- Verification Example Extended Moment End-Plate: GeometryDocument5 pagesVerification Example Extended Moment End-Plate: Geometryngocnn100% (2)

- Pipe Support CalculationDocument2 pagesPipe Support Calculationthanh100% (1)

- Seafastening For Pelikan - 12mm Thickness PlateDocument12 pagesSeafastening For Pelikan - 12mm Thickness PlateHafidNo ratings yet

- ASME FlangeDocument1 pageASME FlangeHanda Bin AdiNo ratings yet

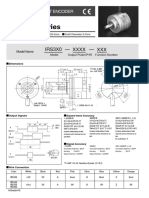

- Series: IRS3X0 XXXX XXXDocument3 pagesSeries: IRS3X0 XXXX XXXjackyNo ratings yet