Professional Documents

Culture Documents

Table 8-4. Entering and Tightening Clearances, In. Conventional ASTM A325 and A490 Bolts

Table 8-4. Entering and Tightening Clearances, In. Conventional ASTM A325 and A490 Bolts

Uploaded by

MiguelRagasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Table 8-4. Entering and Tightening Clearances, In. Conventional ASTM A325 and A490 Bolts

Table 8-4. Entering and Tightening Clearances, In. Conventional ASTM A325 and A490 Bolts

Uploaded by

MiguelRagasCopyright:

Available Formats

BOLTED CONSTRUCTION

8 - 13

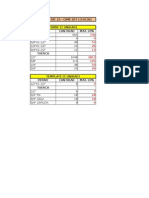

Table 8-4.

Entering and Tightening Clearances, in.

Conventional ASTM A325 and A490 Bolts

Aligned Bolts

C2

socket

H1

C1

Nominal

Bolt Dia., Socket

in.

Dia., in.

H2

C1

C1

5

8

3

4

7

8

H2

1

C3

1 1 8

1 1 4

1 3 8

1 1 2

fillet

13 4

21 4

21 2

25 8

27 8

31 8

31 4

31 2

C3

H1

25

64

15

32

35

64

39

64

11

16

25

32

27

32

15

16

H2

C1

11 4

13 8

11 2

15 8

17 8

2

21 8

21 4

1

11 4

13 8

17 16

19 16

11116

13 4

15 16

C2

11

16

3

4

7

8

15

16

11 16

11 8

11 4

15 16

Circular Clipped

11

16

3

4

7

8

9

16

11

16

13

16

7

8

1

11 8

11 4

13 8

11 2

1

11 8

11 4

15 16

Staggered Bolts

Stagger P, in.

Nominal Bolt Diameter, in.

5

8

3

4

7

8

1

1 1 4

1 3 8

15 8

11 2

11 2

17 16

115 16

17 8

23 16

1 1 2

1 5 8

1 3 4

1 7 8

11 4

11 4

13 16

11 8

113 16

13 4

11116

19 16

21

13

11

C1

P

2 1 4

2 3 8

2 1 2

2 5 8

2 3 4

2 7 8

118

114

1 3 8

1 1 2

21 8

21 16

2

115 16

25 16

25 16

21 4

23 16

29 16

29 16

21 2

213 16

23 4

3

3

33 4

11 2

13 8

11 4

11 8

113 16

11116

19 16

11 2

21 8

2

17 8

13 4

27 16

23 8

21 4

21 8

23 4

21116

25 8

21 2

215 16

215 16

27 8

213 16

31 4

33 16

33 16

31 8

13 8

13 16

15 8

11 2

13 8

13 16

27 16

25 16

21 8

21 16

23 4

27 8

21 2

23 8

31 16

3

27 8

213 16

2

17 8

13 4

15 8

21 4

21 8

2

115 16

21116

21 2

23 8

21 4

13 8

11 16

13 4

19 16

15 16

21 8

2

17 8

11116

15

16

3

31

C1 = tightening

clearance

16

3 1 4

3 3 8

115

16

17 8

13 4

15 8

11 2

11 4

15

16

31

standard

socket

35

3 3 4

3 7 8

4

Notes:

H1 = height of head, in.

H2 = maximum shank extension,* in.

C1 = clearance for tightening, in.

C2 = clearance for entering, in.

C3 = clearance for fillet,* in.

P = bolt stagger, in.

F = clearance for tightening staggered bolts, in.

*Based on one standard hardened washer.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

13 8

8 - 14

BOLTS, WELDS, AND CONNECTED ELEMENTS

Table 8-5.

Entering and Tightening Clearances, in.

Tension-Control ASTM A325 and A490 Bolts

Aligned Bolts

Nominal

Bolt

Dia, in.

Tools

C3

H1

3

4

7

8

C1

H2

2 /2

C1

C2

Circular Clipped

16

5

8

13 8

11 2

13 4

17 8

17 8

17 8

1

11 8

2 1 2-in. Diameter Critical

2

3

4

7

8

1

C3

1

9

16

5

8

13 8

11 2

13 4

13 8

13 8

13 8

1

11 8

3-in. Diameter Critical

Small Tools

fillet

5

8

3

4

7

8

21/2 2

C2

H2

C1

1

1

1 /2 3 /8

33/8

H1

C1

H2

3 3 8-in. Diameter Critical

Large Tools

16

1

2

9

16

11 4

13 8

11 2

15 8

15 8

15 8

13

7

16

8

11

11

16

3

4

7

8

2 3 16-in. Diameter Critical

3

2 /16

5

8

3

4

7

8

16

1

2

9

16

11 4

13 8

11 2

11 8

11 8

11 8

13

7

16

8

16

3

4

7

8

Staggered Bolts

Stagger P, in.

Nominal Bolt Diameter, in.

C1

P

5

8

11

113

installation

tool

3

4

7

8

16

1 3 8

13 4

21 16

21 4

27 16

1 1 2

1 5 8

1 3 4

1 7 8

11116

19 16

11 2

17 16

2

17 8

113 16

13 4

23 16

21 16

2

17 8

23 8

21 4

23 16

21 8

15 16

11 4

13 16

11 8

15 8

19 16

11 2

13 8

13 4

11116

19 16

11 2

2

115 16

17 8

13 4

15 16

13 16

11 8

13 8

15 16

13 16

11 8

11116

19 16

11 2

13 8

2 1 8

2 1 4

2 3 8

C1 = tightening

clearance

2 1 2

2 5 8

2 3 4

2 7 8

3

3 3 8

15 16

15 16

Notes:

H1 = height of head, in.

H2 = maximum shank extension,* in.

C1 = clearance for tightening, in.

C2 = clearance of entering, in.

C3 = clearance for fillet,* in.

P

= bolt stagger, in.

F

= clearance for tightening staggered

bolts, in.

*Based on one standard hardened washer.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

You might also like

- 2520 z000 STD 1780 06 - B Anchor Bolt DetailDocument2 pages2520 z000 STD 1780 06 - B Anchor Bolt Detailabdul mujeebNo ratings yet

- Astm A70Document1 pageAstm A70Anand KesarkarNo ratings yet

- Sample Assembly TemplateDocument1 pageSample Assembly TemplateMiguelRagasNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Pip SupportDocument167 pagesPip SupportCristian DehnNo ratings yet

- JIS SectionDocument2 pagesJIS SectionthakrarhitsNo ratings yet

- Pipe Dimensions and Friction FactorDocument24 pagesPipe Dimensions and Friction FactorJuan Pablo ApazaNo ratings yet

- Ring FederDocument0 pagesRing Federrudolf_laszlokNo ratings yet

- Pulsating Heat Pipe ReportDocument65 pagesPulsating Heat Pipe ReportIdul Azharul HoqueNo ratings yet

- 5026-PS-001 - 0 Supply of Piping MaterialsDocument17 pages5026-PS-001 - 0 Supply of Piping MaterialsCARLOS OLIVEROSNo ratings yet

- Comparison of FEM, HMI and CMAA Classifications - ProservCrane GroupDocument3 pagesComparison of FEM, HMI and CMAA Classifications - ProservCrane Groupengin gürayNo ratings yet

- Horizontal MultiStage Pump Data SheetDocument6 pagesHorizontal MultiStage Pump Data Sheetسمير البسيونىNo ratings yet

- Pump Shaft Repair Recommendation GuidelinesDocument4 pagesPump Shaft Repair Recommendation Guidelineschiz escudero100% (2)

- Asce - Natural Period Vertical Vessel UniformDocument1 pageAsce - Natural Period Vertical Vessel UniformpeyostailNo ratings yet

- Eye Bolt CalculationDocument4 pagesEye Bolt CalculationAlok KumarNo ratings yet

- ISO 15207 - Belt IdlersDocument5 pagesISO 15207 - Belt IdlersMinh TríNo ratings yet

- Special Purpose Gear Units Api 613 Fifth Edition Data Sheet Si UnitsDocument4 pagesSpecial Purpose Gear Units Api 613 Fifth Edition Data Sheet Si UnitstutuionutNo ratings yet

- Platewithshear&anchorbolts NPTEL PDFDocument5 pagesPlatewithshear&anchorbolts NPTEL PDFMadhubalan AlagarNo ratings yet

- API 682 Accumulator Data SheetDocument1 pageAPI 682 Accumulator Data SheetBhyrappaNo ratings yet

- Bolt Preload Calculation: AnswerDocument2 pagesBolt Preload Calculation: AnswerPedja100% (1)

- Un 2004-03 - Ud-Au-000-Eb-00009 PDFDocument3 pagesUn 2004-03 - Ud-Au-000-Eb-00009 PDFManjeet SainiNo ratings yet

- Tekla Structures Drawing - GDocument1 pageTekla Structures Drawing - GMj Edin0% (1)

- Durco Microfinish and General Purpose Threaded Ball Valves: Presenting The NewDocument10 pagesDurco Microfinish and General Purpose Threaded Ball Valves: Presenting The Newmanish thakurNo ratings yet

- Mss sp-67 PDFDocument18 pagesMss sp-67 PDFPratik DesaiNo ratings yet

- Rules For Reusing BoltsDocument4 pagesRules For Reusing Boltsaataylor83No ratings yet

- Din 743 E-AssisstDocument24 pagesDin 743 E-AssisstSezgin BayrakNo ratings yet

- Trapezoidal ThreadsDocument5 pagesTrapezoidal ThreadsSaraswantoNo ratings yet

- EagleBurgmann - Fabric Expansion Jont PDFDocument28 pagesEagleBurgmann - Fabric Expansion Jont PDFAnh VoNo ratings yet

- Design and Analysis of Storage Tank - ANSYS AnalysisDocument8 pagesDesign and Analysis of Storage Tank - ANSYS AnalysisrosemaryNo ratings yet

- Submersible Sump Pumps 83-TMSS-01, Rev 0Document12 pagesSubmersible Sump Pumps 83-TMSS-01, Rev 0Pageduesca RouelNo ratings yet

- Iso 10893 9 2011Document9 pagesIso 10893 9 2011basusonuNo ratings yet

- Astm F952 12Document6 pagesAstm F952 12Yasir NASSERALLAHNo ratings yet

- The Definitive O Ring Design GuideDocument31 pagesThe Definitive O Ring Design GuideChezNo ratings yet

- Analyzing Taper Fits For ManufacturingDocument7 pagesAnalyzing Taper Fits For Manufacturingsalgado_24No ratings yet

- Counter Weight Drawing MCT85Document14 pagesCounter Weight Drawing MCT85Nirmalya SenNo ratings yet

- Steel Tables by R Agor, Birla Publications PDFDocument97 pagesSteel Tables by R Agor, Birla Publications PDFankitNo ratings yet

- Loaded Flat Plates PDFDocument6 pagesLoaded Flat Plates PDFantoninoNo ratings yet

- Spile Bar DeflectionDocument9 pagesSpile Bar DeflectionIsaac KendallNo ratings yet

- Draft VTUSA Conveyor Bridge Report v4Document219 pagesDraft VTUSA Conveyor Bridge Report v4ken stanleyNo ratings yet

- Api 682 Datasheetes PDFDocument2 pagesApi 682 Datasheetes PDFNovi Wulansari100% (1)

- Design Example of Pipe Rack StructureDocument16 pagesDesign Example of Pipe Rack StructureJimit PayNo ratings yet

- HKIE Seminar 20140320 - FinalDocument71 pagesHKIE Seminar 20140320 - FinalAnonymous H7nHUOGUsNo ratings yet

- Knife Gate Valve - AVKCMSDocument2 pagesKnife Gate Valve - AVKCMSjuantamad02No ratings yet

- Gasket BrochureDocument8 pagesGasket BrochureKumar JbsNo ratings yet

- API617 - Axial and Centrifugal Compressors, and ExpanderDocument13 pagesAPI617 - Axial and Centrifugal Compressors, and ExpanderMahmoud AbdellatifNo ratings yet

- R435319004PB PDFDocument9 pagesR435319004PB PDFMuhammed SulfeekNo ratings yet

- White Paper DIN FittingsDocument7 pagesWhite Paper DIN FittingsSiddhant JoglekarNo ratings yet

- 06 05 16 Heko Bucket ElevatorDocument36 pages06 05 16 Heko Bucket ElevatorLeoncio Alexander Maza InfantesNo ratings yet

- Metric ThreadDocument27 pagesMetric Threadlucian lunaNo ratings yet

- Principal of DPTDocument5 pagesPrincipal of DPTAkshith SulliaNo ratings yet

- Asme Sa 106 Grade B PipesDocument1 pageAsme Sa 106 Grade B PipesFerroPipENo ratings yet

- Worm and Worm Wheel NomenclatureDocument1 pageWorm and Worm Wheel NomenclaturemuhdqasimNo ratings yet

- Course 4 EDocument45 pagesCourse 4 ESzabolcs KovacsNo ratings yet

- VECTOR TECHLOK CLAMP CONNECTOR TECHNICAL BROCHURE - PDFDocument9 pagesVECTOR TECHLOK CLAMP CONNECTOR TECHNICAL BROCHURE - PDFmariusmihaibNo ratings yet

- WPIL LR-LN Split Casing PumpDocument6 pagesWPIL LR-LN Split Casing Pumpfaisalshabir12inNo ratings yet

- Awwa C207 2018Document40 pagesAwwa C207 2018JacobUnda100% (1)

- Case-Record NLIU SIAC LL-Partners Justice R.K. - Tankha Memorial International Moot 2020Document40 pagesCase-Record NLIU SIAC LL-Partners Justice R.K. - Tankha Memorial International Moot 2020Rahul BarnwalNo ratings yet

- MSS SP 6 - Standard Finishes For Contact Faces of Pipe Flanges and Connecting-End Flanges of Valves and Fittings - 2001Document6 pagesMSS SP 6 - Standard Finishes For Contact Faces of Pipe Flanges and Connecting-End Flanges of Valves and Fittings - 2001vladmir18No ratings yet

- Profile of the International Pump Industry: Market Prospects to 2010From EverandProfile of the International Pump Industry: Market Prospects to 2010Rating: 1 out of 5 stars1/5 (1)

- Elastic Stability of Circular Cylindrical ShellsFrom EverandElastic Stability of Circular Cylindrical ShellsRating: 5 out of 5 stars5/5 (1)

- Bolts - LRFDDocument6 pagesBolts - LRFDalexortiz83No ratings yet

- Upper Plate Spec.Document1 pageUpper Plate Spec.MiguelRagasNo ratings yet

- SK 240Document4 pagesSK 240MiguelRagasNo ratings yet

- Worm Gear Screw Jacks Ctuk PDFDocument84 pagesWorm Gear Screw Jacks Ctuk PDFMiguelRagasNo ratings yet

- Item # 41324, Metric Shoulder Eye Bolt: 1110 Fullerton Road City of Industry, CA 91748Document2 pagesItem # 41324, Metric Shoulder Eye Bolt: 1110 Fullerton Road City of Industry, CA 91748MiguelRagasNo ratings yet

- Phe 1160tgrsbDocument1 pagePhe 1160tgrsbMiguelRagasNo ratings yet

- Chain Din766 PDFDocument5 pagesChain Din766 PDFMiguelRagas100% (1)

- Lifting Lug Design-MrDocument5 pagesLifting Lug Design-MrMiguelRagasNo ratings yet

- Manual Lodestar XLDocument52 pagesManual Lodestar XLMiguelRagasNo ratings yet

- TM Assembly Partlist-RevDocument33 pagesTM Assembly Partlist-RevMiguelRagasNo ratings yet

- Vegawell 52Document20 pagesVegawell 52MiguelRagasNo ratings yet

- Perneria Tat 15M - CimeDocument1 pagePerneria Tat 15M - CimeMiguelRagasNo ratings yet

- Base Plate and Anchor Bolt Design - MailDocument5 pagesBase Plate and Anchor Bolt Design - MailMiguelRagasNo ratings yet

- American SteelBook 2Document472 pagesAmerican SteelBook 2MiguelRagasNo ratings yet

- Anexo 1D Antena MW 1.2mDocument5 pagesAnexo 1D Antena MW 1.2mMiguelRagasNo ratings yet

- 1 - Dimensiones y Marcas PDFDocument2 pages1 - Dimensiones y Marcas PDFMiguelRagasNo ratings yet

- NEMA CatalogDocument59 pagesNEMA CatalograiNo ratings yet