Professional Documents

Culture Documents

Hatlapa Towing Winches

Hatlapa Towing Winches

Uploaded by

NMHaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hatlapa Towing Winches

Hatlapa Towing Winches

Uploaded by

NMHaCopyright:

Available Formats

TOWING WINCHES

STRUCTURAL FEATURES:

Single and double drum in waterfall design or

linear design

Driving systems for Hatlapa towing winches:

Low-pressure hydraulic drive type Hatlapa

High-pressure hydraulic drive

A.C. electric drive

Quick release function

Torque transmission by means of friction clutch

Towing drum with spooling device

The design corresponds to the IMO Guidelines for Safe

Ocean Towing as well as to the regulations of all inter-

nationally recognised classifcation societies

Load measuring device

Rope speed and length measuring device

Tailor-made to customer requirements

TOWING WINCHES

ADVANTAGES:

The exclusive use of friction clutches guarantees that

during every possible towing situation the towing drum can

be disengaged without endangering the operative driving

components.

For towing winch capacities of more than 600 kN with

the corresponding speed the use of double low-pressure

drives ensures suffcient capacity reserves in case of failure

of one motor, thus guaranteeing continuing operation.

For example: By installation of an additional planetary

gear stage it is possible to change the direction of

rotation of the drum and simultaneously increasing the pull

to carry out anchoring operations.

The winch design is adapted to the geometry of the tug,

either in waterfall or adjacent arrangement to allow a free

view on the drum and rope for the operator from the bridge

during all towing operations.

For the possible special use of the towing winch

for escorting operation the necessary steps have been

taken, which fulfll the requirements of the classifcation

societies for an auto-tensioning winch system.

In case of sudden overload due to dynamic seaway con-

ditions, the winch slips and later the original rope length is

automatically re-set.

Example: Double drum towing winch in

waterfall arrangement 2000/3000 kN

Illustrations, technical data, weights and dimensions are subject to alteration without previous notice.

V

e

r

s

i

o

n

:

0

4

/

2

0

1

4

Holding load

Fst: 3200 kN (1st layer)

Pull

F dyn: 1000/2000 kN (1st layer)

FK dyn: 850 kN

Features

Electro-hydraulic, remotely-

controlled friction clutches

Electro-hydraulic, remotely

controlled spindle band brakes

Spooling device

You might also like

- DMT ATW 211-H19 350 KN Anchor Towing Winch Technical Manual (DWG 10002-2 DMT Order No. 218126) For YN 513520 (MANUAL-I - 4086177 - 1 - A) - 1Document40 pagesDMT ATW 211-H19 350 KN Anchor Towing Winch Technical Manual (DWG 10002-2 DMT Order No. 218126) For YN 513520 (MANUAL-I - 4086177 - 1 - A) - 1phankhoa83-1100% (1)

- User Manual: Net WinchDocument92 pagesUser Manual: Net WinchAlejandro ContrerasNo ratings yet

- 16.5.user Manual - Davit HMD A15 MacGregorDocument110 pages16.5.user Manual - Davit HMD A15 MacGregorGabriel Nogueira100% (1)

- F-29 Hose Handling CraneDocument100 pagesF-29 Hose Handling CraneSHANANDNo ratings yet

- MC Gregor Crane and 501-MOB-boat-davit - CARGOTEC - Manual SP2423-1-15 UMDocument193 pagesMC Gregor Crane and 501-MOB-boat-davit - CARGOTEC - Manual SP2423-1-15 UMHristo67% (3)

- Docdoss 5138Document419 pagesDocdoss 5138naved ahmedNo ratings yet

- Windlass NotesDocument2 pagesWindlass NotessbdmanNo ratings yet

- MacGregor GLB Cargo Crane PDFDocument2 pagesMacGregor GLB Cargo Crane PDFTbayu100% (1)

- Deck Machinery TTS-KocksDocument63 pagesDeck Machinery TTS-KocksBui Duy Thanh50% (2)

- Provision Crane PDFDocument68 pagesProvision Crane PDFKaushalKishoreNo ratings yet

- Instruction Manual Hydraulic Winches ASD Tug 2.0 3212-2913-2813 V0Document85 pagesInstruction Manual Hydraulic Winches ASD Tug 2.0 3212-2913-2813 V0phankhoa83-1100% (1)

- Specs 1270-33 18 X 18Document22 pagesSpecs 1270-33 18 X 18Hery Mardiono Hery100% (2)

- Flyer TL-FADocument20 pagesFlyer TL-FAmingo622No ratings yet

- Stelkraft CT ProductsDocument40 pagesStelkraft CT ProductsLuis GonzalezNo ratings yet

- TTS Hose Handling CranesDocument4 pagesTTS Hose Handling CranesCaptIsqanNo ratings yet

- 60t Crane SP2552-1-15-1 UMDocument400 pages60t Crane SP2552-1-15-1 UMkodrysNo ratings yet

- Active Heave Compensation Winch System - ACE Winches PDFDocument24 pagesActive Heave Compensation Winch System - ACE Winches PDFxxshNo ratings yet

- Group 2 WindlassDocument17 pagesGroup 2 WindlassUser NameNo ratings yet

- 420118-Gantry Crane ManualDocument17 pages420118-Gantry Crane ManualAndreyOsyanin100% (1)

- Towing Winch Emergency Release Systems-Cu Aplicare Din 2020Document4 pagesTowing Winch Emergency Release Systems-Cu Aplicare Din 2020tonyNo ratings yet

- Gravit 2Document15 pagesGravit 2Ivan MaltsevNo ratings yet

- Winch, Rolls-RoyceDocument202 pagesWinch, Rolls-RoyceOleksandr RakshaNo ratings yet

- Bow Thruster Tb35tDocument5 pagesBow Thruster Tb35tGiyan Arpero ManiaNo ratings yet

- TTS Crane User Manual 11857-Rev.2Document256 pagesTTS Crane User Manual 11857-Rev.2armagan100% (3)

- SEC Deck Machinery - EMW 160Document146 pagesSEC Deck Machinery - EMW 160john smith100% (2)

- Deck Machinery - 2012 PDFDocument32 pagesDeck Machinery - 2012 PDFMOXAMARISA50% (2)

- 80 Ton AHTS Specification Rev 0Document81 pages80 Ton AHTS Specification Rev 0Mark Samsel RohanNo ratings yet

- HATLAPA Electrically Driven Deck MachineryDocument2 pagesHATLAPA Electrically Driven Deck MachineryKristomiDerMarine-IngenieurNo ratings yet

- Damen Winch - OperatingManual - v1Document25 pagesDamen Winch - OperatingManual - v1phankhoa83-1No ratings yet

- ASD Tug Specification PTB PDFDocument29 pagesASD Tug Specification PTB PDFAndi irfanNo ratings yet

- Anchor-Capstan Winch Manual YN513301Document62 pagesAnchor-Capstan Winch Manual YN513301phankhoa83-1100% (1)

- CM P4683-86 Issue-ADocument231 pagesCM P4683-86 Issue-AVitaliy Romashko0% (1)

- 4x 65 Ton AHTS Specification Rev 0Document85 pages4x 65 Ton AHTS Specification Rev 0pal_malay100% (1)

- LH 185 DS 0062 6Document6 pagesLH 185 DS 0062 6Primelift Safety Resources LimitedNo ratings yet

- ACE WinchDocument24 pagesACE Winche_qdaNo ratings yet

- 12 Peiner Grab Accessories Service 130124-MinDocument114 pages12 Peiner Grab Accessories Service 130124-MintrobasNo ratings yet

- HS - Marine KatalogDocument20 pagesHS - Marine KatalogGogyNo ratings yet

- Hatchcover Crane 2-15 KWDocument207 pagesHatchcover Crane 2-15 KWValerija SilinaNo ratings yet

- 02 - Operation Instructions - Stern RollerDocument15 pages02 - Operation Instructions - Stern Rollermiguel100% (1)

- Viking: Product ManualDocument26 pagesViking: Product ManualCristian RobiconNo ratings yet

- Ace 02380 001 R8 PDFDocument1 pageAce 02380 001 R8 PDFClarkFedele27No ratings yet

- Mooring and Anchor Handling EquipmentDocument38 pagesMooring and Anchor Handling EquipmentTee Jay GarcesNo ratings yet

- Manual PDFDocument70 pagesManual PDFUsama PopatiaNo ratings yet

- Deck Machinery 1525480545 PDFDocument10 pagesDeck Machinery 1525480545 PDFDaniel Alejandro MoreiraNo ratings yet

- 125 Ton AHTSSV SpecificationDocument86 pages125 Ton AHTSSV SpecificationChakma NhikiNo ratings yet

- Design Criterions For Crane PedestalsDocument5 pagesDesign Criterions For Crane PedestalsRPDeshNo ratings yet

- General Arrangement PDFDocument33 pagesGeneral Arrangement PDFJeesonAntonyNo ratings yet

- Instruction Manual: Board CraneDocument10 pagesInstruction Manual: Board CraneKL PetrachkovNo ratings yet

- ZP10-1430 Stinger Winch Operator's ManualDocument22 pagesZP10-1430 Stinger Winch Operator's ManualIvan MaltsevNo ratings yet

- MM-2-5 Seal & Stern T BRG PDFDocument76 pagesMM-2-5 Seal & Stern T BRG PDFndlong60No ratings yet

- Windlas PDFDocument96 pagesWindlas PDFInfant RajNo ratings yet

- UR A Pdf148 Mooring AnchoringDocument21 pagesUR A Pdf148 Mooring AnchoringMeleti Meleti MeletiouNo ratings yet

- ASD Tug Specification - PTBDocument29 pagesASD Tug Specification - PTBNasrulSyahruddinNo ratings yet

- G01 General Arrangement (27M TUG)Document1 pageG01 General Arrangement (27M TUG)Ahmad RezkaNo ratings yet

- Syncro LiftDocument3 pagesSyncro Liftjoshivishal800No ratings yet

- GTC 400EX Trifold2013Document6 pagesGTC 400EX Trifold2013RobertNo ratings yet

- Options For BETA PROLINE Electric Wire Rope WinchesDocument2 pagesOptions For BETA PROLINE Electric Wire Rope Winches86babuNo ratings yet

- Tadano CranesDocument6 pagesTadano CranesvikrantparikhNo ratings yet

- Spacemaster SX: Electric Wire Rope Hoists Electric Wire Rope HoistsDocument6 pagesSpacemaster SX: Electric Wire Rope Hoists Electric Wire Rope Hoistssarexcuca2010No ratings yet

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- VTOS Crew Competency MatrixDocument1 pageVTOS Crew Competency MatrixNMHaNo ratings yet

- Tên Công Ty: Stock CompanyDocument6 pagesTên Công Ty: Stock CompanyNMHaNo ratings yet

- Quantity and Price Conversion Chart: Quantity Comparison Pricing ComparisonDocument1 pageQuantity and Price Conversion Chart: Quantity Comparison Pricing ComparisonNMHaNo ratings yet

- M/V Elsa Leigh: 254' DP1 DWT 1696LTDocument3 pagesM/V Elsa Leigh: 254' DP1 DWT 1696LTNMHaNo ratings yet

- Ram Xii and Ram Xiv: Crane (Ram) Hydraulic & PropulsionDocument4 pagesRam Xii and Ram Xiv: Crane (Ram) Hydraulic & PropulsionNMHaNo ratings yet

- Ram Viii, Ram X and Ram Xi: Liftboat Class 175Document3 pagesRam Viii, Ram X and Ram Xi: Liftboat Class 175NMHaNo ratings yet

- Class 270 MV Ram Country 6162015Document4 pagesClass 270 MV Ram Country 6162015NMHaNo ratings yet

- M/V Ram Challenger: 220 Class Z Drive DP1 DWT 1461LTDocument2 pagesM/V Ram Challenger: 220 Class Z Drive DP1 DWT 1461LTNMHaNo ratings yet

- Aries Application 2015 FormDocument2 pagesAries Application 2015 FormNMHaNo ratings yet

- M/V Elsa Leigh: 254' ! DP1 DWT 1461LTDocument2 pagesM/V Elsa Leigh: 254' ! DP1 DWT 1461LTNMHaNo ratings yet

- Ram Xvi and Ram Xvii: DimensionsDocument3 pagesRam Xvi and Ram Xvii: DimensionsNMHaNo ratings yet

- M/V Betty Pfankuch: DP 2 ! Solas ! Fifi 1 DWT 5,553Document4 pagesM/V Betty Pfankuch: DP 2 ! Solas ! Fifi 1 DWT 5,553NMHaNo ratings yet

- Ram Viii, Ram X and Ram Xi: Liftboat Class 175'Document3 pagesRam Viii, Ram X and Ram Xi: Liftboat Class 175'NMHaNo ratings yet

- M/V Ram Charger: 220 Class Z Drive DP1 DWT 1461LTDocument2 pagesM/V Ram Charger: 220 Class Z Drive DP1 DWT 1461LTNMHaNo ratings yet

- Ram XV: Liftboat Class 175'Document3 pagesRam XV: Liftboat Class 175'NMHaNo ratings yet

- Ram Vii: Liftboat Class 145'Document3 pagesRam Vii: Liftboat Class 145'NMHaNo ratings yet

- Annex A - 1 - Ship Man 98Document1 pageAnnex A - 1 - Ship Man 98NMHaNo ratings yet

- Annex "B" (Details of Crew) To The Baltic and International Maritime Council (Bimco) Standard Ship Managementagreement - Code Name: "Ship MAN 98"Document1 pageAnnex "B" (Details of Crew) To The Baltic and International Maritime Council (Bimco) Standard Ship Managementagreement - Code Name: "Ship MAN 98"NMHaNo ratings yet

- M/V Abigail Claire: Class 220' ! DPII DWT 2600LTDocument2 pagesM/V Abigail Claire: Class 220' ! DPII DWT 2600LTNMHaNo ratings yet

- 220 Class Calvin Bayne SpecsDocument2 pages220 Class Calvin Bayne SpecsNMHaNo ratings yet

- Ram I, Ram Iii, Ram Iv, Ram V and Ram Vi: Liftboat Class 130'Document4 pagesRam I, Ram Iii, Ram Iv, Ram V and Ram Vi: Liftboat Class 130'NMHaNo ratings yet

- M/V Kylie Williams: Class 220' DP 2 DWT 2,940Document2 pagesM/V Kylie Williams: Class 220' DP 2 DWT 2,940NMHaNo ratings yet

- The Baltic and International Maritime Council (Bimco) Standard Ship Management AgreementDocument1 pageThe Baltic and International Maritime Council (Bimco) Standard Ship Management AgreementNMHaNo ratings yet

- Annex A - 2 - Ship Man 98Document1 pageAnnex A - 2 - Ship Man 98NMHaNo ratings yet

- 3 MAR.2014 VM-13 Alarm Safety Tests For Automation, Electrical Emergency EquipmentDocument162 pages3 MAR.2014 VM-13 Alarm Safety Tests For Automation, Electrical Emergency EquipmentNMHaNo ratings yet

- Type Serial No Spec Output Speed Type No Spec Output Speed TypeDocument2 pagesType Serial No Spec Output Speed Type No Spec Output Speed TypeNMHaNo ratings yet

- Datenblatt Natalie English WebDocument5 pagesDatenblatt Natalie English WebNMHaNo ratings yet

- M.D.O and Lubricating Oil Monthly ReportDocument4 pagesM.D.O and Lubricating Oil Monthly ReportNMHaNo ratings yet

- M/V Atlantic Eagle: Running HoursDocument6 pagesM/V Atlantic Eagle: Running HoursNMHaNo ratings yet

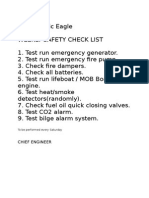

- Weekly Safety Check ListDocument1 pageWeekly Safety Check ListNMHaNo ratings yet