Professional Documents

Culture Documents

Chapter9 GMAW FCAW Welding

Chapter9 GMAW FCAW Welding

Uploaded by

rusf123Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter9 GMAW FCAW Welding

Chapter9 GMAW FCAW Welding

Uploaded by

rusf123Copyright:

Available Formats

feeders has made GMAW more useful.

Welding using

GMAW is easy to learn, especially if a welder has already

learned to weld using a different process. GMAW equip-

ment is relatively low in cost. Also, this process deposits

more weld metal in lbs./hr. (kg/hr) than the shielded

metal arc or gas tungsten arc welding processes. The low

purchase cost, the ability to weld continuously, and the

ability to deposit weld metal faster, make GMAW an

attractive choice for welding.

GMAW can be used to produce high-quality welds on

all commercially important metals such as aluminum,

magnesium, stainless steels, carbon and alloy steels,

copper, and others. GMAW may also be done easily in all

welding positions.

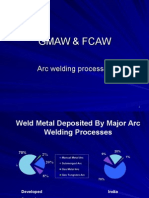

9.1 Gas Metal Arc Welding Principles

Gas metal arc welding is generally used because of

its high productivity. GMAW is done using solid wide

electrodes. FCAW uses flux cored wire electrodes. See

Figure 9-1. A shielding gas or gas mixture must be used

with GMAW.

GMAW is done using DCEP (DCRP). Alternating

current is never used. DCEN (DCSP) is rarely used for

GMA welding, but has found very limited use for

surfacing. DCEN (DCSP) is used with only one special

electrode, called an emissive electrode. (AWS designation

E70U-1).

For every pound of solid electrode wire used, 92%-

98% becomes deposited weld metal. Flux cored arc

welding wire is deposited with a wire efficiency of 82%-

92%. As a comparison, shielded metal arc welding

(SMAW) deposits 60%-70% of the electrode wire as weld

metal. Some spatter does occur in the GMAW and FCAW

processes. Very little stub loss occurs when continuously

fed wire is used.

There is a very thin glass-like coating over the weld

bead after GMA welding. No heavy slag is developed

because the weld area is shielded by a gas. When FCAW, a

slag covering is present. Some of the flux in the FCAW

233

Learning Objectives

After studying this chapter, you will be able to:

1 Contrast the various GMAW metal transfer

methods, considering arc characteristics, weld

characteristics, and the possibility of performing

out-of-position welds.

1 Select the proper arc welding machine, wire

feeder, shielding gas, flow rate, contact tube,

nozzle size, and electrode wire type to produce

an acceptable GMAweld.

1 Contrast the various types of shielding gases

used when GMAW, and how they affect the

shape and penetration of the completed welds.

1 Properly assemble and adjust all the equipment

required to produce an acceptable GMA and

FCAweld.

1 Correctly prepare metals for welding, and

perform acceptable welds on all types of joints in

all positions using GMAW and FCAW.

1 Identify the potential safety hazards involved in

the GMAW and FCAW process in a working

environment; be able to describe ways of safely

dealing with these hazards.

1 Be able to pass a safety test on the proper use of

the GMAW and FCAW process.

The gas metal arc welding (GMAW) process uses a

solid wire electrode that is continuously fed into the weld

pool. The wire electrode is consumed and becomes the

filler metal. Flux cored arc welding (FCAW) is very similar

to gas metal arc welding. One big difference is that FCAW

uses an electrode wire with flux inside the wire. For an

overview of these processes, refer to Headings 4.3 and 4.4

and also to Figures 4-3 and 4-4.

The growth in the use of GMAW is the result of

several events. The continuous development and refine-

ment of constant voltage arc power sources and wire

Chapter 9

Gas Metal Arc Welding

forms a gas around the weld area. Some of the flux forms

a slag, covering the weld. Shielding gas may or may not be

used when FCAW. More welder time can be spent on the

welding task with a continuously fed wire process. This

improves the cost efficiency of GMAand FCAwelding.

The GMAW process can be adapted to a variety of job

requirements by choosing the correct shielding gas, elec-

trode size, and welding parameters. Welding parameters

include the voltage, travel speed, and wire feed rate. The

arc voltage and wire feed rate will determine the filler

metal transfer method.

Metal transfer occurs in two ways. One is by the short

circuiting method. The second is to transfer metal across

the arc. Methods of transferring metal across the arc

include:

Globular transfer.

Spray transfer.

Pulsed spray transfer.

9.1.1 Short Circuit GMAW

Short circuit gas metal arc welding (GMAW-S) is

used with relatively low welding currents. It also uses elec-

trode wire sizes under 0.045 (1.1mm). This process is

particularly useful on thin metal sections in all positions.

All position welds are made easily because there is no

metal transfer across the arc. The weld pool cools and

solidifies rapidly using the short circuiting arc. Short

circuiting transfer has a low heat input into the base metal.

Since short circuit gas metal arc welding has a low

heat input, it is also used to weld thick sections in the over-

head or vertical welding position. It is very effective in

filling the large gaps of poorly fitted parts.

Refer to Figure 9-2 to see how the short circuiting arc

method deposits metal. When the electrode touches the

molten weld pool, the arc is no longer present. The surface

234 Modern Welding

Shielding

gas

Contact

tube

Wire

motion

Electrode

Gas

nozzle

(GMAW)

Gas metal Arc welding

Wire

motion

Shielding

gas

(if used)

Contact

tube

Gas nozzle

(if used)

(FCAW)

Flux cored arc welding

Flux cored

electrode

Figure 9-1. Schematic views of GMAW and FCAW gas nozzles and electrodes. Shielding gas is not always used with FCAW.

If shielding gas is not used, no nozzle is required.

Arc

reignites

Wire nears

another short

circuit

Metal short

circuits to

weld pool

Pinch force

squeezing

off droplet

Pinch

force

Shielding

gas

envelope

Figure 9-2. The sequence of metal transfer during the short

circuit GMAW method.

This sample chapter is for review purposes only. Copyright The Goodheart-Willcox Co., Inc. All rights reserved.

tension of the pool pulls the molten metal from the end of

the electrode into the pool. The pinch force around the

electrode squeezes the molten end of the electrode. The

combined effects of surface tension and the pinch force

separate the molten metal and the electrode. The arc then

reestablishes itself. The continuously fed electrode again

touches the molten pool and the process repeats. The

droplet transfer or short circuiting process repeats itself

about 20 to 200 times per second. The strength of the pinch

force depends on the arc voltage, the slope of the power

source or welding machine, and the circuit resistance.

These factors voltage, slope, and resistance affect the

welding current. The frequency of the pinch force and the

formation of droplets is controlled by the inductance of the

power source.

If a 150A current is set on the arc welding machine,

the amperage may rise rapidly to the maximum output of

the machine when the electrode short-circuits. This could

be 500A or more. To control and slow down this possible

rapid rise in current, an inductance circuit is built into the

arc welding machine.

Inductance is the property in an electric circuit that

slows down the rate of the current change. Some arc

welding machines have an electric coil built in near the

welding current transformer coils. See Heading 5.2.1 for a

discussion of inductance. The current traveling through an

inductance coil creates a magnetic field. This magnetic

field creates a current in the welding circuit that is in oppo-

sition to the welding current. Increasing inductance in a

welding machine will slow down the increase of the

welding current. Decreasing the inductance will increase

the rate of change of the welding current.

When too little inductance is used, the current rises too

rapidly. The pinch force is so great that the molten metal at

the end of the electrode literally explodes. A great deal of

spatter occurs in this case. When too much inductance is

used, the current will not rise fast enough. The molten end

on the electrode is not heated sufficiently.

By properly balancing the inductance and slope, an

ideal droplet transfer rate and pinch force can be obtained.

See Figure 9-3 for the metal deposition rate for the short

circuiting transfer method. Shielding gas also has an effect

on short circuiting transfer. Inert gases must be used on all

nonferrous base metals. Nonferrous base metals are those

that do not contain iron as the main element. This

grouping includes everything except steels, steel alloys,

and cast irons. Adding helium to argon will increase the

penetration. Argon and helium mixtures are used only on

nonferrous base metals.

Carbon dioxide (CO

2

) may be used as a shielding gas

when GMAwelding carbon and low-alloy steels. CO

2

will

produce greater penetration, but will create more spatter

than an inert gas used for shielding. Mixtures of argon and

CO

2

are often used. They provide a good combination of

improved penetration with minimal spatter. Stainless steel

usually requires a mix of three gases. A typical mixture is

90% helium, 7 1/2% argon, and 2 1/2% CO

2

.

9.1.2 Globular Transfer

Globular metal transfer gas metal arc welding occurs

when the welding current is set slightly above the range

used for short circuiting metal transfer. In the globular

metal transfer process, the metal transfers across the arc as

large, irregularly shaped drops. See Figure 9-4. The drops

are usually larger than the electrode diameter.

Chapter 9 Gas Metal Arc Welding 235

GMAW

Method

Metal Deposited

lbs/hr kg/hr

Short circuiting

Globular

Spray

Pulsed spray

2-6

4-7

6-12

2-6

0.9-2.7

1.8-3.2

2.7-5.4

0.9-2.7

Figure 9-3. The approximate rate at which filler metal is

deposited with various GMAW methods.

(American Welding Society)

Arc

Shielding

gas

envelope

Spatter

Deep

weld

pool

Irregular large droplet

forming

Droplet may short

circuit when it falls

Droplet may fall erratically

and cause spatter

Buried arc helps to contain

droplet to reduce spatter

Figure 9-4. GMAW globular metal transfer. Drops may fall

erratically and cause spatter. Note that the buried arc may

help contain the drops to reduce spatter.

Drops form on the end of the electrode. Each drop

grows so large that it falls from the electrode due to its own

weight. When a high percentage of inert gas is used for

shielding, the drops will fall into the weld pool. When

a high percentage of carbon dioxide is used, the drops

travel across the arc in random patterns, creating spatter.

To minimize spatter, a shorter arc length can be used.

However, a short arc will allow large drops to short to the

work. The drops will explode, still creating a lot of spatter.

One way to minimize spatter when using CO

2

is to

increase the current slightly. This will create a deep weld

pool that is below the metal surface. This is referred to as a

buried arc or submerged arc. Using a buried arc, much of

the spatter is contained within the deep weld pool. With a

buried arc, a combination of globular and short circuiting

transfer occurs. Deeper penetration occurs when using a

buried arc.

Welds of sufficient quality for many applications can

be produced with this process. When using globular

transfer, welding can be done only in the flat welding posi-

tion, because the molten metal falls into the weld pool.

Welds may be made faster with this process than with the

short circuiting transfer method. See Figure 9-3 for the rate

at which metal is deposited with this method.

9.1.3 Spray Transfer

Spray transfer gas metal arc welding will occur when

the current and voltage settings are increased above those

required for globular transfer. When spray transfer occurs,

very fine droplets of metal form. These droplets travel at a

high rate of speed directly through the arc stream to the

weld pool. Figure 9-5 illustrates the spray arc metal

transfer method.

Spray transfer will only take place when a high

percentage of argon is used. When welding nonferrous

metals and alloys, 100% argon shielding gas is used. When

using spray transfer on carbon or low-alloy steels or stain-

less steels, a shielding gas mixture containing at least 90%

argon is used

Before spray transfer can occur, a current setting

above the transition current level must be made on the

welding machine. The transition current varies with the

electrode diameter, its composition, and the amount of

electrode extension. Ahigher transition current is required

for steel than aluminum. The transition current increases

with the electrode diameter. It decreases as the electrode

extends farther from the contact tube. See Figure 9-40.

Until the transition current is exceeded, the metal transfers

as large globules. Above the transition current level, the

pinch force becomes great enough to squeeze the metal off

the tip of the electrode as fine droplets. See Figure 9-6 for

various transition current levels.

The droplets are squeezed off cleanly and transferred

across the arc gap in a straight path. Spray transfer occurs

only when at least 90% argon is used as the shielding gas.

Common shielding gas mixtures for carbon and low-alloy

steels are: 98% Ar plus 2% O

2

; 95% Ar plus 5% O

2

; 95% Ar

plus 5% CO

2

; and 90% Ar plus 10% CO

2

. The spray

transfer method produces deep penetration. The arc can be

directed easily by the welder. This is because the arc and

metal spray pattern are stable and concentrated. Spray

transfer is best done in the flat or horizontal welding posi-

tion, and on metal over 1/8 (3mm) thick. See Figure 9-3

for the metal deposition rate.

9.1.4 Pulsed Spray Transfer

The pulsed spray transfer gas metal arc welding

method is similar to the spray transfer method. See Figure

9-7. The current level for pulsed spray must be above the

transition current level. Special circuits within the power

source (welding machine) cause the current to pulse. A

low-level current in the globular transfer range is used to

maintain the arc. This current is called the background

current. The current is increased at a regular frequency to

the peak current. The peak current is above the transition

current level. Since the background current is on for only a

short time, no globular transfer actually occurs. During the

peak current time period, spray transfer occurs. In this

236 Modern Welding

Stage 1

Stage 2

Metal

droplets

Wire

necks

down

Shielding

gas

envelope

Arc

Figure 9-5. Spray transfer method. Note how the droplets

are concentrated in the center of the arc. Spray transfer will

occur only when a high percentage of argon gas is used.

method, no necking down of the wire occurs. The metal

leaves the electrode in a spray of small droplets.

Spray transfer does not occur continually, therefore,

the name pulsed spray transfer. The rate of metal transfer

increases and the droplet size decreases as the pulse

frequency increases. Basic welding machines with pulse

capabilities allow the welder to select pulse frequencies of

60 or 120 pulses per second. Some machines allow the user

to adjust the pulse frequencies. Pulse frequencies can go

much higher than 120 pulses per second. The coolest spray

transfer occurs at 60 pulses per second.

Alower average current level is used in pulsed spray

than in spray transfer. This lower average current level

makes it possible to weld out of position. Thin metal

sections may also be welded more easily with the pulsed

spray. This method creates very little metal spatter.

The pulsed spray transfer method can use larger-

diameter electrode wire. This is an advantage. Larger-

diameter electrodes are cheaper. Also, nonferrous wires of

larger diameter can be fed through the wire drive unit

more easily without kinking.

See Figure 9-3 for the metal deposition rate for the

pulsed spray transfer method. Pulsed spray is also used to

weld parts with silicon bronze filler wire. This process is

sometimes called MIG brazing. Light steel parts in auto

repair shops can be welded with very low heat inputs.

This reduces the problems of distortion and melt-through.

9.2 GMAW Power Sources

Welding power sources for GMAW provide a

constant voltage. The most common types of power

Chapter 9 Gas Metal Arc Welding 237

Wire electrode

type

Mild steel

Mild steel

Mild steel

Mild steel

Stainless steel

Stainless steel

Stainless steel

Aluminum

Aluminum

Aluminum

Deoxidized copper

Deoxidized copper

Deoxidized copper

Silicon bronze

Silicon bronze

Silicon bronze

Wire

electrode

diameter

Shielding gas

Minimum

spray arc

current, A

0.76

0.89

1.14

1.59

0.89

1.14

1.59

0.76

1.14

1.59

0.89

1.14

1.59

0.89

1.14

1.59

98% argon-2% oxygen

98% argon-2% oxygen

98% argon-2% oxygen

98% argon-2% oxygen

99% argon-1% oxygen

99% argon-1% oxygen

99% argon-1% oxygen

argon

argon

argon

argon

argon

argon

argon

argon

argon

150

165

220

275

170

225

285

95

135

180

180

210

310

165

205

270

Note: Spray transfer will only occur when high percentage of argon are used.

in. mm

0.030

0.035

0.045

0.062

0.035

0.045

0.062

0.030

0.045

0.062

0.035

0.045

0.062

0.035

0.045

0.062

Figure 9-6. Approximate transition current levels to obtain spray transfer for various metals. (American Welding Society)

Droplets

form at

a constant

rate

Shielding

gas

envelope

Droplet

forms

without

necking

of wire

Figure 9-7. Pulsed spray metal transfer method. Spray

transfer only occurs during peak current.

sources are transformer-rectifier machines. GMAW is done

using DCEP. DCEN can be used in special applications. Ac

is not used for gas metal arc welding.

Inverter power sources are much smaller and lighter

than traditional transformer-rectifier machines. This type

of power source is gaining in popularity. Quite often, an

inverter arc welding machine will provide a choice of

constant current or constant voltage from the same

machine. The welder must select the constant voltage

mode when GMAW. Performance of an inverter machine

is very similar to a transformer-rectifier constant voltage

machine.

Machines used for GMAW may have a wire feeder

built into the power supply. The wire feeder may be an

external unit, as seen in Figure 9-8.

Inverter machine controls are very similar to those

on a transformer-rectifier machine. If the inverter

machine has the ability to do multiple processes, select

GMAW or the constant voltage setting. After making this

selection, the main control setting on the inverter

machine is used to set the voltage. The wire feed speed

adjustment sets the wire feed speed and also sets the

appropriate current. The output and performance of an

inverter are the same as those of a transformer-rectifier

type machine. Refer to Heading 5.2.3 for more informa-

tion on inverter machines.

9.3 Setting Up the GMAW Station

Figure 9-9 illustrates a complete GMAW outfit. The

same equipment may be used for flux cored arc welding.

Remember, self-shielding FCAW does not require any

shielding gas.

To prepare a GMAW or FCAW outfit for welding, the

following steps should be taken:

1. Connect a separate wire feed unit to the welding

power source, if required. The manufacturers

instructions should be followed to make these

connections. Usually, a single cable assembly is

enough to electrically connect the wire feeder to the

welding machine. The welding lead from the positive

terminal of the welding machine is usually connected

to the wire feeder. Connecting the positive lead to the

wire feeder will provide DCEP current. A shielding

gas hose may also need to be connected.

2. Mount the desired electrode wire reel (spool) onto

the wire feeder.

3. Determine what shielding gas is required. See

Heading 9.3.3. No shielding gas is required when

using self-shielded FCAW. Properly secure the

cylinder (if used) to prevent it from being knocked

over. Check that the regulator and gas flowmeter are

attached properly. Connect a hose from the flowmeter

to the welding machine or wire feeder as required.

The hose and fittings should be checked to make sure

there are no leaks.

4. Connect the welding gun to the correct place on the

welding machine or wire feeder. Quite often there are

two connections to be made. See Figure 9-8. One is the

main cable, that is connected where the electrode wire

exits the wire feeder. Attach this part of the cable

assembly to its proper place. The second connection is

for the electrical control circuit. This part of the cable

assembly also must be connected to its proper place.

Awater-cooled gun will have additional connections.

5. Connect the workpiece lead to the welding machine.

Both the welding gun cable assembly and the work-

piece lead should be checked for any signs of wear or

cuts. Such wear or cuts on the outside may indicate

damage to the leads.

6. The workpiece clamp should be checked. The clamp

should be clean so it can make a good electrical

connection.

238 Modern Welding

Remote contactor

cable connection

Cable to

welding gun

Figure 9-8. An inverter power source with a separate wire

feeder mounted on top of the welder.

(Miller Electric Mfg. Co.)

Transformer-rectifier machines are designed to

control voltage. Voltage is one of the two important vari-

ables used to set the welding parameters for GMAW. On

the front of the machine, there is a control that is used to

set the voltage.

The second important variable is the wire feed speed.

This control will be on the welding power source if

the wire feeder is built into the power source. If the wire

feeder is not in the power source, the wire feed speed is set

on the external wire feeder. When the welder sets the wire

feed speed, the wire feed speed and the appropriate

welding current are being adjusted. A higher wire feed

speed requires a higher current to melt the electrode wire

faster. A slower wire feed speed requires less current to

melt the electrode wire.

7. If a water cooler is used, connect it to the welding

machine or to the gun according to the manufactures

recommendations. Usually, the welding machine,

wire feeder, or welding gun is connected to the outlet

on the water cooler. This way, cool water flows from

the cooler to the gun. Warm water returning from the

gun is connected to the inlet on the water cooler.

When setting up the GMAW station, look for all

potential safety problems. Spatter from GMAW or FCAW

can cause a fire. All flammable materials must be removed

from the welding area.

9.3.1 Setting Up the GMAW Power Source

Properly setting up of a GMAW power source is

necessary to obtain the desired transfer method. Before

setting up the power source, the following information

needs to be known:

The type of base metal to be welded.

Base metal thickness.

The type of transfer method to be used.

The type of shielding gas to be used.

The type and diameter of electrode wire.

Once these are known, the welding machine can be

properly set up. Only a few controls must be set prior to

welding. Figure 9-10 shows a welding machine and its

controls.

Two switches must be set. One is to allow the voltage

to be set on the panel or remote. The second switch allows

a choice between a remote or panel contactor. Once these

two switches are set, they are rarely changed. Once the

remote or panel voltage and contactor switch are set, the

only adjustments that need to be made are the voltage and

wire feed speed.

The next adjustment is the voltage setting. The

voltage determines the arc length and helps determine the

electrode transfer method. Other factors also affect the

transfer method as discussed in Headings 9.1.1 through

9.1.4.

Welding machines with a wire feeder built in will

have the wire feed speed adjustment on the machine itself.

If the wire feeder is a separate unit, the wire feed speed

adjustment is on the wire feeder. When adjusting the wire

Chapter 9 Gas Metal Arc Welding 239

Wire speed control

Gas out

Switch

Wire reel

Gas in

Flowmeter

Shielding

gas

source

Regulator

Voltage

control

Wire feed

drive motor

Contactor control

110V supply

Welding power source

Contactor cable

Manually

held gun

Work

Figure 9-9. Diagram of a complete gas metal arc welding (GMAW) outfit.

Remote/panel

selector

Voltage

selector

Volts

Amps

Power

on/off

Figure 9-10. A cc/cv welding power source.

(Miller Electric Mfg. Co.)

feed speed, the welder is adjusting the nominal amperage

of the welding machine.

The following figures list the voltage and amperage

settings for welding different base metals using both short

circuiting transfer and spray transfer.

Metal Figure

Metal Transfer Method No.

Mild and low- Short circuit 9-11

alloy steel Spray transfer 9-12

Stainless steel Short circuit 9-13

(300 series) Spray transfer 9-14

Aluminum and Short circuit 9-15

aluminum alloys Spray transfer 9-16

Globular transfer voltages and amperages will fall in

the range between those shown for short circuiting and

spray transfer. Pulsed spray background voltage settings

will be slightly higher than the values shown for short

circuiting transfer. The peak current must be above the

transition current.

Figure 9-17 shows a welding machine on which

welding variables are set and stored in electronic memory.

The welding machine has a microprocessor inside. A

microprocessor can be considered a small computer. The

240 Modern Welding

Electrode

diameter

0.030

0.035

0.045

Arc

voltage

Amperage

range

in. mm

0.76

0.89

1.14

15-21

16-22

17-22

70-130

80-190

100-225

Note: The values shown are based on the use of CO

2

for mild steel and

argon CO

2

for low-alloy steel.

Figure 9-11. Approximate machine settings for short

circuiting metal transfer on mild and low-alloy steel.

Electrode

diameter

0.030

0.035

0.045

1/16

3/32

Arc

voltage

Amperage

range

in. mm

0.76

0.89

1.14

1.59

2.38

24-28

24-28

24-30

24-32

24-33

150-265

175-290

200-315

275-500

350-600

Note: The values shown are based on the use of argon with 2%-5% oxygen

for mild and low-alloy steel.

Figure 9-12. Approximate machine settings for spray

transfer on mild or low-alloy steel.

Electrode

diameter

0.030

0.035

0.045

Arc

voltage

Amperage

range

in. mm

0.76

0.89

1.14

17-22

17-22

17-22

50-145

65-175

100-210

Note: The values shown are based on a mixture of 90% helium; 7 1/2% argon;

2 1/2% CO

2

. The flow rates were about 20 cfh (9.44 L/min.).

Figure 9-13. Approximate machine settings for short

circuiting transfer on 300 series stainless steel.

Electrode

diameter

0.030

0.035

0.045

1/16

3/32

Arc

voltage

Amperage

range

in. mm

0.76

0.89

1.14

1.59

2.38

24-28

24-29

24-30

24-32

24-32

160-210

180-255

200-300

215-325

225-375

Note: The values shown are based on the use of argon-oxygen shielding gas.

The oxygen percentage varies from 1-5%.

Figure 9-14. Approximate machine settings for spray

transfer on 300 series stainless steel.

Electrode

diameter

0.030

0.035

0.047

(3/64)

Arc

voltage

Amperage

range

in. mm

0.76

0.89

1.19

15-18

17-19

16-20

45-120

50-150

60-175

Note: The values shown are based on the use of argon shielding gas.

Figure 9-15. Approximate machine settings for short

circuiting transfer on aluminum and aluminum alloys.

Electrode

diameter

0.030

0.035

0.047

(3/64)

1/16

3/32

Arc

voltage

Amperage

range

in. mm

0.76

0.89

1.19

1.59

2.38

22-28

22-28

22-28

24-30

24-32

90-150

100-175

120-210

160-300

220-450

Note: The values shown are based on the use of argon as the shielding gas.

Figure 9-16. Approximate machine settings for spray

transfer on aluminum and aluminum alloys.

microprocessor is programmed by the manufacturer with

a set of welding values. Based on a set of input data about

a weld, the microprocessor determines the best settings or

parameters for the welding application. Since the welding

machine has determined the welding parameters, the type

of transfer is also determined by the welding machine.

A welder using a microprocessor-equipped welding

machine enters the following type information about the

weld to be made: electrode wire type, wire diameter, type

of shielding gas, and metal thickness. The microprocessor

sets the voltage, wire feed speed, and possibly the slope,

thus determining the type of metal transfer that will be

used. Standard welding values are preprogrammed into

the welding machine. Special welding parameters can

also be saved as a program in the machine. This program,

or any preset values, can be recalled at any time in the

future. Because the welding values are stored electroni-

cally, the welding machine will be set up exactly the same

way each time.

Some power sources allow the slope to be changed.

Many machines have a preset value for the slope. Heading

7.10 discusses slope.

Power sources that have the ability to pulse weld

have additional controls to set up. These controls include

an on-off switch, a background voltage adjustment, a

peak amperage adjustment, and sometimes a pulses

per second adjustment. The background voltage is set

relatively low, in the globular transfer range. The peak

amperage is fairly high to cause spray transfer to occur.

This peak amperage must be above the transition current.

The pulses per second adjustment is used to set the

number of times per second the current will pulse from the

low value to the high value. Figure 9-18 shows a GMAW

machine with a power supply, wire feeder, and shielding

gas cylinder.

9.3.2 Setting Up the Wire Feeder

Most wire feeders use a 115V ac motor; however,

24V dc motors are becoming very popular. Figure 9-19

shows a complete wire drive unit. Two mated gears are

located in the wire drive unit. One gear is driven by an

electric variable-speed motor. Aroll is attached to each gear.

Figure 9-20 illustrates a two-drive-roll wire drive system.

The lower roll on the wire drive unit shown in

Figure 9-20 is adjustable in and out. The lower drive gear

has spring washers behind it. By turning the adjustment

bolt in the center of this gear, the gear and drive roll can be

moved inward or outward. This adjustment is provided to

align the groove in the wire drive roll with the center of the

wire. Figure 9-21 illustrates the adjustment of the wire

drive rolls.

Chapter 9 Gas Metal Arc Welding 241

Figure 9-17. A microprocessor-controlled power source

and wire feeder with digital displays. (Lincoln Electric)

Wire feed

speed

Amp/volt

display

selector

On/off

Welding process

selector

Arc power

inductance

control

Pulsed GMAW

schedule

selector

Figure 9-18. A portable GMAW power source. The control

panel includes a pulse schedule selector.

(Hobart Brothers Co.)

guide should be adjusted as close to the drive rolls as

possible without touching them. After the wire guide is set,

the securing bolt is tightened to hold the guide in place.

One problem that occurs occasionally during wire

feeder operation is the wire getting jammed and forming

a birds nest. Abirds nest is a tangle of electrode wire that

did not feed properly through the rolls and into the guide

tube. Figure 9-24 shows such a birds nest.

242 Modern Welding

Wire spool

spindle

Selector

switch for

2 preset

wire feed

conditions

Digital voltage

readout

Digital amperage

readout

Figure 9-19. A wire feeder with multiple feed control

programs. (Thermal Arc, a Thermadyne Company)

Pressure

roll

Drive

roll

In/out

adjustment

bolt

Well-adjusted

pressure roll:

down far enough

and in alignment

Wire too loose:

adjust pressure

roll downward

Rolls misaligned:

adjust drive roll outward

Figure 9-21. Adjusting drive rolls. The pressure (upper) roll

is adjusted up and down by means of the pressure-

adjusting knob, as in Figure 9-20. The lower drive roll is

adjusted in and out by means of an adjustment screw.

Main

drive gear

Figure 9-22. A four-wheel wire drive system. The parts are

similar to a two-wheel wire drive. The main drive gear is in

the center below the two lower rolls. The main gear drives

the gears behind the lower rolls. (Lincoln Electric Co.)

Upper gear swings up

to disengage gears

Outer wire

guide

In and out

adjustment

for wire

guide

In and out

adjustment

for drive roll

Drive housing bolt

Drive

housing

Drive roll with

drive gear behind it

Wire pressure adjusting knob

Inlet wire

guide

Pressure roll

with gear

behind it

Figure 9-22 shows a wire drive unit with four drive

rolls. This drive unit is similar to the two drive roll unit

shown in Figure 9-20. The unit shown in Figure 9-22

has three wire guides. Wire guides must be in alignment

with each other and with the center of the drive rolls.

Figure 9-23 illustrates properly and improperly adjusted

wire guides. The alignment of the wire guides is made at

the factory. In time, an adjustment may be necessary. See

drive units in Figures 9-20 and 9-22. The end of each wire

Figure 9-20. A two-drive roll wire drive system. The upper

pressure roll is pivoted out of the way when the wing nut

is loosened and the gear cover lifted up.

(Miller Electric Mfg. Co.)

To eliminate the birds nest and continue welding, the

following steps should be taken:

1. Turn off the power source and the wire feeder.

2. Raise the upper pressure roll.

3. Cut the birds nest wire at the outlet of the inlet wire

guide and at the entry of the outlet wire guide. See

Figure 9-24.

4. Remove the electrode wire from the cable assembly

going to the welding gun. This has eliminated the

birds nest.

5. Feed new wire into the cable assembly and lower the

upper pressure roller.

6. Feed the electrode wire to the gun by pulling the

trigger on the gun, or by pressing the inch switch.

To load a spool of electrode wire, place the spool onto

the hub on the wire feeder. Secure the spool using the

method available on the type of wire feeder being used.

Pressure rolls have one or two grooves cut in them.

Select and install pressure rolls that have the same groove

diameter as the diameter of the electrode wire being used.

Remember to change the pressure rolls if the electrode

diameter changes.

The final adjustment is to apply the proper force from

the rolls to the electrode. Adjustment is made using a

spring-loaded wing nut or knob. Tighten the knob to

apply only enough force to drive the wire without slip-

page. Too much force on the rolls and wire may cause the

solid wire to flatten (especially if the wire is aluminum).

Flux cored electrodes may be crushed. If the wire is

damaged, it will not feed through the wire cable and torch

properly. If not enough force is applied to the wire, the

rolls will slip and not drive the wire consistently.

Once the adjustments discussed so far have been

made, the wire feeder is ready to feed wire continuously.

Only the wire feed speed needs to be adjusted to meet the

requirements for each welding job. Adjust the feed speed

to obtain the amperage and transfer method desired.

Chapter 9 Gas Metal Arc Welding 243

A birds nest can be caused by the following

conditions:

Stubbing the electrode onto the base metal. This

is caused by holding the gun too close to the

work, using too-low a voltage or by using too-

high a wire feed speed.

Misaligned guide tubes and rolls.

Ablockage in the cable or liner.

To correct the cause of a birds nest, use the correct

contact tube-to-work distance (see Figure 9-40) or adjust

the settings on the welding machine or wire feeder. If this

does not solve the problem, determine if there is a

misalignment of the guide tubes and rolls or if there is a

blockage in the cable or liner. Correcting these problems

will eliminate the cause of the birds nesting.

Wire

Inlet wire

guide

Outlet wire

guide

Drive roll

Drive

housing

Drive housing

attaching

bolt(s)

Good Wire bent down Wire bent up

Drive housing and

wire guides too low.

To correct: raise

drive housing

Drive housing and

wire guides too high.

To correct: lower

drive housing

Drive rolls and wire

guides properly aligned

Figure 9-23. Properly and improperly aligned wire guides. If the wire bends going through the drive rolls, adjust the drive

housing up or down. Loosen the drive housing bolts, align, and tighten the bolts.

Figure 9-24. Removing a birds nest by cutting the elec-

trode wire behind the inlet wire guide and before the outlet

wire guide.

Figures 9-28 and 9-29 list shielding gases to be used

with different metals and transfer methods. The shielding

gases listed for short circuiting transfer are usually also

used for globular transfer. Those gases listed for spray

transfer are also used for pulsed spray transfer.

Inert gases, such as argon and helium, are chemically

inactive and do not unite with other chemical elements.

Nitrogen, oxygen, and carbon dioxide are reactive gases.

They will mix or react with metals in a weld. With the

exception of CO

2

, reactive gases are not used alone as

shielding gases. Nitrogen gas is used in Europe to weld

copper.

As noted earlier, each gas and gas mixture has an

effect on the type of metal transfer, and on the bead size,

penetration, welding speed, and undercutting tendencies.

Each of the important gases or gas mixtures is discussed in

the following paragraphs. Also refer to Heading 7.12.

Argon

This gas causes a squeezing (constricting) of the arc.

The results are a high current density (concentration) arc,

deep penetration, a narrow bead, and almost no spatter.

Argon ionizes more easily than helium and it conducts

some electricity. Therefore, lower arc voltages are required

for a given arc length. Argon conducts heat through the

arc more slowly than helium. Argon has a lower thermal

(heat) conductivity. It is an excellent choice for use on thin

metal. It is also good for out-of-position welds because of

the low voltages required.

Argon is the most common inert gas used for welding

nonferrous metals. It is used for all types of metal transfer.

When welding steel and steel alloys using spray transfer,

high percentages of argon, 90% or greater, must be used.

Pure argon used on carbon steel will cause undercut-

ting using the spray transfer method. Because this under-

cutting is not acceptable, argon is usually mixed with

small amounts of oxygen or carbon dioxide. Argon is

244 Modern Welding

Figure 9-26. Two gas mixers. The one on the left mixes up

to 50% CO

2

with argon. The one on the right mixes up to

10% oxygen with argon. (Thermco Instrument Corp.)

Other features on wire feeders often include an inch

switch or jog switch. This switch is used to feed wire to the

gun at a relatively slow speed to prevent kinking the wire.

Another switch is the purge switch. This is used to allow

the shielding gas to flow, so that the shielding gas will fill

the hose and remove (purge) all air.

Some wire feeders have a display that shows either

the set or actual voltage or wire speed. Figure 9-25 shows

such a wire feeder.

9.3.3 Inert Gases and Gas Mixtures Used for

GMAW

The inert shielding gases and other gases used in

shielding gas mixtures for GMAW are argon (Ar), helium

(He), oxygen (O

2

), carbon dioxide (CO

2

), and nitrogen

(N

2

).

Inert gases used should be of a welding grade. Carbon

dioxide gas is generally supplied 100% pure. Gas

mixtures can be purchased from a welding gas distributor

or can be mixed using a gas mixer like the one shown in

Figure 9-26.

Each shielding gas and mixture of gases will have a

different effect on the shape of the bead and the penetra-

tion. See Figure 9-27.

Factors that must be considered when choosing a

shielding gas are:

The type of metal transfer desired: short

circuiting, globular, spray, or pulsed spray

transfer.

The desired bead shape, width, and weld pene-

tration.

The required welding speed.

The undercutting tendencies of the gas.

Wire speed

display

Voltage display

Figure 9-25. A wire drive unit. The visual displays will

show set or actual wire speed and voltage. (Lincoln Electric

Co.)

heavier than helium, therefore, less gas is needed to

protect a weld.

Helium

The inert gas helium (He) has a high heat-conducting

ability. It transfers heat through the arc better than argon.

Helium is used to weld thick metal sections. This gas is also

used to weld metals that conduct heat well. Such metals as

aluminum, magnesium, and copper will conduct heat

away from the weld zone rapidly. More heat must be put

into the metal, therefore, helium gas is the best choice. The

arc voltages required for helium are higher and spatter is

greater. Helium will allow filler metal to be deposited at a

Chapter 9 Gas Metal Arc Welding 245 Chapter 9 Gas Metal Arc Welding 245

Argon &

oxygen

Argon Helium &

argon

Helium

Arc

Figure 9-27. Bead contours and penetration shapes that occur with various gases using DCEP polarity.

Metal Shielding

gas

Advantages

Aluminum,

copper,

magnesium,

nickel, and

their alloys

Steel,

carbon

Steel,

low-alloy

Steel,

stainless

argon and

argon-

helium

argon-

20-25% CO

2

argon-

50% CO

2

CO

2

a

60-70% helium-

25-35% argon-

4-5% CO

2

argon-

20-25% CO

2

90% helium-

7.5% argon-

2.5% CO

2

Argon satisfactory on sheet metal; argon-helium

preferred on thicker sheet metal.

Less than 1/8 (3mm) thick; high welding speeds

without melt-through; minimum distortion and spatter;

good penetration.

Greater than 1/8 (3mm) thick; minimum spatter;

clean weld appearances; good weld pool control

in vertical and overhead positions.

Deeper penetration; faster welding speeds; minimum

cost.

Minimum reactivity; good toughness; excellent arc

stability, wetting characteristics, and bead contour;

little spatter.

Fair toughness; excellent arc stability; wetting characteristics,

and bead contour; little spatter.

No effect on corrosion resistance; small heat-

affected zone; no undercutting; minimum distortion;

good arc stability.

a - CO

2

is used with globular transfer also.

Figure 9-28. Suggested gases and gas mixtures for use in GMAW short circuiting transfer.

faster rate than is possible with argon. This gas is often

used on nonferrous metals. It produces welds with wider

bead reinforcements. Helium is lighter than argon and will

require a greater gas flow to protect a weld as well as argon.

In addition to requiring a greater flow rate that uses more

shielding gas, helium is about 10% more expensive than

argon. Even though the cost for helium may be greater than

that for argon, the benefits of helium for the right welding

application make helium an excellent choice.

Carbon dioxide

This gas has a higher thermal (heat) conductivity than

argon. It requires a higher voltage than argon. Since carbon

dioxide (CO

2

) is heavy, it covers the weld well. Therefore,

less gas is needed.

CO

2

costs about 80% less than argon. This price differ-

ence will vary from location to location. Beads made with

CO

2

have a very good contour. The beads are wide and

have deep penetration and no undercutting. The arc in a

CO

2

atmosphere is unstable and a great deal of spattering

occurs. This is reduced by holding a short arc. Deoxidizers

like aluminum, manganese, or silicon are often added to

the filler metal. The deoxidizers remove the oxygen from

the weld metal. Good ventilation is required when using

pure CO

2

. About 7%-12% of the CO

2

becomes dangerous

CO (carbon monoxide) in the arc. The amount of CO

increases with the arc length.

Nitrogen

In Europe, nitrogen (N

2

) is used where helium is not

readily available. Mixtures containing nitrogen have been

used to weld copper and copper alloys. One mixture used

contains 70% argon and 30% nitrogen.

Argon-helium

Mixtures of argon and helium help to produce welds

and welding conditions that are a balance between deep

penetration and a stable arc. A mixture of 25% argon and

246 Modern Welding

Metal Shielding

gas

Advantages

Aluminum

Copper, nickel,

& their alloys

Magnesium

Reactive metals

(titanium,

zirconium,

tantalum)

argon

75% helium-

25% argon

90% helium-

10% argon

argon

helium-argon

argon

argon

argon-

2-5% oxygen

0.1-1 (0.25mm-25mm) thick; best metal transfer and arc

stability; least spatter.

1-3 (25-76mm) thick; higher heat input than argon.

3 (76mm) thick; highest heat input; minimizes porosity.

Provides good wetting; good control of weld pool for thickness

up to 1/8 (3mm).

Higher heat inputs of 50% and 75% helium mixtures offset

high heat conductivity of heavier gages.

Excellent cleaning action.

Good arc stability; minimum weld contamination. Inert gas

backing is required to prevent air contamination on back

of weld area.

Good arc stability; produces a more fluid and controllable

weld pool; good coalescence and bead contour, minimizes

undercutting; permits higher speeds, compared with argon.

Steel,

carbon

argon-

2% oxygen

Minimizes undercutting; provides good toughness. Steel,

low-alloy

argon-

1% oxygen

Good arc stability; produces a more fluid and controllable

weld pool, good coalescence and bead contour, minimizes

undercutting on heavier stainless steels.

Steel,

stainless

argon-

2% oxygen

Provides better arc stability, coalescence, and welding speed

than 1% oxygen mixture for thinner stainless steel materials.

Figure 9-29. Suggested gases and gas mixtures for use in GMAW spray transfer.

75% helium will give deeper penetration with the arc

stability of a 100% argon gas. Spatter is almost zero when

a 75% helium mixture is used. Argon-helium mixtures are

used on thick nonferrous sections.

Argon-carbon dioxide

Mixing CO

2

in argon makes the molten metal in the

weld pool more fluid. This helps to eliminate undercutting

when GMA welding carbon steels using spray transfer.

CO

2

also stabilizes the arc, reduces spatter, and promotes a

straight-line (axial) metal transfer through the arc.

Argon-oxygen

Argon-oxygen gas mixtures are used on low-alloy,

carbon, and stainless steels. A1%-5% oxygen mixture will

produce beads with penetration that is wider and less

finger-shaped. Oxygen also improves the weld contour,

makes the weld pool more fluid, and eliminates undercut-

ting. Oxygen seems to stabilize the arc and reduce spatter.

The use of oxygen will cause the metal surface to oxidize

slightly. This oxidization will generally not reduce the

strength or appearance of the weld to an unacceptable

level. If more than 2% oxygen is used with low-alloy steel,

a more expensive electrode wire with additional deoxi-

dizers must be used.

Helium-argon-carbon dioxide

This shielding gas mixture is used to weld austentic

stainless steel, using the short circuiting transfer method.

The following mixture is often used and produces a low

bead: 90% He; 7 1/2% Ar; 2 1/2% CO

2

.

Metal transfer methods

The various GMAW metal transfer methods, and the

gases suggested for use with them follow.

Short circuiting transfer

Pure argon or helium, or argon and helium mixtures,

are used on aluminum and other nonferrous metals and

their alloys. For carbon steels, pure CO

2

or a mixture of

75% argon and 25% CO

2

is often used. A mixture of

helium, argon, and CO

2

is used to weld stainless steel.

Globular transfer

Argon with high percentages of CO

2

, or pure CO

2

, are

used to weld low-carbon steels with globular transfer.

With CO

2

, the globules leave the wire in a random way

and spatter is high. When argon or a high argon

percentage gas mixture is used, the metal is squeezed off

the wire and travels in a straighter line to the metal.

Spray and pulsed spray transfer

The spray transfer method will occur only in an

atmosphere that has a high argon percentage. Pure argon

or an argon-helium mixture is used on nonferrous metals.

The following argon mixtures are used when welding low-

carbon steels: argon with 2%-5% oxygen (O

2

), and also

argon with 5%-10% CO

2

.

Small amounts of oxygen lower the transition current.

Oxygen appears to decrease the surface tension of the

molten metal on the wire. This allows the molten metal

droplets to leave the electrode more easily. Oxygen makes

the weld pool more fluid and reduces undercutting. It also

acts to stabilize the arc.

Figure 9-30 lists shielding gas selections for GMAW

on a number of metals.

9.3.4 Selecting the Proper Shielding Gas Flow

Rate for GMAW

Enough gas must flow to create a straight line

(laminar) flow. If too much gas comes out of the nozzle, the

gas may become turbulent. See Figure 9-31. If it becomes

turbulent, the shielding gas will mix with the atmosphere

around the nozzle area. This will cause the weld to become

contaminated. To create a steady laminar gas flow, a gas

lens may be used. See Figure 7-23.

When too little gas flows, the weld area is not prop-

erly protected. The weld will become contaminated and

porosity will occur. The recommended rate of flow for a

given nozzle is generally provided by the manufacturer.

Once the correct flow rate is known, it can be used at all

wire speeds. Too little gas will give a popping sound.

Spatter will occur, the weld will have porosity showing,

and the bead will be discolored. Refer to Figure 9-32 for

some suggested gas flow rates for use with various metals

and thicknesses. Set the proper flow rate, using the

flowmeter.

The heavier shielding gases like CO

2

and argon will

tend to drop away from the weld area when welding out

of position. Therefore, the gas flow rates must be increased

as the position moves from the flat to the horizontal,

vertical, and overhead welding positions.

When a gas mixture is used, it may be necessary to

use a double- or triple-unit gas mixer. Such units have a

separate pressure regulator and flowmeter for each gas.

See Figure 9-26. Premixed gas mixtures can be purchased

from welding gas suppliers in cylinders, just like pure

argon or oxygen.

9.3.5 Selecting the Correct Gas Nozzles and

Contact Tubes

The gas nozzle is located at the end of the GMAW

gun. See Figures 9-33 and 9-34A and B. It is designed to

deliver the shielding gas to the weld area in a smooth,

unrestricted manner. The gas nozzle is usually made of

copper, which is a very good heat conductor. A copper

nozzle will resist melting when exposed to the heat gener-

ated in the welding operation. GMAW nozzles and FCAW

nozzles (if used) are the same. The construction of the

nozzle end of a GMAW gun is shown in Figure 9-34.

Nozzles are made with different exit diameters. Gun

manufacturers usually provide information on the correct

nozzle to use for various applications. A general-purpose

Chapter 9 Gas Metal Arc Welding 247

nozzle is often used and will work well for most applica-

tions. Avariety of nozzles is shown in Figure 9-35. It can be

seen that some nozzles thread onto the gun. Other nozzles

are designed to slip onto or over a nozzle adaptor and are

held by tension. Special nozzle shapes are also manufac-

tured, as illustrated in Figure 9-36.

Under the nozzle lies the electrode contact tube. A

contact tube makes the electrical connection between the

welding gun and the electrode.

The contact tube is threaded into a part of the gun

called a diffuser or an adaptor. See Figures 7-49 and 9-35.

One end of the diffuser or adaptor threads into the

welding gun. The other end has threads for installing the

contact tube. Diffusers have holes around them to allow

shielding gas to escape into the nozzle. Shielding gas exits

the end of the nozzle to protect the weld area.

Contact tubes, also called contact tips, are made with a

variety of inside diameters (ID) and lengths. The contact

248 Modern Welding

Metals Gases % Uses and results

Aluminum Ar Good transfer, stable arc, little spatter. Removes oxides

50%Ar-50%He Hot arc - 3/8 to 3/4 (10mm to 19mm) thickness. Remove oxides.

25%Ar-75%He

He

Hot arc, less porosity, removes oxides - 1/2 to 1 (13mm to 25mm)

Hotter, more gas; 1/2 (13mm) and up. Removes oxides.

Magnesium Ar

75%He-25%Ar

Good cleaning.

Hotter, less porosity, removes oxides.

Copper (deox.) 75%He-25%Ar

Ar

Preferred. Good wetting, hot.

For thinner materials.

Carbon steel CO

2

Short circuiting arc: high quality, low current, out-of-position,

medium spatter

Ar-5% O

2

Ar-2% O

2

Fast, stable, good bead shape,

little undercut, fluid weld pool.

75%Ar-25%CO

2

Short circuiting arc: fast, no melt-through, little distortion and spatter.

50%Ar-50%CO

2

Short circuiting arc: deep penetration, low spatter.

Low-alloy steel Ar-2% O

2

Removes oxides, eliminates undercut, good properties.

High-strength steels 60%He-35%Ar-

5%CO

2

Short circuiting arc: stable arc, good wetting and bead contour,

little spatter. Good impacts.

75%Ar-25%CO

2

Short circuiting arc: same except low impact.

Stainless steel Ar-1% O

2

No undercutting. Stable arc, fluid weld, good shape.

Ar-5% O

2

More stable arc .

90%He-7 1/2% Ar-

2 1/2% CO

2

Short circuiting arc: small heat-affected zone, no undercut, little warping.

Nickel, monel Ar Good wetting - decreases fluidity.

Inconel Ar-He Stable arc on thinner material.

Globular arc: fast, cheap, spattery, deep penetration.

Figure 9-30. Some shielding gas selections for GMAW of various metals.

Chapter 9 Gas Metal Arc Welding 249

Contact

tube

Nozzle

Laminar

(straight

line)

Gas flow

A B

Turbulent

gas flow

Figure 9-31. Effects of gas flow rate. ALaminar gas flow is the result of the proper gas flow rate. BTurbulence occurs

when too much gas is used.

Metal

Aluminum and

aluminum

alloys

Type

joint

Thickness

Weld

position

Argon flow

in. mm

Stainless

steel

Nickel and

nickel alloys

Magnesium

All

Butt

Butt

60 Bevel

60 Double Bevel

Lap, 90 Fillet

1/16

3/32

1/8

3/16

1/4

3/8

3/4

1.59

2.38

3.18

4.76

6.35

9.53

19.05

F

F,H,V,O

F,H,V,O

F,H,V,O

F

H,V

O

F

H,V

O

F

H,V,O

25

30

30

23-27

40

45

60

50

55

80

60

80

11.80

14.16

14.16

10.85-12.74

18.88

21.24

28.32

23.60

25.96

37.76

28.32

37.76

ft

3

/hr. L/min

1/16

1/8-3/16

1.59

3.18-4.76

30

(98Ar-2O

2

)

35

14.16

16.52

1/4-1/2 6.35-12.7 35 16.52

1/2-5/8 12.7-15.88 35 16.52

1/8-5/16 3.18-7.94 35 16.52

All Up to 3/8 Up to 9.53 25 11.80

Butt 0.025-0.190

0.250-1.000

0.64-4.83

6.35-25.4

40-60

50-80

18.88-28.32

23.60-37.76

Figure 9-32. Suggested gas flow rates for various metals and thicknesses.

tube must be designed for the diameter of electrode wire

being used. Agood sliding electrical contact must be made

with the electrode wire. Each time the wire diameter is

changed, the contact tube must be changed so that the ID

matches the diameter of the wire.

Most manufacturers of contact tubes make them in

different lengths. Different lengths are used to help obtain

different transfer methods. The longest tubes for a gun are

usually used for short circuiting transfer. When using

short circuiting transfer, the contact tube should be flush

with the end of the nozzle or should stick out about 1/16

(1.6mm) beyond the end of the nozzle. With a long contact

tube, minimal resistance heating of the wire takes place.

See Figure 9-37.

Resistance heating of the electrode takes place after

the electrode wire exits from the contact tube. The elec-

trode extension distance, shown in Figure 9-40, is the

distance over which the electrode is heated. The longer this

distance, the more heating takes place. Figure 9-37 shows

that a long contact tube minimizes the electrode extension

and reduces the resistance heating of the electrode wire.

A medium-length contact tube is used for spray

transfer. A medium-length contact tube usually keeps the

end of the contact tube inside the end of the nozzle. This

allows the welding current to preheat the wire more than

when using a long contact tube.

Short contact tubes are used for flux cored arc

welding. Aflux cored electrode must be heated to a higher

temperature than a solid electrode so that some of the flux

will vaporize and create a shielding atmosphere around

the weld. Ashorter contact tube allows the electrode to be

heated to a higher temperature. See Figure 9-37.

Contact tubes will wear and must be changed regu-

larly. Eight hours of continuous welding with a steel elec-

trode can excessively wear a contact tube. Regular

replacement of the contact tube will ensure a continuous

good electrical contact with the electrode wire.

Look at the contact tube occasionally. If the round

hole is becoming elongated or if the arc appears to be fluc-

tuating while welding, it is time to replace the tube. Afluc-

tuating arc may be due to a worn contact tube not making

consistent contact with the electrode.

While arc welding, the inside and outside of the

noz-zle and the outside of the contact tube can become

spattered. This spatter can be kept from sticking by

spraying or dipping the nozzle with a special proprietary

anti-stick compound. If the inside of the nozzle becomes

250 Modern Welding

Gun

tube

Electrode

cable

Nozzle

adaptor

Insulator

Nozzle

Metal

O-rings

Electrode

Electrode

contact

tube

Contact

tube adaptor

or diffuser

Figure 9-34. AA schematic drawing of the nozzle end of

a GMAW or FCAW torch. BAn exploded view of a gas

cooled GMAW gun showing the parts.

(Beech & Associates)

Handle

Torch

tube

Difusser

Nozzle holder

Electrode contact tube

Nozzle

Shielding

gas

passage

Figure 9-33. A GMAW gun. The nozzle on this gun is held

in place by tension. (Miller Electric Mfg. Co.)

A

B

spattered, the flow of shielding gas will become turbulent.

Gas turbulence may cause weld contamination. To

remove the spatter from the nozzle, a special cleaning

reamer is used.

9.3.6 Selecting and Installing a Liner

The electrode wire travels from the wire feeder to the

welding gun in a cable. Inside the cable a liner, also called

a conduit, is installed. The liner protects the cable from the

continuous wear of the electrode wire. The liner also

prevents the electrode wire from getting tangled or stuck

while traveling through the cable.

There are two types of liners. One is a hardened steel

wire wound in a tight coil to form a tube. This wound steel

liner is used for hard materials like steel and stainless steel

wires. See Figure 9-38.

The second type liner is made of Teflon

. Teflon is a

type of plastic. It is much softer than the wound steel liner

material. Teflon liners are used with softer materials, espe-

cially aluminum wires.

Fine metal filings can accumulate in a coiled liner. It is

a good idea to occasionally blow compressed air through

this type of liner to remove these very fine particles. The

electrode must not be in the liner when it is being blown

out. When blowing out the liner, always point the open

end of the liner toward the floor or a trash can. Never

allow the open end to point toward yourself or any other

person.

Chapter 9 Gas Metal Arc Welding 251

Nozzles

Contact tube

adaptors

Nozzle adaptor

Contact

tubes

Figure 9-35. A number of different GMAW nozzles, contact tubes, and contact tube adaptors. (American Torch Tip Co.)

Figure 9-36. Special GMAW nozzle for spot or tack

welding.

Long

contact

tube Nozzle

Short contact

tube

Electrode

extension

Visible

extension

Electrode

extension

Figure 9-37. The length of the contact tube and the amount

of electrode extension affects the amount of heating that

the electrode wire receives. The heating takes place in the

length of electrode wire that extends from the contact tube.

With a long contact tube, there is less extension and thus,

less heating.

Occasionally, liners get worn or become clogged with

fine metal particles. A problem also can occur if the liner

ever gets kinked. When any of these happen, the electrode

wire will not feed smoothly. The liner must be replaced.

To replace a liner, or to change from one type to the

other, disconnect the gun cable from the wire feeder.

Remove the nozzle, contact tip, diffuser, and any setscrews

used to keep the liner in place. Then, remove the liner from

the gun and cable. Install the new liner. Push it firmly until

it bottoms out against the far end of the cable. Secure the

liner in place. Most liners are made slightly long and must

be trimmed to a specific length. Each manufacturer has

directions to follow. Reassemble the welding gun. Attach

the cable to the wire feeder, then refeed the wire through

the cable and liner to the gun.

9.3.7 Selecting the Correct GMAW or FCAW

Electrode

Smaller-diameter wire usually costs more than larger-

diameter wire. The rate at which filler metal is deposited

when using small-diameter wire makes up for its added

cost. Because of the small diameter and the high currents

generally used in GMAW and FCAW, small-diameter elec-

trode wire is melted more rapidly than larger-diameter

wire. Small-diameter wire is thus deposited at a much

higher rate.

The electrode wire used must match, or be compatible

with, the base metal being welded. When CO

2

or O

2

is

used on steel-based metals, it causes oxidation of the weld

metal. Deoxidizer types of electrode wires must be used to

neutralize this oxidation. Manganese, silicon, and

aluminum are used as deoxidizers in steel electrode wires.

Titanium, silicon, and phosphorus are the deoxidizers in

copper electrodes.

For more information regarding GMAW electrodes,

see Heading 7.14. Also refer to Figure 7-51 for carbon steel

electrodes and Figure 7-52 for low-alloy electrodes. More

information about FCAW electrodes may be found in

Heading 7.18 and Figure 7-60.

Once the correct electrode is selected it should be

loaded in the wire feeder as stated in Heading 9.3.2. The

correct-size drive wheels must be used in the wire feeder.

The wire should be fed through the electrode cable using

the inch switch until about 2 to 3 (50mm to 75mm)

extend beyond the nozzle. Cut the electrode wire so that its

extension is correct for the type of welding being done.

Refer to Heading 9.5.

9.4 Preparing Metal for Welding

Metal surfaces usually may be cleaned mechanically

or chemically. Abrasive cloth or wire brushing may be

used. On severely corroded areas, grinding may be used.

Welding may be done on an oxidized (rusted) carbon steel

or low-alloy steel surface without cleaning. However, if

the surface is rusty, a deoxidizing electrode wire should be

used. This reduces oxidation and weld porosity.

Joint designs for GMAW and FCAW are similar to

those used for SMAW. The groove angle used when

GMAW or FCAW may be smaller than the angle used

when SMAW. See Figure 9-39. This narrower angle is

possible for two reasons. The wire diameters used are

smaller and GMAW penetrates better than SMAW. A 45

groove angle will take less filler metal to fill than a 75

groove angle. Welding time will also be less. Therefore,

savings in filler metal and welder's time are possible.

9.5 Electrode Extension

Electrode extension is the amount that the end of the

electrode wire sticks out beyond the end of the contact

tube. See Figure 9-40. This distance is sometimes referred

to as stickout.

A good extension for use with the short circuit

GMAW transfer method is about 1/4 to 1/2 (6mm to

13mm). The correct electrode extension for all other

transfer methods varies between 1/2 and 1 (13mm and

25mm). An electrode extension used for gas-shielded

FCAW may vary from 1/2 to 1 1/2 (13mm to 38mm).

The suggested electrode extension for use with self-

shielding FCAW is 3/4 to 3 3/4 (19mm to 95mm).

Contact tips are made in different lengths. The

different lengths help to establish the correct electrode

extension. Longer tips are used for short circuiting

transfer; shorter tips are used for spray transfer and

FCAW. Heading 9.3.5 discusses different contact tip

lengths.

As the electrode extension increases, the resistance

heating of the electrode increases. Resistance causes the

current to heat the wire along the electrode extension dis-

tance. Along extension may cause too much filler metal to

be deposited with low heating by the arc. This may cause

spatter, shallow penetration, and a low weld bead shape.

252 Modern Welding

Trigger switch

connection

Coiled wire liner

Combination

gun cable

Figure 9-38. A coiled wire liner may be used in a GMAW

cable to guide the electrode wire. The wire liner sticking

out of this welding gun cable is replaced when worn.

9.6 Welding Procedures

Before beginning to weld, the welding station

should be checked for safety. All electrical, gas, and

water connections must be checked for tightness.

Weldments should be tack welded or placed into

fixtures prior to welding. When complete joint penetration

is required, backing is often recommended. Backing is

used to control the penetration and may be in the form of

a backing plate, strip, ring, or other design.

Most arc welding processes require the welder to

control the arc length, welding speed, and torch or gun

angle to obtain a good weld. In GMAW and FCAW, the arc

length will remain constant and is determined by the arc

voltage. The welder doing GMAW must watch and control

the distance from the nozzle or contact tube to the work.

See Figure 9-40. By controlling the nozzle-to-work

distance, the welder will control the electrode extension

distance. Heading 9.3.5 explains the importance of elec-

trode extension.

Chapter 9 Gas Metal Arc Welding 253

A

B

60-75

30-45

SMAW

GMAW

Figure 9-39. Arc welding beads compared. ATypical groove angle and weld bead for SMAW. BTypical groove angle

and weld bead for GMAW and FCAW. Notice that less filler metal is required to fill the groove at B. Welding time will also

be less.

Nozzle-

to-work

distance

Electrode

extension

distance

Contact tube-

to-work

distance

Base metal

Exit diameter

Arc length

Electrode

wire

Contact

tube

Nozzle

Figure 9-40. Electrode extension distance. Other distances important in GMAW and FCAW are also shown.

The welding speed will be determined by the appear-

ance of the bead width and penetration. Torch angle will

also affect the bead width and penetration. The terms fore-

hand, backhand, and perpendicular welding are used.

In forehand welding, the tip of the electrode points in

the direction of travel. When backhand welding, the elec-

trode tip points away from the direction of travel.

Perpendicular welding is done with the electrode at 90 to

the base metal. Figure 9-41 shows the effects of these

various methods.

The backhand method will give the best penetration.

A 25 angle forward of perpendicular will give the best

penetration in the flat welding position, as shown in

Figure 9-41C. For the best control of the weld pool, an

angle of 5-15 forward of perpendicular is preferred for all

positions.

To start welding, tip the top of the gun 5-15 in the

direction of travel and place the helmet down over your

eyes. To start the arc, the wire feeder and the gas, squeeze

the trigger on the gun. The wire will arc as soon as it feeds

out far enough to touch the metal. No striking or up-and-

down motion is required to start the arc as required with

SMAW.

As the weld pool reaches the proper width, which

occurs rapidly, the welder moves the welding gun

forward. Continue to move the gun along the weld,

watching the width of the weld pool to maintain a uniform

size. Continue this procedure until the end of the weld is

reached. Arun-off tab may be used to ensure a full-width

bead to the end of the weld. Without a run-off tab, the end

of the weld may have a crater (depression). This depres-

sion can be reduced by moving the electrode to the end of

the weld and then back over the completed bead about

1/2 (13mm). At the end of this reverse travel, the

contactor switch is released. To shield the end of the weld,

hold the gun in position to allow the gas postflow to

protect the weld until it cools.

More than one pass may be required to fill a weld

groove. Each pass should be cleaned before the next pass