Professional Documents

Culture Documents

MD 1 PDF

MD 1 PDF

Uploaded by

Diego Fernado AvendañoCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Review Module 40 - Steel 4 - Part 1Document2 pagesReview Module 40 - Steel 4 - Part 1Andrea MagtutoNo ratings yet

- Use of Nanomaterials in Automobile IndustriesDocument24 pagesUse of Nanomaterials in Automobile IndustriesAnonymous mzF3JvyTJsNo ratings yet

- Compression and Capillary Pipe FittingsDocument2 pagesCompression and Capillary Pipe FittingsstarykltNo ratings yet

- Screenshot Ast ScholrshipDocument1 pageScreenshot Ast ScholrshipAnonymous mzF3JvyTJsNo ratings yet

- Rowan Atkinson: O'Clock News (1979-82), Receiving The 1981 BAFTA For BestDocument6 pagesRowan Atkinson: O'Clock News (1979-82), Receiving The 1981 BAFTA For BestAnonymous mzF3JvyTJsNo ratings yet

- 2Nd Moment of Area: Part 1: Simple ShapesDocument10 pages2Nd Moment of Area: Part 1: Simple ShapesAnonymous mzF3JvyTJsNo ratings yet

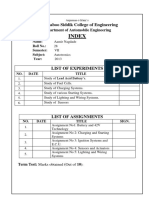

- Index: M.H. Saboo Siddik College of EngineeringDocument1 pageIndex: M.H. Saboo Siddik College of EngineeringAnonymous mzF3JvyTJsNo ratings yet

- Q 1) Answer The Following (02 Marks Questions)Document1 pageQ 1) Answer The Following (02 Marks Questions)Anonymous mzF3JvyTJsNo ratings yet

- Annexure - I A: Program Cadre Qualification ExperienceDocument7 pagesAnnexure - I A: Program Cadre Qualification ExperienceAnonymous mzF3JvyTJsNo ratings yet

- A304 Feb 2016Document2 pagesA304 Feb 2016Anonymous mzF3JvyTJsNo ratings yet

- S.No. Rule/Criteria: Sharp Edges On Chassis Mandatorily To Be RemovedDocument7 pagesS.No. Rule/Criteria: Sharp Edges On Chassis Mandatorily To Be RemovedAnonymous mzF3JvyTJsNo ratings yet

- Maharashtra State Board of Secondary and Higher Secondary Education, PuneDocument1 pageMaharashtra State Board of Secondary and Higher Secondary Education, PuneAnonymous mzF3JvyTJsNo ratings yet

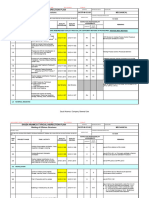

- M.H.Saboo Siddik College of Engineering, Mumbai: First Half/Second Half 20Document1 pageM.H.Saboo Siddik College of Engineering, Mumbai: First Half/Second Half 20Anonymous mzF3JvyTJsNo ratings yet

- Structural ModelingDocument34 pagesStructural ModelingAnonymous mzF3JvyTJs100% (1)

- Dbit Project TitlesDocument1 pageDbit Project TitlesAnonymous mzF3JvyTJsNo ratings yet

- Region Wise - North Region 17-32Document1 pageRegion Wise - North Region 17-32Anonymous mzF3JvyTJsNo ratings yet

- Digital Modeling and Rapid PrototypingDocument28 pagesDigital Modeling and Rapid PrototypingAnonymous mzF3JvyTJsNo ratings yet

- Absence Warning LetterDocument1 pageAbsence Warning LetterAnonymous mzF3JvyTJsNo ratings yet

- Assignment No 02MDIDocument1 pageAssignment No 02MDIAnonymous mzF3JvyTJsNo ratings yet

- Absence Warning LetterDocument1 pageAbsence Warning LetterAnonymous mzF3JvyTJs0% (1)

- Kinetic Theory & ThermodynamicsDocument253 pagesKinetic Theory & ThermodynamicswecharriNo ratings yet

- HS-420 Accelerometer: 4-20ma Velocity Output Via PUR CableDocument1 pageHS-420 Accelerometer: 4-20ma Velocity Output Via PUR CableJeremiah CayondongNo ratings yet

- Catalogo Tecnico StulzDocument1 pageCatalogo Tecnico StulzJulie Ane CavalcantiNo ratings yet

- Technical Datasheet: Engineering SteelDocument1 pageTechnical Datasheet: Engineering Steelraaspoy2007No ratings yet

- 3664 PDFDocument80 pages3664 PDFfisplNo ratings yet

- CompressorDocument456 pagesCompressorsatfasNo ratings yet

- QM 34 - TanksDocument10 pagesQM 34 - Tanksmohamed elmasryNo ratings yet

- mm39 PDFDocument36 pagesmm39 PDFVic3501No ratings yet

- Quotation - AUX FLDIDocument2 pagesQuotation - AUX FLDIFritz NatividadNo ratings yet

- Pipe Size Rules of ThumbDocument6 pagesPipe Size Rules of ThumbIndunil Warnasooriya100% (1)

- Lotus Engineering Software - An Approach To Model-Based DesignDocument20 pagesLotus Engineering Software - An Approach To Model-Based DesignKrish ManglaniNo ratings yet

- API Mpms 5.6 CoriolisDocument4 pagesAPI Mpms 5.6 CoriolisadatahdNo ratings yet

- Culvert PDFDocument12 pagesCulvert PDFAmeer eng 9 7No ratings yet

- TUFF Static Scissor Lift TablesDocument1 pageTUFF Static Scissor Lift TablesRarisgrup OficialNo ratings yet

- LarsLap Model CDocument4 pagesLarsLap Model CHải Nguyễn TrọngNo ratings yet

- SATIP-W-013-01 Welding of Offshore Structures.Document5 pagesSATIP-W-013-01 Welding of Offshore Structures.mathew.genesis.inspNo ratings yet

- 5-2 Static Friction: Figure 5.2: On A Frictionless Floor, Your ShoeDocument2 pages5-2 Static Friction: Figure 5.2: On A Frictionless Floor, Your ShoeAydan QuliyevaNo ratings yet

- Docc 1982Document4 pagesDocc 1982swchenNo ratings yet

- Fridge Shop CERA (Workshop Practice Refrigeration& Air Condition)Document48 pagesFridge Shop CERA (Workshop Practice Refrigeration& Air Condition)Md ZakariaNo ratings yet

- ME2258 Manufacturing Technology Lab IIDocument14 pagesME2258 Manufacturing Technology Lab IIதியாகராஜன் அரிதாஸ்No ratings yet

- Brake Control System: SectionDocument54 pagesBrake Control System: SectionYB MOTOR Nissan - Datsun SpecialistNo ratings yet

- Enfriador Electrico Panel Sec-2001bDocument1 pageEnfriador Electrico Panel Sec-2001braul salinasNo ratings yet

- Drager Fabius TechDocument304 pagesDrager Fabius TechCami 10100% (1)

- Critical Wear Areas & Vacuum Test Locations: JF016E Lower Valve BodyDocument4 pagesCritical Wear Areas & Vacuum Test Locations: JF016E Lower Valve BodyМихаил БолотинNo ratings yet

- Optional Fire Safe, API 607 4th Edition Certified: 1 Piece Reduced Port Ball Valves: / "-2"Document2 pagesOptional Fire Safe, API 607 4th Edition Certified: 1 Piece Reduced Port Ball Valves: / "-2"Oscar Horta PolaniaNo ratings yet

- CFD Simulation of NACA Airfoilsat Various Angles of AttackDocument12 pagesCFD Simulation of NACA Airfoilsat Various Angles of AttackdaifrahunaNo ratings yet

- VIAJET 12 ENG EinzelseitenDocument6 pagesVIAJET 12 ENG Einzelseiten77ztfNo ratings yet

- Groupe Nom Prénom #De VideoDocument7 pagesGroupe Nom Prénom #De VideoMohamed TAGUIOUINENo ratings yet

MD 1 PDF

MD 1 PDF

Uploaded by

Diego Fernado AvendañoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MD 1 PDF

MD 1 PDF

Uploaded by

Diego Fernado AvendañoCopyright:

Available Formats

MachineComponentDesignI

(INME4011)

by

PabloG.CaceresValencia

(B.Sc.,Ph.D.U.K.)

GENERALINFORMATION

CourseNumber INME4011

CourseTitle MachineComponentDesignI

CreditHours 3

Instructor Dr.PabloG.CaceresValencia

Office Luccetti L212PhoneExt.2358

OfficeHours TuTh from7:30to10:45am

email pcaceres@me.uprm.edu

Website http://academic.uprm.edu/pcaceres

Assessment

Thecoursewillbeassessedinthefollowingmanner:

1

st

PartialExam 22%

2

nd

PartialExam 24%

Project 22%

Quizzes 24%(*)

ClassParticipationandAttendance 8%(**)

(*)DatedueMoodle QuizzesandPopQuizzes(max8).Missedquizzeswill

begradedwithzero.LackofaccesstoInternet(Moodle)isnotanexcusefor

notsubmittingyouranswers.

(**)ClassparticipationandAttendance.Afterthethirdmissedclass,one

pointwillbedeductedinthefinalgradeforeachmissedclass(upto8

points).

Grades

FinalGradeRange FinalLetterGrade

100 90 A

89 80 B

79 70 C

69 60 D

59 0 F

Attendance

Attendanceandparticipationinthelecturearecompulsory andwill

beconsideredinthegrading.Studentsshouldbringcalculators,

rulers,penandpencilstobeusedduringthelectures.Studentsare

expectedtokeepupwiththeassignedreadingandbepreparedto

solveproblemsinclassandforthepopquizzes.Pleaserefertothe

BulletinofInformationforUndergraduateStudiesforthe

DepartmentandCampusPolicies.

Texbooks

Mylecturenotesareavailableinthewebat

http://academic.uprm.edu/pcaceres

FundamentalsofMachineElements B.J.Hamrock,S.R.Schmid,B.Jacobson

MachineDesign:AnIntegratedApproach RobertNorton,3erEd.PrenticeHall

MechanicalEngineeringDesign J.E.Shigley,C.R.Mischke,R.G.Budynas.

Exams

Allexamswillbeconductedoutsidelectureperiodsonthespecified

dates.Thefinalprojectduedateisthedatefortheendofclasses.

Therewillbenofinalexam.

Neatnessandorderwillbetakingintoconsiderationinthegradingof

theexams.Uptotenpointscanbedeductedforthelackofneatness

andorder.Youmustbringcalculators,classnotesandblankpagesto

theexams.

TENTATIVESDATES

Week Week

09/13 IntroductiontoDesign,ReviewLoad,

Stress,Strain.

09/20

10/04

10/18

11/01

11/08 MaterialsandManufacturing

Q4

11/15 MaterialsSelection/Fracture

Toughness

12/20 FinalProjectPresentation

ClassesEnd

12/27 FinalProjectPresentation

ClassesEnd GRADES

11/29

12/13

ReviewLoad,Stress,Strain.

Q1

09/27 BasicElasticity BasicElasticity.

Q2

10/11 3DStressesandStrains StressConcentration.

Q3

10/25 StaticFailureTheories

Exam1

MidTermProjectPresentation

11/22 FractureToughness

Q5

FailurePredictionCyclic&Impact

12/06 FailurePredictionCyclic&Impact

Q6

FailurePredictionCyclic&Impact

Q7Exam2

01/10

Outcomes

Uponthecompletionofthecoursethestudentshouldbeableto:

Calculatetheprincipalstressesandstrainsinaloaded

component

Identifythelocationofthecriticalpointonamachine

componentandcalculatethestressesatthatpoint.

Applythebasicstatictheoriesoffailureinthedesigningof

machinessubjectedtostaticloading.

Applythebasicfatiguefailuretheoriesinthedesigningof

machinesubjectedtodynamicloading

Evolution of Engineering

Research & Education

1910

1960

2010

Sputnik

Quantum

Mechanics

Information

Technology

Nano-Bio-Info

Tables, formulae, etc.

If it moves, its Mechanical,

if it doesnt move, its Civil,

and If you cant see it, its Electrical

The era of science-based

engineering

We are entering an era of

integrated science &

engineering, during which

the boundaries of the

disciplines will grow

increasingly indistinct

Engineering disciplines

Engineering disciplines

Sciences

Engineering

Science

?

Taken from Tim Sands, Prof. UC. Berkeley

This approach is driven by the understanding that ME is

founded in and perpetuated through the innovation and

creation of products and therefore ME students should be

able to apply learned concepts and make real-world

connections.

Product Realization in Mechanical Engineering

The key to 21st century competitive advantage will be the

development of products with increasing levels of functionality.

Smart Materials will play a critical role in this development, where

we define these as materials that form part of a smart structural

system that has the capability to sense its environment and the

effects thereof and, if truly smart, to respond to that external

stimulus via an active control mechanism.

Smart Materials for the 21st century a publication of the Institute of Materials, Minerals

and Mining (IOM3) http://www.iom3.org/foresight/Smart%20materials%20web.pdf

Design

Transformation of concepts and ideas into useful machinery.

Machine

Combination of mechanisms and other components that

transforms, transmit or uses energy, load or motion for a specific

purpose

Design of Machine Component

Fundamental practice in engineering.

Code of Ethics for Engineers (ASME 1997)

Engineers shall hold paramount the safety, health and welfare of

the public in the performance of their professional duties

Product Scope and Characteristics

http://www.prz.tu-berlin.de/~www-kt/lehre/hs/ed/dokumente_ed_vl/2005,WS,ED,VL-01.Termin,Vortrag.pdf

Design

A design must be:

Functional- fill a need or customer expectation

Safe- not hazardous to users or bystanders

Reliable- conditional probability that product will perform

its intended function without failure to a certain age.

Competitive- contender in the market

Usable- accommodates human size and strength

Manufacturable- minimal number of parts and suitable for

production

Marketable- product can be sold and serviced

Effects of Manufacturing and Assembly

Design of a Reciprocating Power Saw: Effects on Manufacturing and

Assembly

(1) Original Design: 41 parts, assembly time: 6:37min.

(2) Modified Design: 29 parts, assembly time: 2:58min. (Boothroyd 1992)

Approaches to

Product

Development

(a) Over-The-Wall Engineering

Approach (from Kalpakjian

[1997]).

(b) Concurrent Engineering

Approach (adapted from Pugh

[1996]).

Over-the-Wall (OTW)

One designer applies his/her particular skill and send it OTW to the

next step in development. If a problem is discovered, for example

in manufacturing, the product is send back to be redesigned.

The design is sent to

The design is sent to

the manufacturer

the manufacturer

In manufacturing:

an Engineer must first design something.

an Engineer must first design something.

The design phase

The design phase

For every design there

For every design there

is eventually a

is eventually a

manufacturing phase

manufacturing phase

Design

Manufacture

In practice, the design may well be impossible to manufacture.

In practice, the design may well be impossible to manufacture.

Concurrent Engineering Approach

Philosophy of involving many disciplines from the beginning of a

design effort and keeping them involved throughout product

development.

Design is a multidisciplinary endeavor

Boeing 747 being

manufactured in

Seattle

Examples of

Examples of

manufacturing

manufacturing

Boeing 777

One of the first examples of Concurrent Engineering

Design Methodology: what engineers do

Define the function

component to carry a load

Material Selection

Component Design

Tentative component design

Approximate stress analysis

Tentative choice of material

Assemble Materials Data

Analysis of Materials Performance

iterate

from Ashby and Jones; Engineering Materials 2

Detailed Specifications and Design

Choice of Production Methods

Prototype Testing

Establish Production

Further Development

iterate

iterate

iterate

Example: A Cantilever

This Cantilever Stand is intended for moderate to heavy-duty use

with either the Frontier III or Glas-Hide Boards in certain lengths on

residential pools. There are no unusual climatic restrictions for this

stand's use.

Look at the Engineering Science of this design scheme:

Define the function

component to carry a load

Material Selection

Component Design

Tentative component design

Approximate stress analysis

Tentative choice of material

Assemble Materials Data

End Load

Uniform Distribution

End Moment

Intermediate Load

Triangular Distribution

Choose materials for components from

metals, ceramics, plastics, composites?

Assemble Materials Data?

Cost, density, elastic properties, yield

stress, hardness, tensile stress, strength

to weight ratio, ductility, fracture

toughness, fatigue stress, thermal

expansion coefficient, thermal

conditioning, specific heat, thermal

shock resistance, creep,

oxidation/corrosion rates

Codes and Standards

Code- a set of specifications for the analysis, design, manufacture,

and construction of something

Standard- a set of specifications for parts, materials, or processes

intended to achieve uniformity, efficiency, and a specified quality

Product Liability

Strict liability concept prevails in the U.S.

Manufacturers are liable for any damage or harm that

results from a defect.

Organizations

Aluminum Association (AA)

American Gear Manufacturers

Association (AGMA)

American Institute of Steel

Construction (AISC)

American Iron and Steel Institute

(AISI)

American National Standards

Institute (ANSI)

American Society for Metals

(ASM)

American Society of Mechanical

Engineers (ASME)

American Society of Testing

Materials (ASTM)

American Welding Society (AWS)

American Bearing Manufacturers

Association (ABMA)

British Standards Institute (BSI)

Industrial Fasteners Institute (IFI)

Institution of Mechanical

Engineers (I. Mech. E.)

International Bureau of Weights

and Measures (BIPM)

International Standards

Organization (ISO)

National Institute for Standards

and Technology (NIST)

Society of Automotive Engineers

(SAE)

American Society of Agricultural

and Biological Engineers

(ASABE)

Design Philosophy

Also check deflection!!

Also check deflection!!

Design

If the load is known and

the geometry is specified,

determine the material and

the safety factor.

If the load is known and

the material is specified,

determine the safety factor

and the geometry

(dimensions).

Analysis

If the load is known

and the material and

geometry are specified,

determine the safety

factor Is it safe??

Critical Section

The critical section is the location in the design where the largest

internal stress is developed and failure is most likely.

In general, the critical section will often occur at locations of

geometric non-uniformity, such as where a shaft changes its

diameter along a fillet.

Safety Factors

N = 1.25 to 2.0 Static loading, high level of confidence in all design

data

N = 2.0 to 2.5 Dynamic loading, average confidence in all design

data

N = 2.5 to 4.0 Static or dynamic with uncertainty about loads,

material properties, complex stress state, etc

N = 4.0 or higher Above + desire to provide extra safety

FOR DUCTILE MATERIALS:

Uncertainty

Stochastic Design Factor Method- uncertainty in stress

and strength is quantified for linearly proportional

loads

Stress Average

Strength Average

= =

s

n

d

Measures of

Strength

S Strength

S

s

Shear Strength

S

y

Yield Strength

S

u

Ultimate Strength

- Mean Strength

S

Measures of Stress

Shear Stress

Normal Stress

1

Principal Stress

y

Stress in y-direction

r

Radial Stress

t

Tangential Stress

Stress Allowable (AISC)

Tension: 0.45 S

y

all

0.60 S

y

Shear:

all

= 0.40 S

y

Bending: 0.60 S

y

all

0.75 S

y

Bearing:

all

= 0.90 S

y

SUGGESTED SAFETY (DESIGN) FACTORS FOR ELEMENTARY WORK

based on yield strength - according to Juvinall & Marshek op cit.

1.25 - 1.5 for exceptionally reliable materials used under controllable

conditions and subjected to loads and stresses that can be determined

with certainty - used almost invariably where low weight is a

particularly important consideration

1.5 - 2 for well-known materials under reasonably constant

environmental conditions, subjected to loads and stresses that can be

determined readily.

2 - 2.5 for average materials operated in ordinary environments and

subjected to loads and stresses that can be determined.

2.5 - 3 for less tried materials or for brittle materials under average

conditions of environment, load and stress.

3 - 4 for untried materials used under average conditions of

environment, load and stress. It should also be used with better-

known materials that are to be used in uncertain environments or

subject to uncertain stresses.

Repeated Cyclic loads : the factors established above are acceptable

but must be applied to the endurance limit (ie. a fatigue strength )

rather than to the yield strength of the material.

Impact forces : the factors given above are acceptable, but an impact

factor (the above dynamic magnification factor ) should be

included.

Brittle materials : the

ultimate strength is

used as the theoretical

maximum, the factors

presented above should

be doubled.

Where higher factors

might appear desirable,

a more thorough

analysis of the problem

should be undertaken

before deciding on

their use.

Need to take into account

the statistical nature of

materials properties

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Review Module 40 - Steel 4 - Part 1Document2 pagesReview Module 40 - Steel 4 - Part 1Andrea MagtutoNo ratings yet

- Use of Nanomaterials in Automobile IndustriesDocument24 pagesUse of Nanomaterials in Automobile IndustriesAnonymous mzF3JvyTJsNo ratings yet

- Compression and Capillary Pipe FittingsDocument2 pagesCompression and Capillary Pipe FittingsstarykltNo ratings yet

- Screenshot Ast ScholrshipDocument1 pageScreenshot Ast ScholrshipAnonymous mzF3JvyTJsNo ratings yet

- Rowan Atkinson: O'Clock News (1979-82), Receiving The 1981 BAFTA For BestDocument6 pagesRowan Atkinson: O'Clock News (1979-82), Receiving The 1981 BAFTA For BestAnonymous mzF3JvyTJsNo ratings yet

- 2Nd Moment of Area: Part 1: Simple ShapesDocument10 pages2Nd Moment of Area: Part 1: Simple ShapesAnonymous mzF3JvyTJsNo ratings yet

- Index: M.H. Saboo Siddik College of EngineeringDocument1 pageIndex: M.H. Saboo Siddik College of EngineeringAnonymous mzF3JvyTJsNo ratings yet

- Q 1) Answer The Following (02 Marks Questions)Document1 pageQ 1) Answer The Following (02 Marks Questions)Anonymous mzF3JvyTJsNo ratings yet

- Annexure - I A: Program Cadre Qualification ExperienceDocument7 pagesAnnexure - I A: Program Cadre Qualification ExperienceAnonymous mzF3JvyTJsNo ratings yet

- A304 Feb 2016Document2 pagesA304 Feb 2016Anonymous mzF3JvyTJsNo ratings yet

- S.No. Rule/Criteria: Sharp Edges On Chassis Mandatorily To Be RemovedDocument7 pagesS.No. Rule/Criteria: Sharp Edges On Chassis Mandatorily To Be RemovedAnonymous mzF3JvyTJsNo ratings yet

- Maharashtra State Board of Secondary and Higher Secondary Education, PuneDocument1 pageMaharashtra State Board of Secondary and Higher Secondary Education, PuneAnonymous mzF3JvyTJsNo ratings yet

- M.H.Saboo Siddik College of Engineering, Mumbai: First Half/Second Half 20Document1 pageM.H.Saboo Siddik College of Engineering, Mumbai: First Half/Second Half 20Anonymous mzF3JvyTJsNo ratings yet

- Structural ModelingDocument34 pagesStructural ModelingAnonymous mzF3JvyTJs100% (1)

- Dbit Project TitlesDocument1 pageDbit Project TitlesAnonymous mzF3JvyTJsNo ratings yet

- Region Wise - North Region 17-32Document1 pageRegion Wise - North Region 17-32Anonymous mzF3JvyTJsNo ratings yet

- Digital Modeling and Rapid PrototypingDocument28 pagesDigital Modeling and Rapid PrototypingAnonymous mzF3JvyTJsNo ratings yet

- Absence Warning LetterDocument1 pageAbsence Warning LetterAnonymous mzF3JvyTJsNo ratings yet

- Assignment No 02MDIDocument1 pageAssignment No 02MDIAnonymous mzF3JvyTJsNo ratings yet

- Absence Warning LetterDocument1 pageAbsence Warning LetterAnonymous mzF3JvyTJs0% (1)

- Kinetic Theory & ThermodynamicsDocument253 pagesKinetic Theory & ThermodynamicswecharriNo ratings yet

- HS-420 Accelerometer: 4-20ma Velocity Output Via PUR CableDocument1 pageHS-420 Accelerometer: 4-20ma Velocity Output Via PUR CableJeremiah CayondongNo ratings yet

- Catalogo Tecnico StulzDocument1 pageCatalogo Tecnico StulzJulie Ane CavalcantiNo ratings yet

- Technical Datasheet: Engineering SteelDocument1 pageTechnical Datasheet: Engineering Steelraaspoy2007No ratings yet

- 3664 PDFDocument80 pages3664 PDFfisplNo ratings yet

- CompressorDocument456 pagesCompressorsatfasNo ratings yet

- QM 34 - TanksDocument10 pagesQM 34 - Tanksmohamed elmasryNo ratings yet

- mm39 PDFDocument36 pagesmm39 PDFVic3501No ratings yet

- Quotation - AUX FLDIDocument2 pagesQuotation - AUX FLDIFritz NatividadNo ratings yet

- Pipe Size Rules of ThumbDocument6 pagesPipe Size Rules of ThumbIndunil Warnasooriya100% (1)

- Lotus Engineering Software - An Approach To Model-Based DesignDocument20 pagesLotus Engineering Software - An Approach To Model-Based DesignKrish ManglaniNo ratings yet

- API Mpms 5.6 CoriolisDocument4 pagesAPI Mpms 5.6 CoriolisadatahdNo ratings yet

- Culvert PDFDocument12 pagesCulvert PDFAmeer eng 9 7No ratings yet

- TUFF Static Scissor Lift TablesDocument1 pageTUFF Static Scissor Lift TablesRarisgrup OficialNo ratings yet

- LarsLap Model CDocument4 pagesLarsLap Model CHải Nguyễn TrọngNo ratings yet

- SATIP-W-013-01 Welding of Offshore Structures.Document5 pagesSATIP-W-013-01 Welding of Offshore Structures.mathew.genesis.inspNo ratings yet

- 5-2 Static Friction: Figure 5.2: On A Frictionless Floor, Your ShoeDocument2 pages5-2 Static Friction: Figure 5.2: On A Frictionless Floor, Your ShoeAydan QuliyevaNo ratings yet

- Docc 1982Document4 pagesDocc 1982swchenNo ratings yet

- Fridge Shop CERA (Workshop Practice Refrigeration& Air Condition)Document48 pagesFridge Shop CERA (Workshop Practice Refrigeration& Air Condition)Md ZakariaNo ratings yet

- ME2258 Manufacturing Technology Lab IIDocument14 pagesME2258 Manufacturing Technology Lab IIதியாகராஜன் அரிதாஸ்No ratings yet

- Brake Control System: SectionDocument54 pagesBrake Control System: SectionYB MOTOR Nissan - Datsun SpecialistNo ratings yet

- Enfriador Electrico Panel Sec-2001bDocument1 pageEnfriador Electrico Panel Sec-2001braul salinasNo ratings yet

- Drager Fabius TechDocument304 pagesDrager Fabius TechCami 10100% (1)

- Critical Wear Areas & Vacuum Test Locations: JF016E Lower Valve BodyDocument4 pagesCritical Wear Areas & Vacuum Test Locations: JF016E Lower Valve BodyМихаил БолотинNo ratings yet

- Optional Fire Safe, API 607 4th Edition Certified: 1 Piece Reduced Port Ball Valves: / "-2"Document2 pagesOptional Fire Safe, API 607 4th Edition Certified: 1 Piece Reduced Port Ball Valves: / "-2"Oscar Horta PolaniaNo ratings yet

- CFD Simulation of NACA Airfoilsat Various Angles of AttackDocument12 pagesCFD Simulation of NACA Airfoilsat Various Angles of AttackdaifrahunaNo ratings yet

- VIAJET 12 ENG EinzelseitenDocument6 pagesVIAJET 12 ENG Einzelseiten77ztfNo ratings yet

- Groupe Nom Prénom #De VideoDocument7 pagesGroupe Nom Prénom #De VideoMohamed TAGUIOUINENo ratings yet