Professional Documents

Culture Documents

Theory of Constraints PDF

Theory of Constraints PDF

Uploaded by

Adri SanchoCopyright:

Available Formats

You might also like

- Normas Siemens VaiDocument668 pagesNormas Siemens VaiLeonardo CarvalhoNo ratings yet

- The SWOT Analysis: A key tool for developing your business strategyFrom EverandThe SWOT Analysis: A key tool for developing your business strategyRating: 3.5 out of 5 stars3.5/5 (10)

- Nonprofit Business Plan Development (Health Georgia)Document20 pagesNonprofit Business Plan Development (Health Georgia)cpersels001100% (2)

- Change Is Inevitable. Growth Is Optional.Document32 pagesChange Is Inevitable. Growth Is Optional.chanishaNo ratings yet

- Lesson Plan - Variables On Both Sides With NotesDocument2 pagesLesson Plan - Variables On Both Sides With Notesapi-279820315No ratings yet

- A3 Reports - Tool For Org TransformationDocument6 pagesA3 Reports - Tool For Org TransformationGerard EgertonNo ratings yet

- Bahan Makalah Individu OdDocument6 pagesBahan Makalah Individu OdNina AsterinaNo ratings yet

- Forces. Internal Driving Forces Are Those Kinds of Things, Situations, or Events That Occur Inside TheDocument6 pagesForces. Internal Driving Forces Are Those Kinds of Things, Situations, or Events That Occur Inside TheAhmad AliNo ratings yet

- Organization Development The Management of ChangeDocument5 pagesOrganization Development The Management of Changehedyaguila100% (5)

- Assignment Task 1. Edited2Document8 pagesAssignment Task 1. Edited2Khánh LyNo ratings yet

- Organisation Change and DevelopmentDocument5 pagesOrganisation Change and DevelopmentPulkit Saini0% (1)

- The Change Management Life Cycle:: How To Involve Your People To Ensure Success at Every StageDocument16 pagesThe Change Management Life Cycle:: How To Involve Your People To Ensure Success at Every StageHaniff SofianNo ratings yet

- How To Conduct A Case Analysis v2Document3 pagesHow To Conduct A Case Analysis v2xpNo ratings yet

- Organizational Development ProcessDocument21 pagesOrganizational Development ProcessAngie FerrerNo ratings yet

- Case Study 1 - Change ManagementDocument5 pagesCase Study 1 - Change ManagementHimanshu TiwariNo ratings yet

- Describe One Thing You Could Do To Maximise Participation in and Support For Organisational Development in Each of The Following AreasDocument3 pagesDescribe One Thing You Could Do To Maximise Participation in and Support For Organisational Development in Each of The Following AreasSushan PradhanNo ratings yet

- Analysis of Business EnvironmentDocument6 pagesAnalysis of Business EnvironmentLapi Boy MicsNo ratings yet

- Notes - Lateral Thinking and Problem Solving - PGDM - 21-23 Trimester IIIDocument8 pagesNotes - Lateral Thinking and Problem Solving - PGDM - 21-23 Trimester IIIsharventhiriNo ratings yet

- OrganizationalDevelopment ReportDocument4 pagesOrganizationalDevelopment ReportMary Alwina TabasaNo ratings yet

- OD Lecture 1 - Organizational DevelopmentDocument6 pagesOD Lecture 1 - Organizational DevelopmentAgui ChaiNo ratings yet

- Unit 1Document37 pagesUnit 1Madhu MasihNo ratings yet

- HSM 543 Health Services Finance Week 7 Course Project AnswerDocument64 pagesHSM 543 Health Services Finance Week 7 Course Project AnswerMike RussellNo ratings yet

- Environmental Scanning and MonitoringDocument25 pagesEnvironmental Scanning and MonitoringRico BartolomeNo ratings yet

- 11-Planning and Budgeting-Easing The Pain, Maximizing The Gain (Pages 65-72)Document8 pages11-Planning and Budgeting-Easing The Pain, Maximizing The Gain (Pages 65-72)newaznahianNo ratings yet

- 5 - ToCBasics PDFDocument9 pages5 - ToCBasics PDFFadi ShamistiNo ratings yet

- Contracting and DiagnosticDocument9 pagesContracting and DiagnosticMecheal ThomasNo ratings yet

- Organization and Management 1 Quarter Lesson 3: The Firm and Its EnvironmentDocument4 pagesOrganization and Management 1 Quarter Lesson 3: The Firm and Its EnvironmentSayno, Samantha Jade C.No ratings yet

- Bsbinn601: Lead and Manage Organizational Change: Chapter 2 Develop Change Management StrategyDocument27 pagesBsbinn601: Lead and Manage Organizational Change: Chapter 2 Develop Change Management StrategyManpreet KaurNo ratings yet

- TOC With Gender Sensitivity - FINALDocument9 pagesTOC With Gender Sensitivity - FINALMaria Ana PulidoNo ratings yet

- Schnetzer - Sayed, Mostafa Abdelmoneim Omar - Digital StrategizingDocument12 pagesSchnetzer - Sayed, Mostafa Abdelmoneim Omar - Digital StrategizingMostafa OmarNo ratings yet

- OD Interventions PDFDocument11 pagesOD Interventions PDFimranpathan30100% (4)

- Training Needs AssessmentDocument11 pagesTraining Needs AssessmentIskandar ZulkarnaenNo ratings yet

- Strategy and The Changing EnvironmentDocument10 pagesStrategy and The Changing EnvironmentJoawanna TuduNo ratings yet

- BSBMGT616: Develop and Implement Strategic PlansDocument31 pagesBSBMGT616: Develop and Implement Strategic PlansChunhui Lo100% (1)

- Fundamental Concepts of Theory of Constraints: An Emerging PhilosophyDocument7 pagesFundamental Concepts of Theory of Constraints: An Emerging PhilosophyRamiro ShevchenkoNo ratings yet

- Managing For Quality Essay QuestionsDocument28 pagesManaging For Quality Essay QuestionsKimNo ratings yet

- What Is Theory of Constraints by DR Alan BarnardDocument10 pagesWhat Is Theory of Constraints by DR Alan BarnardAniekan EsenamNo ratings yet

- OCDDocument25 pagesOCD2ndbabluNo ratings yet

- Case StudiesDocument5 pagesCase Studiesapi-3854705No ratings yet

- Assignment 2Document23 pagesAssignment 2Khushboo KhannaNo ratings yet

- Process of Organisational ChangeDocument10 pagesProcess of Organisational ChangeSuman PayraNo ratings yet

- Research Paper On Organizational Development PDFDocument7 pagesResearch Paper On Organizational Development PDFxkcwaaqlgNo ratings yet

- IGNOU MBA-2007-Solved Assignment MS 01 Management Functions and BehaviourDocument7 pagesIGNOU MBA-2007-Solved Assignment MS 01 Management Functions and BehaviourPoonam Girde HajareNo ratings yet

- Change Management - Chapter Review Question AnswersDocument3 pagesChange Management - Chapter Review Question AnswersRashminNo ratings yet

- Organization Development and Change ManagementDocument37 pagesOrganization Development and Change ManagementNimrit KaurNo ratings yet

- Module9 Business Planning 0 PDFDocument17 pagesModule9 Business Planning 0 PDFAndrigail CodillaNo ratings yet

- Basic Model of Strategic ManagementDocument14 pagesBasic Model of Strategic ManagementPrabhakar KumarNo ratings yet

- Impact Analysis MethodDocument2 pagesImpact Analysis MethodOzair ShaiqNo ratings yet

- Assignment On PaDocument24 pagesAssignment On PaAli XafarNo ratings yet

- Quality Improvement AssignmentDocument15 pagesQuality Improvement AssignmentChiaki Hidayah0% (1)

- Unit 5 IT ConsultingDocument8 pagesUnit 5 IT ConsultingFatima AliNo ratings yet

- 3 and 4 Planning Process and Strategy LogfriamDocument33 pages3 and 4 Planning Process and Strategy LogfriambbilaspaNo ratings yet

- Lesson IV. Analyzing The External Environment of The Firm & Lesson V Assessing The Internal Environment of The Firm 4252022 2Document68 pagesLesson IV. Analyzing The External Environment of The Firm & Lesson V Assessing The Internal Environment of The Firm 4252022 2Neekah JoyNo ratings yet

- Research 2 OdDocument20 pagesResearch 2 OdPlik plikNo ratings yet

- ViewMarkedAssignment4 PDFDocument15 pagesViewMarkedAssignment4 PDFrefilwe0% (1)

- Reena Sekhon 2Document14 pagesReena Sekhon 2randhawarobinNo ratings yet

- Business Analysis Is The DisciplineDocument10 pagesBusiness Analysis Is The DisciplineBineesh Thomas100% (2)

- Using TOC To Do More With Less in Less Time in The Public Sector - by DR Alan Barnard - Feb2009Document8 pagesUsing TOC To Do More With Less in Less Time in The Public Sector - by DR Alan Barnard - Feb2009Alan BarnardNo ratings yet

- ChangeDocument7 pagesChangemazorodzesNo ratings yet

- Approaches To Organizational EffectivenessDocument9 pagesApproaches To Organizational EffectivenessdennohNo ratings yet

- Unesco - Eolss Sample Chapters: Principles and Tools of Total Quality ManagementDocument0 pagesUnesco - Eolss Sample Chapters: Principles and Tools of Total Quality ManagementKin SkyeNo ratings yet

- Making Change Work: Practical Tools for Overcoming Human Resistance to ChangeFrom EverandMaking Change Work: Practical Tools for Overcoming Human Resistance to ChangeRating: 5 out of 5 stars5/5 (2)

- Nota TP: Topik 7 - Asas Fotografi 5 - Penjagaan Dan Penyelenggaraan KameraDocument15 pagesNota TP: Topik 7 - Asas Fotografi 5 - Penjagaan Dan Penyelenggaraan KameraPaRaDoX eLaKSaMaNaNo ratings yet

- Nota TP: Topik 7 - Asas Fotografi 6 - Kaedah Mengambil GambarDocument25 pagesNota TP: Topik 7 - Asas Fotografi 6 - Kaedah Mengambil GambarPaRaDoX eLaKSaMaNaNo ratings yet

- Nota TP: Topik 7 - Asas Fotografi 5 - Penjagaan Dan Penyelenggaraan KameraDocument15 pagesNota TP: Topik 7 - Asas Fotografi 5 - Penjagaan Dan Penyelenggaraan KameraPaRaDoX eLaKSaMaNaNo ratings yet

- APCEIU Teachers Training Manual On EIU and ESDDocument349 pagesAPCEIU Teachers Training Manual On EIU and ESDPaRaDoX eLaKSaMaNaNo ratings yet

- Sistem Pencernaan (Digestion System)Document28 pagesSistem Pencernaan (Digestion System)PaRaDoX eLaKSaMaNaNo ratings yet

- Sistem Metabolisme Dan NutrisiDocument35 pagesSistem Metabolisme Dan NutrisiPaRaDoX eLaKSaMaNaNo ratings yet

- Nota TP: Topik 7 - Asas Fotografi 6 - Kaedah Mengambil GambarDocument25 pagesNota TP: Topik 7 - Asas Fotografi 6 - Kaedah Mengambil GambarPaRaDoX eLaKSaMaNaNo ratings yet

- Sistem Otot Muskular 1 (Muscular System)Document36 pagesSistem Otot Muskular 1 (Muscular System)PaRaDoX eLaKSaMaNaNo ratings yet

- Teknologi Pendidikan: Topik 10 - Penerbitan Video Pendidikan 2 - Asas Edit VideoDocument11 pagesTeknologi Pendidikan: Topik 10 - Penerbitan Video Pendidikan 2 - Asas Edit VideoPaRaDoX eLaKSaMaNaNo ratings yet

- Sains - Tahun 6 (English)Document46 pagesSains - Tahun 6 (English)Sekolah Portal96% (24)

- HE Penerimaan Bukan Islam Terhadap Proses Islamisasi Di MalaysiaDocument19 pagesHE Penerimaan Bukan Islam Terhadap Proses Islamisasi Di MalaysiaFarah ZulkipliNo ratings yet

- Sistem Otot Muskular 2 (Muscular System)Document38 pagesSistem Otot Muskular 2 (Muscular System)PaRaDoX eLaKSaMaNaNo ratings yet

- Sistem Rangka (Skeletel System)Document60 pagesSistem Rangka (Skeletel System)PaRaDoX eLaKSaMaNaNo ratings yet

- Matematik - Tahun 2Document68 pagesMatematik - Tahun 2Sekolah Portal97% (37)

- Sains - Tahun 3Document37 pagesSains - Tahun 3Sekolah Portal100% (11)

- Education For International UnderstandingDocument48 pagesEducation For International UnderstandingPaRaDoX eLaKSaMaNaNo ratings yet

- Sains - Tahun 4Document63 pagesSains - Tahun 4Sekolah Portal100% (41)

- Huraian Sukatan Pelajaran Matematik Tahun 4Document46 pagesHuraian Sukatan Pelajaran Matematik Tahun 4Mat Jang100% (26)

- Sains - Tahun 5Document60 pagesSains - Tahun 5Sekolah Portal100% (9)

- Hubungan Etnik Nota Topik 7 Agama Amp Hubungan Etnik BuddhismDocument8 pagesHubungan Etnik Nota Topik 7 Agama Amp Hubungan Etnik BuddhismWistarLimNo ratings yet

- Matematik - Tahun 1Document36 pagesMatematik - Tahun 1Sekolah Portal100% (31)

- Huraian Sukatan Pelajaran Matematik Tahun 5Document60 pagesHuraian Sukatan Pelajaran Matematik Tahun 5Mat Jang100% (23)

- Sains - Tahun 1Document17 pagesSains - Tahun 1Sekolah Portal92% (13)

- Huraian Sukatan Pelajaran Matematik Tahun 6Document43 pagesHuraian Sukatan Pelajaran Matematik Tahun 6Mat Jang100% (26)

- English: Simple, Compound & Complex SentencesDocument12 pagesEnglish: Simple, Compound & Complex SentencesPaRaDoX eLaKSaMaNaNo ratings yet

- Matematik - Tahun 3Document83 pagesMatematik - Tahun 3Sekolah Portal93% (40)

- English: Sentence StructureDocument84 pagesEnglish: Sentence StructurePaRaDoX eLaKSaMaNa100% (1)

- Complex SentencesDocument5 pagesComplex SentencesReem Amin Ul HaqNo ratings yet

- English: Expository Essay 1Document7 pagesEnglish: Expository Essay 1PaRaDoX eLaKSaMaNaNo ratings yet

- "Indigeneity and Indigenous Media On The Global Stage," Pamela Wilson and Michelle Stewart, From Global Indigenous MediaDocument55 pages"Indigeneity and Indigenous Media On The Global Stage," Pamela Wilson and Michelle Stewart, From Global Indigenous MediaPam WilsonNo ratings yet

- Top 10 PCB Assembly Companies in Thailand (Updated 2023)Document13 pagesTop 10 PCB Assembly Companies in Thailand (Updated 2023)jackNo ratings yet

- Co 34Document10 pagesCo 34Baskar Srinivas SNo ratings yet

- Solutions Manual For Introduction To RobDocument10 pagesSolutions Manual For Introduction To RobAndy Tan Fu YangNo ratings yet

- 25 191 1 PB PDFDocument11 pages25 191 1 PB PDFRaihatil UmmiNo ratings yet

- Co2 Lesson PlanDocument5 pagesCo2 Lesson PlanMAY RACHEL NARRAGANo ratings yet

- Sprinkler System Design GuidelinesDocument2 pagesSprinkler System Design GuidelinesaneeshNo ratings yet

- Battery Sizing: DefinitionsDocument4 pagesBattery Sizing: Definitionskrajeev2802No ratings yet

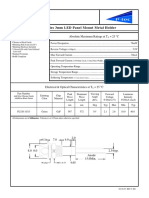

- PL320 Series 3mm LED Panel Mount Metal Holder: Features Absolute Maximum Ratings at T 25 °CDocument1 pagePL320 Series 3mm LED Panel Mount Metal Holder: Features Absolute Maximum Ratings at T 25 °CJajang JajaNo ratings yet

- Quantity Estimate Store Room FinalDocument15 pagesQuantity Estimate Store Room FinalUjjwal ShresthaNo ratings yet

- RUBRICS For ACTIVITY MIL - Camera ShotsDocument2 pagesRUBRICS For ACTIVITY MIL - Camera ShotsJaeneth SimondoNo ratings yet

- Velocity-Outdoor Catalog 2019Document148 pagesVelocity-Outdoor Catalog 2019robertoelripNo ratings yet

- Museums and The WebDocument54 pagesMuseums and The Webartearte2012No ratings yet

- Fleet Strategy - ACS Power TransformersDocument96 pagesFleet Strategy - ACS Power TransformersManojNo ratings yet

- Does Corporate Social Responsibility Disclosure Improve Firm Investment Efficiency? Evidence From ChinaDocument32 pagesDoes Corporate Social Responsibility Disclosure Improve Firm Investment Efficiency? Evidence From ChinaNi Luh Lemi Sushmita DeviNo ratings yet

- Annex 1 Reg 15 Control of Discharge of OilDocument2 pagesAnnex 1 Reg 15 Control of Discharge of OilsibinmgNo ratings yet

- CAMLIFE 2023 ProspectusDocument16 pagesCAMLIFE 2023 Prospectusboydilinh012No ratings yet

- Jurnal Farmasi PDFDocument7 pagesJurnal Farmasi PDFFiona ValenciaNo ratings yet

- Donau CarbonDocument2 pagesDonau CarbonLim Chee SiangNo ratings yet

- Handbook of Practical Electrical Design, 3rd Edition: IEEE Electrical Insulation Magazine December 1999Document2 pagesHandbook of Practical Electrical Design, 3rd Edition: IEEE Electrical Insulation Magazine December 1999James FitzGeraldNo ratings yet

- RE 2.3 MioDocument4 pagesRE 2.3 MioAngel Perez100% (1)

- Recreationalactivities 140317203039 Phpapp01 PDFDocument27 pagesRecreationalactivities 140317203039 Phpapp01 PDFRodjan MoscosoNo ratings yet

- Big Data Analytics (2017 Regulation) : Unit - 2 Clustering and ClassificationDocument7 pagesBig Data Analytics (2017 Regulation) : Unit - 2 Clustering and ClassificationcskinitNo ratings yet

- Digital BankingDocument3 pagesDigital BankingDPC Gym100% (1)

- Replikasi, Transkripsi Dan Translasi DnaDocument19 pagesReplikasi, Transkripsi Dan Translasi DnaEllizabeth LilantiNo ratings yet

- ADVANCE COPY 20230218 DILG ADVISORY No 02 On The LPADocument2 pagesADVANCE COPY 20230218 DILG ADVISORY No 02 On The LPABarangay MabuloNo ratings yet

- Attitude of Customers About Milma ProductsDocument30 pagesAttitude of Customers About Milma ProductsAswanth JNo ratings yet

- The Erosion of Four Materials Using Seven Erodents - Towards An UnderstandingDocument11 pagesThe Erosion of Four Materials Using Seven Erodents - Towards An UnderstandinganuragNo ratings yet

Theory of Constraints PDF

Theory of Constraints PDF

Uploaded by

Adri SanchoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Theory of Constraints PDF

Theory of Constraints PDF

Uploaded by

Adri SanchoCopyright:

Available Formats

The Theory of Constraints and

its Thinking Processes

A Brief Introduction to TOC

Copyright 2001-2009 Avraham Y. Goldratt Institute, LP. All rights reserved. This paper may be downloaded, reproduced and distributed.

However, distribution of this paper to the public by sale, rental or lease is strictly prohibited. This paper shall not be used as part of or

incorporated into any other written work or publication except with the written permission of the Avraham Y. Goldratt Institute, LP.

No derivative works may be created based on this paper except with the written permission of the Avraham Y. Goldratt Institute, LP.

2

TABLE OF CONTENTS

INTRODUCTION............................................................... 3

PROCESS-A HEALTHCARE ANALOGY................................ 4

APPLYING TOC TO ORGANIZATIONS............................... 5

WHAT TO CHANGE............................................... 5

WHAT TO CHANGE TO .......................................... 6

HOW TO CAUSE THE CHANGE...............................7

OVERCOMING RESISTANCE TO CHANGE................ 8

THE FIVE FOCUSING STEPS OF TOC.............................. 9

The core constraint of virtually every

organization AGI - Goldratt Institute

has worked with over the past 20+

years is that organizations are

structured, measured, and managed

in parts, rather than as a whole. The

results of this are lower than ex-

pected overall performance results,

difficulties securing or maintaining a

strategic advantage in the market-

place, financial hardships, seemingly

constant firefighting, customer

service expectations being rarely

met, the constraint constantly

shifting from one place to another,

and chronic conflicts between people

representing different parts of the

organization, to name a few.

Once the barriers that block those

parts from working together as an

integrated system are removed,

significant and sustainable improve-

ment in each and every problem

mentioned above is the result.

What blocks organizations from

tearing down these barriers? Organi-

zations are often so consumed by

the pressures to achieve their short-

term performance targets, that taking

the time to plan for the future is a

luxury they cant afford. Or, they

have plans for the future, but are

faced with the difficulties of balancing

the risks of change with the opportu-

nities they create if it aint broke,

dont fix it!

Is it possible to use change to create

a competitive advantage? Is it

possible to do that quickly, without

risk, and while creating a reliable

platform from which to seize the

opportunities of tomorrow?

Summary of an Independent Study

Sampling of Companies Using TOC

Source: The World of the Theory of Constraints, Vicky Mabin

and Steven Balderstone, St. Lucie Press, 1999.

Due Date Performance

(On-time Delivery):

Mean Improvement

Revenue/Throughput:

Mean Increase

Combined Financial

Variable:

Mean Increase

Lead Times:

Mean Reduction

Cycle Times:

Mean Reduction

Inventory Levels:

Mean Reduction

70%

65%

49%

44%

63%

73%

3

In not-for-profit organizations, change

means achieving higher levels of

human or social capital with less

budget.

INTRODUCTION

Today, more than ever, change is essential to satisfying expectations. Cus-

tomers expect higher product and service quality than the price theyre

willing to pay to acquire those products and services. More than ever,

employees expect security in their jobs. Shareholders expect that todays

investments will yield a higher rate of return over a shorter timeframe. Yet,

to make ends meet, management is constantly pressured to keep costs

under control.

In light of todays competitive pressures and a rapidly changing environment,

to not change is to give way to ones competitors. Hence, we should under-

stand that to improve means to change. We know that to improve means we

must:

Provide products and services that solve customers problems

Release products and services consistent with market demand

Reduce variability in our processes

Have measurements that indicate success relative to achieving our

goal

Reward people for their contribution to change

Rather than reacting to external change, or being subjected to random internal

change, many organizations have concluded that a process of on-going

improvement is an absolute necessity. For an organization to have a process

of on-going improvement, certain basic questions need to be answered faster

and more effectively. Those fundamental questions are:

What To Change?

What To Change To?

How To Cause The Change?

This white paper provides an introduction to the Theory of Constraints and its

Thinking Processes.

What are some of AGIs customers using

the TOC Thinking Processes for?

Design of Manufacturing Systems

New product development

New market entry

Pipeline Management

Segmentation of existing markets

Strategic Planning

System of Systems Design

4

PROCESS A HEALTHCARE ANALOGY

The Theory of Constraints (TOC) applies the cause-and-effect thinking

processes used in the hard sciences to understand and improve all systems,

but particularly, organizations. The process a clinician applies to treating a

patient is an excellent analogy for explaining how TOC recommends going

about solving a systems problem. If we were to describe the overall process

used by a clinician treating a patient it would look something like:

1. Diagnosis: Knowing the futility of treating the symptoms,

a clinician begins with a list of observable symptoms and

uses cause and effect to seek out the underlying common

cause for all of them, the disease or core problem.

2. Design of a Treatment Plan: Considering the unique-

ness of the patient and his/her diagnosis, a treatment plan

is developed that first and foremost treats the disease

(e.g., surgery), but also suggests what other things must

be done alongside that cure to ensure the treatment will

work (e.g., pain relief and bed rest) and that the best

possible health is restored to the patient (e.g., physical

therapy). In this process, any potential side effects of the

treatment are identified, and the means for preventing or

mitigating them become key elements of the treatment.

3. Execution of the Treatment Plan: Taking into consider-

ation, the uniqueness of the patients situation, a plan is

developed for how to implement the treatment (e.g.,

surgery and pre-op work are scheduled, arrangements for

transportation to and from the hospital are secured, hospital

beds to be used at home are ordered).

The Jonah Program

is for individuals and management teams that

want to accelerate the improvement process in their area of responsibil-

ity or throughout their organization. It is also for those who want to

accelerate the improvement process in a subject matter or specific

area of interest.

The Jonah Program

focuses participants common sense and intuition

through the Theory of Constraints Thinking Processes. The results are

detailed answers to each of the three questions for the selected

subject. Participants also gain the tools needed to apply the same

rigorous process to other subject matter.

Jonah Program

is a Registered Service Mark of the Avraham Y. Goldratt Institute, LP.

5

APPLYING TOC TO ORGANIZATIONS

The TOC processes used to improve the health of an organization (or solve

any problem) are almost identical; however, the terminology is changed to

better suit the language of problem-solving in organizations. In TOC, the

process is described via the use of three questions: What to Change?, What

to Change To?, and How to Cause the Change?

1. What to Change? From a list of observable symptoms, cause-and-

effect is used to identify the underlying common cause, the core problem,

for all of the symptoms. In organizations, however, the core problem is

inevitably an unresolved conflict that keeps the organization trapped and/or

distracted in a constant tug-of-war (management versus market, short-

term versus long-term, centralize versus decentralize, process versus

results). This conflict is called a Core Conflict. Due to the devastating

effects caused by Core Conflicts, its common for organizations to create

policies, measurements, and behaviors in attempts to treat those negative

effects (often referred to as band-aid fixes) that, when treating the Core

Conflict, must be removed, modified, or replaced.

What types of organizations have

taken AGIs Jonah Program

?

Accounting

Aerospace

Automotive

Consulting

Defense

Healthcare

High-Tech

Lumber

Manufacturing

Metals & Mining

Semiconductor

Steel

Telecommuncations

Textile

Universities and Colleges

1. Identify the Core Conflict causing the

symptoms, or UnDesireable Effects

(UDEs), of the chosen subject using the

Three-Cloud Process.

2. Build a Current Reality Tree that validates the

identification of the Core Conflict, helps us

understand the existing cause-and-effect relation-

ships of the subject and identifies the conspiring

formal and informal policies, measurements and

behaviors that support the existence of the UDEs.

UDE: UnDesireable Effect

dee - n. something that exists

in reality that is negative, and

has penalties for its continued

existence. pl. UDEs (deez)

syn. problem, symptom.

What to Change?

UDE

UDE

UDE

UDE

2. Current Reality Tree:

Is the core conflict really

the core conflict?

1. Core Conflict Cloud:

What core conflict is

responsible for all the

UDEs?

D

A

A

B

B

C

C

D

D

D

Core Conflict

Jonah Program

is a Registered Service Mark of the Avraham Y. Goldratt Institute, LP.

6

2. What to Change To? By challenging the logical assumptions behind the

Core Conflict, a solution to the Core Conflict is identified. This is only the

starting point for the development of a complete solution a strategy for

resolving all of the initial symptoms, and many others, once and for all. As

in the Design of a Treatment Plan above, the strategy must also include

the changes that must be made alongside the solution to the Core Conflict

to ensure that the solution works and that the organization is restored to its

best possible health. Respectively, these are often the changes to the

policies, measurements, and behaviors identified in What to Change?, as

well as the organizations strategic objectives. Lastly, the strategy is not

complete until all potential negative side-effects of the strategy have been

identified, and the means for preventing or mitigating them become key

elements of the strategy. Trimming these negatives side-effects allows an

organization to intentionally and systematically create strategies that are a

win for all those affected.

Some AGI customers that have

applied the TOC Thinking Pro-

cesses:

Air Force Flight Test Center

Air Force Operational Test &

Evaluation Center (AFOTEC)

Alphamet Ltd.

The Boeing Company

Fairchild Semiconductor

F-22 System Program Office

General Motors Corporation

Institute for Defense Analyses

ITT Night Vision

Japan Research Institute, Ltd.

Kiowa Corporation

Lockheed Martin - Aero

Lucent Technologies

Media Automotive

DE: Desireable Effect

deeee - n. something that we

want to have exist in place of

the UDE; opposite of the UDE.

pl. DEs (deeeez)

3. Identify and break the

assumptions that allow the

Core Conflict to persist

4. Construct a Future Reality Tree that lays

out the complete solution/strategy that:

Resolves all of the UDEs by making

their opposites, the Desired Effects,

exist

Ensures alignment with the Strategic

Objectives (SO) of the bigger system

that the subject is a part

Ensures that no new negative side-

effects (Negative Branches) will

occur from implementing the

solution/strategy

Identifies what changes in the culture

(formal and informal policies, mea-

surements and procedures) of the

system and/or sub-system must be

made to ensure the symptoms are

resolved

Leverages the existing TOC applica-

tions that are needed to make the

solution/ strategy work, and

Quantifies the bottom line value of

achieving those DEs and SOs

4. Future Reality Tree:

Ensures that the starting

injection will lead to all

the DEs without creating

negative branches.

What to Change To?

3. Core Conflict Cloud:

What assumption(s) are

we going to challenge?

D

DE

DE

DE

DE

D C

B

A

Great Idea!

TO

TO

Assumption

Injection

7

3. How to Cause the Change? Taking into consideration the unique culture

which exists in every organization, a plan is developed to transition an

organization from where it is today to realizing the strategy. In other

words, a plan for successfully implementing the strategy is created,

including what actions must be taken, by whom and when. Because

resistance to change can block even the most perfectly laid strategies

and plans, building active consensus and collaboration, or buy-in is crucial.

Six Layers of Resistance

to Change

Layer 1: Has the right problem been

identified?

Layer 2: Is this solution leading us in

the right direction?

Layer 3: Will the solution really solve

the problems?

Layer 4: What could go wrong with the

solution? Are there any

negative side-effects?

Layer 5: Is this solution implementable?

Layer 6: Are we all really up to this?

mine mine mine mine mine

Internalize TOCs 6 Steps of Buy-In to achieve the needed approvals, buy-in, or

active collaboration to proceed with implementation via the design/customization

(again, using TRTs) and role-playing of specific buy-ins the participant will have to

perform in their subject environment, and

Transform action plans into a complete project network that can be effectively

managed using project management techniques (preferably, TOCs Critical Chain

project management solution).

5. Build a Tactical Objectives Map that charts

the overall course for getting from the

current reality to the future reality, where

the solution/strategy is fully implemented.

Flesh out the details of what each part of

the system/sub-system must contribute,

and when, to achieve each of the mile-

stones of the TO Map using a PreRequisite

Tree (PRT)

6. Create detailed task interdependency

diagram, using Transition Trees (TRTs) when

necessary to flesh out crucial actions

How to Cause the Change?

6. Transition Trees:

What actions must we take to

implement the PreRequisite Tree?

5. PreRequisite Tree:

In what order do we implement the T.O.s

and what blocks their implementation?

All TOs implemented

TO TO

Obs

Obs

Obs

Obs

Obs

Obs

Action

IO

IO

IO

IO IO

IO

IO

IO

IO

Action

8

OVERCOMING RESISTANCE TO CHANGE

TOC has developed a process based on the psychology of change that

acknowledges and systematically addresses the questions people intuitively

ask when evaluating a change.

a. Is the right problem being addressed - mine?

b. Is the general direction that the solution is heading a good one?

c. Will the solution really work to solve the problems and whats in it

for me?

d. What could go wrong? Who might get hurt?

e. How the heck are we going to implement this thing?

f. Are we really up to this? Do we have the leadership and the

commitment to pull this change off successfully?

If these questions arent answered frankly and effectively with both the

people who must implement the change and those who will be affected by it,

the proposed change will not have the buy-in and support to succeed. Like

most changes, no matter how great the idea or tremendous the value, the

strategy and tactics are doomed from the outset.

The three questions, What to Change?, What to Change To?, and How to

Cause the Change?, provide the framework for whats called the TOC

Thinking Processes. The Thinking Processes are a set of tools and processes

that allows an individual or group to solve a problem and/or develop an

integrated strategy using the rigor and logic of cause-and-effect, beginning

with the symptoms and ending with a detailed action plan that coordinates

the activities of all those involved in implementing the solution.

As a result of applying TOCs Thinking Processes to countless organizations

over three decades, generic TOC solutions have emerged that have applica-

bility across all organizations, both for-profit or not-for-profit. To this day

these applications continue to evolve, resulting in more and more significant

and sustainable overall and bottom line performance improvements where

implemented.

Results reported by customers using

the TOC Thinking Processes:

41 percent reduction in cycle

time = $7 million savings in

capitalization

New Product Introduction

cycle times reduced 50

percent

21 percent increase in Net

Sales Dollars

Tripled development capacity

with no staffing increases

80 percent increase in Operat-

ing Profit

New job startup in 60 percent

less time

100 percent on-time delivery

40 percent growth in revenues

$5.5 million dollars growth in

revenue per year

First to market five weeks

ahead of schedule eliminated

competitors entry of new

products

300 percent increase in net

profit

Annual inventory turns up

from four to twelve

Gross Margin increase from

29 to 41 percent

Pre-tax profit improvement in

excess of 3,500 percent

9

THE FIVE FOCUSING STEPS OF TOC

How can any generic solution have such broad applicability? It turns out

that no matter what an organizations offering is products and/or services

the methods for most effectively and efficiently managing processes and

resources are basically the same. To use another powerful analogy: just as

the strength of a chain is dictated by its weakest link, the performance of

any value-chain is dictated by its constraint. Recognizing this, the result-

ing steps to maximizing the performance of a value-chain are:

1. Identify the constraint.

2. Decide how to exploit the constraint.

3. Subordinate and synchronize everything else to the above decisions.

To improve the performance of that same value-chain, continue:

4. Elevate the performance of the constraint.

5. If in any of the above steps the constraint has shifted, go back to Step

1.

WARNING

DO NOT LET INERTIA BECOME THE

SYSTEMS CONSTRAINT

These are called the 5 Steps of TOC and provide the foundation for many

of TOCs generic solutions, which include, the management of processes,

inventory, supply chains, product development and projects (single and

multiple), personnel, and decision-making.

Although the 5 Steps of TOC can be applied to every process at every level

in an organization, which is how TOC is frequently often implemented, the

true power - and results - comes from:

Understanding the interdependencies between and across processes

that contribute to delivering a product or service,

Understanding the impact that those interdependencies and normal

variability have on their combined, overall performance, and

Appropriately buffering for interdependencies and normal variability

so that that performance can be predictably and consistently high.

Market Demand-Pull

AGIs TOC Supply Chain

Management Solution

For supply chain, plant operations

and distribution managers who are

dealing with the challenges of

ensuring availability of the right

products at the right place and time

while maintaining profitable

operations, the TOC Supply Chain

Solution enables the organization to:

Rapidly respond to actual

market demand

Improve on-time deliveries

Reduce the need for overtime

and expediting

Better utilize capacity to meet

customer expectations

TOC Project Management

Solution

For organizations and project manag-

ers who are working to improve their

ability to continually meet the three

seemingly illusive project commit-

ments budget, time and content,

the TOC Project Management Solution

provides a comprehensive tool set that

addresses:

The nature of project planning

Project scheduling

Resource behavior

Project visibility and control

Multiple project synchronization

10

Understanding these three points allows the 5 Steps of TOC to be much

more than simply another methodology for managing processes, but in fact,

to be a methodology for consistently and significantly increasing the

overall performance of systems.

The 5 Steps of TOC implemented in this context enables an organization to

create a stable and reliable value delivery system from which its leadership

can quickly respond to any opportunity that presents itself. The TOC

Thinking Processes enable it to develop strategies to seize those opportu-

nities in a way that result in significant strategic advantage and value to all

stakeholders. An organization using TOC is only limited by how big it

dares to think. Imagine!

For more information regarding the Theory of Constraints and its

Thinking Processes, or AGI - Goldratt Institutes products and ser-

vices, please contact us at 1.800.394.GOAL or +1.203.624.9026.

AGI - Goldratt Institute

442 Orange Street

New Haven, Connecticut 06511 USA

1.800.394.GOAL

+1.203.624-9026

fax +1.203.624.9607

www.goldratt.com

Copyright 2001-2009 Avraham Y. Goldratt Institute, LP.

Why AGI?

AGI brings to the table a high-octane

blend of technical competence, dedica-

tion, enthusiasm, and implementation

techniques that get results. With over 20

years experience, they continue working

in a spirit of close partnership with their

customers to deliver the maximum

impact for the least investment, leading

as quickly as possible to organizational

self-sufficiency in a sustainable culture of

ongoing improvement.

You might also like

- Normas Siemens VaiDocument668 pagesNormas Siemens VaiLeonardo CarvalhoNo ratings yet

- The SWOT Analysis: A key tool for developing your business strategyFrom EverandThe SWOT Analysis: A key tool for developing your business strategyRating: 3.5 out of 5 stars3.5/5 (10)

- Nonprofit Business Plan Development (Health Georgia)Document20 pagesNonprofit Business Plan Development (Health Georgia)cpersels001100% (2)

- Change Is Inevitable. Growth Is Optional.Document32 pagesChange Is Inevitable. Growth Is Optional.chanishaNo ratings yet

- Lesson Plan - Variables On Both Sides With NotesDocument2 pagesLesson Plan - Variables On Both Sides With Notesapi-279820315No ratings yet

- A3 Reports - Tool For Org TransformationDocument6 pagesA3 Reports - Tool For Org TransformationGerard EgertonNo ratings yet

- Bahan Makalah Individu OdDocument6 pagesBahan Makalah Individu OdNina AsterinaNo ratings yet

- Forces. Internal Driving Forces Are Those Kinds of Things, Situations, or Events That Occur Inside TheDocument6 pagesForces. Internal Driving Forces Are Those Kinds of Things, Situations, or Events That Occur Inside TheAhmad AliNo ratings yet

- Organization Development The Management of ChangeDocument5 pagesOrganization Development The Management of Changehedyaguila100% (5)

- Assignment Task 1. Edited2Document8 pagesAssignment Task 1. Edited2Khánh LyNo ratings yet

- Organisation Change and DevelopmentDocument5 pagesOrganisation Change and DevelopmentPulkit Saini0% (1)

- The Change Management Life Cycle:: How To Involve Your People To Ensure Success at Every StageDocument16 pagesThe Change Management Life Cycle:: How To Involve Your People To Ensure Success at Every StageHaniff SofianNo ratings yet

- How To Conduct A Case Analysis v2Document3 pagesHow To Conduct A Case Analysis v2xpNo ratings yet

- Organizational Development ProcessDocument21 pagesOrganizational Development ProcessAngie FerrerNo ratings yet

- Case Study 1 - Change ManagementDocument5 pagesCase Study 1 - Change ManagementHimanshu TiwariNo ratings yet

- Describe One Thing You Could Do To Maximise Participation in and Support For Organisational Development in Each of The Following AreasDocument3 pagesDescribe One Thing You Could Do To Maximise Participation in and Support For Organisational Development in Each of The Following AreasSushan PradhanNo ratings yet

- Analysis of Business EnvironmentDocument6 pagesAnalysis of Business EnvironmentLapi Boy MicsNo ratings yet

- Notes - Lateral Thinking and Problem Solving - PGDM - 21-23 Trimester IIIDocument8 pagesNotes - Lateral Thinking and Problem Solving - PGDM - 21-23 Trimester IIIsharventhiriNo ratings yet

- OrganizationalDevelopment ReportDocument4 pagesOrganizationalDevelopment ReportMary Alwina TabasaNo ratings yet

- OD Lecture 1 - Organizational DevelopmentDocument6 pagesOD Lecture 1 - Organizational DevelopmentAgui ChaiNo ratings yet

- Unit 1Document37 pagesUnit 1Madhu MasihNo ratings yet

- HSM 543 Health Services Finance Week 7 Course Project AnswerDocument64 pagesHSM 543 Health Services Finance Week 7 Course Project AnswerMike RussellNo ratings yet

- Environmental Scanning and MonitoringDocument25 pagesEnvironmental Scanning and MonitoringRico BartolomeNo ratings yet

- 11-Planning and Budgeting-Easing The Pain, Maximizing The Gain (Pages 65-72)Document8 pages11-Planning and Budgeting-Easing The Pain, Maximizing The Gain (Pages 65-72)newaznahianNo ratings yet

- 5 - ToCBasics PDFDocument9 pages5 - ToCBasics PDFFadi ShamistiNo ratings yet

- Contracting and DiagnosticDocument9 pagesContracting and DiagnosticMecheal ThomasNo ratings yet

- Organization and Management 1 Quarter Lesson 3: The Firm and Its EnvironmentDocument4 pagesOrganization and Management 1 Quarter Lesson 3: The Firm and Its EnvironmentSayno, Samantha Jade C.No ratings yet

- Bsbinn601: Lead and Manage Organizational Change: Chapter 2 Develop Change Management StrategyDocument27 pagesBsbinn601: Lead and Manage Organizational Change: Chapter 2 Develop Change Management StrategyManpreet KaurNo ratings yet

- TOC With Gender Sensitivity - FINALDocument9 pagesTOC With Gender Sensitivity - FINALMaria Ana PulidoNo ratings yet

- Schnetzer - Sayed, Mostafa Abdelmoneim Omar - Digital StrategizingDocument12 pagesSchnetzer - Sayed, Mostafa Abdelmoneim Omar - Digital StrategizingMostafa OmarNo ratings yet

- OD Interventions PDFDocument11 pagesOD Interventions PDFimranpathan30100% (4)

- Training Needs AssessmentDocument11 pagesTraining Needs AssessmentIskandar ZulkarnaenNo ratings yet

- Strategy and The Changing EnvironmentDocument10 pagesStrategy and The Changing EnvironmentJoawanna TuduNo ratings yet

- BSBMGT616: Develop and Implement Strategic PlansDocument31 pagesBSBMGT616: Develop and Implement Strategic PlansChunhui Lo100% (1)

- Fundamental Concepts of Theory of Constraints: An Emerging PhilosophyDocument7 pagesFundamental Concepts of Theory of Constraints: An Emerging PhilosophyRamiro ShevchenkoNo ratings yet

- Managing For Quality Essay QuestionsDocument28 pagesManaging For Quality Essay QuestionsKimNo ratings yet

- What Is Theory of Constraints by DR Alan BarnardDocument10 pagesWhat Is Theory of Constraints by DR Alan BarnardAniekan EsenamNo ratings yet

- OCDDocument25 pagesOCD2ndbabluNo ratings yet

- Case StudiesDocument5 pagesCase Studiesapi-3854705No ratings yet

- Assignment 2Document23 pagesAssignment 2Khushboo KhannaNo ratings yet

- Process of Organisational ChangeDocument10 pagesProcess of Organisational ChangeSuman PayraNo ratings yet

- Research Paper On Organizational Development PDFDocument7 pagesResearch Paper On Organizational Development PDFxkcwaaqlgNo ratings yet

- IGNOU MBA-2007-Solved Assignment MS 01 Management Functions and BehaviourDocument7 pagesIGNOU MBA-2007-Solved Assignment MS 01 Management Functions and BehaviourPoonam Girde HajareNo ratings yet

- Change Management - Chapter Review Question AnswersDocument3 pagesChange Management - Chapter Review Question AnswersRashminNo ratings yet

- Organization Development and Change ManagementDocument37 pagesOrganization Development and Change ManagementNimrit KaurNo ratings yet

- Module9 Business Planning 0 PDFDocument17 pagesModule9 Business Planning 0 PDFAndrigail CodillaNo ratings yet

- Basic Model of Strategic ManagementDocument14 pagesBasic Model of Strategic ManagementPrabhakar KumarNo ratings yet

- Impact Analysis MethodDocument2 pagesImpact Analysis MethodOzair ShaiqNo ratings yet

- Assignment On PaDocument24 pagesAssignment On PaAli XafarNo ratings yet

- Quality Improvement AssignmentDocument15 pagesQuality Improvement AssignmentChiaki Hidayah0% (1)

- Unit 5 IT ConsultingDocument8 pagesUnit 5 IT ConsultingFatima AliNo ratings yet

- 3 and 4 Planning Process and Strategy LogfriamDocument33 pages3 and 4 Planning Process and Strategy LogfriambbilaspaNo ratings yet

- Lesson IV. Analyzing The External Environment of The Firm & Lesson V Assessing The Internal Environment of The Firm 4252022 2Document68 pagesLesson IV. Analyzing The External Environment of The Firm & Lesson V Assessing The Internal Environment of The Firm 4252022 2Neekah JoyNo ratings yet

- Research 2 OdDocument20 pagesResearch 2 OdPlik plikNo ratings yet

- ViewMarkedAssignment4 PDFDocument15 pagesViewMarkedAssignment4 PDFrefilwe0% (1)

- Reena Sekhon 2Document14 pagesReena Sekhon 2randhawarobinNo ratings yet

- Business Analysis Is The DisciplineDocument10 pagesBusiness Analysis Is The DisciplineBineesh Thomas100% (2)

- Using TOC To Do More With Less in Less Time in The Public Sector - by DR Alan Barnard - Feb2009Document8 pagesUsing TOC To Do More With Less in Less Time in The Public Sector - by DR Alan Barnard - Feb2009Alan BarnardNo ratings yet

- ChangeDocument7 pagesChangemazorodzesNo ratings yet

- Approaches To Organizational EffectivenessDocument9 pagesApproaches To Organizational EffectivenessdennohNo ratings yet

- Unesco - Eolss Sample Chapters: Principles and Tools of Total Quality ManagementDocument0 pagesUnesco - Eolss Sample Chapters: Principles and Tools of Total Quality ManagementKin SkyeNo ratings yet

- Making Change Work: Practical Tools for Overcoming Human Resistance to ChangeFrom EverandMaking Change Work: Practical Tools for Overcoming Human Resistance to ChangeRating: 5 out of 5 stars5/5 (2)

- Nota TP: Topik 7 - Asas Fotografi 5 - Penjagaan Dan Penyelenggaraan KameraDocument15 pagesNota TP: Topik 7 - Asas Fotografi 5 - Penjagaan Dan Penyelenggaraan KameraPaRaDoX eLaKSaMaNaNo ratings yet

- Nota TP: Topik 7 - Asas Fotografi 6 - Kaedah Mengambil GambarDocument25 pagesNota TP: Topik 7 - Asas Fotografi 6 - Kaedah Mengambil GambarPaRaDoX eLaKSaMaNaNo ratings yet

- Nota TP: Topik 7 - Asas Fotografi 5 - Penjagaan Dan Penyelenggaraan KameraDocument15 pagesNota TP: Topik 7 - Asas Fotografi 5 - Penjagaan Dan Penyelenggaraan KameraPaRaDoX eLaKSaMaNaNo ratings yet

- APCEIU Teachers Training Manual On EIU and ESDDocument349 pagesAPCEIU Teachers Training Manual On EIU and ESDPaRaDoX eLaKSaMaNaNo ratings yet

- Sistem Pencernaan (Digestion System)Document28 pagesSistem Pencernaan (Digestion System)PaRaDoX eLaKSaMaNaNo ratings yet

- Sistem Metabolisme Dan NutrisiDocument35 pagesSistem Metabolisme Dan NutrisiPaRaDoX eLaKSaMaNaNo ratings yet

- Nota TP: Topik 7 - Asas Fotografi 6 - Kaedah Mengambil GambarDocument25 pagesNota TP: Topik 7 - Asas Fotografi 6 - Kaedah Mengambil GambarPaRaDoX eLaKSaMaNaNo ratings yet

- Sistem Otot Muskular 1 (Muscular System)Document36 pagesSistem Otot Muskular 1 (Muscular System)PaRaDoX eLaKSaMaNaNo ratings yet

- Teknologi Pendidikan: Topik 10 - Penerbitan Video Pendidikan 2 - Asas Edit VideoDocument11 pagesTeknologi Pendidikan: Topik 10 - Penerbitan Video Pendidikan 2 - Asas Edit VideoPaRaDoX eLaKSaMaNaNo ratings yet

- Sains - Tahun 6 (English)Document46 pagesSains - Tahun 6 (English)Sekolah Portal96% (24)

- HE Penerimaan Bukan Islam Terhadap Proses Islamisasi Di MalaysiaDocument19 pagesHE Penerimaan Bukan Islam Terhadap Proses Islamisasi Di MalaysiaFarah ZulkipliNo ratings yet

- Sistem Otot Muskular 2 (Muscular System)Document38 pagesSistem Otot Muskular 2 (Muscular System)PaRaDoX eLaKSaMaNaNo ratings yet

- Sistem Rangka (Skeletel System)Document60 pagesSistem Rangka (Skeletel System)PaRaDoX eLaKSaMaNaNo ratings yet

- Matematik - Tahun 2Document68 pagesMatematik - Tahun 2Sekolah Portal97% (37)

- Sains - Tahun 3Document37 pagesSains - Tahun 3Sekolah Portal100% (11)

- Education For International UnderstandingDocument48 pagesEducation For International UnderstandingPaRaDoX eLaKSaMaNaNo ratings yet

- Sains - Tahun 4Document63 pagesSains - Tahun 4Sekolah Portal100% (41)

- Huraian Sukatan Pelajaran Matematik Tahun 4Document46 pagesHuraian Sukatan Pelajaran Matematik Tahun 4Mat Jang100% (26)

- Sains - Tahun 5Document60 pagesSains - Tahun 5Sekolah Portal100% (9)

- Hubungan Etnik Nota Topik 7 Agama Amp Hubungan Etnik BuddhismDocument8 pagesHubungan Etnik Nota Topik 7 Agama Amp Hubungan Etnik BuddhismWistarLimNo ratings yet

- Matematik - Tahun 1Document36 pagesMatematik - Tahun 1Sekolah Portal100% (31)

- Huraian Sukatan Pelajaran Matematik Tahun 5Document60 pagesHuraian Sukatan Pelajaran Matematik Tahun 5Mat Jang100% (23)

- Sains - Tahun 1Document17 pagesSains - Tahun 1Sekolah Portal92% (13)

- Huraian Sukatan Pelajaran Matematik Tahun 6Document43 pagesHuraian Sukatan Pelajaran Matematik Tahun 6Mat Jang100% (26)

- English: Simple, Compound & Complex SentencesDocument12 pagesEnglish: Simple, Compound & Complex SentencesPaRaDoX eLaKSaMaNaNo ratings yet

- Matematik - Tahun 3Document83 pagesMatematik - Tahun 3Sekolah Portal93% (40)

- English: Sentence StructureDocument84 pagesEnglish: Sentence StructurePaRaDoX eLaKSaMaNa100% (1)

- Complex SentencesDocument5 pagesComplex SentencesReem Amin Ul HaqNo ratings yet

- English: Expository Essay 1Document7 pagesEnglish: Expository Essay 1PaRaDoX eLaKSaMaNaNo ratings yet

- "Indigeneity and Indigenous Media On The Global Stage," Pamela Wilson and Michelle Stewart, From Global Indigenous MediaDocument55 pages"Indigeneity and Indigenous Media On The Global Stage," Pamela Wilson and Michelle Stewart, From Global Indigenous MediaPam WilsonNo ratings yet

- Top 10 PCB Assembly Companies in Thailand (Updated 2023)Document13 pagesTop 10 PCB Assembly Companies in Thailand (Updated 2023)jackNo ratings yet

- Co 34Document10 pagesCo 34Baskar Srinivas SNo ratings yet

- Solutions Manual For Introduction To RobDocument10 pagesSolutions Manual For Introduction To RobAndy Tan Fu YangNo ratings yet

- 25 191 1 PB PDFDocument11 pages25 191 1 PB PDFRaihatil UmmiNo ratings yet

- Co2 Lesson PlanDocument5 pagesCo2 Lesson PlanMAY RACHEL NARRAGANo ratings yet

- Sprinkler System Design GuidelinesDocument2 pagesSprinkler System Design GuidelinesaneeshNo ratings yet

- Battery Sizing: DefinitionsDocument4 pagesBattery Sizing: Definitionskrajeev2802No ratings yet

- PL320 Series 3mm LED Panel Mount Metal Holder: Features Absolute Maximum Ratings at T 25 °CDocument1 pagePL320 Series 3mm LED Panel Mount Metal Holder: Features Absolute Maximum Ratings at T 25 °CJajang JajaNo ratings yet

- Quantity Estimate Store Room FinalDocument15 pagesQuantity Estimate Store Room FinalUjjwal ShresthaNo ratings yet

- RUBRICS For ACTIVITY MIL - Camera ShotsDocument2 pagesRUBRICS For ACTIVITY MIL - Camera ShotsJaeneth SimondoNo ratings yet

- Velocity-Outdoor Catalog 2019Document148 pagesVelocity-Outdoor Catalog 2019robertoelripNo ratings yet

- Museums and The WebDocument54 pagesMuseums and The Webartearte2012No ratings yet

- Fleet Strategy - ACS Power TransformersDocument96 pagesFleet Strategy - ACS Power TransformersManojNo ratings yet

- Does Corporate Social Responsibility Disclosure Improve Firm Investment Efficiency? Evidence From ChinaDocument32 pagesDoes Corporate Social Responsibility Disclosure Improve Firm Investment Efficiency? Evidence From ChinaNi Luh Lemi Sushmita DeviNo ratings yet

- Annex 1 Reg 15 Control of Discharge of OilDocument2 pagesAnnex 1 Reg 15 Control of Discharge of OilsibinmgNo ratings yet

- CAMLIFE 2023 ProspectusDocument16 pagesCAMLIFE 2023 Prospectusboydilinh012No ratings yet

- Jurnal Farmasi PDFDocument7 pagesJurnal Farmasi PDFFiona ValenciaNo ratings yet

- Donau CarbonDocument2 pagesDonau CarbonLim Chee SiangNo ratings yet

- Handbook of Practical Electrical Design, 3rd Edition: IEEE Electrical Insulation Magazine December 1999Document2 pagesHandbook of Practical Electrical Design, 3rd Edition: IEEE Electrical Insulation Magazine December 1999James FitzGeraldNo ratings yet

- RE 2.3 MioDocument4 pagesRE 2.3 MioAngel Perez100% (1)

- Recreationalactivities 140317203039 Phpapp01 PDFDocument27 pagesRecreationalactivities 140317203039 Phpapp01 PDFRodjan MoscosoNo ratings yet

- Big Data Analytics (2017 Regulation) : Unit - 2 Clustering and ClassificationDocument7 pagesBig Data Analytics (2017 Regulation) : Unit - 2 Clustering and ClassificationcskinitNo ratings yet

- Digital BankingDocument3 pagesDigital BankingDPC Gym100% (1)

- Replikasi, Transkripsi Dan Translasi DnaDocument19 pagesReplikasi, Transkripsi Dan Translasi DnaEllizabeth LilantiNo ratings yet

- ADVANCE COPY 20230218 DILG ADVISORY No 02 On The LPADocument2 pagesADVANCE COPY 20230218 DILG ADVISORY No 02 On The LPABarangay MabuloNo ratings yet

- Attitude of Customers About Milma ProductsDocument30 pagesAttitude of Customers About Milma ProductsAswanth JNo ratings yet

- The Erosion of Four Materials Using Seven Erodents - Towards An UnderstandingDocument11 pagesThe Erosion of Four Materials Using Seven Erodents - Towards An UnderstandinganuragNo ratings yet