Professional Documents

Culture Documents

Ground Granulated Blast-Furnace Slag As A Cementitious Constituent in Concrete

Ground Granulated Blast-Furnace Slag As A Cementitious Constituent in Concrete

Uploaded by

ron_dany0 ratings0% found this document useful (0 votes)

18 views18 pagesGround Granulated Blast-Furnace Slag as a

Cementitious Constituent in Concrete

Original Title

233r_95

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentGround Granulated Blast-Furnace Slag as a

Cementitious Constituent in Concrete

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

18 views18 pagesGround Granulated Blast-Furnace Slag As A Cementitious Constituent in Concrete

Ground Granulated Blast-Furnace Slag As A Cementitious Constituent in Concrete

Uploaded by

ron_danyGround Granulated Blast-Furnace Slag as a

Cementitious Constituent in Concrete

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 18

233R-1

The use of iron blast-furnace slag as a constituent of concrete, either as an

aggregate or as a cementing material, or both, is well known. The use of

ground granulated blast-furnace (GGBF) slag in the production of blended

cements began in 1905 in the United States. Recent attention has been

given to the use of GGBF slag as a separate cementitious constituent of

concrete. This report primarily addresses the use of GGBF slag as a sepa-

rate cementitious material added along with portland cement in the pro-

duction of concrete. Other slags derived from the smelting of materials

other than iron ores are not discussed in this report. The reader should be

aware that the material characteristics described and the recommenda-

tions for use pertain solely to ground granulated iron blast-furnace

(GGBF) slag.

Keywords: blast-furnace slag; concretes; granulated materials; mix pro-

portioning; mortars (material); pelletized; portland cements; specications.

CONTENTS

Chapter 1General information, p. 233R-2

1.1History

1.2Scope and objective

1.3Definitions

1.4Origin of blast-furnace slag

1.5Chemical and physical properties

1.6Processing

1.7Specifications

1.8Hydraulic reactivity

1.9Factors determining cementitious properties

Chapter 2Storage, handling, and batching, p. 233R-5

2.1Storage

2.2Handling

2.3Batching

Chapter 3Proportioning concrete containing GGBF

slag, p. 233R-5

3.1Proportioning with GGBF slag

3.2Ternary systems

3.3Use with chemical admixtures

Chapter 4Effects on properties of fresh concrete, p.

233R-7

4.1Workability

4.2Time of setting

4.3Bleeding

4.4Rate of slump loss

Chapter 5Effects on properties of hardened concrete,

p. 233R-8

5.1Strength and rate of strength gain

5.2Modulus of elasticity

5.3Creep and shrinkage

5.4Influence of curing on the performance of GGBF

slag

5.5Color

5.6Effects on temperature rise in mass concrete

Ground Granulated Blast-Furnace Slag as a

Cementitious Constituent in Concrete

Reported by ACI Committee 233

ACI 233R-95

ACI Committee Reports, Guides, Standard Practices, and Com-

mentaries are intended for guidance in designing, planning, ex-

ecuting, or inspecting construction and in preparing speci-

fications. Reference to these documents shall not be made in the

Project Documents. If items found in these documents are de-

sired to be part of the Project Documents, they should be

phrased in mandatory language and incorporated in the Project

Documents.

ACI 233R-95 (reapproved 2000) supersedes and replaces ACI 226.1RR-87 and

became effective October 1, 1995.

Copyright 2000, American Concrete Institute.

All rights reserved including rights of reproduction and use in any form or by any

means, including the making of copies by any photo process, or by any electronic or

mechanical device, printed, written, or oral, or recording for sound or visual reproduc-

tion or for use in any knowledge or retrieval system or device, unless permission in

writing is obtained from the copyright proprietors.

Stanley J. Virgalitte

Chairman*

Mark D. Luther

Secretary*

Jere H. Rose

Technical Subcommittee Chairman*

Bryant Mather

Editorial Subcommittee Chairman*

Leonard W. Bell* Bryce A. Ehmke* Paul Klieger* Della M. Roy

Bayard M. Call* R. Douglas Hooton* Donald W. Lewis* Mauro J. Scali

Ravindra K. Dhir Gunnar M. Idorn V. M. Malhotra*

* Members of the Subcommittee who prepared this report.

The committee also wishes to acknowledge the contributions of Associate Member Graham R. H. Grieve to the development of this report.

(Reapproved 2000)

233R-2

ACI COMMITTEE REPORT

5.7Permeability

5.8Resistance to sulfate attack

5.9Reduction of expansion due to alkali-silica reaction

(ASR)

5.10Resistance to freezing and thawing

5.11Resistance to deicing chemicals

5.12Resistance to the corrosion of reinforcement

Chapter 6Uses of GGBF slag in concrete, p. 233R-15

6.1Introduction

6.2Ready-mixed concrete

6.3Concrete products

6.4Mortars and grouts

Chapter 7References, p. 233R-16

7.1Specified and/or recommended references

7.2Cited references

CHAPTER 1GENERAL INFORMATION

1.1History

The use of ground granulated blast-furnace (GGBF) slag

as a cementitious material dates back to 1774 when Loriot

made a mortar using GGBF slag in combination with slaked

lime (Mather 1957).

In 1862, Emil Langen proposed a granulation process to

facilitate removal and handling of iron blast-furnace slag

leaving the blast furnace. Glassy iron blast-furnace slags

were later investigated by Michaelis, Prussing, Tetmayer,

Prost, Feret, and Green. Their investigation, along with that

of Pasow, who introduced the process of air granulation,

played an important part in the development of iron blast-

furnace slag as a hydraulic binder (Thomas 1979). This de-

velopment resulted in the first commercial use of slag-lime

cements in Germany in 1865. In France, these slag cements

were used as early as 1889 to build the Paris underground

metro system (Thomas 1979). The use of GGBF slags in the

production of blended cements accounted for nearly 20 per-

cent of the total hydraulic cement produced in Europe (Hog-

an and Meusel 1981).

The first recorded production of portland blast-furnace

slag cement was in Germany in 1892; the first United States

production was in 1896. Until the 1950s, GGBF slag was

used in production of cement or as a cementitious material in

two basic ways: as a raw material for the manufacture of

portland cement, and as a cementitious material combined

with portland cement, hydrated lime, gypsum, or anhydrite

(Lewis 1981).

Since the late 1950s, use of GGBF slag as a separate ce-

mentitious material added at the concrete mixer with port-

land cement has gained acceptance in South Africa,

Australia, the United Kingdom, Japan, Canada, and the Unit-

ed States. Separate grinding of GGBF slag and portland ce-

ment, with the materials combined at the mixer, has two

advantages over the interground blended cements: 1) each

material can be ground to its own optimum fineness and 2)

the proportions can be adjusted to suit the particular project

needs.

Production capacity for GGBF slag is estimated to be ap-

proximately two million metric tons annually in North

America. A part of this is used stabilizing mine tailings and

industrial waste materials.

There are five companies providing GGBF slag in North

America. According to the 1991 Bureau of Mines Annual

Report, 13,293,000 metric tons of blast-furnace slag were

sold or used in the United States during that year (Solomon

1991). Today, much of this material could be used for the

production of cementitious material if granulating facilities

were available at all furnace locations. Additional sources of

GGBF slag may become available for energy and environ-

mental reasons.

1.2Scope and objective

This state-of-the-art report presents a detailed discussion

of the composition and production of GGBF slag, its use in

concrete, and its effects on the properties of concrete and

mortar.

Other types of slag not produced in the iron-making pro-

cess, (i.e., those derived from the production of copper, lead,

and steel) may differ greatly in composition and perfor-

mance from

GGBF slags, and their performance in concrete cannot be

predicted from the information provided in this report.

The objective of this report is to compile and present ex-

periences in research and field use of GGBF slag in concrete

and mortar, and to offer guidance in its selection, proportion-

ing, and use.

1.3Definitions

1.3.1 ACI definitionsACI 116R contains the following:

Blast-furnace slagThe nonmetallic product, consisting

essentially of silicates and aluminosilicates of calcium and of

other bases, that is developed in a molten condition simulta-

neously with iron in a blast furnace.

1. Air-cooled blast-furnace slag is the material resulting

from solidification of molten blast-furnace slag under atmo-

spheric conditions; subsequent cooling may be accelerated

by application of water to the solidified surface.

2. Expanded blast-furnace slag is the lightweight, cellular

material obtained by controlled processing of molten blast-

furnace slag with water, or water and other agents, such as

steam or compressed air, or both.

3. Granulated blast-furnace slag is the glassy granular ma-

terial formed when molten blast-furnace slag is rapidly

chilled, as by immersion in water.

Cement, blendedA hydraulic cement consisting essen-

tially of an intimate and uniform blend of granulated blast-

furnace slag and hydrated lime; or an intimate and uniform

blend of portland cement and granulated blast-furnace slag,

portland cement and pozzolan, or portland blast-furnace slag

cement and pozzolan, produced by intergrinding portland

cement clinker with the other materials or by blending port-

land cement with the other materials, or a combination of in-

tergrinding and blending.

Cement, portland blast-furnace slagA hydraulic cement

consisting of an intimately interground mixture of portland-

GROUND GRANULATED BLAST FURNACE SLAG 233R-3

cement clinker and granulated blast-furnace slag or an inti-

mate and uniform blend of portland cement and fine granu-

lated blast-furnace slag in which the amount of the slag

constituent is within specified limits.

Cement, slagA hydraulic cement consisting mostly of

an intimate and uniform blend of granulated blast-furnace

slag and hydrated lime in which the slag constituent is more

than a specified minimum percentage.

1.3.2 ASTM definition

GlassASTM C 162 defines glass as an inorganic prod-

uct of fusion which has cooled to a rigid condition without

crystallization.

1.4Origin of blast-furnace slag

In the production of iron, the blast furnace is continuously

charged from the top with iron oxide (ore, pellets, sinter,

etc.), fluxing stone (limestone and dolomite), and fuel

(coke). Two products are obtained from the furnace: molten

iron that collects in the bottom of the furnace (hearth) and

liquid iron blast-furnace slag floating on the pool of iron.

Both are periodically tapped from the furnace at a tempera-

ture of about 1500 C.

1.5Chemical and physical properties

The composition of blast-furnace slag is determined by

that of the ores, fluxing stone, and impurities in the coke

charged into the blast furnace. Typically, silicon, calcium,

aluminum, magnesium, and oxygen constitute 95 percent or

more of the blast-furnace slag. Table 1.1 indicates the chem-

ical analysis range for elements (reported as oxides) in blast-

furnace slags produced in the United States and Canada in

1988.

The ranges in composition from source to source shown in

Table 1.1 are much greater than those from an individual

plant. Modern blast-furnace technology produces very low

variability in the compositions of both the iron and the slag

from a single source.

To maximize hydraulic (cementitious) properties, the mol-

ten slag must be chilled rapidly as it leaves the blast furnace.

Rapid quenching or chilling minimizes crystallization and

converts the molten slag into fine-aggregate-sized particles

(generally smaller than a 4.75 mm (No. 4) sieve, composed

predominantly of glass. This product is referred to as granu-

lated iron blast-furnace slag. The cementitious action of a

granulated blast-furnace slag is dependent to a large extent

on the glass content, although other factors will also have

some influence. Slowly cooled slags are predominately crys-

talline and therefore do not possess significant cementitious

properties.

1.6Processing

Quenching with water is the most common process for

granulating slags to be used as cementitious materials. Sim-

ple immersion of the molten slag in water was often used in

the past; more efficient modern granulation systems use

high-pressure water jets that impinge on the stream of mol-

ten slag at a water-slag ratio of about 10 to 1 by mass. The

blast-furnace slag is quenched almost instantaneously to a

temperature below the boiling point of water, producing par-

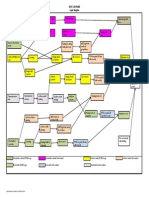

ticles of highly glassy material (Fig. 1.1).

Another process, sometimes referred to as air granulation,

involves use of the pelletizer (Cotsworth 1981). In this pro-

cess, the molten slag passes over a vibrating feed plate,

where it is expanded and cooled by water sprays. It then

passes onto a rotating, finned drum, which throws it into the

air where it rapidly solidifies to spherical pellets. The result-

ing product may also have high glass content and can be used

either as a cementitious material, or in the larger particle siz-

es, as a lightweight aggregate (Fig. 1.2). Other processes for

combining slag with water which are used primarily for the

production of lightweight aggregates are also capable of pro-

ducing a sufficiently glassy slag for successful cementitious

use (Robertson 1979).

After the granulated blast-furnace slag is formed, it must

be dewatered, dried, and ground before it is used as a cemen-

titious material. Magnets are often used before and after

grinding to remove residual metallic iron. Typically, the slag

is ground to an air-permeability (Blaine) fineness exceeding

that of portland cement to obtain increased activity at early

ages. As with portland cement and pozzolans, the rate of re-

action increases with the fineness.

Table 1.1Range of chemical composition of blast-

furnace slags in the United States and Canada

Chemical constituents (as oxides)*

Range of composition percent by

mass

SiO

2

32-42

Al

2

O

3

7-16

CaO 32-45

MgO 5-15

S 0.7-2.2

Fe

2

O

3

0.1-1.5

MnO 0.2-1.0

* Except for sulfur.

Fig. 1.1Conguration of GGBF slag water granulator to

include steam-condensing tower (Hogan and Meusel 1981)

233R-4

ACI COMMITTEE REPORT

1.7Specifications

ASTM C 989, first adopted in 1982, provides for three

strength grades of GGBF slags, depending on their respec-

tive mortar strengths when blended with an equal mass of

portland cement. The classifications are Grades 120, 100,

and 80,

*

based on the slag-activity index expressed as:

SAI = slag-activity index, percent = (SP/P x 100)

SP = average compressive strength of slag-reference ce-

ment mortar cubes, psi

P = average compressive strength of reference cement

mortar cubes, psi

Classification is in accordance with Table 1.2 (adapted

from ASTM C 989) as follows:

The slag-activity index test is influenced by the portland

cement used; ASTM C 989 specifies total alkalies and 28-

day compressive strengths for the reference cement. The pre-

cision of this test is such that the coefficient of variation is

4.1 percent for single laboratory testing and 5.7 percent for

multilaboratory testing.

In addition to requirements on strength performance, the

specification limits the residue on a 45-m (No. 325) sieve

to 20 percent and the air content of a mortar containing only

GGBF slag to a maximum of 12 percent.

The specification also includes two chemical require-

ments: one limiting the sulfide sulfur (S) to a maximum of

2.5 percent and the other limiting the sulfate content (report-

ed as SO

3

) to a maximum of 4.0 percent.

Canadian standards CSA A363 and CSA A23.5 differen-

tiate between GGBF slags that react hydraulically with water

and those that require activators to develop their cementi-

tious properties quickly.

Blended cements, in which the GGBF slags are combined

with portland cement, are covered by ASTM C 595. Three

types of such cements are addressed: 1) slag-modified port-

land cement [Type I (SM)], in which the GGBF slag constit-

uent is less than 25 percent of the total mass; 2) portland

blast-furnace slag cement (Type IS), which contains 25 to 70

percent GGBF slag; and 3) slag cement (Type S), containing

* The literature referenced in this report does not always identify the slag by grade

because the standard for grade determination was not recognized prior to 1982.

70 percent or more GGBF slag. While the specifications per-

mit the GGBF slag and the other ingredients to be ground ei-

ther together or separately and blended, most portland blast-

furnace slag cements have been interground. Such cements

have been used worldwide for almost 100 years, and have

excellent service records (Lea 1971).

1.8Hydraulic activity

There is general agreement among researchers (Smolczyk

1978), that the principal hydration product that is formed

when GGBF slag when it is mixed with portland cement and

water is essentially the same as the principal product formed

when portland cement hydrates, i.e., calcium-silicate hydrate

(CSH). As seen in the ternary diagram in Fig. 1.3, portland

cement and GGBF slag lie in the same general field, al-

though portland cement is essentially in the tricalcium sili-

cate (C

3

S) field whereas GGBF slag is found essentially in

the dicalcium silicate (C

2

S) field of the diagram.

GGBF slag hydrates are generally found to be more gel-

like than the products of hydration of portland cement, and

so add denseness to the cement paste.

When GGBF slag is mixed with water, initial hydration is

much slower than portland cement mixed with water; there-

fore, portland cement or alkali salts or lime are used to in-

crease the reaction rate. Hydration of GGBF slag in the

presence of portland cement depends largely upon break-

down and dissolution of the glassy slag structure by hydrox-

yl ions released during the hydration of the portland cement.

In the hydration of GGBF slag, the GGBF slag reacts with

alkali and calcium hydroxide (Ca(OH)

2

) to produce addi-

tional CSH. Regourd (1980) showed that a very small imme-

diate reaction also takes place when GGBF slag is mixed

with water, preferentially releasing calcium and aluminum

ions to solution. The reaction is limited, however, until addi-

tional alkali, calcium hydroxide, or sulfates are available for

reaction.

Research by Regourd (1980), Vanden Bosch (1980), and

Roy and Idorn (1982) has suggested that, in general, hydra-

tion of GGBF slag in combination with portland cement at

normal temperature is a two-stage reaction. Initially and dur-

ing the early hydration, the predominant reaction is with al-

kali hydroxide, but subsequent reaction is predominantly

with calcium hydroxide. Calorimetric studies of the rate of

Fig. 1.2GGBF slag pelletization process, using a minimum

of water usually applied at the vibrating feed plate (Hogan

and Meusel 1981)

Table 1.2Slag-activity index standards for various

grades as prescribed in ASTM C 989

Grade

Slag-activity index, minimum percent

Average of last ve con-

secutive samples Any individual sample

7-day index

80

100 75 70

120 95 90

28-day index

80 75 70

100 95 90

120 115 110

GROUND GRANULATED BLAST FURNACE SLAG 233R-5

heat liberation show this two-stage effect, in which the major

amount of GGBF slag hydration lags behind that of the port-

land-cement component (Fig. 1.4).

With increasing temperature, the alkali hydroxides from

the cement have greater solubility; therefore, they predomi-

nate in promoting the early reactions of the GGBF slag.

GGBF slag is thus able to chemically bind a larger amount

of alkali in the CSH because of the calcium to silica ratio of

the CSH formed from GGBF slag is lower than that formed

from portland cement (Regourd 1987). Forss (1982) and

Voinovitch, Raverdy, and Dron (1980) have shown that al-

kali hydroxide alone, i.e., without calcium hydroxide from

portland cement hydration, can hydrate GGBF slag to form

a strong cement paste structure which may be used in special

application.

1.9Factors determining cementitious properties

The clarification of the basic principles of slag hydration

makes it possible to identify the primary factors that in prac-

tice will influence the effectiveness of the uses of GGBF slag

in hydraulic cement. These factors are:

a) chemical composition of the GGBF slag

b) alkali concentration of the reacting system

c) glass content of the GGBF slag

d) fineness of the GGBF slag and portland cement

e) temperature during the early phases of the hydration

process

Due to the complexity of the influencing factors, it is not

surprising that earlier attempts to relate the hydration of

GGBF slag to simplified chemical moduli failed to provide

adequate evaluation criteria for practice (Mather 1957,

Hooton and Emery 1980). The complexity of the reacting

system suggests that direct performance evaluations of

workability, strength characteristics, and durability are the

most satisfactory measures of the effectiveness of GGBF

slag use. The ASTM C 989 slag-activity index is often used

as a basic criterion for evaluating the relative cementitious

potential of a GGBF slag. Furthermore, proportioning for

particular performance requirements should be based on

tests of concrete including the same materials intended to be

used in the work.

CHAPTER 2STORAGE, HANDLING, AND

BATCHING

2.1Storage

As is the case with portland cement and most pozzolans,

GGBF slag must be stored in bins or silos to provide protec-

tion from dampness and contamination. Color and fineness

of GGBF slag can be similar to those of portland cement;

therefore, necessary precautions should be taken to clearly

mark handling and storage equipment. When compartment-

ed bins are used, periodic checks for leaks between adjacent

bins should be conducted to avoid contamination of the

stored materials.

2.2Handling

GGBF slags are handled with the same kinds of equipment

as portland cement. The most commonly used items of

equipment are pneumatic pumps, screw conveyors, air

slides, and bucket elevators. Unlike some other finely-divid-

ed materials that are extremely fluid when aerated, GGBF

slags do not require special gates or feeders. Since GGBF

slags are cementitious, periodic emptying and cleaning of

the screws, air slides, weigh hoppers, and associated equip-

ment is advised.

2.3Batching

GGBF slag should be batched by weight in accordance

with the requirements of ACI 304R and ASTM C 94. When

GGBF slag is batched cumulatively in the same weighing

apparatus with portland cement, the GGBF slag should fol-

low the weighing of portland cement. When the GGBF slag

is introduced into the mixer, it is preferable to introduce it

along with the other components of the concrete mixture.

CHAPTER 3PROPORTIONING CONCRETE

CONTAINING GGBF SLAG

3.1Proportioning with GGBF slag

In most cases, GGBF slags have been used in proportions

of 25 to 70 percent by mass of the total cementitious materi-

Fig. 1.3Ternary diagram indicating composition of port-

land cement and blast-furnace slag in the system CaO-SiO

2

-

Al

2

O

3

[based on Lea (1971) and Bakker (1983)]

Fig. 1.4Rate of heat liberation of cements with and with-

out GGBF slag at 27 C (80 F) (Roy and Idorn 1982)

233R-6

ACI COMMITTEE REPORT

al. These proportions are in line with those established by

ASTM C 595 for the production of portland blast-furnace

slag cement. In South Africa, its use has been predominantly

at 50 percent replacement of cement due to convenience in

proportioning (Wood 1981).

The use of GGBF slag in alkali-activated systems where

no portland cement is used has been found to provide special

properties in the CSIR and several European countries ac-

cording to Talling and Brandstetr (1989).

Mary (1951) described the preparation of slag cement by

the Trief wet process and its use in the Bort-les-Orgues Dam.

This was done after World War II when the supply of port-

land cement was limited. The dam involved 660,000 m

3

(863,000 yd

3

) of concrete. The slag was ground wet and

charged into the mixer as a thick slurry.

A sample of the Trief wet process cement was obtained by

the Corps of Engineers in December 1950 and tested at the

Waterways Experiment Station (WES 1953). In the WES

tests the behavior of the ground slag from Europe was com-

pared with slag ground in the laboratory from expanded slag

from Birmingham, Alabama. Each slag was activated with

1.5 percent sodium hydroxide and 1.5 percent sodium chlo-

ride by weight, with generally similar results. Such systems

are not in commercial use in the U.S.A.

The proportion of GGBF slag should be dictated by the

purposes for which the concrete is to be used, the curing tem-

perature, the grade (activity) of GGBF slag, and the portland

cement or other activator. Where GGBF slags are blended

with portland cement, the combination of cementitious ma-

terial will result in physical properties that are characteristic

of the predominant material. For example, as the percentage

of GGBF slag increases, a slower rate of strength gain should

be expected, particularly at early ages, unless the water con-

tent is substantially reduced or accelerators are used or accel-

erated curing is provided.

There appears to be an optimum blend of GGBF slag that

produces the greatest strength at 28 days as tested by ASTM

C 109. This optimum is usually found to be 50 percent of the

total cementitious material, although this relationship varies

depending on the grade of GGBF slag (Hogan and Meusel

1981, Fulton 1974). Other considerations that will determine

the proportion of GGBF slag to be used will depend on the

requirements for temperature rise control, time of setting and

finishing, sulfate resistance, and the control of expansion due

to the alkali-silica reaction. For example, where high sulfate-

resistance is required, the GGBF slag content should be a

minimum of 50 percent of the total cementitious material,

unless previous testing with a particular GGBF slag has in-

dicated that a lower percentage is adequate (Chojnacki 1981;

Hogan and Meusel 1981; Fulton 1984; Lea 1971; Hooton

and Emery 1983).

The proportioning techniques for concretes incorporating

GGBF slags are similar to those used in proportioning con-

cretes made with portland cement or blended cements. Meth-

ods for proportioning are given in ACI 211.1. However, due

to the high proportions of GGBF slag commonly used, al-

lowances should be made for changes in solid volume due to

the difference in specific gravity of slags (2.85 to 2.94) and

portland cement (3.15). Concrete with GGBF slag typically

has greater placeability and ease of compaction, hence great-

er volumes of coarse aggregate may be used to reduce water

demand. Often an increase in coarse aggregate is desirable,

since it often reduces the stickiness of concrete mixtures

(Wood 1981; Fulton 1974). This is particularly true when

high cement contents are used. GGBF slags are usually sub-

stituted for portland cement on a one-to-one basis by mass

and are always considered in the determination of the water-

cementitious material ratio.

Water demand for given slump may generally be 3 to 5

percent lower than that found with concrete without GGBF

slags (Meusel and Rose 1983). Exceptions can be found and

should be accounted for in the trial mixture proportioning

studies.

3.2Ternary systems

The use of GGBF slag in combination with portland ce-

ment and pozzolans such as fly ash and silica fume is not un-

common. Typically the use of a ternary system is for

economic reasons, but it may also be used for improving en-

gineering properties.

Combinations of GGBF slag, cement and silica fume were

used in concrete mixtures in high-strength applications for

the Scotia Plaza in Toronto (Bickley et al. 1991) and Society

Tower (Engineering News Record 1991) in Cleveland, Ohio.

Combinations of GGBF slag, fly ash, and portland cement

have all been used as ballast for tunnel sections when low

heat generation in mass concrete was desired. In addition,

the combination of GGBF slag, fly ash, and portland cement

appears to be the most appropriate binding material for the

solidification and stabilization of low-level nuclear waste

forms (Langton 1989, Spence et al. 1989).

As reported by Malhotra (1987), all of these systems can

provide concrete properties similar to those found with port-

land cement with the exception that in freezing and thawing

environments, a minimum of 200 kg/m

3

(337 lb/yd

3

) of port-

land cement and a low water-cementitious materials ratio are

desired to provide adequate resistance to freezing-and-thaw-

ing environments.

Among the effects resulting from adding silica fume to ter-

nary systems are increased strength and reduced permeabili-

ty. In addition, GGBF slag has been used in combination

with portland cement and ground quartz (silica flour) in au-

toclaved concrete masonry (Hooton and Emery 1980).

3.3Use with chemical admixtures

Effects of chemical admixtures on the properties of con-

crete containing GGBF slags are similar to those for con-

cretes made with portland cement as the only cementitious

materials. Information regarding the effect of admixtures on

the properties of concrete can be obtained from the report of

ACI Committee 212. Small increases in the dosage rate of

air-entraining admixtures are sometimes necessary, if the

fineness of the GGBF slag is higher than that of the portland

cement. The amount of high-range water-reducing admix-

tures required to produce flowing concrete is usually 25 per-

cent less than that used in concretes not containing GGBF

GROUND GRANULATED BLAST FURNACE SLAG 233R-7

slag (Wu and Roy 1982). A given amount of retarder will

have a greater retarding effect as the proportion of GGBF

slag in the concrete is increased.

CHAPTER 4EFFECTS ON PROPERTIES OF

FRESH CONCRETE

4.1Workability

Wood (1981) reported that the workability and placeabili-

ty of concrete containing GGBF slag yielded improved char-

acteristics when compared with concrete not containing

GGBF slag. He further stated that this result was due to the

surface characteristics of the GGBF slag, which created

smooth slip planes in the paste. He also theorized that, due to

the smooth, dense surfaces of the GGBF slag particles, little

if any water was absorbed by the GGBF slag during initial

mixing, unlike portland cement. Fulton (1974) investigated

the phenomenon in greater detail and suggested that cemen-

titious matrix containing GGBF slags exhibited greater

workability due to the increased paste content and increased

cohesiveness of the paste. Wu and Roy (1982) found that

pastes containing GGBF slags exhibited different rheologi-

cal properties compared to paste of portland cements alone.

Their results indicate a better particle dispersion and higher

fluidity of the pastes and mortars, both with and without wa-

ter-reducing admixtures.

It also appears (Fig. 4.1) that concrete containing GGBF

slag is normally consolidated under mechanical compaction

more easily than concrete that does not contain GGBF slag.

Using conventional test procedures for workability, this phe-

nomenon was never substantiated with any degree of confi-

dence. Fulton (1974) states, practically all standard work-

ability tests involve a measure of the amount of work neces-

sary to remold the concrete from a compacted state to anoth-

er state. Cohesion is a valuable and important property of a

fresh mix, but obviously in such tests, it has an adverse effect

on the particular index measured--an effect which is not re-

lated to the compaction of concrete on the construction site.

Considering this, Fulton devised a test using the Vebe ap-

paratus, in which uncompacted concrete was molded by vi-

bration and differences in molding time of mixtures with and

without slag were compared. In all cases, the placeability of

the concrete containing 50 percent GGBF slag was superior

to that of mixtures without GGBF slag. Meusel and Rose

(1983) found that increased slump was obtained with all

GGBF slag blends tested when compared to concrete with-

out GGBF slag at the same water content (Fig. 4.2).

Osborne (1989) showed test results of slump, Vebe, and

compacting factor for concretes containing 0, 40 and 70 per-

cent GGBF slag. As the percentage of GGBF slag increased,

the ratio of water-cementitious materials had to be reduced

to maintain workability properties more or less similar to the

concrete mix with 0 percent GGBF slag. Wimpenny et al.

(1989) found, in concretes with constant water-cementitious

ratio and increasing GGBF replacement, that the slump in-

creased significantly with increasing GGBF slag replace-

ment.

4.2Time of setting

Usually, an increase in time of setting can be expected

when GGBF slag is used as a replacement for part of the

portland cement in concrete mixtures. The degree to which

the time of setting is affected is dependent on the initial tem-

perature of the concrete, the proportion of the blend used, the

water-cementitious materials ratio, and the characteristics of

the portland cement (Fulton 1974). Typically, the time of ini-

tial setting is extended one-half to one hour at temperatures

of 23 C (73 F); little if any change is found at temperatures

above 29 C (85 F) (Hogan and Meusel 1981). Although sig-

nificant retardation has been observed at low temperatures,

the additions of conventional accelerators, such as calcium

chloride or other accelerating admixtures, can greatly reduce

or eliminate this effect. Since the amount of portland cement

Fig. 4.1Relationship between response to vibration of concrete mixtures made with

portland cement and with mixture containing 50 percent GGBF slag

233R-8

ACI COMMITTEE REPORT

in a mixture usually determines setting characteristics,

changing the GGBF slag proportions may be considered in

cold weather. At higher temperatures, the slower rate of set-

ting is desirable in most cases, but care may need to be taken

to minimize plastic shrinkage cracking.

4.3Bleeding

Bleeding capacity and bleeding rate of concrete are mostly

affected by the ratio of the surface area of solids to the unit

volume of water. Therefore, when GGBF slags are used,

these effects can be estimated depending on the fineness of

the GGBF slag as compared to that of the cement and the

combined effect of the two cementitious materials. When the

GGBF slag is finer than the portland cement and is substitut-

ed on an equal-mass basis, bleeding is reduced; conversely,

when the GGBF slag is coarser, the rate and amount of

bleeding may increase.

Cesareni and Frigione (1968) found that in all GGBF slags

tested, both total amount and rate of bleeding increased with

the addition of slag. No explanation was given for the phe-

nomenon, but since the cement and GGBF slag were ground

to the same fineness, the results contradict what is normally

found with finely divided materials. Time of setting of the

concrete and nonabsorptive qualities of the dense GGBF slag

are likely to have contributed to the increased bleeding.

4.4Rate of slump loss

Little information is available regarding slump loss when

GGBF slags are used. Frigione (1983) reports a reduced rate

of slump loss, whereas Meusel and Rose (1983) indicate that

concrete containing GGBF slag at 50 percent substitution

rate yielded slump loss equal to that of concrete without

GGBF slag. Experiences in the United Kingdom indicate re-

duced slump loss, particularly when the portland cement

used in the blend exhibits rapid slump loss, such as that

caused by false-set characteristics of the cement (Lea 1971).

CHAPTER 5EFFECTS ON PROPERTIES OF

HARDENED CONCRETE AND MORTAR

5.1Strength and rate of strength gain

Compressive and flexural strength-gain characteristics of

concrete containing GGBF slag can vary over a wide range.

When compared to portland cement concrete, use of Grade

120 slag typically results in reduced strength at early ages (1

to 3 days) and increased strength at later ages (7 days and be-

yond) (Hogan and Meusel 1981). Use of grade 100 results in

lower strengths at early ages (1 to 21 days), but equal or

greater strength at later ages. Grade 80 gives reduced

strength at all ages. The extent to which GGBF slags affect

strength is dependent on the slag activity index of the partic-

ular GGBF slag, and the ratio in which it is used in the mix-

ture. Fig. 5.1 indicates that the mortar strength potential of

50-percent blends is dependent upon the grade of GGBF slag

as defined in ASTM C 989. Consistent and stable long-term

strength gain beyond 20 years has been documented for con-

crete made with portland blast-furnace slag cement (Type

1S) while exposed to moist or air curing (Wood 1992).

Other factors that can affect the performance of GGBF

slag in concrete are water-cementitious materials ratio, phys-

ical and chemical characteristics of the portland cement, and

curing conditions. As seen in Fig. 5.2, the percentage of

strength gain achieved with a Grade 120 GGBF slag is great-

er in concrete mixtures which have high water-cementitious

materials ratio than in mixtures with a low water-cementi-

tious materials ratio (Fulton 1974; Meusel and Rose 1983).

The same trend was also noted by Malhotra (1980).

Fig. 4.2Effect of water content on slump of concrete mix-

tures with and without GGBF slag (Meusel and Rose 1983)

(25.4 mm = 1 in.; 1 kg/m

3

= 169 lb/yd

3

)

Fig. 5.1Strength relationship of mortar containing typi-

cal GGBF slag meeting ASTM C 989 requirements, com-

pared to portland cement mortar (data originates from

Task Group E-38.06.02 report) (1 ksi = 6.89 MPa)

GROUND GRANULATED BLAST FURNACE SLAG 233R-9

The temperature at which the concrete is cured will have a

great effect on the strength of the concrete, particularly at

early ages. Concrete containing GGBF slag is found to re-

spond very well under elevated temperature curing condi-

tions in accordance to the Arrhenius Law reported by Roy

and Idorn (1982). In fact, strength exceeding that of port-

land-cement concrete at 1 day and beyond has been reported

for accelerated curing conditions (Hogan and Meusel 1981;

Fulton 1974; Lea 1978). Conversely, strength reduction at

early ages is expected with concrete containing GGBF slag,

when cured at normal or low temperatures.

The proportion of the GGBF slag used also affects the

strength and rate of strength gain as noted in Fig. 5.3. When

highly active GGBF slags have been tested, the greatest 28-

day strengths are found with blends of 40 to 50 percent (Ful-

ton 1974; Hogan and Meusel 1981; Meusel and Rose 1983).

Where early strengths are concerned, the rate of strength

gain is generally inversely proportional to the amount of

GGBF slag used in the blend. The compressive strength

properties of the various blends of GGBF slag and portland

cement, as compared to a portland-cement mixture, are

shown in Fig. 5.4.

Of particular interest is the effect of GGBF slag when con-

crete is tested for flexural strength (modulus of rupture).

When comparisons are made between concrete with and

without GGBF slag, where the GGBF slag used is at propor-

tions designed for greatest strength, the blends generally

yield increasing modulus of rupture at ages beyond 7 days

(Fulton 1974; Malhotra 1980; Hogan and Meusel 1981) (Fig.

5.5). This is believed to be a result of the increased denseness

of the paste and improved bond at the aggregate-paste inter-

face.

5.2Modulus of elasticity

Most work in this area has been with blended cement con-

taining GGBF slag. Klieger and Isberner (1967) found es-

sentially the same modulus of elasticity in concretes

containing portland blast-furnace slag cement as compared

with Type I cement concrete. Stutterheim, as quoted by Ful-

ton (1974), also confirmed this, using concrete containing

equal amounts of GGBF slag and portland cement and con-

crete with portland cement only.

5.3Creep and shrinkage

There are few data available on creep and shrinkage of

concrete containing GGBF slag, and the limited test data

show conflicting results. For example, Klieger and Isberner

(1962) found few differences when portland blast-furnace

slag cement was compared to portland cement. On the other

hand, Fulton (1974) reports generally greater creep and

shrinkage where various blends of GGBF slag were used. It

is believed that the increased shrinkage may be due to the

greater volume of paste in the concrete when GGBF slag is

substituted on an equal mass basis. An example of the effects

of blends on shrinkage is seen in Fig. 5.6 (Hogan and Meusel

1981). Other investigators indicate that where shrinkage is

found to be greater, the addition of gypsum to the GGBF slag

will reduce the shrinkage much the same as with portland ce-

ment (Hogan and Meusel 1981).

5.4Influence of curing on the performance of GGBF

slag

Regardless of the cement or the blends of cementitious

materials used, concrete must be kept in a proper moisture

and temperature condition during its early stages if it is to

fully develop its strength and durability potential. There has

been considerable discussion regarding the effects of curing

on concrete containing portland blast-furnace slag cement

and concrete containing GGBF slag as a separate constitu-

ent. In Mathers 1957 study comparing Type II cement with

portland blast-furnace slag cement, he found that both ce-

ments suffered strength loss to the same degree when curing

was stopped at 3 days. Conversely, Fulton (1974) reports

that concrete containing GGBF slag is more susceptible to

poor curing conditions than concrete without GGBF slag

where the GGBF slag is used in percentages higher than 30

Fig 5.2Effect of water-cementitious materials ratio on

compressive strength of GGBF slag levels, expressed as a

percentage of mixtures made with portland cement (Meusel

and Rose 1983)

Fig. 5.3Inuence of GGBF slag replacement on mortar

cube compressive strength (Hogan and Meusel 1981) (1 ksi

= 6.89 MPa)

233R-10

ACI COMMITTEE REPORT

percent. He attributes this susceptibility to reduced forma-

tion of hydrate at early ages leading to increased loss of

moisture which would otherwise be available for hydration

to continue. There is no doubt that, as with all cementitious

materials, the rate and degree of hydration is affected by the

loss of moisture at an early age, with a decrease in strength

gain. To attain proper strength and durability, curing should

follow the procedures prescribed in ACI 308.

5.5Color

GGBF slag is considerably lighter in color than most port-

land cements and will produce a lighter color in concrete af-

ter curing. In certain operations, up to 30 percent GGBF slag

has been used to replace white portland cements without a

noticeable color change in the cured product. There is a

unique characteristic of concrete containing GGBF slag, ei-

ther added separately or in blended cements, in that during

the second to fourth days after casting, a blue-green colora-

tion may appear, which then diminishes with age as oxida-

tion takes place. This coloration is attributed to a complex

reaction of the sulfide sulfur in the GGBF slag with other

compounds in the cement. The degree and extent of the col-

oration depends on the rate of oxidation, the percentage of

GGBF slag used, curing conditions, and porosity of the con-

crete surfaces. Where color is important, correctly timed ex-

posure to air, sunlight, or wetting and drying promotes

oxidation of the concrete surface. Concrete containing

GGBF slag has been found to yield extended blue coloration

when continuously exposed to water or when sealers were

applied at early ages. The interior of the concrete will retain

a deep blue-green coloration for a considerable time, as ob-

served in normal compressive test specimens when broken.

Fig. 5.4Compressive strength of concrete containing various blends of GGBF slag,

compared to concrete using only portland cement as cementitious material (Hogan

and Meusel 1981) (1 ksi = 6.89 MPa)

GROUND GRANULATED BLAST FURNACE SLAG 233R-11

However, when these faces are exposed to the atmosphere,

such as split-face concrete block, they will oxidize to a uni-

form color.

5.6Effects on temperature rise in mass concrete

GGBF slags have been used commonly as an ingredient of

portland blast-furnace slag cement and as a separate cemen-

titious constituent to reduce the temperature rise in mass

concrete (Bamforth 1980; Fulton 1974; Mather 1951; Lea

1971). There are cases where mixtures with and without

GGBF slag were tested using the heat of solution method

(ASTM C 186) and the mixtures with GGBF slag produced

Fig. 5.5Flexural strength (modulus of rupture) of concrete containing various blends

of GGBF slag, compared to concrete using only portland cement as cementitious mate-

rial (Hogan and Meusel 1981) (1 ksi = 6.89 MPa)

Fig. 5.6Drying shrinkage of non-air-entrained concrete for various slag replacements

(w/c = 0.55) (Hogan and Meusel 1981)

233R-12

ACI COMMITTEE REPORT

the greater cumulative heats (Bamforth 1980; Hogan and

Meusel 1981; Roy and Idorn 1982). It is important to note

that, although the heat-of-solution method indicates the total

heat release potential of cement, it does not indicate the rate

of heat rise which is also important in mass concrete applica-

tions. In all cases the incorporation of GGBF slag reduced

the early rate of heat generation; this reduction is directly

proportional to the proportion of GGBF slag used. The re-

duction in peak temperature and rate of heat gain are seen in

Fig. 5.7, where in-situ measurements were reported by Bam-

forth (1980) comparing concrete without GGBF slag to con-

crete with 30 percent fly ash and concrete with 75 percent

GGBF slag.

The heat of hydration is dependent on the portland cement

used and the activity of the GGBF slag. Roy and Idorn

(1982) found a correlation of heat of hydration to strength

potential of various blends of GGBF slag and portland ce-

ment. Reduced heat of hydration can be expected when

GGBF slags are used to replace equal amounts of cement.

Studies on heat generation of concrete containing GGBF

slab by Kokubu, Takahashi, and Anzai (1989) indicate that

blends of 35 to 55 percent GGBF slag produced greater total

heat than the portland cement mixtures, even though the rate

of heat rise was less. Where blends of highly active GGBF

slags are used, proportions of at least 70 percent GGBF slag

may be needed to meet low heat of hydration requirements

when evaluated by heat-of-solution method (ASTM C 186).

5.7Permeability

The use of GGBF slag in hydraulic structures is well doc-

umented. The permeability of mature concrete containing

GGBF slag is greatly reduced when compared with concrete

not containing GGBF slag (Hooton and Emery 1990; Roy

1989; Rose 1987). As the GGBF slag content is increased,

permeability decreases. It is found that the pore structure of

the cementitious matrix is changed through the reaction of

GGBF slag with the calcium hydroxide and alkalies released

during the portland cement hydration (Bakker 1980; Roy and

Idorn 1982). Pores in concrete, normally containing calcium

hydroxide, are then, in part, filled with calcium silicate hy-

drates (Bakker 1980; Mehta 1980; Roy and Idorn 1982). As

pointed out by Mehta (1980), the permeability of concrete

depends on its porosity and pore-size distribution. Reduc-

tion in pore size which GGBF slags impart is seen in Fig. 5.8,

Fig. 5.7Comparison of heat generated in mass concrete with portland cement, portland

cement-y ash, and portland cement-slag concrete mixtures (Bamforth 1980)

GROUND GRANULATED BLAST FURNACE SLAG 233R-13

comparing paste with and without GGBF slags. Where

GGBF slags are used, reduction in the pore size has been not-

ed prior to 28 days after mixing (Bakker 1980; Mehta 1980;

Roy and Idorn 1981). Another example of the reduced per-

meability is seen in Fig. 5.9 taken from Smolczyk (1977)

where concretes of varying water-cementitious materials ra-

tio and GGBF slag proportions were evaluated for chloride

diffusion, over a period of 2 years.

5.8Resistance to sulfate attack

Partial replacement of portland cement with GGBF slag is

found to improve the sulfate resistance of concrete. High re-

sistance to sulfate attack has been demonstrated when the

GGBF slag proportion exceeds 50 percent of the total ce-

mentitious material where Type II cements were used (Hog-

an and Meusel 1981). Additional testing of GGBF slag in

Canada showed that 50-percent blends of GGBF slag with

Type I portland cement containing up to 12 percent C

3

A

have sulfate resistance equivalent to that of Type V cements.

The GGBF slag was reported to have 7 percent Al

2

O

3

(Chojnacki 1981). As reported by Hooton and Emery (1990),

a minimum amount of GGBF slag is required to provide high

sulfate resisting properties to concrete. Their results, using

ASTM C 1012, indicate that this minimum would be 50 per-

cent or greater when used with Type I portland cement hav-

ing a C

3

A content up to 12 percent as long as the Al

2

O

3

content of the GGBF slag was lower than 11 percent, Fig.

5.10.

Where GGBF slag is used in sufficient quantities, several

changes occur which improve resistance to sulfate attack.

Those changes include: 1) The C

3

A content of the mixture is

proportionally reduced depending on the percentage of

GGBF slag used. However, Lea (1971) reports that increased

sulfate resistance is not only dependent on the C

3

A content

of portland cement alone, but also the alumina content of the

GGBF slag. Lea further reports from tests made by Locher

that where the alumina content of the GGBF slag is less than

11 percent, increased sulfate resistance was found regardless

of the C

3

A content of the portland cement where blends be-

tween 20 and 50 percent GGBF slag were used. 2) Through

the reduction of soluble calcium hydroxide in the formation

of calcium silicate hydrates, the environment for the forma-

tion of calcium sulfoaluminate is reduced. 3) Investigations

indicate that resistance to sulfate attack is greatly dependent

on the permeability of the concrete or cement paste (Bakker

1983; Mehta 1980; Roy and Idorn 1982). Again, the forma-

tion of calcium silicate hydrates in pore spaces, normally oc-

cupied by alkalies and calcium hydroxide, reduces the

permeability of the paste and prevents the intrusion of the ag-

gressive sulfates. Expansion of mortar bars due to sulfate at-

tack is illustrated in Fig. 5.11 where bars made using GGBF

slag blends are compared to bars made using Type II and

Type V portland cements (Hogan and Meusel 1981).

Buck (1985) reported results of tests by a procedure gen-

erally similar to ASTM C 1012 using Type IS cements from

Alabama, Michigan, and Pennsylvania, and two cements

containing GGBF slag made in Germany. The IS cements

contained about 25 percent GGBF slag. The committee be-

lieves the test results showed relatively poor sulfate resis-

tance due to too low a proportion of GGBF slag.

5.9Reduction of expansion due to alkali-silica reaction

(ASR)

Use of GGBF slag as a partial replacement for portland ce-

Fig. 5.8Comparison of pore-size distribution of paste

containing portland cement and paste containing 40 per-

cent slag and 60 percent portland cement, tested by mer-

cury intrusion (Roy and Parker 1983)

Fig. 5.9Results of chloride content in 20.3 to 40.6 mm

(0.8 to 1.6 in.) deep layers in concrete beams stored in 3.0

molar solution of NaCl (Smolczyk 1977)

233R-14

ACI COMMITTEE REPORT

ment is known to reduce the potential expansion of concrete

due to alkali-silica reaction (Bakker 1980; Hogan and Meu-

sel 1981). It is reported in the Appendix of ASTM C 989 that

where GGBF slags were used in quantities greater than 40

percent of the total cementitious material, reduced expansion

due to the alkali-silica reaction is found with cement having

alkali contents up to 1.0 percent. It is reported by Hogan and

Meusel (1981) (Fig. 5.12) that where slag contents are used

in percentages from 40 to 65 percent of total cementitious

material, expansion was virtually eliminated when tested in

accordance with ASTM C 227. Their test used highly reac-

tive Pyrex glass to obtain maximum expansion. Similar re-

sults were reported by Klieger and Isberner (1967), where

portland blast-furnace slag cements were used.

Resistance to ASR is attributed to the following influences

on the cementitious media: (1) reduced permeability, (2)

change of the alkali-silica ratio, (3) dissolution and con-

sumption of the alkali species, (4) direct reduction of avail-

able alkali in the system, and (5) reduction of calcium

hydroxide needed to support the reaction.

Results of tests using GGBF slag as a partial replacement

for high-alkali cement with aggregate known to exhibit alka-

li-silica and alkali-carbonate reactions were reported by

Fig. 5.10Effect of various slag replacement levels on expansions in 50,000 mg/1 SO

4

as Na

2

SO

4

(slag Al

2

O

3

= 8.4 percent)

Fig. 5.11Sulfate resistance of mortar bars, Wolochow

test, Type II (Hogan and Meusel 1981)

Fig. 5.12ASTM C 227 potential alkali-aggregate reac-

tivity for various slag replacements (Hogan and Meusel

1981)

GROUND GRANULATED BLAST FURNACE SLAG 233R-15

Soles, Malhotra, and Chen (1989). After two years of obser-

vation the GGBF slag blends were found to be effective in

reducing expansion, but the reduction was less than that

found with the low-alkali cement. When used in combina-

tion with high-alkali cement, blends of 40 percent GGBF

slag appear to be effective in reducing the potential of alkali-

carbonate reactions, and blends of 50 percent GGBF slag ap-

pear to be effective in reducing the potential of alkali-silica

reactions.

5.10Resistance to freezing and thawing

Many studies have been made where GGBF slags were

used in concrete as a portion of blended cement. Results of

these studies generally indicate that when concrete made

with portland blast-furnace slag cement was tested in com-

parison with Type I and Type II cements, their resistances to

freezing and thawing in water were essentially the same

(Fulton 1974; Klieger and Isberner 1967; Mather 1957). As

with all hydraulic cement concrete, proper air content and

bubble spacing are necessary for adequate protection in

freezing-and-thawing environments.

Most recently, air-entrained concrete containing GGBF

slag used as 50 percent of the total cementitious material was

found to be frost resistant even though a measurable differ-

ence in weight loss was found when compared to the con-

crete made with Type II portland cement and tested using

ASTM C 666 (Hogan and Meusel 1981). Similar results

were found by Malhotra (1980) using various percentages of

GGBF slag with portland cement. This weight loss does not

appear significant and is probably due to comparing con-

cretes of unequal strengths.

5.11Resistance to deicing chemicals

Although some laboratory tests with Type IS cement indi-

cate less resistance to deicing salts, many researchers have

found, in field exposure, little difference when compared to

concrete not containing slag (Klieger and Isberner 1967).

Similar results were reported using blends of 50 percent

GGBF slag and 50 percent portland cement, by Hogan and

Meusel (1981). Most research indicates that scaling is usual-

ly found when the concrete has a high water-cementitious

materials ratio and high percentages of GGBF slag are used.

5.12Resistance to the corrosion of reinforcement

Many investigations have shown that reduced permeabili-

ty of concrete containing GGBF slag significantly reduces

the penetration of chloride to all depths within the concrete

(Bakker 1980; Bakker 1983; Fulton 1974; Mehta 1980; Roy

1989; Rose 1987; Mehta 1980; Meusel and Hogan 1981).

The reduction in permeability and the resistance to chloride

intrusion increases as the level of GGBF slag increases in the

concrete mixture of mortar. The use of GGBF slag is found

to reduce the permeability of concrete by several orders of

magnitude.

During the early use of concrete containing portland blast-

furnace slag cement, there was considerable concern regard-

ing the potential harmful effects of sulfur in GGBF slag.

Since then, many investigations have shown that the use of

GGBF slags has no negative effect on the corrosion of steel

(Fulton 1974; Lea 1971; Hogan and Meusel 1981). It has

been found that a slight reduction in the pH of pore solution

does not have a negative impact on the passivity of reinforc-

ing steel, and that use of GGBF slag in good quality con-

crete, reduces concrete permeability, thus reducing the

penetration of chlorides and carbon dioxide which promote

corrosion of steel.

CHAPTER 6USES OF GGBF SLAG IN

CONCRETE AND MORTAR

6.1Introduction

Type IS blended cement is considered equivalent to Type

I portland cement. Therefore, Type IS is used in all concrete

applications except where high early strengths are required

under normal curing conditions. As in its use in blended ce-

ment, GGBF slag mixed with portland cement at the con-

crete mixer may also be used in all applications and

processes. The flexibility of using different blends of GGBF

slag depends upon the desired qualities of concrete which are

most important to the concrete designer and producer.

6.2Ready-mixed concrete

Most of the producers of ready-mixed concrete that use

GGBF slag do so in proportions of 50 percent of total cemen-

titious material when the weather is warm and the GGBF

slag is highly active (Wood 1981). Not only is this blend

convenient, but with a highly active GGBF slag this blend

usually produces the greatest strength and most favorable

cost to benefit ratio. Proportions of GGBF slag as low as 20

to 30 percent have been used with less active GGBF slags or

during periods of colder weather. In those jobs requiring spe-

cial qualities, such as sulfate resistance or low temperature

rise, blends containing more than 50 percent GGBF slag are

recommended. On the other hand, when early strengths are

required to facilitate quick form removal or when thin sec-

tions are placed at low temperatures, blends containing less

than 50 percent are recommended.

Particular advantages in the use of GGBF slag as a sepa-

rate cementitious material in ready-mixed concrete are: a) in-

creased flexibility to meet individual job requirements; b)

reduced cost of cementitious material; c) improved work-

ability; d) reduced strength loss in concrete subject to hot

weather application; and e) increased compressive and flex-

ural strength with GGBF slag grade of 100 or better.

6.3Concrete products

The use of GGBF slag in precast concrete products is usu-

ally restricted by the requirements for early strength (1 day)

and the curing cycle used. Under normal curing conditions,

1-day strength is usually lower in concrete containing GGBF

slag, particularly when high percentages of GGBF slag are

substituted for the portland cement. Therefore, reduced

blends of GGBF slag or the use of accelerating admixtures

or both are required to achieve the desired stripping and han-

dling strength.

233R-16

ACI COMMITTEE REPORT

Where accelerated curing conditions are used, normal

GGBF slag blends of 40 to 60 percent of total cementitious

material are applicable in most concrete mixtures and curing

cycles. GGBF slags respond favorably to accelerated curing,

and increased strength at 1 day may be obtained when Grade

120 slags are used with curing temperatures exceeding 130

F (Hogan and Meusel 1981). The positive response, i.e., im-

proved early strength, of GGBF slag to accelerated curing is

an important attribute in the manufacture of precast and pre-

stressed components for marine exposure where high dura-

bility is needed.

Using GGBF slag is also beneficial in those products made

from no-slump concrete mixtures. The increased workability

found during mechanical compaction allows for a reduction

in water demand, usually resulting in greater density and

strength (Fulton 1974).

6.4Mortars and grouts

The use of GGBF slags typically improves the strength,

permeability, flow, and cohesive characteristics of mortars

and grouts. In this application, GGBF slags are used in pro-

portions similar to those used in the production of concrete.

Using GGBF slag in the form of blended cements or sep-

arately blended with lime and portland cement for masonry

mortars is well known. The same general properties found in

concrete are also to be expected in mortars and grouts.

Special uses of GGBF slag in grouts for the stabilization

and solidification of waste materials were reported by Lang-

ton (1989). The combination of ultra-fine GGBF slag, hav-

ing air-permeability finenesses greater than 1000 m

2

/kg, and

portland cement or alkali salts are being used for the grouting

of fine cracks in existing dams and the stabilization of fine

sands.

CHAPTER 7REFERENCES

7.1Specified and/or recommended references

The documents of the various standards-producing organi-

zations referred to in this document are listed below with

their serial designation. Since some of these documents are

revised frequently, generally in minor detail only, the user of

this document should check directly with the sponsoring

group if it is desired to refer to the latest revision.

American Concrete Institute

116R Cement and Concrete Terminology

211.1 Standard Practice for Selecting Proportions for Nor-

mal, Heavyweight, and Mass Concrete

212.2R Guide for Use of Admixtures in Concrete

304R Guide for Measuring, Mixing, Transporting, and

Placing Concrete

308 Standard Practice for Curing Concrete

ASTM

C 94 Specification for Ready-Mixed Concrete

C 109 Test Method for Compressive Strength of Hydrau-

lic Cement Mortars (Using 2-in. or 50-mm Cube

Specimens)

C 162 Definition of Terms Relating to Glass and Glass

Products

C 186 Test Method for Heat of Hydration of Hydraulic

Cement

C 227 Test Method for Potential Alkali Reactivity of Ce-

ment-Aggregate Combinations (Mortar-Bar Meth-

od)

C 595 Specification for Blended Hydraulic Cements

C 666 Test Method for Resistance of Concrete to Rapid

Freezing and Thawing

C 989 Specification for Ground Iron Blast-Furnace Slag

for Use in Concrete and Mortars

C 1012 Test Method for Length Change of Hydraulic-Ce-

ment Mortars Exposed to a Sulfate Solution

C 1073 Test Method for Hydraulic Activity of Ground Slag

by Reaction with Alkali

Canadian Standards Association

A23.5 Supplemental Cementing Materials and Their Use

in Concrete Construction

A363 Cementitious Hydraulic Slag

These publications may be obtained from the following

organizations:

American Concrete Institute

P. O. Box 9094

Farmington Hills, MI 48333

ASTM

1916 Race Street

Philadelphia, PA 19103

Canadian Standards Association

178 Rexdale Blvd.

Rexdale, Ontario M9W 1R3

Canada

7.2Cited references

Bakker, R. F. M., On the Cause of Increased Resistance

of Concrete Made from Blast-Furnace Cement to Alkali Re-

action and to Sulfate Corrosion, Thesis RWTH-Aachen,

1980, 118 pp. (Translated from the German, Den s'Hertoge-

nbosch, The Netherlands.)

Bakker, Robert F. M., Permeability of Blended Cement

Concrete, Fly Ash, Silica Fume, Slag, and Other Mineral

By-Products in Concrete, SP-79, American Concrete Insti-

tute, Detroit, 1983, pp. 589-605.

Bamforth, P. B., In Situ Measurement of the Effect of

Partial Portland Cement Replacement Using Either Fly Ash

or Ground Granulated Blast-Furnace Slag on the Perfor-

mance of Mass Concrete, Proceedings, Institution of Civil

Engineers (London), Part 2, V. 69, Sept. 1980, pp. 777-800.

Bickley, J. A., Ryell, J., Rogers, C., and Hooton, R. D.,

Some Characteristics of High Strength Structural Con-

crete, Canadian Journal of Civil Engineering, V. 18, No. 5,

1991, pp. 885-889.

GROUND GRANULATED BLAST FURNACE SLAG 233R-17

Buck, Alan D., Sulfate Resistance of Hydraulic Cements

Containing Blast-Furnace Slag, USAEWES Miscellaneous

Paper SL-85-14, Vicksburg, MS, 1985, 15 pp. (Also CTIAC

Report No. 72).

Cesareni, D., and Frigione, G., A Contribution to the

Study of the Physical Properties of Hardened Paste of Port-

land Cements Containing Granulated Blast-Furnace Slag,

Proceedings, 5th International Symposium on the Chemistry

of Cement, Cement Association of Japan, Tokyo, V. 4, 1968,

pp. 237-247.

Chojnacki, B., Sulfate Resistance of Blended (Slag) Ce-

ment, Report No. EM-52, Ministry of Transportation and

Communications, Downsview, Ontario, Canada, 1981.

Cotsworth, R.P., National Slag's Pelletizing Process,

Symposium on Slag Cement, University of Alabama, Bir-

mingham, 1981.

Engineering News Record, Society Tower, Concrete

Today, May 6, 1991, p. C-72.

Forss, B., F-Cement, A Low-Porosity Slag Cement for

the Precast Industry, International Conference on Slag and

Blended Cements, University of Alabama, Birmingham,

1982, 12 pp.

Fulton, F. S., The Properties of Portland Cement Con-

taining Milled Granulated Blast-Furnace Slag, Monograph,

Portland Cement Institute, Johannesburg, 1974, pp. 4-46.

Hogan, F. J., and Meusel, J. W., Evaluation for Durability

and Strength Development of a Ground Granulated Blast-

Furnace Slag, Cement, Concrete, and Aggregates, V. 3, No.

1, Summer, 1981, pp. 40-52.

Hooton, R. D., and Emery, J. J., Pelletized Slag Cement:

Autoclave Reactivity, Proceedings, 7th International Con-

gress on the Chemistry of Cement, Paris, 1980, V. II, pp. III-

43-47.

Hooton, R. D., and Emery, J. J., Sulfate Resistance of a

Canadian Slag, ACI Materials Journal, V. 87, No. 6, Nov.-

Dec. 1990, pp. 547-555.

Hooton, R. D., and Emery J. J., Glass Content Determi-

nation and Strength Development Predictions for Vitrified

Blast Furnace Slag, Fly Ash, Silica Fume, Slag and Other

Mineral By-Products in Concrete, V. M. Malhotra, Ed., V.

II, SP-79, American Concrete Institute, Detroit, 1983, pp.

943-962.

Klieger, Paul, and Isberner, Albert W., Laboratory Stud-

ies of Blended CementPortland Blast-Furnace Slag Ce-

ments, Journal, PCA Research and Development Depart-

ment Laboratories, V. 9, No. 3, Sept. 1967, pp. 2-22.

Kokubu, K., Takahashi, S., and Anzai, H., Effect of Cur-

ing Temperatures on the Hydration and Adiabatic Tempera-

ture Characteristics of Portland Cement-Blast Furnace Slag

Concrete, Fly Ash, Silica Fume, Slag and Natural Poz-

zolans in Concrete, V. M. Malhotra, Ed., SP-114, American

Concrete Institute, Detroit, 1989, pp. 1366-1371.

Langton, C. A., Slag Based Materials for Toxic Based

Metal and Radioactive Waste Stabilization, Fly Ash, Silica

Fume, Slag and Natural Pozzolans in Concrete, V. M. Mal-

hotra, Ed., SP-114, American Concrete Institute, Detroit,

1989, pp. 1697-1706.

Lea, F. M., The Chemistry of Cement and Concrete, 3rd

edition, Chemical Publishing Co., New York, 1971, pp. 454-

489.

Lewis, D. W., History of Slag Cements, Symposium on

Slag Cement, University of Alabama, Birmingham, 1981.

Malhotra, V. M., Strength and Durability Characteristics

of Concrete Incorporating a Pelletized Blast Furnace Slag,

Fly Ash, Silica Fume, Slag, and Other Mineral By-Products

in Concrete, V. M. Malhotra, ed., SP-79, V. 2, American

Concrete Institute, Detroit, 1980, pp. 891-922.

Malhotra, V. M., Strength and Freeze-Thaw Characteris-

tics of Concrete Incorporating Granulated Blast-Furnace

Slag, CANMET, I.R. 79-38, Energy, Mines & Resources,

Ottawa, Canada, 1980.

Malhotra, V. M., Carette, G. G., and Bremner, T. W., Du-

rability of Concrete Containing Supplementary Cementing

Materials in Marine Environment, J. Scanlon, Ed., SP-100,

American Concrete Institute, Detroit, 1987, pp. 1227-1258.

Mary, M., Preparation du Cimeut di Latier par Voie Ho-

mide le Proced Trief et Son Aplication au Barrage de Bort-

les-orgues, Annales de l'institute technique du Batiment et

des travaux publiques, No. 200, July-Aug. 1951 (Translation

52-4, Oct. 1952, U.S. Army Engineer Waterways Experi-

ment Station, Vicksburg, MS).

Mather, Bryant, Laboratory Tests of Portland Blast-Fur-

nace Slag Cements, ACI Journal, V. 54, No. 3, Sept. 1957,

pp. 205-232.

Mehta, P. Kumar, Durability of Concrete in Marine En-

vironmentA Review, Performance of Concrete in Ma-

rine Environment, SP-65, American Concrete Institute,

Detroit, 1980, pp. 1-20.

Mehta, P. Kumar, Pozzolanic and Cementitious Byprod-

ucts as Mineral Admixtures for ConcreteA Critical Re-

view, Fly Ash, Silica Fume, Slag and Other Mineral By-

Products in Concrete, V. M. Malhotra, Ed., SP-79, Ameri-

can Concrete Institute, V. 1, Detroit, 1983, pp. 1-46.

Meusel, J. W., and Rose, J. H., Production of Granulated

Blast Furnace Slag at Sparrows Point, and the Workability

and Strength Potential of Concrete Incorporating the Slag,

Fly Ash, Silica Fume, Slag and Other Mineral By-Products

in Concrete, SP-79, American Concrete Institute, Detroit,

1983, pp. 867-890.

NSA Report 188-1, Slag, The All Purpose Construction

Aggregate, National Slag Association, Washington, 1988.

Osborne, G. J., Carbonation and Permeability of Blast-

Furnace Slag Cement Concretes from Field Structures, Fly

Ash, Slag and Natural Pozzolans in Concrete, V. M. Mal-

hotra, Ed., SP-114, American Concrete Institute, Detroit,

1989, pp. 1209-1237.

Regourd, M., Structure and Behavior of Slag Portland

Cement Hydrates, Proceedings, 7th International Congress

on the Chemistry of Cements (Paris), Editions Septima, Par-

is, V. 1, III-2, 1980, pp. 10-18.

Regourd, M., Characterization of Thermal Activation of

Slag Cements, Proceedings, 7th International Congress on

the Chemistry of Cements (Paris), Editions Septima, Paris,

V. 2, III-3, 1980, pp. 105-111.

233R-18

ACI COMMITTEE REPORT

Regourd, M., Microanalytical Studies (X-Ray Photo

Electron Spectrometry) of Surface Hydration Reactions of

Cement Compounds, Philosophical Transactions (Lon-

don), Series A., V. 310 (No. 1511) R.S., 1980, pp. 85-91.

Regourd, M., Slags and Slag Cements, Ch. 3, Cement

Replacement Materials, R. N. Swamy, Ed., Surrey Universi-

ty Press, 1987, pp. 73-99.

Robertson, J. L., At Submicron Fineness, Expanded Slag

is a Cement Replacement, Rock Products, April 1982.

Rose, J. H., The Effects of Cementitious Blast-Furnace

Slag on Chloride Permeability of Concrete, Corrosion,

Concrete, and Chlorides, V. M. Malhotra, Ed., SP-102,

American Concrete Institute, Detroit, 1987, pp. 107-125.

Roy, D. M., and Idorn, G. M., Hydration, Structure, and

Properties of Blast Furnace Slag Cements, Mortars, and

Concrete, Proceedings, ACI JOURNAL V. 79, No. 6, Nov.-

Dec. 1983, pp. 445-457.

Roy, D. M., and Parker, K. M., Microstructures and Prop-

erties of Granulated Slag-Portland Cement Blends at Normal

and Elevated Temperatures, Fly Ash, Silica Fume, Slag and