Professional Documents

Culture Documents

Kim PDF

Kim PDF

Uploaded by

Celeste Romero LongarCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Sine Sweep Rate ExcerptDocument4 pagesSine Sweep Rate ExcerptramanollaNo ratings yet

- Influence of Surface Treatments On Fatigue Life ofDocument13 pagesInfluence of Surface Treatments On Fatigue Life oframanollaNo ratings yet

- Tips and Tricks - Modeling Virtual Fluid Mass in OptiStruct With MFLUIDDocument8 pagesTips and Tricks - Modeling Virtual Fluid Mass in OptiStruct With MFLUIDramanollaNo ratings yet

- Comparisonof Matlaband SimulinkDocument13 pagesComparisonof Matlaband SimulinkramanollaNo ratings yet

- IMAC XIII 13th 13 13 3 Complex Modes Origins Limits PDFDocument11 pagesIMAC XIII 13th 13 13 3 Complex Modes Origins Limits PDFramanollaNo ratings yet

- Chapter 2 Creating and Editing Screens: 2.1 Scredit (Screen Editor) SetupDocument4 pagesChapter 2 Creating and Editing Screens: 2.1 Scredit (Screen Editor) SetupryoNo ratings yet

- CPT & Suctioning Rle ExamDocument2 pagesCPT & Suctioning Rle ExamJojo JustoNo ratings yet

- The Word Wall: Chants and Cheers ActivitiesDocument5 pagesThe Word Wall: Chants and Cheers Activitieseva.bensonNo ratings yet

- New Microsoft Word DocumentDocument4 pagesNew Microsoft Word DocumentVinothan VasavanNo ratings yet

- D296 DetectorDocument4 pagesD296 Detectorventas2.fireproofcolNo ratings yet

- 329672001-Jacobs Engineering Group IncDocument5 pages329672001-Jacobs Engineering Group IncJaram Johnson67% (3)

- Financial Deepening and Economic Development of NiDocument16 pagesFinancial Deepening and Economic Development of NiVictoria MaciasNo ratings yet

- Ayamas Journal PDFDocument8 pagesAyamas Journal PDFRaajKumarNo ratings yet

- Math in Focus 3B WorksheetDocument6 pagesMath in Focus 3B WorksheetBobbili PooliNo ratings yet

- Online QDA - How and What To CodeDocument5 pagesOnline QDA - How and What To CodeRockyNo ratings yet

- MATH7 - PPT - Q2 - W1 - Day1 - Measuring QuantitiesDocument28 pagesMATH7 - PPT - Q2 - W1 - Day1 - Measuring QuantitiesEveNo ratings yet

- 001 GEYSERSD23Final PDFDocument100 pages001 GEYSERSD23Final PDFVasu ThakurNo ratings yet

- Report On VSATDocument19 pagesReport On VSATchinu meshramNo ratings yet

- The Lord's Day Celebration: Opening CeremonyDocument7 pagesThe Lord's Day Celebration: Opening CeremonyWil-Ly de la CernaNo ratings yet

- Integrated Door Motor Controller User Manual: Shenyang Bluelight Automatic Technology Co., LTDDocument56 pagesIntegrated Door Motor Controller User Manual: Shenyang Bluelight Automatic Technology Co., LTDJulio Cesar GonzalezNo ratings yet

- Company / Project Title: Overview - The Quick PitchDocument3 pagesCompany / Project Title: Overview - The Quick PitchMauro Domingo'sNo ratings yet

- ESS Questionnaire StaffDocument2 pagesESS Questionnaire StaffSarita LandaNo ratings yet

- 2.15 Punching Shear Strength of RC Slabs Using Lightweight ConcreteDocument8 pages2.15 Punching Shear Strength of RC Slabs Using Lightweight Concretejack21abNo ratings yet

- BC 367 Experiment 4 Kinetic Properties of Acid Phosphatase: Roh + Hpo Phosphatase + H ODocument8 pagesBC 367 Experiment 4 Kinetic Properties of Acid Phosphatase: Roh + Hpo Phosphatase + H OAliceKeikoNo ratings yet

- Starkville Dispatch Eedition 11-4-18Document32 pagesStarkville Dispatch Eedition 11-4-18The DispatchNo ratings yet

- Advertisement in E-CommerceDocument49 pagesAdvertisement in E-CommerceKenz VillanuevaNo ratings yet

- Electromagnetic Compatibility: Interference Caused by The TransmitterDocument12 pagesElectromagnetic Compatibility: Interference Caused by The TransmitterpalahobaraNo ratings yet

- EnPI V5.0 Algorithm DocumentDocument14 pagesEnPI V5.0 Algorithm DocumentDalila AmmarNo ratings yet

- DB en Macx MCR T Ui Up 104595 en 10Document49 pagesDB en Macx MCR T Ui Up 104595 en 10Dante LupuNo ratings yet

- Cyclotron PDFDocument5 pagesCyclotron PDFRaju YadavNo ratings yet

- March of The Metro Gnome Lesson PlanDocument2 pagesMarch of The Metro Gnome Lesson Planapi-607297153No ratings yet

- MatrixDocument30 pagesMatrixauras2065No ratings yet

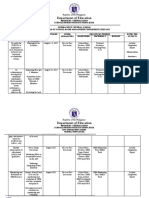

- Department of Education: Republic of The PhilippinesDocument3 pagesDepartment of Education: Republic of The PhilippinesRussel RapisoraNo ratings yet

- Summer Farm: By: Norman Maccaig Group: Camila Luna and Estrella LinDocument8 pagesSummer Farm: By: Norman Maccaig Group: Camila Luna and Estrella LinJamieDuncanNo ratings yet

- OLD 2900 Downflow Manual PDFDocument32 pagesOLD 2900 Downflow Manual PDFintermountainwaterNo ratings yet

Kim PDF

Kim PDF

Uploaded by

Celeste Romero LongarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kim PDF

Kim PDF

Uploaded by

Celeste Romero LongarCopyright:

Available Formats

The Pennsylvania State University

The Graduate School

College of Engineering

DESIGN AND ANALYSIS OF ROTOR SYSTEMS WITH

MULTIPLE TRAILING EDGE FLAPS AND RESONANT

ACTUATORS

A Thesis in

Aerospace Engineering

by

Jun-Sik Kim

c _ 2005 Jun-Sik Kim

Submitted in Partial Fulllment

of the Requirements

for the Degree of

Doctor of Philosophy

December 2005

The thesis of Jun-Sik Kim was reviewed and approved

by the following:

Edward C. Smith

Professor of Aerospace Engineering

Thesis Co-Advisor

Co-Chair of Committee

Kon-Well Wang

William E. Diefenderfer Chaired Professor in Mechanical Engineering

Thesis Co-Advisor

Co-Chair of Committee

Farhan S. Gandhi

Associate Professor of Aerospace Engineering

Joseph F. Horn

Assistant Professor of Aerospace Engineering

Mary I. Frecker

Associate Professor of Mechanical Engineering

George A. Lesieutre

Professor of Aerospace Engineering

Head of the Department of Aerospace Engineering

Signatures are on le in the Graduate School.

Abstract

The purpose of this thesis is to develop piezoelectric resonant actuation systems

and new active control methods utilizing the multiple trailing-edge aps congu-

ration for rotorcraft vibration suppression and blade loads control.

An aeroelastic model is developed for a composite rotor blade with multiple

trailing-edge aps. The rotor blade airloads are calculated using quasi-steady blade

element aerodynamics with a free wake model for rotor inow. A compressible

unsteady aerodynamics model is employed to accurately predict the incremental

trailing edge ap airloads. Both the nite wing eect and actuator saturation for

trailing-edge aps are also included in an aeroelastic analysis.

For a composite articulated rotor, a new active blade loads control method is

developed and tested numerically. The concept involves straightening the blade

by introducing dual trailing edge aps. The objective function, which includes

vibratory hub loads, bending moment harmonics and active ap control inputs,

is minimized by an integrated optimal control/optimization process. A numerical

simulation is performed for the steady-state forward ight of an advance ratio of

0.35. It is demonstrated that through straightening the rotor blade, which mimics

the behavior of a rigid blade, both the bending moments and vibratory hub loads

can be signicantly reduced by 32% and 57%, respectively.

An active vibration control method is developed and analyzed for a hingeless

rotor. The concept involves deecting each individual trailing-edge ap using a

compact resonant actuation system. Each resonant actuation system could yield

high authority, while operating at a single frequency. Parametric studies are con-

ducted to explore the nite wing eect of trailing-edge aps and actuator satura-

tion. A numerical simulation has been performed for the steady-state forward ight

( = 0.15 0.35). It is demonstrated that multiple trailing-edge ap congura-

tion with the resonant actuation system can reduce the required trailing-edge ap

hinge moments by 37% to 61% in each individual actuator compared to single-ap

iii

conguration for high speed ight conditions.

A novel resonant actuation concept is developed to eciently realize the heli-

copter vibration and blade loads control. The resonant actuation system (RAS) is

achieved through both mechanical and electrical tailoring. With mechanical tun-

ing, the resonant frequencies of the actuation system (includes the piezoelectric

actuator and the related mechanical and electrical elements for actuation) can be

adjusted to the required actuation frequencies. This obviously will increase the

authority of the actuation system. To further enhance controllability and robust-

ness, the actuation resonant peak can be signicantly broadened and attened with

electrical tailoring through the aid of an electric network of inductance, resistance,

and negative capacitance.

A piezoelectric resonant actuation system model is derived for active ap ro-

tors. The optimal values of the electrical components are explicitly determined.

An equivalent electric circuit model emulating the physical actuation system is

derived and experimentally tested to investigate the initial feasibility of the piezo-

electric resonant actuation system. It is demonstrated that the proposed resonant

actuation system can indeed achieve both high active authority and robustness.

It is shown that the actuator authority is signicantly increased from 1.25 to 4.5

degrees as compared to the static value, with wide operating bandwidth of 8 Hz.

In addition to this, the RAS is compared to an equivalent mechanical system to

provide better physical understanding. Design guidelines of the RAS are derived

in dimensionless forms. Feed-forward controllers are developed to realize the elec-

tric network dynamics and to adapt the phase variation. The control strategy is

then implemented via a digital signal processor (DSP) system. Performance of the

resonant actuation system is analyzed and veried experimentally on a full-scale

piezoelectric tube actuator for helicopter rotor control. Promising results are illus-

trated that the actuator stroke is increased 2 to 3.5 times compared to its static

value with bandwidth of 5 to 10 Hz.

iv

Table of Contents

List of Figures ix

List of Tables xv

List of Symbols xvi

Acknowledgments xxvi

Chapter 1

Introduction 1

1.1 Background and Motivation . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Literature Review . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2.1 Helicopter Vibration Reduction . . . . . . . . . . . . . . . . 7

1.2.2 Active Trailing-edge Flaps . . . . . . . . . . . . . . . . . . . 14

1.2.3 Smart Actuation System Development . . . . . . . . . . . . 20

1.2.4 Piezoelectric Networks . . . . . . . . . . . . . . . . . . . . . 26

1.2.5 Summary of Literature Review . . . . . . . . . . . . . . . . 30

1.3 Problem Statement and Objectives . . . . . . . . . . . . . . . . . . 32

1.4 Overview of Dissertation . . . . . . . . . . . . . . . . . . . . . . . . 36

Chapter 2

Helicopter Model 38

2.1 Preliminary Background . . . . . . . . . . . . . . . . . . . . . . . . 39

2.1.1 Vehicle Kinematics and Coordinate Systems . . . . . . . . . 39

2.1.2 Blade Deformed Kinematics and Coordinate Systems . . . . 41

2.1.3 Nondimensionalization and Ordering Scheme . . . . . . . . . 45

2.1.4 Variational Formulation . . . . . . . . . . . . . . . . . . . . 47

2.2 Structural Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

v

2.2.1 Strain Energy of Rotor Blade . . . . . . . . . . . . . . . . . 49

2.2.2 Kinetic Energy of Rotor Blade . . . . . . . . . . . . . . . . . 57

2.3 Aerodynamic Blade Loads . . . . . . . . . . . . . . . . . . . . . . . 64

2.3.1 Quasi-steady Airloads . . . . . . . . . . . . . . . . . . . . . 68

2.3.2 Noncirculatory Airloads . . . . . . . . . . . . . . . . . . . . 72

2.3.3 Quasi-steady Aerodynamics Implementation . . . . . . . . . 73

2.4 Inow and Free Wake Model . . . . . . . . . . . . . . . . . . . . . . 76

2.4.1 Linear Inow . . . . . . . . . . . . . . . . . . . . . . . . . . 76

2.4.2 Free Wake Model . . . . . . . . . . . . . . . . . . . . . . . . 77

2.5 Aeroelastic Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . 80

2.5.1 Aeroelastic Response . . . . . . . . . . . . . . . . . . . . . . 80

2.5.2 Coupled Propulsive Trim . . . . . . . . . . . . . . . . . . . . 85

Chapter 3

Trailing Edge Flap Formulation 91

3.1 Inertial Contribution . . . . . . . . . . . . . . . . . . . . . . . . . . 92

3.2 Aerodynamic Models . . . . . . . . . . . . . . . . . . . . . . . . . . 97

3.2.1 Incompressible Model . . . . . . . . . . . . . . . . . . . . . . 97

3.2.2 Compressible Model . . . . . . . . . . . . . . . . . . . . . . 98

3.3 Active Trailing Edge Flap Control Algorithm . . . . . . . . . . . . . 102

3.3.1 Feedback Form of Global Controller . . . . . . . . . . . . . . 102

3.3.2 Active-Passive Hybrid Design . . . . . . . . . . . . . . . . . 106

Chapter 4

Active Loads Control Using a Dual Flap Conguration 108

4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

4.2 Description of Analytical Models . . . . . . . . . . . . . . . . . . . 110

4.3 Numerical Results and Discussions . . . . . . . . . . . . . . . . . . 112

4.3.1 Baseline Articulated Rotor Analysis . . . . . . . . . . . . . . 113

4.3.2 Rigid Blade vs. Elastic Blade . . . . . . . . . . . . . . . . . 118

4.3.3 A Single Flap for Moment Reduction . . . . . . . . . . . . . 118

4.3.4 Dual Flap Performance . . . . . . . . . . . . . . . . . . . . . 119

4.3.5 Multicyclic Control for Moment and Vibration Reduction . . 124

4.3.6 Active-Passive Hybrid Design . . . . . . . . . . . . . . . . . 126

4.4 Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Chapter 5

Helicopter Vibration Suppression via Multiple Trailing-Edge

Flaps with Resonant Actuation Concept 132

5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

vi

5.2 Description of Analytical Models . . . . . . . . . . . . . . . . . . . 135

5.3 Results and Discussions . . . . . . . . . . . . . . . . . . . . . . . . 137

5.3.1 Baseline Hingeless Rotor Analysis . . . . . . . . . . . . . . . 137

5.3.2 Flap Eect to Free-Wake Geometry . . . . . . . . . . . . . . 143

5.3.3 Determination of Trailing-Edge Flap Locations . . . . . . . . 147

5.3.4 Finite Wing Eects . . . . . . . . . . . . . . . . . . . . . . . 149

5.3.5 Eectiveness of Multiple-Flap Conguration . . . . . . . . . 151

5.3.6 Vibration Reduction with Multicyclic Control . . . . . . . . 156

5.4 Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Chapter 6

Piezoelectric Actuation System Synthesis 164

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

6.2 Piezoelectric Actuation System Model . . . . . . . . . . . . . . . . 167

6.2.1 Piezoelectric Tube Actuator . . . . . . . . . . . . . . . . . . 167

6.2.2 Inertial and Aerodynamic Loads . . . . . . . . . . . . . . . . 171

6.2.3 Coupled Actuator-Flap-Circuit System . . . . . . . . . . . . 172

6.3 Mechanical Tuning and Electrical Tailoring . . . . . . . . . . . . . . 175

6.3.1 Mechanical Tuning . . . . . . . . . . . . . . . . . . . . . . . 175

6.3.2 Electrical Tailoring . . . . . . . . . . . . . . . . . . . . . . . 176

6.4 Equivalent Electric Circuit Model . . . . . . . . . . . . . . . . . . . 180

6.4.1 Van Dyke Model . . . . . . . . . . . . . . . . . . . . . . . . 180

6.4.2 Analysis and Experimental Verication . . . . . . . . . . . . 183

6.5 Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Chapter 7

Design and Test of Resonant Actuation Systems 188

7.1 Design Guidelines of the RAS . . . . . . . . . . . . . . . . . . . . . 189

7.1.1 Resonant Actuators with R-L elements . . . . . . . . . . . . 189

7.1.2 Resonant Actuation Systems with Additional Capacitance . 195

7.1.3 Summary of Design Guidelines for the RAS circuitry . . . . 199

7.2 Dynamic Characteristics of the RAS in Forward Flight . . . . . . . 202

7.2.1 A Perturbation Method . . . . . . . . . . . . . . . . . . . . 202

7.2.2 Analysis of Time Responses . . . . . . . . . . . . . . . . . . 206

7.2.3 Vibration Reduction Within Available Actuation Authority 212

7.3 Experimental Realization of the RAS . . . . . . . . . . . . . . . . . 214

7.3.1 Controller Design . . . . . . . . . . . . . . . . . . . . . . . . 214

7.3.2 Bench Top Testing . . . . . . . . . . . . . . . . . . . . . . . 218

7.4 Power Consumption of Piezoelectric Resonant Actuation Systems . 224

7.4.1 Piezoelectric resonant actuators without circuitry . . . . . . 224

vii

7.4.2 Piezoelectric resonant actuators with circuitry . . . . . . . . 226

7.5 Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Chapter 8

Conclusions and Recommendations 231

8.1 Summary of Research Eorts and Achievements . . . . . . . . . . . 232

8.2 Recommendations for Future Work . . . . . . . . . . . . . . . . . . 235

Appendix A

Derivation of Strain Measure 238

A.1 Coordinate Transformation . . . . . . . . . . . . . . . . . . . . . . . 240

A.2 Foreshortening Term . . . . . . . . . . . . . . . . . . . . . . . . . . 242

A.3 Deformed Coordinate System . . . . . . . . . . . . . . . . . . . . . 244

Appendix B

Rotor System Matrices and Force Vectors 246

B.1 Strain Energy of Rotor Blades . . . . . . . . . . . . . . . . . . . . . 247

B.1.1 Stiness Coecients of Composite Beam . . . . . . . . . . . 247

B.1.2 Stiness Matrices and Force Vectors . . . . . . . . . . . . . 248

B.2 Kinetic Energy of Rotor Blades . . . . . . . . . . . . . . . . . . . . 249

B.2.1 Stiness Matrix . . . . . . . . . . . . . . . . . . . . . . . . . 249

B.2.2 Mass Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

B.2.3 Damping Matrix . . . . . . . . . . . . . . . . . . . . . . . . 252

B.2.4 Force Vectors . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Appendix C

Formulations using Mathematica 254

C.1 Rotor Strain Energy . . . . . . . . . . . . . . . . . . . . . . . . . . 255

C.2 Rotor Kinetic Energy . . . . . . . . . . . . . . . . . . . . . . . . . . 259

C.3 Rotor Quasi-steady Aerodynamic Loads . . . . . . . . . . . . . . . 266

C.4 Trailing-Edge Flaps Inertial Loads . . . . . . . . . . . . . . . . . . 273

Bibliography 279

viii

List of Figures

1.1 Various sources of a helicopter vibration . . . . . . . . . . . . . . . 2

1.2 Helicopter vibration variation vs. forward ight speed . . . . . . . . 3

1.3 Blade vortex interaction [4] . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Aerodynamic environment in forward ight . . . . . . . . . . . . . . 4

1.5 Vibratory loads transmitted to fuselage [5] . . . . . . . . . . . . . . 5

1.6 Schematic of a dynamic vibration observer [5] . . . . . . . . . . . . 8

1.7 Composite tailoring of helicopter rotor blades [49] . . . . . . . . . . 8

1.8 Active Control of Structural Response (ACSR) systems: (a) engine

platform (b) cabin [20] . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.9 Schematic of Higher Harmonic Control (HHC) . . . . . . . . . . . . 10

1.10 Schematic of Individual Blade Control (IBC) . . . . . . . . . . . . . 11

1.11 Schematic of Active Trailing-edge Flap (ATF) . . . . . . . . . . . . 12

1.12 Schematic of Active Twist Rotor (ATR) . . . . . . . . . . . . . . . 13

1.13 Schematic of semi-active actuators located at blade root region [4] . 13

1.14 Karman SH-2 Seasprite helicopter with servo-aps . . . . . . . . . . 15

1.15 Rotor with on-blade elevons in the NASA Ames Wind Tunnel [30] . 17

1.16 Elevon motion over one rotor revolution with 4/rev voltage excita-

tion (760 RPM, = 0.2) [30] . . . . . . . . . . . . . . . . . . . . . . 17

1.17 Actuator and ap dynamic system model [83] . . . . . . . . . . . . 18

1.18 Blade-pitch indexing for the swashplateless rotor conguration [91] . 19

1.19 Single and dual ap congurations [94] . . . . . . . . . . . . . . . . 20

1.20 AFC being inserted at active blade assembly [3] . . . . . . . . . . . 22

1.21 Macro-Fiber Composite (MFC) actuator . . . . . . . . . . . . . . . 22

1.22 Piezoelectric bender actuators [107] . . . . . . . . . . . . . . . . . . 23

1.23 MD900 Helicopter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1.24 Double X-frame actuators for MD900 Helicopter [112] . . . . . . . . 24

1.25 BK117 Helicopter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1.26 Flap unit assembly for Eurocopter BK117/EC145 [114] . . . . . . . 25

ix

1.27 Piezoelectric tube actuator for ATF [117] . . . . . . . . . . . . . . . 26

1.28 Passive piezoelectric vibration absorber [121] . . . . . . . . . . . . . 27

1.29 Active-Passive Piezoelectric Network (APPN) [121] . . . . . . . . . 27

1.30 Experimental setup (a) Beam with APPN and negative capacitance,

(b) Circuit diagram of negative capacitance [125] . . . . . . . . . . 28

1.31 Performance comparison: voltage driving response : shunt cir-

cuit without negative capacitance; : shunt circuit with negative

capacitance [125] . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

1.32 Scaling of aerodynamic hinge moment and actuator block torque . . 33

1.33 Conceptual diagram of a resonant actuation system . . . . . . . . . 34

2.1 Vehicle and rotating coordinate systems . . . . . . . . . . . . . . . 39

2.2 Undeformed blade coordinate systems . . . . . . . . . . . . . . . . . 41

2.3 Deformed blade coordinate systems . . . . . . . . . . . . . . . . . . 42

2.4 Cross-section coordinates before and after deformation . . . . . . . 43

2.5 Deformations in terms of Euler angles . . . . . . . . . . . . . . . . . 44

2.6 Schematic of the wake, discretized in space and time [131] . . . . . 77

2.7 Flow chart of an aeroelastic analysis with a free wake . . . . . . . . 79

2.8 Finite elements for composite rotor blades . . . . . . . . . . . . . . 81

2.9 Finite element discretization in time . . . . . . . . . . . . . . . . . . 84

2.10 Vehicle conguration for propulsive trim . . . . . . . . . . . . . . . 89

3.1 Schematic of blade cross-section incorporating a trailing edge ap . 92

3.2 Nomenclature for a thin airfoil with a ap . . . . . . . . . . . . . . 97

4.1 Dual ap conguration for active loads control . . . . . . . . . . . . 110

4.2 Conceptual sketch of dual ap mechanism for active loads control . 111

4.3 Articulated blade coupled ap mode shapes . . . . . . . . . . . . . 115

4.4 Articulated blade coupled lag mode shapes . . . . . . . . . . . . . . 116

4.5 Articulated blade torsion mode shapes . . . . . . . . . . . . . . . . 116

4.6 Control settings of articulated rotor, = 0.35 . . . . . . . . . . . . 117

4.7 Blade tip response of articulated rotor, = 0.35 . . . . . . . . . . . 117

4.8 Comparison of vibratory hub loads for active loads control . . . . . 118

4.9 Dual ap prole for moment reduction with 1/rev control . . . . . . 120

4.10 Control settings of baseline and actively controlled rotors . . . . . . 121

4.11 Harmonics of apwise bending moment along the radial station . . 122

4.12 Flapwise bending moment distribution before control . . . . . . . . 123

4.13 Flapwise bending moment distribution after control . . . . . . . . . 123

4.14 Dual ap prole with 1 and 2/rev control inputs . . . . . . . . . . . 124

4.15 Dual ap prole with 1, 2 and 3/rev control inputs . . . . . . . . . 125

x

4.16 Comparison of vibration index and maximum apwise bending mo-

ment with dierent control inputs . . . . . . . . . . . . . . . . . . . 126

4.17 Vibratory hub shears comparison for active loads control . . . . . . 127

4.18 Comparison of vibration index and maximum apwise moment of

hybrid designed rotor . . . . . . . . . . . . . . . . . . . . . . . . . . 128

4.19 Dual ap proles for retrot and hybrid designs . . . . . . . . . . . 128

4.20 Control settings of baseline, retrot and hybrid designed rotors . . . 129

4.21 Blade non-structural mass and pitch-ap composite coupling sti-

ness, K

25

, distribution . . . . . . . . . . . . . . . . . . . . . . . . . 130

5.1 Various congurations of the rotor with trailing-edge aps . . . . . 135

5.2 Hingeless blade coupled ap mode shapes . . . . . . . . . . . . . . . 139

5.3 Hingeless blade coupled lag mode shapes . . . . . . . . . . . . . . . 140

5.4 Hingeless blade torsion mode shapes . . . . . . . . . . . . . . . . . 140

5.5 Control settings of hingeless rotor, = 0.15 . . . . . . . . . . . . . 141

5.6 Control settings of hingeless rotor, = 0.35 . . . . . . . . . . . . . 141

5.7 Blade tip response of hingeless rotor, = 0.15 . . . . . . . . . . . . 142

5.8 Blade tip response of hingeless rotor, = 0.35 . . . . . . . . . . . . 142

5.9 Vertical wake geometry with the number of beam elements and the

presence of the ap for = 0.15 . . . . . . . . . . . . . . . . . . . . 143

5.10 Vertical wake geometry with the number of beam elements and the

presence of the ap for = 0.35 . . . . . . . . . . . . . . . . . . . . 144

5.11 Blade tip responses with the number of beam elements and the

presence of the ap for = 0.15 . . . . . . . . . . . . . . . . . . . . 144

5.12 Blade tip responses with the number of beam elements and the

presence of the ap for = 0.35 . . . . . . . . . . . . . . . . . . . . 145

5.13 Control settings with the number of beam elements and the presence

of the ap for = 0.15 . . . . . . . . . . . . . . . . . . . . . . . . . 145

5.14 Control settings with the number of beam elements and the presence

of the ap for = 0.35 . . . . . . . . . . . . . . . . . . . . . . . . . 146

5.15 Vibration reduction vs. radial locations of trailing-edge aps . . . . 148

5.16 Lift curve slope vs. aspect ratio for elliptical lift distribution . . . . 149

5.17 Vibration reduction by multi-ap conguration with lift ap . . . . 150

5.18 Flap deection harmonics of multi-ap conguration with the lift

ap, advance ratio: = 0.15, actuator saturation:

sat

f

= 4

o

. . . . 150

5.19 Polar diagram of ap motion for single-ap conguration, advance

ratio: = 0.15, actuator saturation:

sat

f

= 2

o

. . . . . . . . . . . . 152

5.20 Polar diagram of ap motion for dual-ap conguration, advance

ratio: = 0.15, actuator saturation:

sat

f

= 2

o

. . . . . . . . . . . . 153

xi

5.21 Flap deections of dual-ap conguration with 4/rev control input,

advance ratio: = 0.15, actuator saturation:

sat

f

= 2

o

. . . . . . . 154

5.22 Hinge moments in single- and dual-ap congurations with 4/rev

control input, advance ratio: = 0.15, actuator saturation:

sat

f

=

2

o

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

5.23 Comparison of vibratory hub loads, advance ratio: = 0.15, actu-

ator saturation:

sat

f

= 4

o

. . . . . . . . . . . . . . . . . . . . . . . 156

5.24 Flap deections of single-ap conguration, advance ratio: = 0.15,

actuator saturation:

sat

f

= 4

o

. . . . . . . . . . . . . . . . . . . . . 157

5.25 Flap deections of multiple-ap conguration, advance ratio: =

0.15, actuator saturation:

sat

f

= 4

o

. . . . . . . . . . . . . . . . . . 158

5.26 Comparison of vibratory hub loads, advance ratio: = 0.35, actu-

ator saturation:

sat

f

= 4

o

. . . . . . . . . . . . . . . . . . . . . . . 159

5.27 Flap deections of single- and multiple-ap conguration, advance

ratio: = 0.35, actuator saturation:

sat

f

= 4

o

. . . . . . . . . . . . 160

5.28 Hinge moments in single- and multiple-ap conguration, advance

ratio: = 0.35, actuator saturation:

sat

f

= 4

o

. . . . . . . . . . . . 161

6.1 A piezoelectric tube actuator conguration . . . . . . . . . . . . . . 167

6.2 Forces and moments acting on the trailing-edge ap . . . . . . . . . 171

6.3 Schematic of the PZT tube with R-L circuit and negative capacitance173

6.4 Fulcrum amplication mechanism for the PZT tube actuator . . . . 175

6.5 Equivalent electric circuit model of the resonant actuation system . 181

6.6 Trailing-edge ap deections of the resonant actuation system for

Mach-scaled rotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

6.7 Realization of the equivalent electric circuit for the resonant actua-

tion system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

6.8 Comparison of analytical and experimental results of the RAS for a

Mach-scaled rotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

7.1 A piezoelectric network with a series R-L circuit . . . . . . . . . . . 189

7.2 Actuator strokes with the optimal tuning ratios and various coupling

coecients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

7.3 Actuator stroke and bandwidth variations with coupling coecients 191

7.4 Actuator strokes with the optimal inductance tuning and various

resistance tuning values, = 0.4 . . . . . . . . . . . . . . . . . . . . 192

7.5 Schematic of an equivalent mechanical system to a piezoelectric ac-

tuation system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

7.6 Electric charges with the optimal tuning ratios for various coupling

coecients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

xii

7.7 A piezoelectric network with a series R-L circuit and an additional

capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

7.8 Schematic of an equivalent mechanical system to a piezoelectric ac-

tuation system with an additional capacitor . . . . . . . . . . . . . 197

7.9 Actuator strokes with additional capacitance for = 0.5 . . . . . . 198

7.10 Relative actuator stroke and bandwidth variations with modied

coupling coecients . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

7.11 Peak-to-peak ap deections of a resonant actuator with various

ight speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

7.12 Variations of instantaneous frequencies along the azimuth . . . . . . 208

7.13 Time history of ap motions of the actuation system without cir-

cuitry with 4/rev voltage excitation, = 0.35 . . . . . . . . . . . . 208

7.14 Peak-to-peak ap deections of the RAS with various ight speeds . 209

7.15 Time history of ap motions of the RAS with 4/rev voltage excita-

tion, = 0.35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

7.16 Time history of ap motions of the nominal actuation system with

4/rev voltage excitation, = 0.35 . . . . . . . . . . . . . . . . . . . 211

7.17 Comparison of vibratory hub loads for an advance ratio of 0.15

within the available actuator authority . . . . . . . . . . . . . . . . 213

7.18 Comparison of vibratory hub loads for an advance ratio of 0.35

within the available actuator authority . . . . . . . . . . . . . . . . 213

7.19 Controller diagram of the resonant actuation system . . . . . . . . . 216

7.20 Diagram of an adaptive phase controller based on Matlab/Simulink 217

7.21 Experimental set-up for the resonant actuation system . . . . . . . 218

7.22 Equipments used in the experiment . . . . . . . . . . . . . . . . . . 219

7.23 Frequency responses of the PZT tube actuator before and after me-

chanical tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

7.24 Analytical predictions of a resonant actuation system: , tuned

system w/o the voltage signal function; , RAS with

= 0.5;

, RAS with

= 0.6 . . . . . . . . . . . . . . . . . . . . . . . . . 221

7.25 Experimental results of a resonant actuation system: , tuned

system w/o the voltage signal function; , RAS with

= 0.5;

, RAS with

= 0.6 . . . . . . . . . . . . . . . . . . . . . . . . . 221

7.26 Time responses of ap deection signal before/after phase control

with 24Hz input signal . . . . . . . . . . . . . . . . . . . . . . . . . 222

7.27 Time responses of ap deection signal before/after phase control

with 26Hz input signal . . . . . . . . . . . . . . . . . . . . . . . . . 223

7.28 Frequency response of current and phase variation for = 0.5 with

dierent resistances . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

7.29 Frequency response of current and its phase with circuitry for = 0.5226

xiii

7.30 Apparent electric power of a piezoelectric actuator with circuitry for

= 0.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

7.31 Actuator strokes under the optimal tuning ratios for = 0.5 . . . . 228

A.1 Thin-walled cross section of rotor blade . . . . . . . . . . . . . . . . 239

xiv

List of Tables

2.1 Nondimensionalized parameters . . . . . . . . . . . . . . . . . . . . 46

2.2 Order of terms used in aeroelastic analysis . . . . . . . . . . . . . . 46

2.3 Vehicle properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

3.1 Order of terms for trailing edge aps . . . . . . . . . . . . . . . . . 94

4.1 Constraints and bounds for design variables . . . . . . . . . . . . . 112

4.2 Baseline articulated rotor properties for active loads control . . . . 113

4.3 Trailing-edge ap properties for active loads control . . . . . . . . . 114

4.4 Natural frequencies of baseline articulated rotor . . . . . . . . . . . 114

4.5 Reduction of maximum bending moments maximum moments . . . 121

4.6 Reduction of vibration and moment reductions with dierent control

inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

4.7 Comparisons of maximum moment, vibration index and control eorts127

5.1 Hingeless rotor and trailing-edge ap properties . . . . . . . . . . . 138

5.2 Natural frequencies of baseline hingeless rotor . . . . . . . . . . . . 139

5.3 Control input sequences and ap locations for multiple-ap cong-

urations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

5.4 Peak-to-peak hinge moments in single- and dual-ap congurations

with 4/rev control input, = 0.15 . . . . . . . . . . . . . . . . . . . 152

5.5 Peak-to-peak hinge moments in single- and multiple-ap congura-

tions, = 0.35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

6.1 Piezoelectric material properties of PZT-5H for a Mach-scaled rotor 183

7.1 Design parameters for the RAS circuitry . . . . . . . . . . . . . . . 201

xv

List of Symbols

a Lift curve slope

A Cross-section area of blade

a Acceleration vector

A

f

Cross-section area of the ap

A

ij

, B

ij

, D

ij

Laminate stiness matrices

A

M

Amplication ratio in the actuation system

A

s

Surface area of the PZT electrode

b Airfoil semi-chord, b = c/2

c Blade chord

c

f

The ap chord

c

o

Constant lift coecient

C

e

p

Total capacitance

C

s

p

Piezoelectric material capacitance

C

p

Structural modal damping of the PZT tube actuator

C

add

Added capacitance in the electric network

c

D

55

Elastic constant (open-circuit)

xvi

c

1

Linear lift coecient

C

l

, C

d

, C

m

Lift, drag, and moment coecients

C

ij

Reduced transformed stiness for laminated composites

C Damping;

Modal damping

C

T

Thrust coecient

C

N

, C

M

, C

H

Unsteady normal, pitching and hinge moment coecients of trailing-

edge ap

C(k) Theodorsens lift deciency function

d Oset from blade elastic axis to the ap hinge

d

o

Constant drag coecient

d

1

Linear drag coecient

d

2

Quadratic drag coecient

d

15

Charge constant in piezoelectricity

D

i

Electric displacement component

e Oset between mid-chord and the ap hinge

e

d

Oset of blade elastic axis and aerodynamic center

e

g

Oset of blade elastic axis and c.g.

E

i

Electric eld component

f

o

Constant moment coecient

f

1

Linear moment coecient

F

A

Centrifugal force in Appendix B

F, F Force vector

f

e

Excitation force in equivalent mechanical system to the piezoelec-

tric actuation system

xvii

F

x

, F

y

, F

z

Resultant blade shear forces;

N

b

/rev vibratory hub shear forces (longitudinal, lateral and verti-

cal)

g

15

Voltage constant in piezoelectricity

H Electric enthalpy density function

h Rotor height above vehicle c.g.

H

1

, , H

4

Beam element shape functions

H

t1

, , H

t6

Temporal element shape functions

h

15

Piezoelectric constant

I Identity matrix

I

b

Blade ap inertia

I

f

Trailing-edge ap mass moment of inertia

J Objective function

k Reduced frequency;

Spring stiness

K Stiness;

Modal stiness;

Spring stiness

K

ij

Composite stiness coecient

K

22

, K

33

, K

55

Flap bending, lag bending, and torsion stiness

K

25

Pitch-ap composite coupling stiness

K

c

Electro-mechanical coupling stiness

K

n

Blade loads vector containing the apwise curvature harmonics

K

Q

Inverse of the PZT tube actuator capacitance

K

a

Q

Inverse of the added capacitance

L Inductance

xviii

L

u

, L

v

, L

w

Blade sectional shear forces

L

C

, D

C

, M

C

Circulatory lift, drag and moment per unit length

L

NC

, M

NC

Noncirculatory lift and moment per unit length

l

p

Length of the PZT tube actuator

L

el

Length of beam element

L

LV

Vibration index

L

m

, R

m

, C

m

Inductance, resistance and capacitance in Van Dyke circuit

M Mach number;

Modal damping

m Blade mass per unit length

m

f

The ap mass per unit length

M

H

The ap hinge moment

M

M

, C

M

, K

M

Mass, damping and stiness of the primary system in equivalent

mechanical system to the piezoelectric actuation system

m

m

, c

m

, k

m

Mass, damping and stiness of the secondary system in equivalent

mechanical system to the piezoelectric actuation system

mk

2

m1

, mk

2

m2

Flapwise and lagwise mass moment of inertia per unit length

m

o

Blade reference mass per unit length

M

x

, M

y

, M

z

Resultant blade sectional moments;

N

b

/rev vibratory hub moments (rolling, pitching and torque)

M

LV

Blade moment index

N Axial force

N

b

Number of blades

N

el

Number of beam elements

N

s

Number of PZT segments

N

t

Number of temporal elements

xix

n, s Contour coordinates in the cross-section of rotor blades

p

i

Applied traction in the piezoelectric actuator

q Generalized displacement

q

R

Normal mode displacement

q

t

Actuator stroke (tip displacement)

Q Electric charge

Q

s

Applied charge density

r Radial blade station;

Resistance tuning ratio

r Position vector

r

p

Radial coordinate in the polar coordinate system

r

I

Trailing-edge ap chordwise c.g. from hinge

r

II

Flap radius of gyration about the ap hinge

R Rotor radius;

Resistance

R

i

Inner radius of the PZT tube

R

o

Outer radius of the PZT tube

S Nondimensional time in unsteady aerodynamics of the ap

s Natural coordinate in the nite element

S

f

The ap rst sectional moment

S

ij

Mechanical strain component in piezoelectricity

t Time

T

1

, , T

14

Theodorsen coecients

T

HI

Rotation matrix between x

H

i

and x

I

i

T

RH

Rotation matrix between x

R

i

and x

H

i

xx

T

uH

Rotation matrix between x

u

i

and x

H

i

T

uR

Rotation matrix between x

u

i

and x

R

i

T

St. Venant torsion

T

Valsov torsion

T

ij

Mechanical stress component in piezoelectricity

u, v, w Displacements in the undeformed coordinate system

U

x

, U

y

, U

z

Relative wind velocity components in the deformed coordinate sys-

tem

V Total relative wind velocity

V

b

Relative wind velocity due to blade motions

V

w

Relative wind velocity due to vehicle forward speed and rotor inow

V

x

, V

y

, V

z

Relative wind velocity components in the undeformed coordinate

system

V

a

Voltage across the PZT

V

c

Control voltage in the actuation system

W Weighting matrices

x, y, z Positions in the undeformed coordinate system

x

CG

, y

CG

Longitudinal and lateral distances from vehicle c.g. to rotor hub

x

e

, y

e

Degrees of freedom in equivalent mechanical system to the piezo-

electric actuation system

x

f

i

, e

f

i

The ap deformed coordinate system

x

F

i

, e

F

i

Vehicle coordinate system

x

H

i

, e

H

i

Hub-xed coordinate system

x

I

i

, e

I

i

Ground-xed inertial coordinate system

x

R

i

, e

R

i

Hub-rotating coordinate system

xxi

x

u

i

, e

u

i

Undeformed blade coordinate system

x Vector containing passive design variables

Z

n

Hub loads vector containing the N

b

/rev harmonics

Angle of attack

s

Longitudinal shaft tilt angle (positive nose down)

w

,

w

,

w

Scalar weighting parameters used in weighting maxtrices

Prandtl-Glauert correction factor

p

Precone angle of the undeformed blade

S

11

Impermittivity in piezoelectricity

Lock number

ij

Engineering shear strain component

Variational operator;

Inductance tuning ratio

f

Trailing-edge deection angle

n

Control vector of trailing-edge ap harmonics

sat

Actuator saturation angle

U First variation of strain energy

V First variation of kinetic energy

W First variation of virtual work done by external forces

Incremental quantity

Small parameter in perturbation method

Small parameter in ordering scheme

ij

Normal strain component

T

11

Dielectric constant

xxii

Coordinate in the deformed coordinate system;

Nondimensionalized damping coecient

Coordinate in the deformed coordinate system

t

Temporal nodal displacement

Coordinate in the polar coordinate system

o

Collective pitch angle (rigid blade pitch)

tw

Linear pretwist angle of a rotor blade

tr

Tail rotor collective pitch

1

Total blade pitch angle

75

Rigid blade pitch angle at 75% radial location of blade

1c

Lateral cyclic pitch angle

1s

Longitudinal cyclic pitch angle

x

,

y

,

z

Euler angles

Vector of control settings

ij

Curvature component

x

,

y

Drees linear inow parameters

Axial skew angle

Rotor inow

i

Induced rotor inow

T

Warping function of blade cross-section

Advance ratio (non-dimensionalized forward ight speed)

Coordinate in the deformed coordinate system;

Generalized electro-mechanical coupling coecient

Modied electro-mechanical coupling coecient

Air density

xxiii

p

Piezoelectric material density

s

Material density of rotor blade

Rotor solidity

ij

Stress component

s

Lateral shaft tilt angle (positive advancing side down)

Elastic twist angle of blade

Elastic twist angle with respect to undeformed elastic axis

Modal matrix used in normal mode transformation

s

Applied electric potential

Azimuth angle

Mode shape function of the PZT tube actuator

Angular velocity vector

Nondimensionalized frequency, /

E

D

Open-circuit frequency

E

Short-circuit frequency

E

Short-circuit frequency with added capacitance

p

,

s

Parallel and series frequencies in Van Dyke circuit

Rotor rotational speed

Superscripts

()

A

Aerodynamic quantities

()

E

Short-circuit properties in piezoelectricity

()

D

Open-circuit properties in piezoelectricity

()

fI

Trailing-edge ap inertial contribution

()

fA

Trailing-edge ap aerodynamic contribution

xxiv

()

H

Terms associated with hub

()

I

Inertial quantities

()

L

Linear terms in energy

()

NL

Nonlinear terms in energy

()

o

Baseline value;

Degree with numbers

()

S

Properties at constant strain in piezoelectricity

()

T

Transpose of matrix or vector;

Properties at constant stress in piezoelectricity

()

V

Vehicle quantities

()

1

Inverse of matrix

()

Derivative with respect to a coordinate x.

() Derivative with respect to time t;

Derivative with respect to azimuth in Appendix B

()

Derivative with respect to azimuth ;

Optimal tuning ratios in the electric network

() Terms and responses associated with added capacitance

Subscripts

()

r

Main rotor contributions

()

f

Trailing-edge ap contributions

()

ST

Static response

xxv

Acknowledgments

It is a pleasure to thank the many people who made this thesis possible. It is

dicult to overstate my gratitude to my Ph.D. supervisors, Dr. Edward C. Smith

and Dr. Kon-Well Wang. With their enthusiasm, their inspiration, and their

great eorts to explain things clearly and simply, they helped to make research

fun for me. They provided encouragement, sound advice, good teaching, and lots

of good ideas. I would have been lost without them. I would also like to express

my appreciation to Dr. Farhan S. Gandhi, Dr. Joseph F. Horn and Dr. Mary I.

Frecker for their helpful comments and being advisory committee members.

I would like to thank the many people who have taught me aerospace engineer-

ing: my undergraduate teachers at Inha University (especially Dr. Si-Yoong Ryu,

Dr. Ki-Ook Kim and Dr. Jin-ho Kim) and my graduate teachers (especially Dr.

Maenghyo Cho).

I am indebted to my many student colleagues for providing a stimulating and

fun environment in which to learn and grow. I am especially grateful to Dr.

Jianhua Zhang, Dr. Joseph Sze, Dr. Phuriwat Anusonti-Inthra and Jose Palacios

at Rotorcraft Center of Exellence, and to Dr. Ronald Morgan, Dr. David Heverly,

David Belasco and Dr. Michael Philen at Structural Dynamics and Control Lab.

David and Michael were particularly helpful to conduct experiments, patiently

teaching me how to use an apparatus.

I wish to thank my korean friends Dr. Dooyong Lee, Youngtae Ahn (especially

for providing a ride) and Seongkyu Lee for their friendship. I musk thank all of

the support sta, specically Debbie Mottin and Robin Grandy in the aerospace

department, and Karen Thal in the mechanical department.

I would like to express my deepest appreciation to my family for their support

and encouragement. I wish to thank my parents, my parents-in-law and my sisters.

Lastly, and most importantly, I would like to thank my wonderful wife Eun-Ae for

her love, patience, and the many sacrices she has made.

xxvi

Dedication

This thesis is dedicated to my lovely wife Eun-Ae Ayu.

xxvii

Chapter 1

Introduction

Many methodologies have been explored to reduce helicopter vibration. Trailing

edge aps for such a purpose have been studied for the past twenty years. A brief

overview of the introduction of active vibration controls using trailing edge aps

and smart actuators is presented in the rst section. In the second section, the

previous works in rotorcraft vibration controls and smart actuator development

are described. In the third section, the problem statement and research objectives

of the thesis are presented. The overview of this thesis is presented in the last

section.

2

1.1 Background and Motivation

A rotorcraft has been a very important mode of aerial transportation due to its

capability of vertical take-o and landing, enabling many unique missions such as

rescue operation at sea. It has, however, also been under several serious constraints

such as poor ride quality due to high levels of vibration [1] and noise, restricted

ight envelope, low fatigue life of the structural components, and high operating

cost.

Unlike the wings of conventional xed wing aircraft, helicopter rotor blades

experience periodic motions that result in 1/rev variation of aerodynamic and in-

ertial loads along the azimuth. They also undergo a signicant load uctuation

along the rotor spanwise direction. These operations will cause two major issues.

One is the vibratory load of the rotor hub, coming from higher harmonic compo-

nents of aerodynamic and inertial loads of rotor blades (Figure 1.1). This is the

principal source of helicopter fuselage vibration and has an impact on helicopter

performance, fatigue life of onboard equipment, and passenger comfort. The other

issue is the bending moment of rotor blades, which is a primary source of blade

fatigue stresses.

Figure 1.1. Various sources of a helicopter vibration

3

Vibratory loads in helicopters arise from a variety of sources such as the main

rotor system, the aerodynamic interaction between the rotor and the fuselage,

the tail rotor, the engine and transmission, and atmospheric turbulence, which

generally has low frequencies. However, the most signicant source of vibration in

a helicopter is the main rotor because of the unsteady aerodynamic environment

acting on highly exible rotating blades. The vibration level is generally low in

hover and increases with higher forward speed. There are two regimes: low speed

ight (transition) and high-speed ight, where the vibration levels are critical

(Figure 1.2). At low forward speed ( = 0.1), the blade tip vortices in the wake

stay close to the rotor disk, causing a severe blade vortex interaction, which results

in a substantially higher harmonic loading (Figure 1.3). At high forward speed,

the rotor disk tilts forward and the wake is swept away from the disk plane; the

wake-induced vibrations become small at high advance ratio.

Figure 1.2. Helicopter vibration variation vs. forward ight speed

Figure 1.3. Blade vortex interaction [4]

4

A typical aerodynamic environment of the helicopter main rotor during for-

ward ight is depicted in Figure 1.4, where helicopter ight velocity adds to the

blade element rotating velocities on the advancing side (0

o

< < 180

o

), and

subtracts from it on the retreating side (180

o

< < 360

o

) [2, 3]. The resulting

aerodynamic environment may be characterized as follows: high tip Mach number

on the advancing side, and blade stall eects on the retreating side. A reverse

ow region is also generated at the inboard on the retreating side. Such a com-

plicated environment results in an instantaneous asymmetry of the aerodynamic

loads acting among the blades at dierent azimuthal locations. This results in a

vibratory response of a exible blade structure, adding more complexity to the air

loads asymmetry.

Figure 1.4. Aerodynamic environment in forward ight

The rotor hub acts as a lter, transmitting to the pylon and then to the cabin

only harmonics of the rotor forces at multiples of N

b

/rev, where N

b

is the number

5

of blades. It has been shown that only the N

b

/rev and N

b

1/rev rotating frame

loads contribute to the N

b

/rev xed frame loads (see Figure 1.5). More specically,

the N

b

/rev thrust and torque are caused by corresponding N

b

/rev rotating frame

loads, whereas the N

b

/rev rotor drag- and side forces, and pitching- and rolling

moments are caused by the corresponding N

b

1/rev rotating frame loads. This

result is based on the assumption that all the blades are identical and have the

same periodic motion. This is strictly true only if the rotor blades are tracked

and the helicopter is in trimmed ight. If the blades are not perfectly tracked,

the blade to blade dissimilarity will result in a 1/rev vibration transmitted to the

fuselage [6].

Figure 1.5. Vibratory loads transmitted to fuselage [5]

Various methodologies for vibration reduction have been proposed in litera-

ture. There are several types of active strategies, such as HHC (Higher Harmonic

Control) [711], IBC (Individual Blade Control) [1215], ACSR (Active Control of

Structural Response) [1621], ATR (Active Twist Rotor) [2225], and ATF (Active

Trailing-edge Flap) [2631]. It has been shown that improvements in helicopter

vibration reduction can be achieved through the implementation of active control

technology by smart material. One of the most promising methods is the IBC

using active trailing-edge aps. Therefore, active trailing-edge aps to reduce the

rotorcraft vibration have been given considerable attention in the research com-

6

munity [32, 33].

It has been shown that improvements in helicopter vibration reduction can

be achieved by smart materials, such as piezoelectric materials. Piezoelectric ac-

tuation systems are expected to be compact, light weight, low actuation power,

and high bandwidth devices that can be used for multi-functional roles such as to

suppress vibration and noise, and increase aeromechanical stability. While piezo-

electric materials-based actuators have shown good potential in actuating trailing

edge aps, they can only provide a limited stroke. This limitation can be critical in

cases where large trailing-edge ap deections are required or with large size rotor

blades. The eorts to improve the piezoelectric actuator performance have been

made by researchers in developing amplication mechanisms of various types [34].

Recently, a piezoelectric stack actuator with a double X-frame amplication de-

vice to deect a full-scale ap on a MD Explorer helicopter has been developed and

tested in whirl tower facility [112]. Flap deection angles of 3.5

o

(at 450 V) were

achieved during whirl tower test. A multiple piezoelectric actuator conguration

has been considered and tested in Eurocopter to adjust the required control power

and surface [114]. In this work, a single ap is segmented into three parts, and all

actuator is controlled by the same command.

On the other hand, multiple trailing-edge ap congurations have been studied

to reduce the vibration of helicopter rotor system, in which each actuator operates

independently. Several research works have shown that dual ap conguration is

superior over a single ap in vibration reduction [78, 94].

In general, a single trailing-edge ap works well for the purpose of vibration

reduction of helicopter rotor. With typical control inputs 3,4,5/rev, it has been

demonstrated via numerical simulations that vibration level can be reduced by

about 80%. As mentioned earlier, however, piezoelectric actuators provide a lim-

ited stroke. For the same trailing edge ap deections, the actuator design speci-

cation in multiple-ap conguration is more relaxed than that in single-ap cong-

uration, because the required hinge moment is less due to the small control surface

area.

7

1.2 Literature Review

This section describes previous studies relevant to the present subject. For conve-

nience, the section is divided into ve parts. The section starts with the overview

of helicopter vibration reduction, where various methodologies were examined in

attempt to reduce the vibration. In Section 1.2.2, previous studies using active

trailing-edge aps are highlightened. The review of smart actuation system devel-

opment is given in Section 1.2.3, followed by piezoelectric networks that can help

to enhance the actuator performance. The last subsection is a summary of the

literature review.

1.2.1 Helicopter Vibration Reduction

There have been considerable eorts to reduce the vibration in helicopter [35, 36],

and vibration alleviation methodologies may be categorized into the four groups:

1. Passive means such as vibration absorbers, isolation devices and blade tai-

loring

2. Active vibration absorbing devices in fuselage

3. Direct modication of the excitation frequencies on the rotor blades

4. Active-passive and semi-active vibration reduction technologies

In the past, numerous vibration control devices have been proposed and de-

veloped. The most common passive devices are the dynamic vibration absorber

and the isolation mount. A typical dynamic absorber is a single degree of free-

dom system with a relatively small mass on a spring (Figure 1.6). If tuned to the

excitation frequency, it can generate opposing oscillating force in resonance with

the excitation to enforce a node on the support structure. For example, the dy-

namic hub absorber such as a simple [37] or bilar pendulum has been successfully

applied to S-76 helicopter [38]. The vibration isolation mount is another typical

passive control device, such as pads of rubber or springs are placed between the

vibrating system, to reduce the transmitted force from the vibrating system to

the support structure. In helicopters, the conventional transmission mounting to

8

the airframe is replaced by elastomeric supports [3941]. The blade structural

and aerodynamic properties are tailored using automated optimization techniques

to reduce the vibration [4246]. Composite tailoring (Figure 1.7) has also been

studied extensively since composite material provides excellent opportunities for

developing light weight/high stiness structures, as well as providing elastic cou-

plings for potential optimal designs [4751]. A passive approach has merit in that it

does not need additional power. Passive methods, however, usually exhibit limited

performance and cannot adapt to system and operating condition changes.

Figure 1.6. Schematic of a dynamic vibration observer [5]

Figure 1.7. Composite tailoring of helicopter rotor blades [49]

In active vibration absorbing devices, active control actions are directly applied

on the airframe. Two successfully ight tested airframe-based active controls are

9

active vibration suppression [16, 17] and Active Control of Structural Responses

(ACSR) tested on a modied S-76B helicopter [1820]. In ACSR system, vibration

sensors are placed at key locations in the fuselage, where minimal vibration is

desired (Figure 1.8). Depending on the vibration levels from sensors, a controller

calculates proper actions for actuators, such as electro-hydraulic, piezoelectric and

inertial force actuators, to reduce the vibration. The ACSR system has successfully

made into production on the helicopter such as the Westland EH101 and the

Sikorsky S-92 Helibus [20].

Figure 1.8. Active Control of Structural Response (ACSR) systems: (a) engine platform

(b) cabin [20]

Passive and active absorbing devices are still used in most of the rotorcraft

ying today although they also bring unavoidable penalties in terms of weight and

tend to aect vibrations only at discrete points. Therefore, eorts to modify di-

rectly the excitation forces have been sought by modifying unsteady aerodynamic

forces acting on the rotor blades. Among them, Higher Harmonic Control (HHC)

systems have received the most attention [711]. In this approach, servo-actuators

are used to excite the conventional swashplate in the collective, longitudinal cyclic

and lateral cyclic modes at the frequency of N

b

, resulting in blade pitching oscilla-

tions at three frequencies of (N

b

1) , N

b

and (N

b

+1) of HHC in the rotating frame

(Figure 1.9). These higher harmonic blade pitch motions can generate additional

10

unsteady aerodynamic and oscillatory inertial loads with the right amplitudes and

phases to alleviate hub vibration. Therefore, the vibration can be suppressed at

the source before it is propagated into the fuselage. Even though HHC is shown

to be highly eective, several drawbacks have impeded the implementation of the

HHC concept on production helicopters. One of drawbacks is that HHC system

uses the primary control system (swashplate and pitch links) to transfer higher

harmonic pitch inputs to the rotor blades. Thus, considerable power is required to

operate the actuators.

Figure 1.9. Schematic of Higher Harmonic Control (HHC)

An alternative to HHC is the Individual Blade Control (IBC) [1215], in which

each blade is individually controlled in the rotating frame over a wide range of

desired frequencies. This control concept is a more general approach that removes

some of the limitations of HHC such as the xed excitation frequency. Usually,

hydraulic actuators are mounted in conjunction with the blade pitch links in the

rotating frame. The control inputs to the actuators are based on the feedback

signals from the sensors mounted on the blades. A hydraulic slip ring unit is

required to transmit the hydraulic power to the actuators in the rotating frame

(Figure 1.10).

Numerous analytical studies, wind tunnel tests and ight tests of HHC or IBC

have demonstrated their potential for the substantial vibration reduction of up

11

Figure 1.10. Schematic of Individual Blade Control (IBC)

to 90 percent. However, both approaches have limitations on their practical im-

plementation. Apart from the considerable weight penalties and high cost, large

actuation power is needed to pitch the entire blades. The complexity of their

actuation systems as well as their adverse impacts on vehicle reliability and main-

tainability has hampered their availability. Furthermore, since both HHC and IBC

introduce control through the conventional swashplate, which is the primary ight

control system of the helicopter, it will inuence the airworthiness of the helicopter.

Another IBC concept using a trailing-edge ap has been explored extensively

for vibration reduction. This concept uses a small ap on each blade to generate

the desired unsteady aerodynamic loads (Figure 1.11). This concept can be equally

eective, but uses less power than the conventional IBC system. In this approach,

a partial span trailing edge ap is located in the outboard region of the blade.

The active ap control inputs aect the blade inertial loads and rotor dynamics

as well as the unsteady aerodynamic loads. Since only a very small portion of the

blade, about 4 5 percent [52], is actuated, this approach needs much less control

power compared to HHC or IBC. Furthermore, this active ap control system is

totally separated from the conventional swashplate; thus, it has little inuence

on airworthiness. A number of analytical simulations [2629, 31], some wind tun-

nel tests [30, 67] and full-scale whirl tower test [112, 114] of the active ap have

demonstrated that it has the potential to signicantly reduce the vibratory loads,

alleviate noise, enhance the rotor performance and handling qualities. Additional

12

information on vibration reduction using active trailing-edge aps can be found in

two recent survey papers [32, 33]. The detailed literature review will be described

on the active trailing-edge aps in Section 1.2.2.

Figure 1.11. Schematic of Active Trailing-edge Flap (ATF)

With the emergence of smart materials, such as Active Fiber Composites (AFC)

[53], Macro-Fiber Composite (MFC) [54] and piezoelectric materials, the Active

Twist Rotor (ATR) concept [2225] has been proposed (Figure 1.12). One of the

advantages is simplicity of its actuation mechanism compared to the active trailing-

edge ap actuation. The ATR concept has also a merit in that it does not increase

the prole drag of the blade just as discrete ap does. While the ATR technology

can produce a signicant vibration reduction, power requirements are expected to

be much higher than those for active trailing-edge aps.

Other vibration reduction technologies are active-passive or semi-active con-

cepts developed to combine the advantages of both purely active and passive con-

cepts. Although active means can more eectively reduce helicopter vibration and

can be adaptive to system operating condition changes, their performances are

often limited by the authority of the actuators. Active-passive approach has been

proposed and investigated to make up for the weak point (actuator authority) in

active ap system. A hybrid design approach can reduce the required ap deec-

tions via active-passive optimization while retaining the same vibration level as

that of the conventional active ap control [5557]. A semi-active approach using

13

Figure 1.12. Schematic of Active Twist Rotor (ATR)

cyclic variation of the eective ap, lag, and torsion stiness or damping varia-

tions has been proposed for helicopter vibration reduction [58, 59]. This approach

involves evaluating sensitivity of hub variation to cyclic changes in stiness and

damping of the blade root region (Figure 1.13).

Figure 1.13. Schematic of semi-active actuators located at blade root region [4]

Active vibration reduction systems are comprised of similar basic components;

sensors, actuators, and a controller. In most active vibration control methodolo-

gies, the major issue is the actuator itself. Thus numerous smart actuators are

under development. These concept designs of smart actuators have been either

wind tunnel tested or bench tested for helicopter vibration reduction. The key to

on-blade vibration control has been the advent of smart structures, in particular

those incorporating electrically driven piezoceramic materials, exhibiting high en-

14

ergy density and high bandwidth. The on-blade smart systems open a new domain

for vibration control, aeromechanical stability augmentation, handling qualities en-

hancement and noise reduction. The detailed literature review of smart actuation

system developments will be described in Section 1.2.3.

1.2.2 Active Trailing-edge Flaps

The trailing edge aps were used to control the 1/rev rotor primary controls (collec-

tive and cyclic) for earlier helicopters,such as Pescara, dAscanio and Kaman. The

extension of this concept for providing control at higher harmonics was identied

in a early work on multicyclic control [60].

In 1970s, the rst investigation of the trailing edge aps (servo-aps, see Fig-

ure 1.14) for multicyclic vibration control was conducted,called as Kaman Multi-

cyclic Controllable Twist Rotor (MCTR). The MCTR utilized the rst harmonic

servo ap inputs incorporated with conventional pitch control, and the multicyclic

control was generated by the electrohydraulic actuators mounted in the rotating

frame. The wind tunnel testing with the maximum ap inputs up to 6 degrees

at frequencies up to 4/rev were conducted, and showed signicant reduction in

vibratory hub loads with appropriate 2/rev inputs [61]. McCloud III has studied

the feasibility of reducing both vibration and blade loads using a single servo-ap,

where he applied the scheduled multi-cyclic control inputs at 1/rev, 2/rev, 3/rev,

and 4/rev to the MCTR [26]. His results have shown that multi-cyclic control can

achieve both vibration and bending moment reductions with a large 1/rev control

input.

With the advances in the development of smart material-based actuators, active

vibration controls using trailing-edge aps are revisited for helicopter vibration

reduction in 1990s. An analytical study on vibration reduction in a four-bladed

hingeless rotor using an actively controlled servo ap was conducted by Millott and

Friedmann [27, 6265]. A time-domain simulation to reduce 4/rev hub loads was

implemented, and the reduction in vibratory hub loads levels around 90 % were

reported. It was noted that spanwise ap position and blade torsional stiness

were key factors governing the performance in vibration reduction. The vibration

15

Figure 1.14. Karman SH-2 Seasprite helicopter with servo-aps

level for rotor with a single trailing-edge ap using both the fully elastic and rigid

blade models was investigated. It was reported that the predicted vibration level

using the rigid blade model is much less than that of using the elastic blade model.

An extensive proof-of-concept investigation of plain trailing edge ap was con-

ducted by McDonnell Douglas Helicopter Systems. A 12-foot diameter Active Flap

Rotor (AFR) model was tested in NASA Langley 14 22 wind tunnel. The trail-

ing edge ap was actuated by a cam-follower and cable arrangement that could

provide various ap inputs by interchanging and rotating the programming cams.

The reductions in hub loads up to 80 % were demonstrated during testing [6668].

Milgram and Chopra [28, 6971] carried out an analytical study on the eec-

tiveness of plain trailing edge aps for vibration suppression. This analysis incor-

porated an unsteady aerodynamic model based on indicial response functions of a

apped airfoil [72, 73] as well as a free wake model [74, 75] that are implemented

into the UMARC [76]. The reductions in vertical hub shear loads up to 98% was

reported using an open-loop controller with actuation frequencies of 3/rev and

4/rev. The validation of the analysis with test results from McDonnell Douglas

AFR test was carried out,and correlation between predicted and measured results

16

was generally fair. It was reported that varying the phase angle of the ap motion

had a signicant eect on the blade 4/rev atwise and inplane bending loads.

Straub and Hassan [29] conducted a conceptual sizing and design study for a full

scale demonstration trailing edge ap system. Structural parameters were investi-

gated to determine a feasible ap/actuator combination with the consideration of

the blade-ap-actuator dynamics.