Professional Documents

Culture Documents

Aluminium in Building and Construction: The History

Aluminium in Building and Construction: The History

Uploaded by

Pulkit Taluja0 ratings0% found this document useful (0 votes)

2 views4 pagesINFO OF LOW COST HOUSING AND HOW TO MAKE A BUILDING ENERGY EFFICIENT

Original Title

EAA Building 09 2008

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentINFO OF LOW COST HOUSING AND HOW TO MAKE A BUILDING ENERGY EFFICIENT

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

2 views4 pagesAluminium in Building and Construction: The History

Aluminium in Building and Construction: The History

Uploaded by

Pulkit TalujaINFO OF LOW COST HOUSING AND HOW TO MAKE A BUILDING ENERGY EFFICIENT

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 4

THE HISTORY

In 1893, the famous winged statue of Eros was

erected in Londons Piccadilly Circus. Made of ele-

gant cast aluminium, it became an iconic symbol of

the city and is now one of its best loved attractions.

In 1898, the dome of San Gioacchinos Church in

Rome was clad in aluminium sheets, which are still

in pristine condition today, more than 100 years

later. The stunning Art Deco-inspired Empire State

Building in New York was the first building to use

anodised aluminium components back in 1931.

More recently, aluminium was used in the con-

struction of the Pyramide du Louvre in Paris (1989)

and for the facades of the European Parliament in

Brussels (1995), which contain around 1000 tonnes

of aluminium.

Aluminium is now utilised for a host of applications

in building and construction and is the material

of choice for curtain walling, window frames and

other glazed structures. It is extensively used for

rolling blinds, doors, exterior cladding and roo-

fing, suspended ceilings, wall panels and partitions,

heating and ventilation equipment, solar sha-

ding devices and complete prefabricated buildings.

Structures like offshore living quarters, helicopter

decks, balustrades, scaffolding and ladders, are

also commonly made of aluminium.

ALUMINIUM IN BUILDING AND CONSTRUCTION

FACTSHEET

THE MARKET

In 2006, the building sector in Western Europe absorbed an estimated 2.9 million tonnes of aluminium

as part of an ongoing upward trend. Around 1.7 million tonnes was used for profiles, making this sector

by far the largest market for extruded products, accounting for about 51% of all such shipments. A more

modest, but still substantial, 1 million tonnes found its way into rolled products, representing approxi-

mately 24% of all rolled aluminium shipments. Finally, in the region of 0.2 million tonnes of aluminium

was used in castings for a range of building applications, representing approximately 8% of all casting

aluminium shipments.

FACTSHEET

ALUMI NI UM I N BUI LDI NG AND CONSTRUCTI ON

Durability: Aluminium building products are

made from alloys, which are weather-proof,

corrosion-resistant and immune to the harmful

effects of UV rays, ensuring optimal performance

over a very long serviceable lifetime.

Design flexibility: The extrusion process offers

an almost infinite range of forms and sections,

allowing designers to integrate numerous func-

tions into one profile. Rolled products may be

manufactured flat, curved, shaped into cassettes,

or sandwiched with other materials. In addi-

tion, aluminium can be sawed, drilled, riveted,

screwed, bent, welded and soldered in the work-

shop or on the building site.

High strength-to-weight ratio: This unique

property allows architects to meet required per-

formance specifications, while minimising the

dead load on a buildings supporting structure.

Thanks to the metals inherent sturdiness, alu-

minium window and curtain wall frames can be

very narrow, maximising solar gains for given

outer dimensions. Moreover, the materials light

weight makes it easier to transport and handle on

site, reducing the risk of work-related injury.

Hundreds of surface finishes: Aluminium can

be anodised or painted in any colour, to any opti-

cal effect, using any number of surface touches,

in order to meet a designers decorative needs.

Such processes also serve to enhance the materi-

als durability and corrosion resistance, as well as

providing an easy-to-clean surface.

High reflectivity: This characteristic feature

makes aluminium a very efficient material for

light management. Aluminium solar collectors

can be installed to lower energy consumption

for artificial lighting and heating in winter, while

aluminium shading devices can be used to reduce

the need for air conditioning in summer.

Heat conductivity: Aluminium is a good con-

ductor of heat, which may be a disadvantage in

some applications. However, this property can

easily be overcome by the profile design and the

use of thermal breaks made of low conductivity

materials.

Fire safety: Aluminium does not burn and is

therefore classed as a non-combustible construc-

tion material (European fire class A1). Aluminium

alloys will nevertheless melt at around 650C,

but without releasing harmful gases. Industrial

roofs and external walls are increasingly made of

thin aluminium cladding panels, intended to melt

during a major fire, allowing heat and smoke to

escape and thereby minimising damage.

Optimal security: Where high security is

required, specially designed, strengthened alu-

minium frames can be used. While the glass for

such applications may well be heavy, the overall

weight of the structure remains manageable

thanks to the light weight of the aluminium

frame.

Low maintenance: Besides routine cleaning for

aesthetic reasons, neither bare nor painted alu-

minium requires any maintenance, which trans-

lates into a major cost advantage over the lifetime

of a product.

ALUMINIUM PERFORMANCE PROPERTIES

ALUMINIUM RECYCLING

The high intrinsic value of aluminium is a major

economic incentive for its recycling. Indeed, alu-

minium scrap can be repeatedly recycled without

any loss of value or properties. Furthermore, the

energy required is a mere fraction of that needed

for primary production, often as little as 5%,

yielding obvious ecological benefits. A study by

Delft University of Technology recently revealed

aluminiums considerable recycling potential in the

building sector. Aluminium collection rates from a

cross-section of commercial and residential buil-

dings in 6 European countries were found to be in

excess of 92%, demonstrating the industrys com-

mitment to sustainable development.

INTELLIGENT BUILDINGS

Intelligent facades incorporating aluminium sys-

tems can decrease energy consumption in buildings

by up to 50%. The key feature of these intelligent

buildings is their constructive interaction with

the exterior, markedly reducing heating, cooling,

ventilation and lighting energy demands. This is

achieved through numerous techniques and pro-

cesses including photovoltaics, optimised ventila-

tion mechanisms and appropriate light and shade

management.

FACTSHEET

ALUMI NI UM I N BUI LDI NG AND CONSTRUCTI ON

SUSTAINABLE CONSTRUCTION

With the building sector coming under increased pressure to provide environmental performance data,

the European Aluminium Association has launched its Sustainable Construction Project and is develo-ping

Environmental Product Declarations (EPDs) for aluminium building products in line with international stan-

dards. An EPD is the most comprehensive and transparent type of environmental labelling, destined for

business-to-business communication. It takes into account the whole product life cycle and computes a

vast quantity of environmental information into a set of internationally recognised indicators, such as use

of primary energy, water consumption, etc. It is, moreover, verified by an independent third party.

Aluminium veranda, windows and blinds

Thermally-broken & bi-colour

aluminium window.

FACTSHEET

ALUMI NI UM I N BUI LDI NG AND CONSTRUCTI ON

Thanks to its unique properties, aluminium is able to provide intelligent solutions for present and future generations. It is lightweight

yet strong, durable and corrosion-resistant, formable, highly conductive, aesthetically pleasing and, above all, recyclable. The European

Aluminium Association, founded in 1981, represents the European aluminium industry, from alumina and primary production,

to manufacture of semi-finished and end-use products, right through to recycling. This industry currently employs around 255 000

people in Western Europe.

For further information, please contact us or go to our website:

Email: eaa@eaa.be

Website: www.aluminium.org

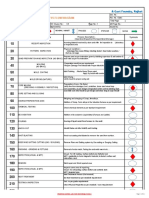

SOME APPLICATIONS

ROOFING OR TILES

CHIMNEY

SOLARPANEL

GUTTER

FACADE SHEETS, PANELS OR

CASSETTE

DOORS

FENCE

SHUTTERS

BALCONY

WINDOW FRAMES & WINDOWSILL

GARAGE DOOR

SHADING DEVICES

EXTERNAL:

INTERNAL:

CEILING SYSTEM

DOORS

ELEVATOR CAB

FLOOR

FURNITURE

PARTITION WALLS

SIGNS

VENETIAN BLINDS

CURTAIN WALL

You might also like

- Use of Aluminium in Building ConstructionDocument9 pagesUse of Aluminium in Building ConstructionbgenNo ratings yet

- Kleiberit PUR 501 - FISPQDocument8 pagesKleiberit PUR 501 - FISPQYuri SouzaNo ratings yet

- Aluminium in Building and Construction: The HistoryDocument4 pagesAluminium in Building and Construction: The HistoryBani Amrit KaurNo ratings yet

- Aluminium & Steel Book Mai SeDocument3 pagesAluminium & Steel Book Mai SeJatin TilwaniNo ratings yet

- Use of Aluminium in Building Construction-1Document6 pagesUse of Aluminium in Building Construction-1aakash purohitNo ratings yet

- Aluminium: Submitted by Group 1Document21 pagesAluminium: Submitted by Group 1Nidhi MehtaNo ratings yet

- ALUMINIUM FinalDocument18 pagesALUMINIUM FinalRamya shree kNo ratings yet

- NALCO Catalogue TECHNICAL 2009 P9-12 Advantages of AluminiumDocument4 pagesNALCO Catalogue TECHNICAL 2009 P9-12 Advantages of AluminiumSRPC CIVILNo ratings yet

- Aluminium and Construction: Mangala Mahanthan J II Semester, BEM, SPADocument12 pagesAluminium and Construction: Mangala Mahanthan J II Semester, BEM, SPAMangala Mahanthan JanakiramanNo ratings yet

- Aluminium Composite Panel As A Facade Material: Priyanka Mohaney, Er. Gaurav SoniDocument6 pagesAluminium Composite Panel As A Facade Material: Priyanka Mohaney, Er. Gaurav Sonind_tengNo ratings yet

- Aluminum Extrusion ProcessDocument4 pagesAluminum Extrusion Processswarna raviNo ratings yet

- Module 3 Mohaney - Soni 2018Document6 pagesModule 3 Mohaney - Soni 2018ADRIAN EMMANUEL CLEMENTENo ratings yet

- Center Enamel Aluminium Dome Roof CatalogDocument3 pagesCenter Enamel Aluminium Dome Roof Cataloggreensolution0084No ratings yet

- Buildimg MaterialsDocument13 pagesBuildimg MaterialsGunjan UttamchandaniNo ratings yet

- Thermal Performance of AluminiumDocument23 pagesThermal Performance of AluminiumdarulrajNo ratings yet

- aluMATTER Aluminium Construction ConstructionDocument2 pagesaluMATTER Aluminium Construction Constructioncelcel@468No ratings yet

- Construction Report: Topic:Aluminium Door and WindowDocument10 pagesConstruction Report: Topic:Aluminium Door and WindowSonali SinghNo ratings yet

- Aluminium in Building ConstructionDocument18 pagesAluminium in Building ConstructionRithas Mohammad PKNo ratings yet

- HISTORYDocument17 pagesHISTORYJannatul HasniNo ratings yet

- Abhishek Singh Review or Research PaperDocument5 pagesAbhishek Singh Review or Research PaperAnonymous V9S84lNo ratings yet

- Advantages of Aluminium PDFDocument27 pagesAdvantages of Aluminium PDFGiri DharanNo ratings yet

- Case Study On AluminiumDocument17 pagesCase Study On AluminiumDev100% (1)

- Aluco PanelDocument4 pagesAluco PanelOindrila GhoshNo ratings yet

- Advantages of AluminiumDocument3 pagesAdvantages of AluminiumMk BhatNo ratings yet

- Aluminium - The Metal of ChoiceDocument5 pagesAluminium - The Metal of ChoiceCristianBanciuNo ratings yet

- Malleability, High Strength To Weight RatioDocument8 pagesMalleability, High Strength To Weight RatioSN2-0620 Theeban Rau A/L ChanthiranNo ratings yet

- Advantages of Aluminium TDDocument3 pagesAdvantages of Aluminium TDAbm MasumNo ratings yet

- AluminumDocument10 pagesAluminumAnushka KulkarniNo ratings yet

- Classification of Bricks: Course Title: Building and Finished MaterialsDocument10 pagesClassification of Bricks: Course Title: Building and Finished MaterialsasadNo ratings yet

- Bhagwan Mahavir College of Architecture: Sub: Building Material Construction Sem 3Document56 pagesBhagwan Mahavir College of Architecture: Sub: Building Material Construction Sem 3Yousif HusseinNo ratings yet

- Aluminium alloys as structural material: A review of researchDocument16 pagesAluminium alloys as structural material: A review of researchBhupendra MishraNo ratings yet

- Aluminium: Chris Grover & Fabian Reeves WhymarkDocument11 pagesAluminium: Chris Grover & Fabian Reeves WhymarkPlymouth3DDesignNo ratings yet

- Module 3 AluminiumDocument34 pagesModule 3 Aluminiumalbatroos earlybirdNo ratings yet

- Pre Fabricated AluminiumDocument6 pagesPre Fabricated AluminiumMahalakshmi R NairNo ratings yet

- General Characteristics of AluminiumDocument2 pagesGeneral Characteristics of AluminiumAjay SinghiNo ratings yet

- Aalco Metals LTD - Aluminium Alloy Introduction To Aluminium and Its Alloys - 9 PDFDocument3 pagesAalco Metals LTD - Aluminium Alloy Introduction To Aluminium and Its Alloys - 9 PDFsourabh yadavNo ratings yet

- Properties of AlluminiumDocument3 pagesProperties of Alluminiumtapan456No ratings yet

- 9-Brochure Novelis J57S J73ADocument20 pages9-Brochure Novelis J57S J73AcontactbakmatNo ratings yet

- Material PaletteDocument10 pagesMaterial PaletteAnuja JadhavNo ratings yet

- 5 Aluminium RecyclingDocument4 pages5 Aluminium Recyclinggosaye desalegn50% (2)

- Aluminum Doors and WindowsDocument3 pagesAluminum Doors and WindowsKuladeep YalamanchiliNo ratings yet

- Wepik Exploring The World of Aluminium Properties Uses and Sustainability 20240221184241ZCaZDocument12 pagesWepik Exploring The World of Aluminium Properties Uses and Sustainability 20240221184241ZCaZshubhammohit1112No ratings yet

- Aluminium Structures ApplicationsDocument4 pagesAluminium Structures ApplicationsmustafagoresNo ratings yet

- Aluminium PDFDocument325 pagesAluminium PDFDeepakNo ratings yet

- Aluminium Composite PanelDocument3 pagesAluminium Composite Panelgouri hooliNo ratings yet

- Aluminium Prices in IndiaDocument12 pagesAluminium Prices in IndiaKumar Chandan JhaNo ratings yet

- Aluminium and Aluminium Alloys Characteristic Advantages and Beneficial Properties of Aluminium Extrusions by Capral AluminiumDocument10 pagesAluminium and Aluminium Alloys Characteristic Advantages and Beneficial Properties of Aluminium Extrusions by Capral AluminiumSRPC CIVILNo ratings yet

- Aluminum and FireDocument3 pagesAluminum and FireRuthNo ratings yet

- It's About SHAPE: Designing With Extrusions For Building & Construction ApplicationsDocument71 pagesIt's About SHAPE: Designing With Extrusions For Building & Construction ApplicationsJuan Andrés Díaz RiveroNo ratings yet

- Muhammad Tayyab Naqash, Antonio Formisano and Gianfranco de MatteisDocument7 pagesMuhammad Tayyab Naqash, Antonio Formisano and Gianfranco de MatteisMIGUEL ENRIQUE MIRAVAL PAJUELONo ratings yet

- Aluminium IngotDocument2 pagesAluminium IngotSoumya BoseNo ratings yet

- Case Study Metals Use of AlloysDocument8 pagesCase Study Metals Use of AlloysNamrata MaheshwariNo ratings yet

- Aluminium and Its AlloysDocument2 pagesAluminium and Its AlloysJanaka MangalaNo ratings yet

- CMT Report - FinalDocument31 pagesCMT Report - Finalamanda_andrew_2No ratings yet

- Project SynopsisDocument3 pagesProject SynopsisAnchal GoheNo ratings yet

- TB 100 Basics of Aluminium CareDocument4 pagesTB 100 Basics of Aluminium CareFabio ChiavaroliNo ratings yet

- Internship ReportDocument3 pagesInternship ReportAditya Ranjan PratihariNo ratings yet

- 2016 Aluminum Formwork Brochure-Email PDFDocument10 pages2016 Aluminum Formwork Brochure-Email PDFJenelle Marie MedinaNo ratings yet

- Triangulation - Applied to Sheet Metal Pattern Cutting - A Comprehensive Treatise for Cutters, Draftsmen, Foremen and Students: Progressing from the Simplest Phases of the Subject to the Most Complex Problems Employed in the Development of Sheet Metal Patterns with Practical Solutions of Numerous Problems of Frequent Occurrence in Sheet Metal ShopsFrom EverandTriangulation - Applied to Sheet Metal Pattern Cutting - A Comprehensive Treatise for Cutters, Draftsmen, Foremen and Students: Progressing from the Simplest Phases of the Subject to the Most Complex Problems Employed in the Development of Sheet Metal Patterns with Practical Solutions of Numerous Problems of Frequent Occurrence in Sheet Metal ShopsRating: 5 out of 5 stars5/5 (1)

- Compendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)From EverandCompendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)No ratings yet

- Contoh Form Rko Obat PRB Per ApotekDocument19 pagesContoh Form Rko Obat PRB Per ApoteksaddamNo ratings yet

- CWAG Rectangular CoordinatesDocument52 pagesCWAG Rectangular CoordinatesRolando MerleNo ratings yet

- Abb Reg615 Ansi Appl 859072 EndDocument124 pagesAbb Reg615 Ansi Appl 859072 EndjppreciadomNo ratings yet

- ProductSheet Iq200 Rackmount SatelliteModemDocument2 pagesProductSheet Iq200 Rackmount SatelliteModemAsim Penkar PenkarNo ratings yet

- Tax System SriLankaDocument44 pagesTax System SriLankamandarak7146No ratings yet

- Grammar 04 18Document5 pagesGrammar 04 18zsuzsi_harangoz2218No ratings yet

- Material Balance PDFDocument31 pagesMaterial Balance PDFApril Joy HaroNo ratings yet

- Carbon Capture Corrosion Current Practice 2023Document12 pagesCarbon Capture Corrosion Current Practice 2023Wayne MonneryNo ratings yet

- Lecture 4Document24 pagesLecture 4Geeta AroraNo ratings yet

- 1 Kawasaki FSDocument16 pages1 Kawasaki FSmatgoffNo ratings yet

- LTE TDD - Network - Export - 2018 - 07 - 04Document3,760 pagesLTE TDD - Network - Export - 2018 - 07 - 04saadNo ratings yet

- Model 621 LR B Data SheetDocument1 pageModel 621 LR B Data SheetMohammed GallowNo ratings yet

- KONAN Emmanuel Sales Technical Engineer 16 Juin 23Document1 pageKONAN Emmanuel Sales Technical Engineer 16 Juin 23EMMANUEL KONANNo ratings yet

- Production of Biodegradable Plastics AsDocument6 pagesProduction of Biodegradable Plastics AsEbenezer EffisahNo ratings yet

- CESCCommunityProjectPlan Brgy - MacarioDaconDocument6 pagesCESCCommunityProjectPlan Brgy - MacarioDaconKennedy BalmoriNo ratings yet

- Structural Engineering Professor Step III: Ucsd Academic Biography/Bibliography FormDocument30 pagesStructural Engineering Professor Step III: Ucsd Academic Biography/Bibliography FormCesar Paul Purihuaman MoraNo ratings yet

- HPB21-0457 FINAL Submittal 09-07-2021 - Ritz Sagamore LOIDocument13 pagesHPB21-0457 FINAL Submittal 09-07-2021 - Ritz Sagamore LOIthe next miamiNo ratings yet

- 3B Reactions of Alcohols and ThiolsDocument27 pages3B Reactions of Alcohols and ThiolsAnloraine GonzalesNo ratings yet

- Form 67 Delivery Unloading and Loading of Materials and PlantDocument6 pagesForm 67 Delivery Unloading and Loading of Materials and PlantMohamed MedhioubNo ratings yet

- Comparison of Three Phase PV System in PSCAD and PowerFactoryDocument8 pagesComparison of Three Phase PV System in PSCAD and PowerFactorymlkz_01No ratings yet

- Asme A13.1 - 1996Document27 pagesAsme A13.1 - 1996lohv100% (1)

- Process Flow Chart - Manufacturing TS: Rejected, Sent Back To SupplierDocument1 pageProcess Flow Chart - Manufacturing TS: Rejected, Sent Back To Suppliersukumar bhowmickNo ratings yet

- Therapeutic Diet Manual: DIRECTIVE #4311Document27 pagesTherapeutic Diet Manual: DIRECTIVE #4311DuNo ratings yet

- Maharastra State Board of Technical Education MumbaiDocument23 pagesMaharastra State Board of Technical Education MumbaiMayuresh PadekarNo ratings yet

- Owner: PT. Baker Hughes User: Cok Gede Reza Description: Modified Safety Pin, Add. Handrail & Add. Anti Slip Step Stair at Pressure Test BayDocument3 pagesOwner: PT. Baker Hughes User: Cok Gede Reza Description: Modified Safety Pin, Add. Handrail & Add. Anti Slip Step Stair at Pressure Test BayMuhammad AlpianNo ratings yet

- NT Seq DatabaseDocument4 pagesNT Seq DatabaseDevinder KaurNo ratings yet

- Process SequenceDocument2 pagesProcess SequenceUmesh SakhareliyaNo ratings yet

- (12942) Sheet Chemical Bonding 4 Theory eDocument8 pages(12942) Sheet Chemical Bonding 4 Theory eAnurag SinghNo ratings yet

- CD Dye RD0005Document7 pagesCD Dye RD0005Juan CarlosNo ratings yet