Professional Documents

Culture Documents

PD PDF

PD PDF

Uploaded by

Saturmercu0 ratings0% found this document useful (0 votes)

20 views67 pagesOriginal Title

PD.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

20 views67 pagesPD PDF

PD PDF

Uploaded by

SaturmercuCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 67

1 .

9 -Lit e r TDI Engine

w it h Pum p I nje ct ion

(Pum pe Dse )

De sign a nd Funct ion

Se lf -St udy Progra m

Course N um be r 8 4 1 3 0 3

Volksw agen of A m erica, Inc.

Service Training

Printed in U .S.A .

Printed 10/2003

C ourse N um ber 841303

2003 Volksw agen of A m erica, Inc.

A ll rights reserved. A ll inform ation contained

in this m anual is based on the latest

inform ation available at the tim e of printing

and is subject to the copyright and other

intellectual property rights of Volksw agen of

A m erica, Inc., its affiliated com panies and its

licensors. A ll rights are reserved to m ake

changes at any tim e w ithout notice. N o part

of this docum ent m ay be reproduced,

stored in a retrieval system , or transm itted

in any form or by any m eans, electronic,

m echanical, photocopying, recording or

otherw ise, nor m ay these m aterials be

m odified or reposted to other sites w ithout

the prior expressed w ritten perm ission of

the publisher.

A ll requests for perm ission to copy and

redistribute inform ation should be referred

to Volksw agen of A m erica, Inc.

A lw ays check Technical B ulletins and the

Volksw agen W orldw ide R epair Inform ation

System for inform ation that m ay supersede

any inform ation included in this booklet.

Tradem arks: A ll brand nam es and product

nam es used in this m anual are trade nam es,

service m arks, tradem arks, or registered

tradem arks; and are the property of their

respective ow ners.

i

Table of Contents

The Self-Study Program provides you w ith inform ation

regarding designs and functions.

The Self-Study Program is not a Repair Manual.

For m aintenance and repair w ork, alw ays refer to the

current technical literature.

Important/Note!

New!

Introduction...............................................................................1

1.9-Liter TD I Engine w ith Pum p Injection System

Engine Mechanics ..................................................................2

D evelopm ent of the 1.9-Liter TD I Engine w ith Pum p

Injection System , Technical D ata 1.9-Liter TD I Engine

w ith Pum p Injection System , Trapezoidal Piston and

C onnecting R od, Toothed B elt D rive

Fuel Supply................................................................................8

Fuel Supply System O verview , Fuel Pum p,

D istributor Pipe, Fuel C ooling System

Pump Injection System..........................................................15

Pum p/Injectors, D esign, Injection C ycle

Engine Management...............................................................28

1.9-Liter TD I Engine ED C 16 System O verview ,

Sensors, A ctuators

Glow Plug System..................................................................53

G low Plug System

Functional Diagram.................................................................54

ED C 16 Functional D iagram for 1.9-Liter TD I Engine

Service......................................................................................56

Self-D iagnosis, Pum p/Injector A djustm ent, Special Tools

Knowledge Assessment.........................................................61

Introduction

1

1.9-Liter TDI Engine with

Pump Injection System

The dem ands on the m odern diesel engine

for increased perform ance and fuel

econom y, and reduced exhaust em issions

and noise levels are grow ing constantly.

G ood fuel and air m ixture preparation is a

key factor in m eeting these requirem ents.

This calls for efficient injection system s that

produce high injection pressures to ensure

that the fuel is w ell atom ized. It is also

necessary to precisely control the start of

fuel injection and the injection quantity.

The pum p injection system m eets

these requirem ents.

In 1905, R udolf D iesel cam e up w ith the

idea of a pum p/injector, com bining the

injection pum p and injector in one unit

in order to dispense w ith high-pressure

lines and achieve high injection pressures.

A t the tim e, how ever, he did not have

the technical m eans to put his idea

into practice.

D iesel engines w ith m echanically controlled

pum p injection system s have been in use

in ships and trucks since the 1950s.

In association w ith B osch, Volksw agen has

succeeded in developing a diesel engine

w ith a solenoid valve controlled pum p

injection system suitable for use in

passenger cars.

The 1.9-liter TD I engine w ith the new pum p

injection system m eets the stringent

dem ands for im proved perform ance and

cleaner em issions.

W ith continuing advances like this one,

R udolf D iesels vision of sm oke- and

odor-free exhaust gasesm ay one day

becom e a reality.

SSP304/032

SSP209/027

Engine Mechanics

2

Development of the

1.9-Liter TDI Engine with

Pump Injection System

The new 100 bhp (74 kW ) 1.9-liter TD I

engine w ith pum p injection system w as

developed from the existing 109 bhp (81

kW ) 1.9-liter TD I engine w ith a distributor

injection pum p and no interm ediate shaft.

The pum p injection system com prises the

only significant difference betw een the

tw o engines.

This Self-Study Program concerns

the design and function of the new pum p

injection system , and the m odifications

to the fuel system , engine m anagem ent

system , and engine m echanical

com ponents to accom m odate the system .

A diesel engine w ith the pum p injection

system has the follow ing advantages over

an engine w ith a distributor injection pum p:

Low com bustion noise.

Low fuel consum ption.

C lean em issions.

H igh efficiency.

These advantages are attributable to:

The high injection pressures of up to

27,846 psi (192,000 kPa / 1,920 bar).

Precise control of the injection cycle.

The pre-injection phase.

SSP209/005

Speed (rpm)

3

Engine Mechanics

Technical Data

1.9-Liter TDI Engine with

Pump Injection System

Engine code

B EW

Type

Four-cylinder in-line engine w ith tw o

valves per cylinder

Displacement

115.7 cu in (1,896 cm

3

)

Bore

3.13 in (79.5 m m )

Stroke

3.76 in (95.5 m m )

Compression ratio

19.0 : 1

Maximum power output

100 bhp (74 kW ) @ 4000 rpm

Maximum torque

177 lbs-ft (240 N m ) @ 1800 to 2400 rpm

Engine management

ED C 16

Firing sequence

1-3-4-2

Emission Control

B in 10 EPA Federal Em issions C oncept,

O B D II, catalytic converter, w ater-cooled

EG R system

SSP209/006

T

o

r

q

u

e

O

u

t

p

u

t

1000 2000 3000 4000 5000

lbs-ft N m

221 300

184 250

148 200

111 150

74 100

37 50

0

hp kW

121 90

101 75

80 60

60 45

40 30

20 15

0

4

Engine Mechanics

Trapezoidal Piston

and Connecting Rod

To accom m odate the higher com bustion

pressures in the 1.9-liter TD I engine w ith

pum p injection system than are

encountered in the base engine, the piston

hub and the connecting rod eye are

trapezoidal in shape.

SSP209/007

5

Engine Mechanics

This distributes the com bustion forces over

a larger area and relieves the load on the

piston pin and connecting rod.

In com parison w ith the conventional

parallelogram -shaped link betw een the

piston and connecting rod, the trapezoidal

connecting rod eye and piston hub have a

larger contact surface area at the piston pin

ow ing to their shape.

SSP209/008

C om bustion Force

C ontact Surface

Force Distribution in a Parallelogram-Shaped

Piston and Connecting Rod

Force Distribution in a Trapezoidal Piston

and Connecting Rod

C om bustion Force

C ontact Surface

SSP209/009

Toothed Belt Drive

H igh pum p forces are required to generate

high injection pressures of up to 27,846 psi

(192,000 kPa / 1,920 bar).

These forces subject the com ponents of

the toothed belt drive to high loads.

To relieve the load on the toothed belt,

several m odifications have been m ade.

A vibration absorber integrated in the

cam shaft gear reduces vibration in

the toothed belt drive.

The toothed belt is about 0.20 inch

(5 m m ) w ider than the toothed belt used

in the base engine. H igher forces can be

transm itted by the larger surface area.

A hydraulic tensioner keeps the

toothed belt evenly tensioned in

different load states.

Som e of the teeth on the crankshaft

tim ing belt gear have a larger gap

clearance to reduce toothed belt w ear.

SSP209/089

SSP209/88

G ap

C learance

To relieve the load on the toothed belt

during the injection cycle, the crankshaft

tim ing belt gear has tw o pairs of teeth w ith

a larger gap clearance than the other teeth.

6

Engine Mechanics

Function

D uring the injection cycle, the high

pum ping forces exert a heavy load on the

toothed belt.

The cam shaft tim ing belt gear is slow ed

dow n by the pum ping forces. A t the sam e

tim e, the com bustion process speeds up

the crankshaft tim ing belt gear. The toothed

belt is stretched and the pitch is tem porarily

increased as a result.

B ecause of the engine firing order, this

stretching process occurs at regular

intervals and the sam e teeth on the tim ing

belt gear are in m esh w ith the toothed belt

every tim e.

Non-uniform tooth gap clearance

O n the 1.9-liter TD I engine w ith pum p

injection system , the crankshaft tim ing belt

gear teeth have a larger gap clearance at

these points to com pensate for the change

in belt tooth pitch and thus reduce toothed

belt w ear.

SSP209/091

7

D eceleration Force

A cceleration Force

P

i

t

c

h

Engine Mechanics

8

Fuel Supply

Fuel Supply System Overview

A m echanical fuel pum p sucks the fuel out

of the fuel tank through the fuel filter and

pum ps it along the supply line in the

cylinder head to the pum p/injectors.

Fuel C ooler C ools the returning fuel

to prevent excessively hot fuel from

being routed back to the fuel tank.

The fuel that is not required for injection is

returned to the fuel tank via the return line

in the cylinder head, a fuel tem perature

sensor, and a fuel cooler.

N on-R eturn Valve Prevents fuel

from the fuel pum p flow ing back into

the fuel tank w hile the engine is not

running. It has an opening pressure

of 2.9 psi (20 kPa / 0.2 bar).

Fuel Filter Protects the injection

system against contam ination and

w ear caused by particles and w ater.

Fuel Tem perature Sensor G 81

D eterm ines the tem perature of the

fuel in the fuel return line and sends a

corresponding signal to the D iesel D irect

Fuel Injection Engine C ontrol M odule J248.

Fuel Tank

9

Fuel Supply

SSP209/018

Fuel R eturn Line Pressure

Lim iting Valve Keeps the

pressure in the fuel return line

at 14.5 psi (100 kPa / 1 bar).

This m aintains a force

equilibrium at the pum p/

injector solenoid valve needle.

Strainer C ollects vapor bubbles in the

fuel supply line. These vapor bubbles are

then separated through the restrictor

into the return line.

Fuel Supply Line Pressure Lim iting Valve

R egulates the fuel pressure in the fuel supply line.

The valve opens w hen the fuel pressure exceeds

109 psi (750 kPa / 7.5 bar). Fuel is routed back to

the suction side of the fuel pum p.

Fuel Pum p R otor Pum ps the fuel from

the fuel tank through the fuel filter and

the fuel supply line in the cylinder head

to the pum p/injectors.

R estrictor Located betw een the

fuel supply line and the fuel return

line. Vapor bubbles in the fuel supply

line are separated through the

restrictor into the fuel return line.

Pressure Lim iting Valve B ypass

If there is air in the fuel system ,

for exam ple w hen the fuel tank

is em pty, the pressure lim iting

valve rem ains closed. The air is

expelled from the system by the

fuel flow ing into the tank.

C ylinder H ead

There is a fitting on the fuel

pum p for connecting pressure

gauge VA S 5187 to check the

fuel pressure in the supply line.

Please refer to the R epair M anual

for instructions.

Fuel Supply

10

Fuel Pump

The fuel pum p is located directly behind

the vacuum pum p at the cylinder head.

It m oves the fuel from the fuel tank to the

pum p/injectors.

B oth pum ps are driven jointly by the

cam shaft. They are collectively know n as

a tandem pum p.

Fuel R eturn Line

SSP209/049

Pressure G auge

C onnection Fitting

Fuel Pum p

Vacuum Pum p

Fuel Supply Line

11

Fuel Supply

The fuel pum p is a blocking vane-cell pum p.

The blocking vanes are pressed against the

pum p rotor by spring pressure. This design

enables the fuel pum p to deliver fuel even

at low engine speeds.

The fuel ducting system w ithin the pum p

is designed so that the rotor alw ays

rem ains w etted w ith fuel, even if the tank

has been run dry. This m akes autom atic

prim ing possible.

SSP209/050

B locking Vanes

R estrictor

C onnection for

Fuel Supply Line

Fuel Supply Line

Pressure Lim iting Valve

To Fuel Supply Line

in C ylinder H ead

Strainer

C onnection for

Fuel R eturn Line

Fuel R eturn

Line Pressure

Lim iting Valve

R otor

From Fuel

R eturn Line in

C ylinder H ead

12

Function

The fuel pum p operates by taking fuel in as

the pum p cham ber volum e increases and

pushing the fuel out under pressure as the

cham ber volum e is reduced.

The fuel is draw n into tw o cham bers and

pum ped out from tw o cham bers. The

intake and delivery cham bers are separated

from one another by the spring-loaded

blocking vanes and the pum p rotor lobes.

Fuel draw n into cham ber 1 is pushed out at

cham ber 2. Fuel draw n into cham ber 3 is

pushed out at cham ber 4.

The rotation of the rotor increases the

volum e of cham ber 1 w hile the volum e of

cham ber 4 is sim ultaneously reduced.

Fuel is pushed out of cham ber 4 to the

fuel supply line in the cylinder head.

Fuel Supply

The rotation of the rotor increases the

volum e in cham ber 3 as it reduces the

volum e in cham ber 2. Fuel draw n in at

cham ber 1 is forced out of cham ber 2 to

the fuel supply line in the cylinder head.

SSP209/052 R otor

C ham ber 4 C ham ber 3

C ham ber 2

C ham ber 1

SSP209/051

C ham ber 1

R otor

C ham ber 4

C ham ber 3

C ham ber 2

13

Fuel Supply

Distributor Pipe

A distributor pipe is integrated in the fuel

supply line in the cylinder head. It distributes

the fuel evenly to the pum p/injectors at a

uniform tem perature.

In the supply line, the fuel m oves through

the center of the distributor pipe tow ard

cylinder 1 at the far end.

The fuel also m oves through the cross

holes in the distributor pipe and enters the

annular gap betw een the distributor pipe

and the cylinder head w all.

This fuel m ixes w ith the hot unused fuel

that has been forced back into the supply

line by the pum p/injectors.

This results in a uniform tem perature

of the fuel in the supply line running to

all cylinders.

A ll pum p/injectors are supplied w ith

the sam e fuel m ass, and the engine

runs sm oothly.

SSP209/039

C ylinder H ead

A nnular G ap

C ross H oles

C ylinder 4 C ylinder 3 C ylinder 2 C ylinder 1

D istributor Pipe

SSP209/040

SSP209/29

C ross H oles

M ixing Fuel in

A nnular G ap

Fuel to Pum p/Injector

Fuel from

Pum p/Injector

14

Fuel Supply

Fuel Cooling Circuit

The heated fuel returning from the pum p/

injectors flow s through the fuel cooler and

its heat transfers to the coolant in the fuel

cooling circuit that also flow s through the

fuel cooler.

The auxiliary w ater cooler reduces the

tem perature of the coolant in the fuel

cooling circuit by dissipating the heat in

the coolant to the am bient air.

Pum p for Fuel C ooler V166 is an electric

recirculation pum p. It circulates the coolant

in the fuel cooling circuit through the

auxiliary w ater cooler and the fuel cooler. It

is sw itched on by the D iesel D irect Fuel

Injection Engine C ontrol M odule J248 via

the R elay for Pum p, Fuel C ooling J445 at

a fuel tem perature of 158F (70C ).

The fuel cooling circuit is largely separate

from the engine cooling circuit. This is

necessary because the tem perature of the

coolant in the engine cooling circuit is too

high to cool dow n the fuel w hen the engine

is at operating tem perature.

The fuel cooling circuit is connected to the

engine cooling circuit near the expansion

tank. This enables replenishm ent of the

coolant for fuel cooling at the coolant

expansion tank. It also allow s

com pensation for changes in volum e due

to tem perature fluctuation.

The fuel cooling circuit is connected so that

the hotter engine cooling circuit does not

have a detrim ental effect on its ability to

cool the fuel.

SSP209/048

Fuel Pum p

Pum p for

Fuel C ooler

V166

Fuel C ooler

A uxiliary

W ater

C ooler

Engine

C ooling

C ircuit

Fuel Tank

C oolant

Expansion

Tank

Fuel

Tem perature

Sensor G 81

Fuel Cooling System

The high pressure generated by the pum p/

injectors heats up the unused fuel so m uch

that it m ust be cooled before it gets back to

the fuel tank.

A fuel cooler is located on the fuel filter.

It cools the returning fuel and thus prevents

excessively hot fuel from entering the fuel

tank and possibly dam aging the Sender for

Fuel G auge G .

15

Pump Injection System

Pump/Injectors

A pum p/injector is, as the nam e im plies, a

pressure-generating pum p com bined w ith a

solenoid valve control unit (Valves for Pum p/

Injectors, C ylinders 1 through 4, N 240,

N 241, N 242, and N 243) and an injector.

Each cylinder of the engine has its ow n

pum p/injector.

This m eans that there is no longer any

need for a high-pressure line or a distributor

injection pum p.

SSP209/012

Just like a conventional system w ith a

distributor injection pum p and separate

injectors, the new pum p injection

system m ust:

G enerate the high injection

pressures required.

Inject fuel into the cylinders in the correct

quantity and at the correct point in tim e.

Solenoid Valve C ontrol U nit

Injector

Pressure-

G enerating

Pum p

16

Pump Injection System

The pum p/injectors are installed directly in

the cylinder head.

SSP209/086

SSP209/087

They are attached to the cylinder head by

individual clam ping blocks.

It is im portant to ensure that

the pum p/injectors are positioned

correctly w hen they are installed.

R efer to the R epair M anual

for instructions.

If the pum p/injectors are not installed

perpendicular to the cylinder head, the

fasteners could loosen. The pum p/injectors

or the cylinder head could be dam aged as

a result.

C lam ping

B lock

17

Pump Injection System

Design

SSP209/023

R oller-Type

R ocker A rm

O -R ing

O -R ing

O -R ing

H eat-

Insulating

Seal

C ylinder H ead

Injector N eedle

Injector N eedle

D am ping Elem ent

Injector Spring

Fuel Supply Line

R etraction

Piston

Fuel R eturn Line

H igh-Pressure

C ham ber

Pum p/Injector

Solenoid Valve

Solenoid

Valve N eedle

Injection C am

Piston Spring

Pum p Piston

B all Pin

18

Pump Injection System

Drive Mechanism

The cam shaft has four additional cam s for

driving the pum p/injectors.

They activate the pum p/injector pum p

pistons w ith roller-type rocker arm s.

Valve C am

SSP209/015

Injection C am

(H idden by

R ocker A rm R oller)

R oller-Type

R ocker A rm

19

Pump Injection System

The gradual slope of the cam trailing edge

allow s the pum p piston to m ove up

relatively slow ly and evenly. Fuel flow s into

the pum p/injector high-pressure cham ber

free of air bubbles.

The injection cam has a steep leading edge

and a gradual slope to the trailing edge.

A s a result of the steep leading edge, the

pum p piston is pushed dow n at high

velocity. A high injection pressure is

attained quickly.

SSP209/016

Pum p

Piston

Injection C am

R oller-Type

R ocker A rm

SSP209/017

Pum p

Piston

Injection C am

R oller-Type

R ocker A rm

20

Pump Injection System

Mixture Formation and

Combustion Requirements

G ood m ixture form ation is a vital factor to

ensure efficient com bustion.

A ccordingly, fuel m ust be injected in the

correct quantity at the right tim e and at high

pressure. Even m inim al deviations can lead

to higher levels of pollutant em issions, noisy

com bustion, or high fuel consum ption.

A short firing delay is im portant for the

com bustion sequence of a diesel engine.

The firing delay is the period betw een the

start of fuel injection and the start of

pressure rise in the com bustion cham ber.

If a large fuel quantity is injected during this

period, the pressure w ill rise suddenly and

cause loud com bustion noise.

Pre-injection phase

To soften the com bustion process, a sm all

am ount of fuel is injected at a low pressure

before the start of the m ain injection phase.

This is the pre-injection phase. C om bustion

of this sm all quantity of fuel causes the

pressure and tem perature in the

com bustion cham ber to rise.

This m eets the requirem ents for quick

ignition of the m ain injection quantity, thus

reducing the firing delay.

The pre-injection phase and the injection

intervalbetw een the pre-injection phase

and the m ain injection phase produce a

gradual rise in pressure w ithin the

com bustion cham ber, not a sudden

pressure buildup.

The effects of this are low com bustion

noise levels and low er nitrogen

oxide em issions.

Main injection phase

The key requirem ent for the m ain injection

phase is the form ation of a good m ixture.

The aim is to burn the fuel com pletely

if possible.

The high injection pressure finely atom izes

the fuel so that the fuel and air can m ix w ell

w ith one another.

C om plete com bustion reduces pollutant

em issions and ensures high engine

efficiency.

End of injection

A t the end of the injection process, it

is im portant that the injection pressure

drops quickly and the injector needle

closes quickly.

This prevents fuel at a low injection

pressure and w ith a large droplet diam eter

from entering the com bustion cham ber.

Fuel does not com bust com pletely under

such conditions, giving rise to higher

pollutant em issions.

Injection curve

The injection curve of the pum p injection

system largely m atches the engine

dem ands, w ith low pressures during the

pre-injection phase, follow ed by an

injection interval,then a rise in pressure

during the m ain injection phase. The

injection cycle ends abruptly.

SSP209/101 SSP209/100

I

n

j

e

c

t

i

o

n

P

r

e

s

s

u

r

e

Tim e

Engine D em and Pum p/Injector

21

Pump Injection System

Injection Cycle

High-Pressure Chamber Fills

D uring the filling phase, the pum p piston

m oves upw ard under the force of the

piston spring and thus increases the

volum e of the high-pressure cham ber.

The pum p/injector solenoid valve is

not activated.

The solenoid valve needle is in its

resting position.

The path is open from the fuel supply line

to the high-pressure cham ber.

The fuel pressure in the supply line

causes the fuel to flow into the

high-pressure cham ber.

Solenoid

Valve N eedle

Fuel Supply Line

SSP209/024

Piston Spring

H igh-Pressure

C ham ber

Injector N eedle

Fuel R eturn Line

Pum p/Injector

Solenoid Valve

Pum p Piston

Injection C am

R oller-Type

R ocker A rm

22

Pump Injection System

Pre-Injection Phase Starts

The injection cam pushes the pum p

piston dow n via the roller-type rocker arm .

This displaces som e of the fuel from the

high-pressure cham ber back into the fuel

supply line.

The D iesel D irect Fuel Injection Engine

C ontrol M odule J248 initiates the injection

cycle by activating the pum p/injector

solenoid valve.

The solenoid valve needle is pressed into

the valve seat and closes the path from

the high-pressure cham ber to the fuel

supply line.

This initiates a pressure build-up in the

high-pressure cham ber.

A t 2,611 psi (18,000 kPa / 180 bar), the

pressure is greater than the force of the

injector spring.

The injector needle is lifted from its seat

and the pre-injection cycle starts.

SSP209/025

R oller-Type

R ocker A rm

R etraction Piston

Injection C am

Injector Spring

Injector N eedle

Solenoid

Valve N eedle

Pum p/Injector

Solenoid Valve

Fuel R eturn Line

Fuel Supply Line

H igh-Pressure

C ham ber

Piston Spring

Pum p Piston

23

Pump Injection System

Injector needle damping

D uring the pre-injection phase, the stroke

of the injector needle is dam pened by a

hydraulic cushion. A s a result, it is possible

to m eter the injection quantity exactly.

A s soon as the dam ping piston plunges into

the bore in the injector housing, the fuel

above the injector needle can only be

displaced into the injector spring cham ber

through a leakage gap.

This creates a hydraulic cushion w hich

lim its the injector needle stroke during the

pre-injection phase.

Function

In the first third of the total stroke, the

injector needle is opened undam ped.

The pre-injection quantity is injected into

the com bustion cham ber.

SSP209/036

D am ping

Piston

H ydraulic

C ushion

Leakage G ap

Injector

H ousing

Injector

Spring

Injector

Spring

C ham ber

SSP209/035

U ndam ped

Stroke

Injector

H ousing

Injector

Spring

Injector

Spring

C ham ber

24

Pump Injection System

Pre-Injection Phase Ends

The pre-injection phase ends im m ediately

after the injector needle opens.

The rising pressure causes the retraction

piston to m ove dow nw ard, thus increasing

the volum e of the high-pressure cham ber.

The pressure drops m om entarily as a

result, and the injector needle closes.

SSP209/026

This ends the pre-injection phase.

The dow nw ard m ovem ent of the retraction

piston pre-loads the injector spring to a

greater extent.

To re-open the injector needle during the

subsequent m ain injection phase, the fuel

pressure m ust be greater than during the

pre-injection phase.

R oller-Type

R ocker A rm

R etraction Piston

Injection C am

Injector Spring

Injector N eedle

Solenoid

Valve N eedle

Pum p/Injector

Solenoid Valve

Fuel R eturn Line

Fuel Supply Line

H igh-Pressure

C ham ber

Piston Spring

Pum p Piston

25

Pump Injection System

Main Injection Phase Starts

The pressure in the high-pressure

cham ber rises again shortly after the

injector needle closes.

The pum p/injector solenoid valve

rem ains closed and the pum p piston

m oves dow nw ard.

A t approxim ately 4,351 psi (30,000 kPa /

300 bar), the fuel pressure is greater

than the force exerted by the pre-loaded

injector spring.

The injector needle is again lifted from

its seat and the m ain injection quantity

is injected.

The pressure rises to betw een 27,121 psi

(187,000 kPa / 1,870 bar) and 27,846 psi

(192,000 kPa / 1,920 bar) because m ore

fuel is displaced in the high-pressure

cham ber than can escape through the

nozzle holes.

M axim um fuel pressure is achieved at

m axim um engine output. This occurs at a

high engine speed w hen a large quantity of

fuel is being injected.

SSP209/027

R oller-Type

R ocker A rm

R etraction Piston

Injection C am

Injector Spring

Injector N eedle

Solenoid

Valve N eedle

Fuel Supply Line

H igh-Pressure

C ham ber

Piston Spring

Pum p Piston

Pum p/Injector

Solenoid Valve

Fuel R eturn Line

26

Pump Injection System

Main Injection Phase Ends

The injection cycle ends w hen the D iesel

D irect Fuel Injection Engine C ontrol M odule

J248 stops activating the pum p/injector

solenoid valve.

The solenoid valve spring opens the solenoid

valve needle, and the fuel displaced by the

pum p piston can enter the fuel supply line.

The pressure drops.

The injector needle closes and the injector

spring presses the bypass piston into its

starting position.

This ends the m ain injection phase.

R oller-Type

R ocker A rm

Injection C am

Injector Spring

Injector N eedle

Solenoid

Valve N eedle

Pum p/Injector

Solenoid Valve

Fuel R eturn Line

Fuel Supply Line

Piston Spring

Pum p Piston

SSP209/028

R etraction Piston

Solenoid

Valve N eedle

27

Pump/Injector Fuel Return

The fuel return line in the pum p/injector has

the follow ing functions:

C ool the pum p/injector by flushing

fuel from the fuel supply line through

the pum p/injector ducts into the fuel

return line.

D ischarge leaking fuel at the

pum p piston.

Separate vapor bubbles from the

pum p/injector fuel supply line through

the restrictors in the fuel return line.

Pump Injection System

SSP209/096

Fuel Supply Line

Leaking Fuel

Pum p Piston

R estrictors

Fuel R eturn Line

Engine Management

28

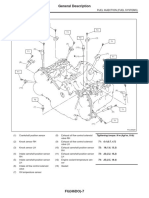

1.9-Liter TDI Engine EDC 16

System Overview

Sensors

D iesel D irect

Fuel Injection

Engine C ontrol

M odule J248

16-Pin

C onnector

(D iagnosis

C onnection)

T16

A B S C ontrol M odule

w ith ED L/A SR /ESP J104

D rivetrain

C A N D ata B us

B arom etric

Pressure

Sensor F96

A dditional Signals

R oad Speed Signal

A ir C onditioner C om pressor R eady

C C S Sw itch

Three-Phase A C G enerator Term inal D F

Fuel Tem perature Sensor G 81

B rake Light Sw itch F

B rake Pedal Sw itch F47

C lutch Vacuum Vent Valve Sw itch F36

M anifold A bsolute Pressure Sensor G 71

Intake A ir Tem perature Sensor G 72

Engine C oolant Tem perature Sensor G 62

Throttle Position Sensor G 79

Kick D ow n Sw itch F8

C losed Throttle Position Sw itch F60

C am shaft Position Sensor G 40

Engine Speed Sensor G 28

M ass A ir Flow Sensor G 70

Engine Management

29

SSP209/053

Actuators

A dditional Signals

C oolant A uxiliary H eater

Engine Speed

C ooling Fan R un-O n

A ir C onditioner C om pressor C ut-O ff

Fuel C onsum ption Signal

R elay for Pum p, Fuel C ooling J445

Pum p for Fuel C ooler V166

C hange-O ver Valve for Intake M anifold Flap N 239

W astegate B ypass R egulator Valve N 75

EG R Vacuum R egulator Solenoid Valve N 18

G low Plug Indicator Light K29

Valve for Pum p/Injector, C ylinder 1 N 240

Valve for Pum p/Injector, C ylinder 2 N 241

Valve for Pum p/Injector, C ylinder 3 N 242

Valve for Pum p/Injector, C ylinder 4 N 243

G low Plugs Q 6

G low Plug R elay J52

Transm ission

C ontrol M odule

J217

30

Sensors

Camshaft Position Sensor G40

The C am shaft Position Sensor G 40 is a

H all-effect sensor.

It is attached to the toothed-belt guard

below the cam shaft gear.

It scans seven teeth on the cam shaft sensor

w heel attached to the cam shaft gear.

Signal application

The D iesel D irect Fuel Injection Engine

C ontrol M odule J248 uses the signal that

the C am shaft Position Sensor G 40

generates to determ ine the relative

positions of the pistons in the cylinders

w hen starting the engine.

Effects of signal failure

In the event of C am shaft Position Sensor

G 40 signal failure, the D iesel D irect Fuel

Injection Engine C ontrol M odule J248 uses

the signal that the Engine Speed Sensor

G 28 generates.

Electrical circuit

G 40 C am shaft Position Sensor

J248 D iesel D irect Fuel Injection Engine

C ontrol M odule

J317 Pow er Supply (Term inal 30, B +) R elay

Engine Management

C am shaft

Sensor W heel

SSP209/054

C am shaft Position

Sensor G 40

SSP209/055

J 248

G40

J 317

S

Engine Management

31

Cylinder recognition when

starting the engine

W hen starting the engine, the D iesel D irect

Fuel Injection Engine C ontrol M odule J248

m ust determ ine w hich cylinder is in the

com pression stroke in order to activate the

correct pum p/injector valve. To achieve this,

it evaluates the signal generated by the

C am shaft Position Sensor G 40, w hich

scans the teeth of the cam shaft sensor

w heel to determ ine the cam shaft position.

Camshaft sensor wheel

Since the cam shaft executes one

360-degree revolution per w orking cycle,

there is a tooth for each individual cylinder

on the sensor w heel. These teeth are

spaced 90 degrees apart.

To differentiate betw een cylinders, the

sensor w heel has an additional tooth w ith

different spacing for each of cylinders

1, 2, and 3.

SSP209/094 C ylinder 2

C ylinder 1

C ylinder 3

C ylinder 4

90

Engine Management

32

Function

Each tim e a tooth passes the C am shaft

Position Sensor G 40, a H all-effect voltage

is induced and transm itted to the D iesel

D irect Fuel Injection Engine C ontrol

M odule J248.

B ecause the teeth are spaced at different

distances apart, the induced voltage occurs

at different tim e intervals.

From this, the D iesel D irect Fuel Injection

Engine C ontrol M odule J248 determ ines

the relative positions of the cylinders and

uses this inform ation to control the

solenoid valves for pum p/injectors.

R efer to Q uick-Start Function(page 34).

SSP209/095a

Signal Pattern, Camshaft Position Sensor G40

90 90 90

C ylinder 1 C ylinder 3 C ylinder 4 C ylinder 2 C ylinder 1

90

33

Engine Management

Engine Speed Sensor G28

The Engine Speed Sensor G 28 is an

inductive sensor. It is attached to the

cylinder block.

SSP209/056

J 248

SSP209/085

Engine speed sensor wheel

The Engine Speed Sensor G 28 scans a

60-2-2 sensor w heel attached to the

crankshaft. This m eans that the sensor

w heel has 56 teeth w ith tw o gaps the w idth

of tw o teeth each on its circum ference.

These gaps are 180 degrees apart and

serve as reference points for determ ining

the crankshaft position.

Signal application

The signal generated by the Engine Speed

Sensor G 28 provides both the engine speed

and the exact position of the crankshaft.

The injection point and the injection quantity

are calculated using this inform ation.

Effects of signal failure

If the signal of the Engine Speed Sensor

G 28 fails, the engine is sw itched off.

Electrical circuit

G 28 Engine Speed Sensor

J248 D iesel D irect Fuel Injection Engine

C ontrol M odule

SSP209/057

G28

34

Engine Management

Quick-Start Function

To allow the engine to be started quickly,

the D iesel D irect Fuel Injection Engine

C ontrol M odule J248 evaluates the signals

generated by the C am shaft Position Sensor

G 40 and the Engine Speed Sensor G 28.

The D iesel D irect Fuel Injection Engine

C ontrol M odule J248 uses the signal that

the C am shaft Position Sensor G 40

generates to determ ine the relative

positions of the pistons in the cylinders

w hen starting the engine.

B ecause there are tw o gaps on the

crankshaft sensor w heel, the D iesel D irect

Fuel Injection Engine C ontrol M odule J248

receives a usable reference signal from the

Engine Speed Sensor G 28 after only half a

turn of the crankshaft.

C ylinder 1 C ylinder 3 C ylinder 4 C ylinder 2

B y interpreting the signals from these tw o

sensors, the D iesel D irect Fuel Injection

Engine C ontrol M odule J248 determ ines

the position of the crankshaft in relation to

the cam shaft and thus the positions of the

pistons in the cylinders at an early stage.

W ith this inform ation, it can activate the

correct solenoid valve at the proper tim e to

initiate the injection cycle in the next

cylinder to reach the com pression stage.

The quick-start function enables an early

engine start because synchronization w ith

the first cylinder is not required.

SSP209/095

Signal G enerated

by Engine Speed

Sensor G 28

Signal

G enerated by

C am shaft Position

Sensor G 40

O ne C rankshaft R otation

O ne C am shaft R evolution

Signal Pattern, Camshaft Position Sensor G40

and Engine Speed Sensor G28

35

Engine Management

Fuel Temperature Sensor G81

The Fuel Tem perature Sensor G 81 is

located in the fuel return line betw een the

fuel pum p and the fuel cooler. It determ ines

the current tem perature of the fuel at

that point.

The Fuel Tem perature Sensor G 81 has a

negative tem perature coefficient. The

sensor resistance decreases w ith

increasing fuel tem perature.

Signal application

The signal generated by the Fuel

Tem perature Sensor G 81 is used by

the D iesel D irect Fuel Injection Engine

C ontrol M odule J248 to determ ine

the fuel tem perature.

This signal is needed to calculate the

start of injection point and the injection

quantity so that allow ance can be m ade

for the density of the fuel at different

tem peratures.

This signal is also used to determ ine

the tim ing for sw itching on the fuel

cooling pum p.

Effects of signal failure

In the event of Fuel Tem perature Sensor

G 81 signal failure, the D iesel D irect Fuel

Injection Engine C ontrol M odule J248

calculates a substitute value from the signal

generated by Engine C oolant Tem perature

Sensor G 62.

Electrical circuit

G 81 Fuel Tem perature Sensor

J248 D iesel D irect Fuel Injection Engine

C ontrol M odule

SSP209/043

SSP209/058

G81

J 248

36

Mass Air Flow Sensor G70

The M ass A ir Flow Sensor G 70 w ith reverse

flow recognition is located in the intake pipe.

It determ ines the intake air m ass.

The opening and closing actions of the

valve produce reverse flow s in the induced

air m ass in the intake pipe.

The M ass A ir Flow Sensor G 70

recognizes and m akes allow ance for the

returning air m ass in the signal it sends

to the D iesel D irect Fuel Injection Engine

C ontrol M odule J248.

The air m ass is accurately m easured.

Signal application

The D iesel D irect Fuel Injection Engine

C ontrol M odule J248 uses the m easured

values from the M ass A ir Flow Sensor G 70

to calculate the injection quantity and the

exhaust gas recirculation rate.

Effects of signal failure

If the signal from the M ass A ir Flow Sensor

G 70 fails, the D iesel D irect Fuel Injection

Engine C ontrol M odule J248 uses a fixed

substitute value.

Engine Management

SSP209/044

37

Engine Management

SSP209/60

Engine Coolant Temperature Sensor G62

The Engine C oolant Tem perature Sensor

G 62 is located at the coolant connection on

the cylinder head. It sends inform ation

about the current coolant tem perature to

the D iesel D irect Fuel Injection Engine

C ontrol M odule J248.

Signal application

The D iesel D irect Fuel Injection Engine

C ontrol M odule J248 uses the coolant

tem perature as a correction value for

calculating the injection quantity.

Effects of signal failure

If the signal from Engine C oolant

Tem perature Sensor G 62 fails, the D iesel

D irect Fuel Injection Engine C ontrol M odule

J248 uses the signal generated by the Fuel

Tem perature Sensor G 81 to calculate the

injection quantity.

38

Accelerator Pedal Sensors

The accelerator pedal sensors are integrated

into a single housing and connected to the

pedal by m echanical linkage.

Throttle Position Sensor G 79

Kick D ow n Sw itch F8

C losed Throttle Position Sw itch F60

Signal application

The D iesel D irect Fuel Injection Engine

C ontrol M odule J248 can recognize the

position of the accelerator pedal from

this signal.

In vehicles w ith an autom atic transm ission,

the Kick D ow n Sw itch F8 indicates to the

D iesel D irect Fuel Injection Engine C ontrol

M odule J248 w hen the driver w ants

to accelerate.

Effects of signal failure

W ithout the signal from Throttle Position

Sensor G 79, the D iesel D irect Fuel Injection

Engine C ontrol M odule J248 is unable to

recognize the accelerator pedal position.

The engine w ill only run at an increased

idling speed.

Engine Management

SSP209/059

39

Engine Management

SSP209/045

Intake Manifold Sensors

The intake m anifold sensors are integrated

into a single m odule and installed in the

intake pipe.

M anifold A bsolute Pressure Sensor G 71

Intake A ir Tem perature Sensor G 72

Manifold Absolute Pressure Sensor G71

Signal application

The M anifold A bsolute Pressure Sensor

G 71 supplies a signal that is required to

check the charge pressure (boost

pressure).

The D iesel D irect Fuel Injection Engine

C ontrol M odule J248 com pares the actual

m easured value w ith the setpoint from the

charge pressure m ap.

If the actual value deviates from the

setpoint, the D iesel D irect Fuel Injection

Engine C ontrol M odule J248 adjusts the

charge pressure via the W astegate B ypass

R egulator Valve N 75.

Effects of signal failure

The charge pressure can no longer

be regulated.

Engine perform ance drops.

Intake Air Temperature Sensor G72

Signal application

The D iesel D irect Fuel Injection Engine

C ontrol M odule J248 requires the signal

generated by the Intake A ir Tem perature

Sensor G 72 as a correction value for

com puting the charge pressure.

It can then m ake allow ance for the effect

of tem perature on the density of the

charge air.

Effects of signal failure

If the Intake A ir Tem perature Sensor G 72

signal fails, the D iesel D irect Fuel Injection

Engine C ontrol M odule J248 uses a

fixed substitute value to calculate the

charge pressure.

This can result in a drop in

engine perform ance.

40

Engine Management

Barometric Pressure Sensor F96

The B arom etric Pressure Sensor F96 is

located inside the D iesel D irect Fuel

Injection Engine C ontrol M odule J248.

Signal application

The B arom etric Pressure Sensor F96

sends the current am bient air pressure to

the D iesel D irect Fuel Injection Engine

C ontrol M odule J248.

This value is dependent on the vehicles

geographical altitude.

W ith this signal the D iesel D irect Fuel

Injection Engine C ontrol M odule J248

can carry out an altitude correction for

charge pressure control and exhaust

gas recirculation.

Effects of signal failure

B lack sm oke occurs at altitude.

Clutch Vacuum Vent Valve Switch F36

The C lutch Vacuum Vent Valve Sw itch F36

is located at the foot controls on vehicles

w ith m anual transm issions.

Signal application

The D iesel D irect Fuel Injection Engine

C ontrol M odule J248 determ ines from

this signal w hether the clutch is engaged

or disengaged.

W hen the clutch is engaged, injection

quantity is reduced briefly to prevent

engine shudder w hen shifting gears.

Effects of signal failure

If the signal from the C lutch Vacuum Vent

Valve Sw itch F36 fails, engine shudder can

occur w hen shifting gears.

SSP209/061

SSP209/062

B arom etric Pressure Sensor F96

41

Engine Management

Brake Pedal Sensors

The brake pedal sensors are integrated

into a single m odule that is m ounted on the

brake pedal bracket.

B rake Light Sw itch F

B rake Pedal Sw itch F47

Signal application

B oth sw itches supply the D iesel D irect

Fuel Injection Engine C ontrol M odule J248

w ith the brake activatedsignal.

The engine speed is regulated w hen the

brake is activated for safety reasons,

since the Throttle Position Sensor G 79

could be defective.

Effects of signal failure

If one of the tw o sw itches fails, D iesel

D irect Fuel Injection Engine C ontrol M odule

J248 reduces the fuel quantity.

Engine perform ance drops.

SSP209/063

42

Engine Management

Cruise control switch

The signal generated by the cruise control

sw itch tells the D iesel D irect Fuel Injection

Engine C ontrol M odule J248 that the cruise

control system has been activated.

Three-phase AC generator terminal DF

The signal supplied by generator term inal

D F indicates the load state of the three-

phase A C generator to the D iesel D irect

Fuel Injection Engine C ontrol M odule J248.

D epending on available capacity, the D iesel

D irect Fuel Injection Engine C ontrol M odule

J248 can sw itch on one, tw o, or three G low

Plugs (C oolant) Q 7 of the coolant auxiliary

heater via the R elay for Preheating C oolant,

Low H eat O utput J359 and the R elay for

Preheating C oolant, H igh H eat O utput J360.

CAN data bus

The D iesel D irect Fuel Injection Engine

C ontrol M odule J248, the A B S C ontrol

M odule w ith ED L/A SR /ESP J104, and the

Transm ission C ontrol M odule J217

interchange inform ation along a

C A N data bus.

Additional Input Signals

Road speed signal

The D iesel D irect Fuel Injection Engine

C ontrol M odule J248 receives the road

speed signal from the vehicle speed sensor.

This signal is used to calculate various

functions, including cooling fan run-on

and engine shudder dam ping w hen

shifting gears.

It is also used to check the cruise control

system for proper functioning.

Air conditioner compressor ready

The air conditioner sw itch sends D iesel

D irect Fuel Injection Engine C ontrol M odule

J248 a signal indicating that the air

conditioner com pressor w ill shortly be

sw itched on.

This enables the D iesel D irect Fuel Injection

Engine C ontrol M odule J248 to increase

the engine idle speed before the air

conditioner com pressor is sw itched on to

prevent a sharp drop in engine speed w hen

the com pressor starts up.

SSP209/083

43

Engine Management

Actuators

Pump/Injector Solenoid Valves

The 1.9-liter TD I engine w ith the new pum p

injection system uses four pum p/injector

solenoid valves:

Valve for Pum p/Injector, C ylinder 1 N 240

Valve for Pum p/Injector, C ylinder 2 N 241

Valve for Pum p/Injector, C ylinder 3 N 242

Valve for Pum p/Injector, C ylinder 4 N 243

The pum p/injector solenoid valves are

attached to their pum p/injectors w ith a

cap nut.

The D iesel D irect Fuel Injection Engine

C ontrol M odule J248 regulates the start of

injection points and injection quantities of

the pum p/injectors by activating their

solenoid valves at the appropriate tim es.

Start of injection point

A s soon as the D iesel D irect Fuel Injection

Engine C ontrol M odule J248 activates a

pum p/injector solenoid valve, the m agnetic

coil presses the solenoid valve needle

dow n into the valve seat and closes off the

path from the fuel supply line to the high-

pressure cham ber of the pum p/injector.

The injection cycle then begins.

Injection quantity

The injection quantity is determ ined by the

length of tim e that the solenoid valve is

activated.

Fuel is injected into the com bustion

cham ber as long as the pum p/injector

solenoid valve is closed.

SSP209/064

44

Effects of failure

If a pum p/injector solenoid valve fails, the

engine w ill not run sm oothly and

perform ance w ill be reduced.

The pum p/injector solenoid valve has a dual

safety function.

If the valve stays open, pressure cannot

build up in the pum p/injector.

If the valve stays closed, the high-pressure

cham ber of the pum p/injector can no longer

be filled.

In either case, no fuel is injected into

the cylinders.

Electrical circuit

J248 D iesel D irect Fuel Injection Engine

C ontrol M odule

N 240 Valve for Pum p/Injector, C ylinder 1

N 241 Valve for Pum p/Injector, C ylinder 2

N 242 Valve for Pum p/Injector, C ylinder 3

N 243 Valve for Pum p/Injector, C ylinder 4

Engine Management

N240 N241 N242 N243

J 248

SSP209/065

45

Engine Management

Pump/injector solenoid valve monitoring

The D iesel D irect Fuel Injection Engine

C ontrol M odule J248 m onitors the electrical

current that actuates the solenoid valves at

the pum p/injectors.

This provides feedback to the D iesel

D irect Fuel Injection Engine C ontrol M odule

J248 of the actual point in tim e w hen

injection begins.

The D iesel D irect Fuel Injection Engine

C ontrol M odule J248 uses this feedback to

regulate the beginning of injection periods

(B IP) during subsequent com bustion

cycles and to detect m alfunctions of the

pum p/injector solenoid valves.

Start of injection is initiated w hen the

pum p/injector solenoid valve is actuated.

A ctuating current applied to a pum p/injector

solenoid valve creates a m agnetic field.

A s the applied current intensity increases,

the valve closes; the m agnetic coil presses

the solenoid valve needle into its valve

seat. This closes off the path from the

fuel supply line to the pum p/injector

high-pressure cham ber and the injection

period begins.

A s the solenoid valve needle contacts its

valve seat, the distinctive signature of an

alternately dropping and rising current flow

is detected by the D iesel D irect Fuel

Injection Engine C ontrol M odule J248. This

point is called the beginning of injection

period (B IP). It indicates the com plete

closure of the pum p/injector solenoid valve

and the starting point of fuel delivery.

Start of injection is the point

in tim e w hen the actuating

current to the pum p/injector

solenoid valve is initiated.

Beginning of injection

period (BIP) is the point in tim e

w hen the solenoid valve needle

contacts the valve seat.

W ith the solenoid valve closed, a holding

current is m aintained at a constant level by

the D iesel D irect Fuel Injection Engine

C ontrol M odule J248 to keep it closed. O nce

the required tim e period for fuel delivery has

elapsed, the actuating current is sw itched

off and the solenoid valve opens.

SSP209/097

Current Pattern - Pump/Injector Solenoid Valve

B eginning of

Injection Period

(B IP) (Valve

C loses)

Tim e

S

o

l

e

n

o

i

d

V

a

l

v

e

A

c

t

u

a

t

i

n

g

C

u

r

r

e

n

t

I

n

t

e

n

s

i

t

y

End of

Valve

A ctuation

Start of

Valve

A ctuation

(Start of

Injection)

Pickup

C urrent

C ontrol

Lim it

H olding

C urrent

46

Engine Management

The actual m om ent at w hich the pum p/

injector solenoid valve closes (B IP) is used

by the D iesel D irect Fuel Injection Engine

C ontrol M odule J248 to calculate the point

of actuation for the next injection period.

If the actual B IP deviates from the m apped

details stored in the D iesel D irect Fuel

Injection Engine C ontrol M odule J248, it w ill

correct the point of valve actuation (start of

injection) for the next com bustion cycle.

To detect pum p/injector solenoid valve

faults, the D iesel D irect Fuel Injection

Engine C ontrol M odule J248 evaluates the

B IP position from the current flow pattern.

If there are no faults, B IP w ill be w ithin the

control lim it. If this is not the case, the

valve is faulty.

Effects of failure

If a fault is detected at the solenoid valve,

start of injection is determ ined based on

fixed values from the control m ap.

R egulation is no longer possible and

perform ance is im paired.

Example

If there is air inside the pum p/injector, the

solenoid valve needle has a low resistance

w hen it closes. The valve closes quickly

and the B IP is earlier than expected.

In this case, the self-diagnosis indicates the

follow ing fault m essage:

B IP below control lim it

47

Engine Management

Change-Over Valve for

Intake Manifold Flap N239

The C hange-O ver Valve for Intake

M anifold Flap N 239 is located in the

engine com partm ent, in the vicinity of

the M ass A ir Flow Sensor G 70.

It sw itches the vacuum for actuating the

intake m anifold flap in the intake pipe.

This stops the engine shuddering w hen

the ignition is turned off.

D iesel engines have a high

com pression ratio.

The engine shudders w hen the ignition is

turned off because of the high com pression

pressure of the induced air.

The intake m anifold flap interrupts the air

supply w hen the engine is turned off. Little

air is com pressed and the engine runs

softly to a halt.

Function

If the engine is turned off, the D iesel D irect

Fuel Injection Engine C ontrol M odule J248

sends a signal to the C hange-O ver Valve for

Intake M anifold Flap N 239, w hich then

sw itches the vacuum for the vacuum m otor.

The vacuum m otor closes the intake

m anifold flap.

2SSP09/068

SSP209/069

0 I

48

Engine Management

Effects of failure

If the C hange-O ver Valve for Intake

M anifold Flap N 239 fails, the intake

m anifold flap stays open.

The tendency of the engine to shudder

w hen sw itched off w ill increase.

Electrical circuit

J217 Transm ission C ontrol M odule

J248 D iesel D irect Fuel Injection Engine

C ontrol M odule

N 239 C hange-O ver Valve for Intake

M anifold Flap

S Fuse

S

J 317

N239

J 248

SSP209/070

49

Engine Management

Relay for Pump, Fuel Cooling J 445

The R elay for Pum p, Fuel C ooling J445 is

located on the engine control m odule

m ounting bracket.

It is activated by the D iesel D irect Fuel

Injection Engine C ontrol M odule J248 at a

fuel tem perature of 158F (70C ) and

sw itches the w orking current for the Pum p

for Fuel C ooler V166.

Effects of failure

If the R elay for Pum p, Fuel C ooling J445

fails, the heated fuel flow ing back from

the pum p/injectors to the fuel tank w ill not

be cooled.

The fuel tank and the Sender for

Fuel G age G can be dam aged.

Electrical circuit

J248 D iesel D irect Fuel Injection

Engine C ontrol M odule

J317 Pow er Supply (Term inal 30, B + ) R elay

J445 R elay for Pum p, Fuel C ooling

S Fuse

V166 Pum p for Fuel C ooler

The O utput C heck D iagnosis

function in the self-diagnosis can

be used to check w hether the

R elay for Pum p, Fuel C ooling

J445 has been activated by the

D iesel D irect Fuel Injection

Engine C ontrol M odule J248.

SSP209/071

SSP209/072

A/

+

S

S

J 445

J 248

J 317

V166

M

50

Engine Management

Wastegate Bypass Regulator Valve N75

The engine has a variable turbine geom etry

for optim ally adapting the charge pressure

to the actual driving conditions.

To regulate the charge pressure, the

vacuum in the vacuum unit for turbocharger

vane adjustm ent is set depending on the

pulse duty factor.

The W astegate B ypass R egulator Valve

N 75 is activated by the D iesel D irect Fuel

Injection Engine C ontrol M odule J248.

Effects of failure

If the W astegate B ypass R egulator Valve

N 75 fails, the vacuum unit reverts to

atm ospheric pressure.

A s a result, charge pressure is low er and

engine perform ance is im paired.

SSP209/075

51

Engine Management

SSP209/075

EGR Vacuum Regulator

Solenoid Valve N18

The EG R Vacuum R egulator Solenoid

Valve N 18 enables the exhaust gas

recirculation system to m ix a portion of

the exhaust gases w ith the fresh air

supplied to the engine.

This low ers the com bustion tem perature

and reduces the form ation of oxides of

nitrogen.

To control the quantity of exhaust gases

returned for com bustion, the D iesel D irect

Fuel Injection Engine C ontrol M odule J248

activates the EG R Vacuum R egulator

Solenoid Valve N 18 w ith duty cycles based

on internal control m aps.

Effects of failure

Engine perform ance is low er and exhaust

gas recirculation is not assured.

Glow Plug Indicator Light K29

The G low Plug Indicator Light K29 is

located in the instrum ent cluster.

It has the follow ing tasks:

It signals to the driver that the pre-

starting glow phase is in progress. In this

case, it is lit continuously.

If a com ponent w ith self-diagnostic

capability becom es faulty, the w arning

lam p flashes.

Effects of failure

The G low Plug Indicator Light K29 com es

on and does not flash.

A fault m essage is stored to the

fault m em ory.

SSP209/077

52

Additional Output Signals

Engine Management

Engine speed

This signal provides inform ation on

engine speed for the tachom eter in the

instrum ent cluster.

Cooling fan run-on

The run-on period of the cooling fan is

controlled according to a characteristic

curve stored in the D iesel D irect Fuel

Injection Engine C ontrol M odule J248.

It is calculated from the current coolant

tem perature and the load state of the

engine during the previous driving cycle.

The D iesel D irect Fuel Injection Engine

C ontrol M odule J248 uses this signal to

activate the cooling fan relay.

Air conditioner compressor cut-off

To reduce engine load, the D iesel D irect

Fuel Injection Engine C ontrol M odule J248

sw itches the air conditioner com pressor off

under the follow ing conditions:

A fter every starting cycle (for

approxim ately six seconds).

D uring rapid acceleration from low

engine speeds.

A t coolant tem peratures in excess of

248F (120C ).

In the em ergency running program .

Fuel consumption signal

This signal provides inform ation on fuel

consum ption for the m ultifunctional display

in the instrum ent cluster.

Coolant auxiliary heater

Thanks to its high efficiency, the 1.9-liter

TD I engine w ith pum p injection system

develops so little heat that sufficient heat

output m ay not be available in

certain circum stances.

In countries w ith cold clim ates, an electrical

auxiliary heater is used to heat the coolant

at low tem peratures.

The coolant auxiliary heater is com prised of

three G low Plugs (C oolant) Q 7. They are

installed to the coolant connection on the

cylinder head.

The D iesel D irect Fuel Injection Engine

C ontrol M odule J248 uses the coolant

auxiliary heater signal to activate the relays

for low and high heat output.

Either one, tw o, or all three G low Plugs

(C oolant) Q 7 are sw itched on depending on

the available capacity of the three-phase

A C generator.

SSP209/084

53

Glow Plug System

Glow Plug System

The glow plug system m akes it easier

to start the engine at low outside

tem peratures. It is activated by the

D iesel D irect Fuel Injection Engine C ontrol

M odule J248 at coolant tem peratures

below 48F (9C ).

The G low Plug R elay J52 is activated by the

D iesel D irect Fuel Injection Engine C ontrol

M odule J248. The G low Plug R elay J52

then sw itches on the w orking current for

the G low Plugs Q 6.

Function

The glow process is divided into tw o

phases, the glow period and the extended

glow period.

Glow Period

The glow plugs are activated w hen the

ignition is sw itched on and outside

tem perature is below 48F (9C ). The G low

Plug Indicator Light K29 w ill light up.

O nce the glow plug period has elapsed, the

G low Plug Indicator Light K29 w ill go out

and the engine can be started.

Extended Glow Period

The extended glow period takes place

w henever the engine is started, regardless

of w hether or not it is preceded by a glow

period.

This reduces com bustion noise, im proves

idling quality and reduces hydrocarbon

em ission.

The extended glow phase lasts no m ore

than four m inutes and is interrupted w hen

the engine speed rises above 2500 rpm .

Glow Plug System Overview

SSP209/099

Engine C oolant

Tem perature

Sensor G 62

G low Plug

Indicator

Light K29

G low Plug

R elay J52

G low Plugs Q 6

D iesel D irect Fuel Injection

Engine C ontrol M odule J248

Engine Speed

Sensor G 28

54

Functional Diagram

EDC 16 Functional Diagram

for 1.9-Liter TDI Engine

Components

E45 C ruise C ontrol Sw itch

F B rake Light Sw itch

F8 Kick D ow n Sw itch

F36 C lutch Vacuum Vent Valve Sw itch

F47 B rake Pedal Sw itch

F60 C losed Throttle Position Sw itch

G 28 Engine Speed Sensor

G 40 C am shaft Position Sensor

G 62 Engine C oolant Tem perature Sensor

G 70 M ass A ir Flow Sensor

G 71 M anifold A bsolute Pressure Sensor

G 72 Intake A ir Tem perature Sensor

G 79 Throttle Position Sensor

G 81 Fuel Tem perature Sensor

J52 G low Plug R elay

J248 D iesel D irect Fuel Injection Engine

C ontrol M odule

J317 Pow er Supply (Term inal 30, B + ) R elay

J359 R elay for Preheating C oolant, Low

H eat O utput

J360 R elay for Preheating C oolant, H igh

H eat O utput

J445 R elay for Pum p, Fuel C ooling

N 18 EG R Vacuum R egulator Solenoid Valve

N 75 W astegate B ypass R egulator Valve

N 239 C hange-O ver Valve for Intake M anifold Flap

N 240 Valve for Pum p/Injector, C ylinder 1

N 241 Valve for Pum p/Injector, C ylinder 2

N 242 Valve for Pum p/Injector, C ylinder 3

N 243 Valve for Pum p/Injector, C ylinder 4

Q 6 G low Plugs (Engine)

Q 7 G low Plugs (C oolant)

S Fuse

V166 Pum p for Fuel C ooler

Additional Signals

A B rake Lights

B Fuel C onsum ption Signal

C Engine Speed Signal

D A ir C onditioner C om pressor C ut-O ff

E A ir C onditioner C om pressor R eadiness

F R oad Speed Signal

G C ruise C ontrol Sw itch Voltage Supply

H C ooling Fan R un-O n

K D iagnosis and Im m obilizer W ire

L G low Period C ontrol

M D rivetrain C A N D ata B us (Low )

N D rivetrain C A N D ata B us (H igh)

O Three-Phase A C G enerator Term inal D F

Color Coding

Input Signal

O utput Signal

Positive

G round

C A N D ata B us

B i-directional

55

Functional Diagram

SSP209/080

30

15

31 31

3

1

B D G

J 317

S S S S

N239 N75 N18

Q7 Q7

J 360

A/+

G70

F60/F8 G79

G28

G81

F F47

E45

G62

F36

J 52

A/+

Q6

G72

C

S

G71

S

S

S

N240 N241 N242 N243

S

G40

E

F

V166

J 445

J 359

A

in out

J 248

H K

L

M

N

O

M

56

Service

Self-Diagnosis

The follow ing functions can be read out

using the Vehicle D iagnosis, Test and

Inform ation System VA S 5051:

01 Interrogate control unit version

02 Interrogate fault m em ory

03 A ctuator diagnosis

04 B asic adjustm ent

05 Erase fault m em ory

06 End of output

07 Encode control unit

08 R ead m easured value block

Function 02 Interrogate fault memory

The color coded com ponents are

stored to the fault m em ory by the

self-diagnosis function.

SSP209/082

SSP209/081

N 240, N 241,

N 242, N 244 F96

J248

J104

V166

Q 6

J445

N 75

N 239

N 18

K29

J217

G 81

G 62

G 79

F8

F60

G 40

G 28

G 70 J52

G 71

G 72

F

F47

57

Service

Pump/Injector Adjustment

A fter installing a pum p/injector, the

m inim um clearance betw een the base of

the high-pressure cham ber and the pum p

piston m ust be adjusted at the pum p/

injector adjusting screw .

This adjustm ent prevents the pum p piston

from knocking against the base of the high-

pressure cham ber due to heat expansion.

For a com plete description of

this adjustm ent procedure,

refer to the R epair M anual.

SSP209/098

H igh-Pressure

C ham ber

M inim um

C learance

Pum p Piston

B all Pin

A djusting Screw

Injection C am

R oller-Type

R ocker A rm

58

Service

Special Tools

Marking Plate

T 10008

H olds the hydraulic toothed belt tensioner

in place w hen installing and rem oving the

toothed belt.

Crankshaft Sealing Ring

Assembly Fixture

T 10053

G uide sleeve and com pression sleeve for

installing the crankshaft sealing ring.

Camshaft Gear Puller

T 10052

C am shaft gear rem oval from the tapered

end of the cam shaft.

Camshaft Gear Counter-Holder

T 10051

C am shaft gear installation.

Crankshaft Stop

T 10050

H olds the crankshaft in place at

the crankshaft gear w hen adjusting

the port tim ing.

SSP209/090a

SSP209/090b

SSP209/090c

SSP209/090d

SSP209/090e

59

Service

Socket Insert

T 10054

Pum p/injector clam ping block fastener

installation.

Pressure Gauge

VA S 5187

Fuel pressure m easurem ent at the supply

line to the fuel pum p.

Shackle

T 10059

This shackle is used to rem ove and install

the engine in the Passat. The engine is

m oved into position using this shackle in

com bination w ith lifting gear 2024A .

Pump/Injector Puller

T 10055

Pum p/injector rem oval from the

cylinder head.

Pump/Injector O-Ring Assembly Sleeves

T 10056

O -ring installation on the pum p/injectors.

SSP209/090f

SSP209/090g

SSP209/090h

SSP209/090k

SSP209/090i

60

Notes

61

Knowledge Assessment

A n on-line Know ledge A ssessm ent (exam ) is available for this Self-Study Program .

The Know ledge A ssessm ent m ay or m ay not be required for C ertification.

You can find this Know ledge A ssessm ent at:

www.vwwebsource.com

From the vw w ebsource.com H om epage, do the follow ing:

C lick on the C ertification tab

Type the course num ber in the Search box

C lick G o!and w ait until the screen refreshes

C lick Startto begin the A ssessm ent

For A ssistance, please call:

Certification Program Headquarters

1 877 CU4 CERT

(1 877 284 2378)

(8:00 a.m. to 8:00 p.m. EST)

O r, E-M ail:

Comments@VWCertification.com

Volksw agen of A m erica, Inc.

3800 H am lin R oad

A uburn H ills, M I 48326

Printed in U .S.A .

O ctober 2003

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)