Professional Documents

Culture Documents

Disadvantages

Disadvantages

Uploaded by

scwanhkerCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Disadvantages

Disadvantages

Uploaded by

scwanhkerCopyright:

Available Formats

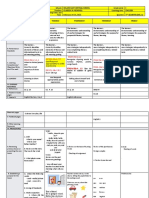

Disadvantages of Gate Valves

1. They cannot be opened and closed quickly. To fully open or close wheel or gearbox actuators, the

shaft should be rotated as many as the full open revolution number. The full open revolution number

is equal to the pitch

2. Assembly, start-up and maintenance require large space.

3. In full closed position, the slow movement of the slide causes high flow speed. Due to vibration

and collision, abrasion and deformation occurs in the seating surfaces and the surface gets damaged

from friction.

4. In systems where high temperature changes irregularly, due to the load in pipe at the valve end,

leakages in gate valves occur.

5. At the place of operation, repair and maintenance of seating surfaces are difficult.

Disadvantages globe valve,

1, fluid resistance, opening and closing force when needed.

2 and does not apply to take larger particles, viscosity, easy coked medium.

3, adjusting performance is poor.

Disadvantages ball valves :

Conventional Ball valves have poor throttling properties

In slurry or other applications, the suspended particles can settle and become trapped in body

cavities causing wear, leakage, or valve failure.

Disadvantages of butterfly valves

The use of butterfly valves for control applications is limited to the valve opening range between

30 degrees to 70 degrees. Throttling using butterfly valves is limited to low pressure drop applications.

Potential cavitation is a concern when butterfly valves are used. Also possibility of a choked flow is a

concern.

Disadvantages of Piston Pumps

Reciprocating pumps give a pulsating flow.

The suction stroke is difficult when pumping viscous liquids.

The cost of producing piston pumps is high. This is due to the very accurate sizes of

the cylinders and pistons. Also, the gearing needed to convert the rotation of the drive

motor into a reciprocating action involves extra equipment and cost.

Ball valves These valves allow quick, quarter turn on-off operation and have poor

throttling characteristics. These valves are also designed to be operated fully open or fully

closed with any liquid containing particles that could scratch the ball. Many people use

them successfully for throttling clear water. Ball valves have low pressure drops, open and

close quickly, are simple, and are trouble free. With the development of Teflon seals, ball

valves have grown in popularity. Opening or closing a ball valve too quickly can cause

fluid hammer.

You might also like

- Animal BehaviorDocument137 pagesAnimal Behaviorrafapedrosaa100% (9)

- Liebherr LTM 1090 1 Wiring Diagram enDocument22 pagesLiebherr LTM 1090 1 Wiring Diagram endavidolson051198pki100% (123)

- Mubarak.. Impact of Jet Lab ReportDocument11 pagesMubarak.. Impact of Jet Lab Reportscwanhker50% (4)

- I Is For InsectsDocument80 pagesI Is For InsectsAlison Steadman95% (230)

- Valve PresentasionDocument26 pagesValve Presentasionynhkng100% (1)

- Define EurocodesDocument2 pagesDefine Eurocodesscwanhker75% (4)

- Valves AssignmentDocument16 pagesValves AssignmentAdil Jutt GNo ratings yet

- ValvesDocument11 pagesValvesJigar BariaNo ratings yet

- Basic Parts of ValveDocument5 pagesBasic Parts of ValveDivyamNo ratings yet

- Types of Manual Valves: TLV Toolbox - For Ios and AndroidDocument5 pagesTypes of Manual Valves: TLV Toolbox - For Ios and AndroidMohsinShaikhNo ratings yet

- Valve Philosophy Valve Application GeneralDocument3 pagesValve Philosophy Valve Application GeneralWade ColemanNo ratings yet

- ValvesDocument27 pagesValveswassliNo ratings yet

- VALVES - NotesDocument17 pagesVALVES - NotesPortifer Harrison Ray Mubanga100% (1)

- Valves in Chemical IndustryDocument14 pagesValves in Chemical IndustryDevendra BangarNo ratings yet

- 2 Equipment DesignDocument26 pages2 Equipment Designshihabz100% (1)

- ةرازو يممعلا ثحبلاو يلاعلا ميمعتلا ةيمك رافلا ا عماجلا يب ة ةمحرملا ةيناثلا: Fluid flow2 ةداملا ريرقت ناونعب Butterfly valve نم بلاطلا لبق باهيا دامح ديلو فارشأب ذاتسلاا: ريملاادبع ةزمحDocument18 pagesةرازو يممعلا ثحبلاو يلاعلا ميمعتلا ةيمك رافلا ا عماجلا يب ة ةمحرملا ةيناثلا: Fluid flow2 ةداملا ريرقت ناونعب Butterfly valve نم بلاطلا لبق باهيا دامح ديلو فارشأب ذاتسلاا: ريملاادبع ةزمحHamzah A. LaftaNo ratings yet

- Typesofvalves 161213105946Document15 pagesTypesofvalves 161213105946shakti sindhuNo ratings yet

- Valves - Hassan ElBanhawiDocument3 pagesValves - Hassan ElBanhawijesus_manrique2753No ratings yet

- Types of ValvesDocument5 pagesTypes of Valvesjeamnard balitaan100% (1)

- Instrumentation Course 2.Document67 pagesInstrumentation Course 2.FACE BOOK100% (1)

- Piping ValvesDocument51 pagesPiping ValvesRohit Kamble100% (3)

- Why Piston Valves Are Better Isolation Shut Off ValveDocument2 pagesWhy Piston Valves Are Better Isolation Shut Off ValveShantanu KulkarniNo ratings yet

- Types of ValveDocument43 pagesTypes of ValvechaitraNo ratings yet

- Valve Types: ClassificationDocument5 pagesValve Types: Classificationskipperz_10No ratings yet

- Technical PapersDocument4 pagesTechnical PapersKanishk PandeyNo ratings yet

- School of Maritime Studies Vels University ThalamburDocument5 pagesSchool of Maritime Studies Vels University ThalamburAayush AgrawalNo ratings yet

- Exhaust Valves: Rocker Operation of Valves Presents Certain ProblemsDocument4 pagesExhaust Valves: Rocker Operation of Valves Presents Certain ProblemscamalielNo ratings yet

- Making of Most of ValvesDocument12 pagesMaking of Most of ValvesShaikh MateenNo ratings yet

- Poppet Valve - Types, Working, Operation, Diagram, Applications, Advantages & DisadvantagesDocument2 pagesPoppet Valve - Types, Working, Operation, Diagram, Applications, Advantages & DisadvantagesAbdul Mohid SheikhNo ratings yet

- Check ValvesDocument17 pagesCheck ValvesGerance Instruccion Piping100% (2)

- Types of Valves in PipingDocument4 pagesTypes of Valves in PipingErza ScarletNo ratings yet

- Valves IntroductionDocument23 pagesValves IntroductionchinnuhodigereNo ratings yet

- Operating Specifications and Precautions For Manual ValvesDocument4 pagesOperating Specifications and Precautions For Manual ValvesMuhammad AwaisNo ratings yet

- Valves Used in Fire Protection SystemDocument20 pagesValves Used in Fire Protection SystemrashalNo ratings yet

- List The Main Features of Globe ValveDocument3 pagesList The Main Features of Globe ValveArvin Rei SanquilosNo ratings yet

- Minggu12 13 PIDDocument19 pagesMinggu12 13 PIDAziz Rizky PratamaNo ratings yet

- Pengetahuan - ValvesDocument8 pagesPengetahuan - ValvesivansanjayaNo ratings yet

- Types of Valves SummaryDocument1 pageTypes of Valves SummarySherwin AgootNo ratings yet

- ValvesDocument12 pagesValvesshiva prasad HyatiNo ratings yet

- Design of A Flow Control Valve: Problem StatementDocument22 pagesDesign of A Flow Control Valve: Problem StatementMohini RajputNo ratings yet

- Fluid Mechanic Assignment OrignalDocument4 pagesFluid Mechanic Assignment OrignalFalcon TechNo ratings yet

- TDCV Om1 6Document18 pagesTDCV Om1 6Metropolitan IndustriesNo ratings yet

- Piping ValvesDocument51 pagesPiping ValvesRohit KambleNo ratings yet

- Lab 11 - Ayesha Noor - Che12ADocument6 pagesLab 11 - Ayesha Noor - Che12Aayesha noorNo ratings yet

- 10 Types of ValvesDocument7 pages10 Types of ValvesLamar TwitchNo ratings yet

- Instrument 5 PDFDocument11 pagesInstrument 5 PDFAli AdnanNo ratings yet

- ValveTypesSelection - ControlsWikiDocument42 pagesValveTypesSelection - ControlsWikiMayur PatelNo ratings yet

- Types of Valve and SupportDocument22 pagesTypes of Valve and SupportViren ParmarNo ratings yet

- Ball ValvesDocument14 pagesBall ValvesMalik DaniyalNo ratings yet

- Steam Stop ValveDocument15 pagesSteam Stop Valveankur raiNo ratings yet

- Isolation Valves - Linear MovementDocument9 pagesIsolation Valves - Linear MovementEmad A.AhmadNo ratings yet

- Process Valv HandbookDocument14 pagesProcess Valv Handbookdenim89100% (1)

- Minggu12 13 PIDDocument19 pagesMinggu12 13 PIDBerdi Nak GbaNo ratings yet

- Minggu12 13 PIDDocument19 pagesMinggu12 13 PIDMuhammad Khairul FikriNo ratings yet

- Valves: Oscar Mauricio Cala Camacho - 2152815 Iván Darío Nova Uribe - 2142795 Facilidades de Superficie Grupo H1 2020-1Document34 pagesValves: Oscar Mauricio Cala Camacho - 2152815 Iván Darío Nova Uribe - 2142795 Facilidades de Superficie Grupo H1 2020-1Oscar CalaNo ratings yet

- Valves in Irrigation Systems: On-Off Service ValvesDocument13 pagesValves in Irrigation Systems: On-Off Service ValvesDaniel CruzNo ratings yet

- Different Valve Types, Applications & SuitabilityDocument10 pagesDifferent Valve Types, Applications & SuitabilityGrazel MDNo ratings yet

- ValvesDocument14 pagesValvesvishnurajrajesh2020No ratings yet

- Diaphragm Valve - Types, Parts, Uses, Working, Application, Material, Advantages & DisadvantagesDocument2 pagesDiaphragm Valve - Types, Parts, Uses, Working, Application, Material, Advantages & DisadvantagesAbdul Mohid SheikhNo ratings yet

- Advantages of Globe ValvesDocument3 pagesAdvantages of Globe ValvesJohn Rey TumalaNo ratings yet

- PDF ValveDocument13 pagesPDF ValveHyperFlickNo ratings yet

- Pump Lose Suction After Some TimeDocument12 pagesPump Lose Suction After Some TimeFahad MaqsoodNo ratings yet

- Basics of Valves 1714449675Document15 pagesBasics of Valves 1714449675Bhaskar KaleNo ratings yet

- Don't Let Slurries Ruin Your SealsDocument5 pagesDon't Let Slurries Ruin Your SealsFaisal DilbaghNo ratings yet

- Popular Mechanics: How to Fix Anything: Essential Home Repairs Anyone Can DoFrom EverandPopular Mechanics: How to Fix Anything: Essential Home Repairs Anyone Can DoRating: 4 out of 5 stars4/5 (2)

- Asphalt Tests: 1.0 Penetration TestDocument10 pagesAsphalt Tests: 1.0 Penetration TestscwanhkerNo ratings yet

- Blowing A Mind Theraphist Is Totally Absurd !Document1 pageBlowing A Mind Theraphist Is Totally Absurd !scwanhkerNo ratings yet

- Introduction To Levelling: "Leveling" Is A General Term Used in Land Surveying ThatDocument50 pagesIntroduction To Levelling: "Leveling" Is A General Term Used in Land Surveying Thatscwanhker0% (1)

- Modul: Politeknik Kementerian Pendidikan MalaysiaDocument6 pagesModul: Politeknik Kementerian Pendidikan MalaysiascwanhkerNo ratings yet

- Trial Pit TesrDocument10 pagesTrial Pit TesrscwanhkerNo ratings yet

- DLL English Q3 Wk2Document9 pagesDLL English Q3 Wk2Clarissa Flores Madlao MendozaNo ratings yet

- Dokumen - Tips Review Text Type ExplanationDocument14 pagesDokumen - Tips Review Text Type ExplanationRamotSilabanNo ratings yet

- Đề Cương Khối Mầm NonDocument189 pagesĐề Cương Khối Mầm Nonthuytien71612No ratings yet

- Life Cycle of A Butterfly & Frog (AutoRecovered)Document2 pagesLife Cycle of A Butterfly & Frog (AutoRecovered)Ayush MukherjeeNo ratings yet

- Soal USBN SMP TQAUDocument12 pagesSoal USBN SMP TQAUNanangHeryanaNo ratings yet

- AK SS G8 T2 Gram Adjec-Adverb PP.121-140Document20 pagesAK SS G8 T2 Gram Adjec-Adverb PP.121-140YASSIEN ELBANNANo ratings yet

- Final Project Climate Change Biology 1 - MinDocument8 pagesFinal Project Climate Change Biology 1 - Minapi-708303783No ratings yet

- Hands-On Science Workbook Primary 4 (Chapter 01)Document7 pagesHands-On Science Workbook Primary 4 (Chapter 01)Sheila YongNo ratings yet

- Butterflyy Lesson PlanDocument2 pagesButterflyy Lesson Planapi-247965295No ratings yet

- Emily Kearny Biology of ButterfliesDocument5 pagesEmily Kearny Biology of ButterfliesCube MaximNo ratings yet

- Demo Butterfly Life Cycle Craft 3 DDiorama Craft Activity 8531748Document12 pagesDemo Butterfly Life Cycle Craft 3 DDiorama Craft Activity 8531748Truvy ColNo ratings yet

- Level 2 Passage 7 PDFDocument3 pagesLevel 2 Passage 7 PDFDeo DelosSantos DelaVirgoNo ratings yet

- A Butterfly SmileDocument15 pagesA Butterfly SmilejenNo ratings yet

- Reflective EssayDocument2 pagesReflective EssayRex RomeroNo ratings yet

- Catarinas 2Document8 pagesCatarinas 2Ginebra ScottNo ratings yet

- Butterfly Life CycleDocument2 pagesButterfly Life Cyclearuna1390No ratings yet

- Text Structure ActivitiesDocument26 pagesText Structure ActivitiesRaquel FiguracionNo ratings yet

- Butterflies and MothsDocument3 pagesButterflies and MothsZoora SavioNo ratings yet

- Lesson Plan Story CatipillarDocument13 pagesLesson Plan Story Catipillarapi-294972079No ratings yet

- Lepis, A Scale, and Pteron, A WingDocument12 pagesLepis, A Scale, and Pteron, A WingmizninaNo ratings yet

- PAS Gnjil XI Bhs Dan Sastra Inggris 2019 - 2020Document21 pagesPAS Gnjil XI Bhs Dan Sastra Inggris 2019 - 2020arif hartoyo50% (2)

- Butterfly Life Cycle Sub FreeDocument13 pagesButterfly Life Cycle Sub Freechad2904_297294572No ratings yet

- VCLA Reading PracticeTest 0111Document31 pagesVCLA Reading PracticeTest 0111ploteusNo ratings yet

- Hokey Pokey With ShapesDocument6 pagesHokey Pokey With ShapesQueenieNo ratings yet

- 10 Animals Totems PowerDocument22 pages10 Animals Totems PowerCarmem67% (3)

- Butterfly Cycle Lesson With TechnologyDocument4 pagesButterfly Cycle Lesson With Technologyapi-338784936No ratings yet

- Simulacro 2017Document4 pagesSimulacro 2017RonaldEscorciaNo ratings yet