Professional Documents

Culture Documents

Momentum 2 2012.ashx

Momentum 2 2012.ashx

Uploaded by

mohammadazraiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Momentum 2 2012.ashx

Momentum 2 2012.ashx

Uploaded by

mohammadazraiCopyright:

Available Formats

1|e maai|re lar ||e emj|a,ees, c+s|amers ara |e, s+jj||ers al H-l \\t0, a c||+m|erer camjar, \a|+me 1:,

:, |+m|er ! !1!

www.miswaco.slb.com

MOMENTUM

STEM Providing a global standard

for ES Equipment maintenance

EDITOR:

Rich Cook

CONTRIBUTORS TO THIS ISSUE:

Marcelo Amaral, Rio de Janeiro,

Brazil

Diane Andrade, Aberdeen, UK

Caitlin Armstrong, Calgary,

Canada

Joe Bacho, Houston, TX

Nikki Botha, Cape Town, South

Africa

Beth Brewer, Denver, CO

Cheryl Cook, Florence, KY

Nestor Daboin, Mexico City,

Mexico

John Decaire, Houston, TX

Jeff Dierig, Florence, KY

Marc Eigner, Dubai, UAE

Stella Espinheiro, Karachi,

Pakistan

Tim Farrell, St. Johns, Canada

Rune Folkvord, Sandnes, Norway

Gary Fout, Houston, TX

Shawn French, Houston, TX

Dan Jefferson, Houston, TX

Renaud Joubert, Houston, TX

Ben Kimball, Singapore,

Singapore

Michal Klunder, Warsaw, Poland

Katie Larg, Calgary, Canada

Janet LeFavre-Hall, Houston, TX

Linda Lindenberg, Houston, TX

Filipe Liporace, Rio de Janeiro,

Brazil

Alan MacLean, Houston, TX

Barbi Messier, Houston, TX

Joan Nunez, Abu Dhabi, UAE

Sylvester Nwadugbo, Lagos,

Nigeria

Steve Orr, Houston, TX

Ben Paiuk, Houston, TX

Colin Patterson, Aberdeen, UK

Bernard Pimentel, Singapore,

Singapore

Kenny Rait, Takoradi, Ghana

Ramy Rashad, Abu Dhabi, UAE

Denise Reeves, Houston, TX

Todd Reid, St. Johns, Canada

Trine Roald, Sandnes, Norway

Jeff Russo, Lafayette, LA

Carla Salomo, Rio de Janeiro,

Brazil

Jaci Seram, Rio de Janeiro,

Brazil

Dave Sorter, Florence, KY

Vic Still, Dubai, UAE

Gustavo Villarroel, Municipio

De Centro, Mexico

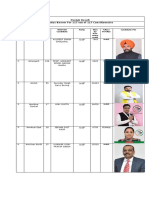

3 LETTER FROM THE

PRESIDENT

Joe Bacho introduces himself

as the new President of

M-I SWACO.

5 WORLD

MOMENTUM

Transocean memorializes

Deepwater Horizon, Still

together after all these years,

Oileld skills to serve others,

M-I SWACO celebrates 3 years

working with OGX, Aberdeen

PCG runs 10k, New ofces

in Ghana.

16 CONTINUOUS

IMPROVEMENT

30 Black Belts, 85 Orange Belts

and 702 White Belts company-

wide, New belt recipients,

Demand Planning.

CONTENTS

MOMENTUM

Cover photo: The STEM program has helped the Scott, LA workshop organize its entire yard, enabling better

management of their entire inventory.

20 UP CLOSE

Tony Clarke and Eric Heath

talk about the ES maintenance

program STEM.

25 TRADE SHOWS AND

CONFERENCES

OTC, ENVIROTHERM NT wins

Harts E&P Award, 2Q and

3Q shows.

26 QHSE

Slop water problems?, First PWM

job in Brazil a success, Eastern

Canada reaches a new milestone

in safety, Pakistan reaches 10

years with no LTI.

32 TECH ROLL CALL

STEM success in LA and Latin

America, Specialized Tools

provides solutions in Brunei,

A bold step into Kenya with

solids control, Poland gaining

momentum.

43 AUTHORS AND PAPERS

41 papers written or presented in 2Q.

45 CAREER DEVELOPMENT

AND TRAINING

Brazil customer DFS, Spanish mud

school graduates 27, Houston

graduates 82 from Basic Mud

School in May and 21 in March,

VSAT classes held in Oklahoma

and Scotland.

48 AWARDS AND

ANNIVERSARIES

Fernando Lopez earns his 10 Year

Service Award, 500 employees reach

service anniversaries.

9

30

2 Momentum

36

14 25

A

llow me to introduce myself. My name is Joe Bacho and I am honored to assume

the role of President of M-I SWACO as Steve Orr is now serving as President of

the Schlumberger Drilling Group. In addition, M-I SWACO has now joined the

Drilling Group as a segment. I look forward to the opportunities that this alignment

presents M-I SWACO, and us as employees, as we establish Schlumberger as the number

one drilling service company.

I joined Magcobar in 1977 as a mud logger. I am a geologist by education and have

worked in the drilling uids segment, holding just about every eld service and

management position throughout the Rocky Mountain region. After a stint in the Global

Technical Service Group in Houston, I returned to the Rockies to run US Land across all

business lines. I moved back to Houston a few years later to serve as VP of Fluids for the

Western Hemisphere, then became Global Fluids VP. In 2006, I was asked to lead the North

American (NAM) team and held this role until May 1.

In this role, I was privileged to lead a highly motivated and skilled management

team, and its dedicated and hardworking employees. I am extremely proud of what

we accomplished together in the past six years during some very challenging market

conditions. I look forward to the opportunity to lead M-I SWACO and work with our skilled

and hardworking teams throughout the world.

As we face new challenges and changes ahead, let me assure you that our strategy,

direction and focus remains unchanged. The foundation of our strategy and what makes

M-I SWACO successful has always been our relentless customer-focused, solutions-

driven culture. Even now as we become an integral part of the Schlumberger Drilling

Group, this will not change and will be even more critical to our future success.

Our culture is supported by the quality of our products and service offerings. However,

products and services alone are not enough. To further support our customer-focused,

solutions-driven culture, we must continue to provide the industrys best trained,

qualied and motivated personnel along with cutting-edge technology that creates value

for our clients.

We have developed world-class infrastructure with a solid global footprint that enables

us to efciently deliver our products and services around the world. That infrastructure

will remain and grow. And nally, we must keep in mind our commitment to a QHSE

culture, where we are committed to do no harm to people or the environment.

TO OUR EMPLOYEES, CUSTOMERS AND SUPPLIERS

Joe Bacho

M-I SWACO President

3

Continued on page 4

In the short term, we are focusing on objectives through Strengthening the Core.

First, it is critical that our core business at M-I SWACO is strong and healthy. A healthy

core business provides the funding, critical mass, and generates the organizational

support for investment that is key to our success.

Next, we will customize and adapt the core business geographically to

capitalize on emerging and evolving market opportunities such as global

shale development, deepwater and arctic exploration.

Third, we want to continue to expand the core business through vertical

and horizontal integration in business such as completions and production

services. We have signicant room to run in this market space, stand-alone

and in conjunction with a number of the Schlumberger segments.

And nally, we must continue to evolve M-I SWACO through innovative

and imaginative business models such as risk reward, pay for performance,

packaging of complementary services and partnerships with third parties.

This has always played a key role in our success in the past and will continue

going forward.

Our aspiration, along with all of Schlumberger, is to achieve revenue and

earnings growth rates greater than our competitors, or as I like to more simply

state it, Beat the Competition. We have the nancial strength, human capital,

infrastructure, technology and skill to execute this strategy; we just need to

seize the opportunities and do so!

I welcome the challenges that lay ahead for me personally and for M-I SWACO. I know

I have a strong management team behind me and a 16,000-strong workforce around the

world that believes in our strategy and works hard every day to Beat the Competition.

Joe Bacho

M-I SWACO President

Continued from page 3

Our strategy, direction

and focus remain

unchanged. The

foundation of our

strategy and what makes

M-I SWACO successful

has always been our

relentless customer-

focused, solutions-

driven culture.

4 Momentum

World Momentum 5

World Momentum

Transocean memorializes Deepwater Horizon fallen with new rig

O

n April 20, 2010, at 9:49 p.m., the Transocean

drilling rig Deepwater Horizon was struck by an

explosion, taking the lives

of eleven crew, including two

M-I SWACO employees, Gordon

Jones and Blair Manuel.

On April 20, 2012, at 9:49 p.m.

CDT, Transocean raised a commem-

orative ag over all of their rigs

and business locations throughout

the world. Flags ew until

10:00 a.m. CDT on April 22, the

approximate time at which the

Deepwater Horizon was lost to

the sea.

To further commemorate the

fallen crew, Transocean named their

newest rig in honor of these men.

The Transocean Honor is rigging up for operations offshore

Malongo, Cabinda Province, Angola. Aboard the TOI Honor,

a wreath-laying ceremony was

held to commemorate the lost

crew. Eleven ower wreaths, each

bearing the name of a Deepwater

Horizon crew member, were

released to the sea by a member

of the parent company of those

who perished.

As the wreaths were released,

attendees echoed sentiment

from Transocean and M-I SWACO

worldwide, saying, We remem-

ber and honor the Deepwater

Horizon crew and their families.

We will never forget.

Eduardo Manuel, left, and Ekanem Mbat, right, prepare

to release the wreath to honor their fallen M-I SWACO

brethren.

Honored were:

Jason Anderson, Toolpusher, by William Meldrum, Transocean

Dewey Revette, Driller, by Donald Mackay, Transocean

Dale Burkeen, Crane Operator, by Nikolajs Zaiceves, Transocean

Donald Clark, Assistant Driller, by Soeharto Wagiu, Transocean

Stephen Curtis, Assistant Driller, by Mladen Sarajlic,

Transocean

Wyatt Kemp, Derrickman, by Pedro Morais, Transocean

Karl Kleppinnger, Floorhand, by Joao Nunvo, Transocean

Shane Roshto, Floorhand, by Moises David, Transocean

Adam Weise, Floorhand, by Pedro Nbanza, Transocean

Gordon Jones, Drilling Fluid Specialist, by Eduardo Manuel,

M-I SWACO

Blair Manuel, Drilling Fluid Specialist, by Ekanem Mbat,

M-I SWACO

8

th

Annual Denver Customer Appreciation Crawsh Boil

The 8th Annual Customer Appreciation Crawsh Boil

was held by M-I SWACO and Schlumberger in Denver,

CO, on Apr. 27. This event has become one of the annual

highlights of the Rocky Mountain oileld. Over 800

customers attended and 2,300 lb (1,043 kg) of crawsh,

175 lb (79 kg) of sausage and 400 steaks were con-

sumed. This years weather started out cloudy and

ended up being sunny with a high temperature of 66 F

(19 C). A wonderful time was had by all, and visiting

went well into the evening. Our customers are already

talking about next years Crawsh Boil. Until next year,

Laissez Les Bon Temp Rouler!

ES Regional Manager for the Western and Northeast areas, Mike

Huval, wearing the red hat, joined the Bluekrewe band and played

the washboard.

6 Momentum

W

o

r

l

d

M

o

m

e

n

t

u

m

Left and right: Arvind Patel

Left and right: Emanuel Stamatakis

Jim Friedheim Jim Friedheim and Emanuel

Stamatakis

I

n early 1987, Arvind Patel, Emanuel Stamatakis and

Jim Friedheim, stepped foot in the North Course lab for

the rst time, relocating their ofces into one location.

Twenty-ve years later, all three are still working together

in the lab. Between them, they have produced over 100

products, written or coauthored 123 technical papers and

produced 65 patents.

Although they have worked together in the lab for the

last 25 years, Emanuel has been with the company for 35

years, Arvind for 31 years and Jim for 28 years. Collectively,

that is a combined total of 94 years experience.

Nowadays, you dont see too many people reach-

ing the 25-year mark in the same lab, says Stamatakis,

recognizing the much higher turnover rate as lab person-

nel move within the Schlumberger organization or on to

other opportunities.

Emanuel, Arvind and Jim are proud of their 25-year mile-

stone together, and what they have been able to accom-

plish for M-I SWACO, both despite and because of changes

in technology and processes.

In those days, said Patel, we were not allowed to type

up our lab notes. We could only have our handwritten

notes. There was a great fear that the typed notes could fall

into the wrong hands and our hard work would be lost to

the competition.

In the beginning, the three were able to work on the proj-

ects and products that they wanted to. They were not

as constrained and were able to respond quickly to

the needs of the eld.

We have always been responsive to the eld,

said Friedheim.

In fact, one product was developed virtually in a

week in response to a need from the eld. Most of the

products the three developed took months of plan-

ning, trial-and-error, testing and retesting both in the

lab and the eld; some took much less time.

We developed the DEFOAM-X

low-toxicity

defoamer in what seemed like one afternoon, said

Friedheim. In reality, it took about a week. We got a

call from the eld on Monday and had the new prod-

uct approved and in the eld by the end of that week.

Back in those days, testing parameters were less

involved than they are today but the fact that so

many of the products created have stood the test of

time is testimony to the development process.

The biggest drivers throughout the years have

been to create products that had less impact on the

environment and do so while costing less and being

more efcient.

Creativity is the key to solving problems,

Stamatakis said.

One of the biggest differences between the early

days and today is how they went about doing much

of their research.

We did not have the internet easily available at

that time and therefore we spent more time in the

laboratory working on chemistry, said Patel. Now,

we spend more time on the computer, some time on

the internet instead of the laboratory. Of course, it

has both advantages and disadvantages. For example,

we use to spend more time in laboratory to do labora-

tory research; however, we used to spend lots of time

to do literature search in library. The availability of

internet search engines has made literature search

Still together after all these years

Continued on page 8

Through the years

World Momentum 7

Products:

DRIL-KLEEN

: Surfactant for anti-bit balling

(patented, 1997)

DEFOAM-X

: Defoamer surfactant for water base mud

(1989)

FAZE-MUL: Amine-based reversible invert emulsier for

FAZEPRO

(patented, 2004)

FAZE-WET

: Phosphate ester oil-wetting agent for

FAZEPRO

KLA-KURE

: Amphoteric shale inhibitor (patented,1995)

VERSA HRP: Oil mud viscosier (patented, 1989)

KLA-GARD

: Environmentally safe shale inhibitor

(patented, 1999)

KLA-STOP

: Polyamine shale inhibitor (patented, 2005)

MEGAMUL: Amido-amine invert emulsier for

MEGADRILL system (2010)

MUL-HTP

: Amine-based invert emulsier for negative

alkalinity OBMs (patented, 1999)

NOVAMUL

: Amido-amine emulsier for NOVA syn-

thetic-based drilling uids (1993)

RHADIANT

system: ULTRA HTHP oil-base system (2011)

MUL XT: EMI-2184 Emulsier for ULTRA HTHP OBM

(2011)

Packer Fluid: ULTRA HTHP Insulating Packer Fluid for

TPAO in Turkey (2011)

ALPINE PA-10: New environmentally improved lubricant

designed for use in offshore drilling (2012)

Shale Gas Fluid: Developed a water-base drilling uid

for the Marcellus shale formations. New uid uses nano

particle for improved performance (2011)

EMI-1743: KLA-GARD powder product (2007)

ULTRADRIL

system: High-performance water-base mud

system (2005)

KLA-GARD: Environmentally safe shale inhibitor

BUBBLE BUSTER

: Defoamer

POLY PLUS RD

: Developed the POLY PLUS RD from

POLY PLUS

Papers:

Dixit, Rahul and Patel, Arvind, Design and Development

of a Novel Process to Treat Drilling-Fluid Slops: A Positive

Environmental and Economic Impact. SPE Drilling &

Completion (Mar. 2010) 53.

Mettath, Sashikumar; Patel, Arvind; Stamatakis, Emanuel,

and Young, Steve. Non-Asphaltic, Fluid-Loss-Control Agent

for High-Temperature Applications in Synthetic-Based

Invert Emulsion Drilling Fluids. AADE-11-NTCE-29, AADE

Fluids Conference, Houston, TX, Apr. 1214, 2011.

Patel, Arvind D. and Stamatakis, Emanuel. Design

of Highly Inhibitive Water-Based Drilling Fluid for

Environmentally Sensitive Land Drilling Applications.

Royal Society of Chemistry: Chemistry in the Oil Industry

XI: Regulation Meets Innovation Moving Forward.

Manchester, England, Nov. 24, 2009.

Patel, Arvind; Stamatakis, Emanuel; Young, Steve and

Friedheim, Jim. Advances in Inhibitive Water-Based

Drilling Fluids Can They Replace Oil-Based Muds? SPE

106476, SPE International Symposium on Oileld Chemistry,

Houston, TX, Feb. 28Mar 2, 2007.

Schlemmer, Robert; Patel, Arvind; Friedheim, Jim and

Young, Steve. Progression of Water-Based Fluids Based

on Amine Chemistry Can the Road Lead to True Oil Mud

Replacements? AADE-03-NTCE-36, AADE National Drilling

Technology Conference, Practical Solutions for Drilling

Challenges, Houston, TX, Apr. 13, 2003.

Arvind Patel, Jim Friedheim and Emanuel Stamatakis, still together

in the lab after 25 years.

Just a few products and papers from

Patel, Friedheim and Stamatakis

8 Momentum

W

o

r

l

d

M

o

m

e

n

t

u

m

Executive managers practice safe driving at

Q1 managers meeting

S

teve Orr and the M-I SWACO executive staff

attended a four-day managers meeting in

Kellyville, OK, in Q1. Unlike most quarterly

managers meetings, the group did not gather to

focus on nancial reporting. Instead, they met

to discuss driving safety and to practice accident

avoidance techniques.

The rst day was a full-day management meet-

ing, said Alan MacLean, VP of QHSE, but unlike

normal meetings, there was no discussion of

nancials. Instead, we talked safety, particularly

driving safety, because that is one of our highest

risk activities.

The remaining three days focused on classroom

training, extended commentary drives and prac-

ticing emergency avoidance maneuvers on the

Kellyville track and skid pan. The executives each

drive the customized Ford F250 that is outtted with

a steerable rear axle. The instructor sits in the pas-

senger seat and controls the rear axle with a joystick. The

driver must counter-steer to keep the truck on the track.

The executives were also challenged in a special car

that could lock brakes on either the front or rear wheels,

simulating different driving emergencies. They learned

and practiced proper counter-maneuvering techniques.

On the drop-wheel simulator, they practiced proper han-

dling of a vehicle if a wheel drops off the road.

Even at 10 mph, said MacLean, a truck will spin if

you drop a wheel and jerk the steering wheel to pull

back onto the road. The proper technique is to take your

foot off the accelerator and slow the vehicle until you

stop. Then carefully and slowly pull back onto the road.

Each attendee was also required to drive, back and

park a medium-duty truck with a gooseneck trailer

attached. Many of the new M-I SWACO systems, includ-

ing the AQUALIBRIUM

water treatment system, are

mounted on trailers with this type of truck-bed mounted

swivel hitch.

The whole idea was to get the executives from around

the world committed to safety, especially driving safety,

and show the leadership commitment, said MacLean.

At the conclusion of the event, each member of the

executive staff signed two large, orange trafc cones

emblazoned with 2012 Executive Management Meeting,

Kellyville, OK. One cone will be put on display at the

North Course facility while the other cone will be sent to

locations throughout the world to be put on temporary

display. The cones will serve as reminders to drive safely

and that the entire executive management team is put-

ting its full support behind the initiative.

Left: VP ES Production Mike Tangedahl waits his turn to drive the customized

Ford F250. Other members of the executive staff wait with him. Right: All of the

members of the executive staff signed two trafc cones to demonstrate their

commitment to driving safety. One is on display at the North Course building.

The other is being sent around the world to be displayed at various ofces.

much easier and quicker and save lots of time. Which

is better? It depends upon how you use the time

you saved.

And creativity led them to develop numerous prod-

ucts that have solved a litany of oileld problems. But of

all of the hundreds of products they have created, they

are most proud of the development of the synthetic

family of uids, from the NOVA products to the recent

RHELIANT PLUS

uid. Second to the synthetics is the

development of the ULTRADRIL

water-base mud.

The ULTRADRIL water-base mud is still being used

today, Friedheim said. And still providing signicant

revenue for M-I SWACO.

While proud of their accomplishments, Emanuel,

Arvind and Jim agree they still have a lot of work to do

and many goals to achieve. Chief among their outstand-

ing goals are the development of a water-base mud that

is as good as an oil-base mud, a conductive oil-base mud,

and an oil-base mud that is truly breakable and then can

be reformed. The latter has applications on the environ-

mental side (ESAR), an oil-base mud that you could break,

clean up and then reform as a drilling uid very quickly

and effectively.

So while styles have changed and theyve seen many

colleagues come and go, Friedheim, Patel and Stamatakis

continue their work developing new and better products

to enable customers to drill faster, further, safer and with

less cost to the bottom line and to the environment.

Continued from page 6

World Momentum 9

R

une Folkvord enjoys his time off from his

work aboard the Gullfaks C production and

drilling platform in the Norwegian North

Sea. When not on the rig, Folkvord enjoys the

beauty of Norway, skiing and camping. He joined

Anchor Drilling Fluids in 1983 as a drilling uids

engineer and while he hasnt changed compa-

nies, the companies have changed around him.

Time off from working on an offshore Norway rig

Im still in same company, he said, but dif-

ferent owners have changed the name on my

coverall several times until now as M-I SWACO, a

Schlumberger company. Before Gullfaks C, I worked

on different drilling/production platforms like semi-

submersibles, jack-ups and also once at a land rig on

Spitsbergen in Arctic.

(All photos by Rune Folkvord.)

Runes wife, Leena, walking across ice ows of a frozen lake.

Left: The maximum

sun height on the

shortest day of the

year in Norway. Photo

taken about 600 m

above sea level in

Ryfylke, close to

Stavanger, Norway.

Below: Rune Folkvord

camping out in a

snow cave.

M-I SWACO hosts golf tourney in Dubai

Recently, M-I SWACO hosted the inau-

gural golf challenge match between

Weatherford and M-I SWACO in Dubai.

The contest was in a match play format,

with six players from each side, result-

ing in the scores being level at the end.

However, Weatherford won the trophy

by way of a count back, from an indi-

vidual stableford contest played at the

same time.

A stableford round scores points

based on the number of strokes taken at

each hole, with the objective of earning

the highest score; more points are given

in relation to par.

A return match will be scheduled for

the fourth quarter and M-I SWACO plans

to win the trophy for the rst time.

The Weatherford team celebrates their win while the M-I SWACO team plots

their strategy for next time.

10 Momentum

W

o

r

l

d

M

o

m

e

n

t

u

m

G

rowing up in America, we have been given an

opportunity, a choice and a chance. With quality

infrastructure, healthcare and schools, it is no

wonder the U.S. has been one of the most sought after

countries to live in. This was increasingly evident to me

after two mission trips to Haiti in 2006. The rst was

to continue building an orphanage and the second

sprang from the greatest need that was ever present

in Haiticlean water.

Most water sources are from unclean surface water,

which is not the best source of drinking water. Seeing

the locals drink this dirty water weighed on me heavily

during that week, but fortunately an opportunity pre-

sented itself. While walking back from a church service

one afternoon, I saw a water-well drilling truck driving

through the local Haitian town and thought if a water-

well drilling truck could get to Haiti, then we can raise

the money to put a well in at the orphanage.

After leaving, raising the money was the easy part;

nding a water-well drilling company to drill the well

was the challenge. Another door was opened and the

incredible people at Living Water International (LWI)

Putting oileld skills to work for faith

By Shawn French, Business Development Manager, Houston, TX

Clean water

transforms.

According to sta-

tistics from LWI,

every 15 seconds

a child dies from

water-related

disease, 1.8 million

children die from diarrhea every year and 884 million

people in the world lack access to safe water. LWI does

not see this as a problem; they see an opportunity, a

chance to change communities (then nations) with

water and a word from God. They bring water to quench

the thirst and the soul.

This past February, I was able to join LWI and

Kingsland Baptist Church on one of their many well

drilling trips. This time we were able to go the beauti-

ful city of Las Tablas, El Salvador. Another community

changed with access to clean water. The amazing thing

about these trips is the change that takes place in me,

by the people I meet. Even with language barriers and

cultural issues, a bond is formed. The one thing that is

Houston mission team and El Salvador drilling team at well in

Las Tablas. Top row: Shawn French, M-I SWACO; Clay Lewis,

ExxonMobil; Jason Hall, Apache Corp; Jim Coleman, HMI; Omar

Garcia, Kingsland Baptist Church; Randy Beard; Carter Moore,

nephew of Stanley Moore. Bottom row: Lloyd Dunlap, BP; Kike,

Fernando, Jeremiah with LWI.

Lloyd Dunlap, BP, shows a child in village of Las Tablas how to pump

water from the well.

Taking a much needed break from the sun

inside an under-construction mud home.

(www.water.cc) in Houston were standing on the

other side. Eight months later, with the help of

LWI, a well was put in the ground in Perches, Haiti,

and is still providing clean drinking water for that

community.

Clean water means lives changed. A quote from

LWI states, Every $1 invested to water and sanitation

generates on average an $8 return in the form

of time saved, increased productivity and reduced

health costs.

true of my travelswhether to a water-well drilling site or

to a deepwater rig offshoreis that no matter where you

live, we all have basic needs. Physical and spiritual thirst

knows no limits. With organizations like Living Water

International, men, women and children all over the world

are beneting from people that will go the extra mile to

help, to offer water and a word.

World Momentum 11

Top: Each employee received a jar of special

M&M candiessome in M-I SWACO orange,

others in Schlumberger blue and Smith green.

Above: The open work areas make it easy to

collaborate on projects and share experience

or ideas with coworkers. In the back are Erika

Scott, LAM accountant, and Delilah Dehoyos,

accounting clerk. Front are Tamara Laughery,

management accountant; Sandy Reyes, senior

accounting clerk; Ezra Carpenter, summer

intern; Rebecca Lee, a temp lling in for Lisa

Jan. Left: A month birthday celebration is held

for the entire staff in the 1200 Club. Anyone

who is celebrating a birthday is recognized

with their name on the whiteboard. The

celebrations facilitate community at the

Houston Financial Hub.

M-I SWACO Finance and IT groups move to new Schlumberger

Houston Financial Hub

B

eginning in early April, members of

the M-I SWACO Finance and Business

Systems (IT) groups moved from

the North Course ofces to a new build-

ing a few miles away at 1200 Enclave. The

new Schlumberger Houston Finance Hub

became the center of all things nancial

and technical for the legacy Schlumberger

companies, including Smith and M-I SWACO.

The Hub is designed with an open layout

to allow greater collaboration and to facilitate integra-

tion between the various nance team members. A year

and a half into the integration of Smith, M-I SWACO and

Schlumberger, both the nance and business systems

groups are still nding ways to work better together.

The workspace layout, said Andrea Shaffer, Houston

Financial Hub manager, was created to help our teams

work together in a more collaborative way. Each group

knows their own processes and we hope that this layout

will encourage a faster integration through cross commu-

nication and training.

All four oors also have numerous small meeting/

huddle rooms and gathering areas where teams can gather

to discuss challenges and nd solutions. One type of area

provides network plugins for up to six computers, each

with a puck device that allows that computer to control

the big-screen television at the end of the table. Whether

at their desks or in the meeting rooms, teams like the

M-I SWACO Business Systems group are better able to work

together on projects.

I only saw my team at our weekly meetings, as

they were always behind cube and ofce walls, said

Christopher Gilbert, M-I SWACO IT Program manager.

Now, I can easily see them and greet them every morning,

as I move through the ofce.

It started with a pilot group of 20 people who moved in

right before March month-end.

The bulk of the employees moved

in during the week of April 16th,

phasing in the groups by oor.

The Houston Financial Hub will

eventually seat 600 people but is

currently seating about half that.

Floors 3 and 4 each have space

for 180 people. On the sixth oor,

the former executive confer-

ence room has been converted

into a Hub Caf named the 1200 Club, which has several

large refrigerators, microwaves and kitchen facilities. Each

oor has two break room areas with a refrigerator and

microwave where employees and visitors can

get coffee, tea and water.

The 1200 Club on the sixth oor has about 24

tables for employees to enjoy lunch. Also in

the area is a foosball table, a ping pong table,

a pool table and a Wii game console on a big

screen TV. Several other televisions run news

and other programing throughout the day.

Just off the 1200 Club is a large training room

that will be used to run the Lean training programs

in the coming months, as well as other training.

The location of the Financial Hub, a few miles south of

the I-10 corridor in West Houston, outside of Beltway 8, was

chosen as a result of an analysis of employee ZIP codes.

When researching appropriate locations, the planners

analyzed ZIP codes of all of the employees who would be

moving to the location. From that data, they determined

the best area that would keep the commute reasonable for

most people.

In addition to a gym facility on site and the 1200 Club, the

building is across the street from Terry Hershey Park, a

popular green space with jogging trails and picnic areas.

12 Momentum

W

o

r

l

d

M

o

m

e

n

t

u

m

T

he VSAT Team was called upon to aid Capital Sales

in closing a multi-rig package deal. Through much

collaboration and teamwork, Bobby Farmer, NAL

screen sales manager, Jeff Russo, VSAT team leader, and

Chris Stagg, capital equipment sales, targeted Felderhoff

Brothers Drilling in an attempt to gain sales on a

broader scale and build on an already existing relation-

ship. The sequence of events leading up to our successes

with Felderhoff Brothers Drilling marks textbook

Teamwork 101 at its best.

Felderhoff Brothers Drilling has approximately 18

land rigs operating at this time spanning from New

Mexico through Odessa, TX, into Ft. Worth, TX. They are

currently building three additional new rigs. Felderhoff

rigs are equipped predominantly with competitor

shakers. Felderhoff advised they found it difcult to get

the attention they needed from the rig manufacturers

representatives and were looking to establish a better

working relationship with an organization that offered

continued service beyond the sale. Through the con-

tinued efforts of Chris Stagg, an opportunity presented

itself and M-I SWACO was ready to answer this call.

On May 23, 2011, Bobby Farmer and Chris Stagg met

with Felderhoff VP of Operations Danny Crow and

discussed the Warranty Program to which M-I SWACO

would extend competitive shaker basket warranties

additionally and up to ve years from the born on date.

The Warranty Program starts off with a full vibratory

systems analysis and test on the shakers; a VSAT report

outlines areas of concern and details shaker inadequa-

cies needing attention that would bring the shaker

back up to manufacturer specs. This is followed up with

an ofcial warranty inspection. During this phase the

inspector is ensuring that the shaker is up to par and the

playing eld is level in that our screens are being given

the best platform for which to perform optimally. Upon

completion of a successful warranty inspection, the

customer is signed up and the extended shaker basket

warranty begins immediately.

The benet to the customer is the extended warranty

program is at no charge as long as M-I SWACO screens

are being used. Periodic visual inspections where

competitive screens are observed to be in use void the

warranty immediately.

On May 26, 2011, Danny Crow asked for information

regarding advantages and benets of MONGOOSE

PT

shakers and how the VSAT Program ts into the pur-

chase of new shakers. Chris Stagg was able to answer

these questions both verbally and with literature.

This sparked enough interest and led to the NAL

VSAT Team unites with Capital Sales to make a big impact

By Jeff Russo, VSAT Team Leader

Screen Sales Group to build a shaker screen warranty/

maintenance proposal that Bobby hand-delivered to

Danny Crow, when Bobby hosted a presentation in

Abilene, TX, to approximately 30 members of Felderhoff

rig personnel, inclusive of the night Tool Pusher crews.

The presentation covered the warranty program as

well as shaker best practices. One week prior to this

presentation, Jeff Russo and Chris Stagg hosted a pre-

sentation in Abilene, TX, for Danny Crow, rig superin-

tendents and approximately 45 members of Felderhoff

rig personnel as well as the day Tool Pusher crews. This

presentation covered the VSAT Program and shaker best

practices, and Q&A was elded from the audience as

they inquired about M-I SWACO services and products.

As of late, Danny Crow asked the team to present

our warranty

program to OXY.

While we are cur-

rently working

with OXY, who is

forecasted to go

from 14 to 25 land

rigs up and run-

ning by the end

of 2011 and then

from 25 to 31 rigs

by April, could

award M-I SWACO

the lions share if

not all the screen

business. But a

meeting as this

only continues

to solidify our

company and our

brand in the industry and in the market.

We have conducted three VSAT inspections on

Felderhoff rigs and are in the process of signing all

of their rigs up in the warranty program as we go.

M-I SWACO has since sold 10 MONGOOSE shakers and

one mud cleaner, and should recognize signicant rev-

enue annually in screen sales in addition to the strong

six gures in equipment sales thus far.

Of the 10 shakers sold, this only encompasses four

rigs of the 21 Felderhoff rigs thus far. It is our intent to

continue to cultivate our relationship with Felderhoff by

offering nothing less than excellence and delivering the

attention theyve sought after for so long in competi-

tors, on an orange platter. Team work at its nest!

The NAL Screen Sales and VSAT

Group would like to introduce

and welcome our newest

addition, Storm McFarland,

to Technical Screen Sales who

will be working out of the

Houston ofce to offer support

as it relates to screen portions

of tenders and gain additional

screen business. Storm comes

from the screen sales division

and has shared many successes

in screen sales and putting the

customer needs rst. Storm

McFarland: 903-952-0590,

JMcFarland3@miswaco.slb.com

World Momentum 13

M-I SWACO celebrates three years working with OGX in Brazil

During the OTC show in Houston, M-I SWACO President Steve

Orr met with Ricardo Juiniti, OGX executive manager, and

Reinaldo Belotti, OGX production ofcer, at the North Course

headquarters and presented them with plaques to commemo-

rate the achievement.

OGX operates eight rigsve offshore and three landand

is responsible for a signicant portion of M-I SWACO Brazils

revenue. In July, the rig count will grow to six offshore and

four land rigs.

M-I SWACO continues to have 100 percent of the OGX

business in Brazil and has developed a close relationship with

the Brazilian oil company

through dedication and hard

work. Eleven M-I SWACO

employees work inside the OGX

ofces on a daily basis, includ-

ing four project engineers, two

project coordinators, two uids

programmers, one WP project

engineer, one ES project engi-

neer and one technical support.

Reinaldo Belotti, right, with Steve Orr. Ricardo Juiniti, right, with Steve Orr.

Marcelo Amaral, left, with Steve Orr.

Aberdeen Process Control Group runs 10K together

Twelve members of the

M-I SWACO Process Control

Group completed the City

of Aberdeen 10K Road Race

in May. Inspired by PCG

Administrator Lynn Jamiesons

initial entry into the compe-

tition, the rest of the group

joined up and trained in the

weeks leading up to the race.

With very few of the group

having any past running expe-

rience they can be proud of

their effort, with Keith Walder

the fastest out of the group

with a time of 46 minutes

1 second.

Team Lineup: Back row, left to right are Neil Mcpherson, Gary McGinnes, Calvin Dodds, Colin

Patterson, Keith Walder, Steven Hosie, Richard McIntosh, Kevin Bowes, Kevin Buchan, Nimesh

Vora. Front row are Lynn Jamieson and Diana Lopez Lucas Andrade.

14 Momentum

W

o

r

l

d

M

o

m

e

n

t

u

m

M-I SWACO Mudslingers take second place in

2012 Schlumberger World Hockey Championships

By Katie Larg, DS Department Assistant, and Derek Clarke, IT Support Analyst

T

he M-I SWACO Mudslingers came out strong on

Thursday night crushing the Grande Prairie OFS

Team 21-5. The team hailed star forward Faron

Duthie as MVP after he scored over half of the teams

goals leading the group to an outstanding victory. They

were off to a great start despite the Cool Runnings

approach with

their coaching staff.

I dont get why

Faron is MVP, said

Assistant Coach

Fernando Navarro,

before being

reminded they

werent playing

soccer. He didnt

kick the ball once

and hardly dove.

After the game,

the Vancouver

Canucks came

looking for Faron

to help them in

the playoffs. After

much consid-

eration, Faron

decided to stick with the team that had the better goalie

and carried on with the tournament. The Mudslingers

only natural Defenseman, Mike McGinnis (who was a

major factor in Game #1) was called away from the rink,

and would miss the remainder of the tournament.

Battling against Red Deer Wireline on Friday after-

noon, the team knew that they would be in for a ght.

Star sniper Jay Safety First Whitecotton was unable to

play, as he was booked into QHSE training. When asked

for comment on his absence, Candace Clare just laughed,

mysteriously

fanning herself

with an envelope

of cash. Despite

this, the team

jumped out to

a 4-1 lead after

two periods,

buoyed by stellar

goaltending

from Mike Is

this game

STILL going?

MacPherson. Going into the third, self-appointed Team

Captain Reg Patterson took one-too-many penalties and

was sent out to the dressing room early. This sparked a

revolt as the team accused him of sneaking away to be

rst in line at the BBQ.

Red Deer Wireline took advantage of the Mudslingers

upset and

shifted the

momentum

with a huge

hit to Walter

Preece. Red Deer

jumped all over

the stunned

Mudslingers

to tie the game

and force it

into a shootout.

Goalie Mike

MacPherson

tried his hardest

to keep the team

in the game, but

found him-

self spending

far too much

time chirping at the referees instead of watching for

pucks. Deated after seeing their lead slip away, the

Mudslingers suffered a loss to their Red Deer rivals.

With only a few hours before the next game, the team

struggled to refuel and rebuild. Goalie Mike MacPherson

was unable to play in the Friday evening faceoff against

Smith D&R, but to everyones delight Reg was back after

his siesta and ready to contribute. Building on his expe-

rience from last year, returning Head Coach Peter Van

Camp remembered that hockey is that game with sticks

and a puck and found a backup goalie to give them a

ghting chance. The backup tried his best, but despite

being the best Korfball player Peter could nd, he was

unable to stop a puck. Trainer Nader Ghobrial com-

mented later that although they were outmatched in

this game, they still managed to get scored on less than

the GP OFS team from the rst game. The game ended as

it started, with the team uninterested, tired and slightly

inebriated. M-I SWACO had dropped another game, 7-2.

Luckily, the huge goal differential in game one allowed

them to take the division crown, which gave them a spot

in the seminals.

The Mudslingers showed up to the rink on Saturday

From left to right: Troy Riggins, Kevin Brown, Rich Kilbride, Chris Leonard, Reg Patterson,

Reid Nesbitt, Jay Whitecotton, Todd Cross, Dave Bezushko, Faron Duthie, Sunny Manget,

Jason Lock, Walter Preece. Front: Mike MacPherson.

Continued on page 15

World Momentum 15

NGA Geomarket moves into new digs in Accra, Ghana

The NGA Geomarket moved into new ofces in Ghanas capital city, Accra. Ghana, Ivory Coast & Remotes Regional

Manager Francois Couffy, Ghana Country Manager Kenny Rait, NGA Financial Controller Tunde Awotunde, NGA

ES Business Manager Yomi Jewisimi and NGA PT Business Manager Santosh Gopi moved into the new building in

March. NGA DS and WP Business Managers joined the operations in June.

We really needed this facility as we expand and grow our business here in Ghana, said Rait.

A small, serene garden surrounds the new ofces.

morning ready for a rematch with Red Deer Wireline

knowing they only had one game left to redeem them-

selves. In typical fashion, Defenseman Sunny Mangat

arrived with 42 seconds to go before warm-up, but was

still the rst man out on the ice. SportChek reports that

they completely sold out of Big Boy Pants on Friday night

and it showed in this match. The fast-paced game kept

the crowd on the edge of their seats and the team on the

edge of the bench, although to be fair, for Reid Nesbitt this

was the only way his feet could reach the oor. Red Deer

Wireline complained to ofcials that they were distracted

by Kevin Brown winking at them, but it fell on deaf ears.

Afterwards, Kevin was noted making the call me gesture

at the refs, who blushed, giggled and whispered in the

corner before giving the Mudslingers a free goal and a 5-3

win. This win, combined with Thursday nights incredible

victory, sent the team to the Gold Medal Game against

Extreme Engineering on Saturday night. Knowing that

the upcoming game was for all the glory, the team knew

theyd have to prepare.

The nal game against Extreme Engineering was a

battle from the opening faceoff. With the title for Most

Hungover Team rmly under their belts, the Mudslingers

went about actually trying to win the tournament. Head

Coach Peter Van Camp was notably absent, choosing

instead to carry on with his dinner reservations

at Subway.

I never expected us to win any games, said Van Camp,

and I had a 2 for 1 coupon that I didnt want to waste.

Assistant Coach Reza Danesh Beheshti tried his hard-

est to help lift the spirits of the team in place of Peter. His

chants of What? IM a coach? were echoed by the crowd

Continued from page 14

Number 10 doing the dive for the goal is Kevin Brown and number 18 is

Reg Patterson!

in an obvious show of support. The Extreme Engineering

goalie was brilliant, ashing the leather, robbing the

stunned Mudslingers and gaining thunderous cheers

from the crowd. Superstar goalie Mike MacPherson tried

his best to rebound, but got things mixed up by wearing

leather and ashing the crowd, gaining himself a ticket

and a future court date. Extreme Engineering managed

to hold on to their lead and pull out a 4-1 win, taking the

Gold. Mudslingers veteran and most optimistic player

Dave Bezushko still thinks M-I SWACO played their best.

They had a great goalie, he said. It was a good game,

but it sucked watching them give the big trophy to the

other team. It probably didnt help that Reza got the equip-

ment mixed up and gave us all golf clubs to play with.

In the end, the Mudslingers go home with the silver and

an upgrade from last years standings.

16 Momentum

Continuous Improvement

CI Belts

White Belts

WB Mexico, from left to right, seated Diana Luz Durand,

Anglica Mendoza, Miriam Ramn, Flora Salgado (instructor),

Sandra Hernndez, Mara de los ngeles Gonzlez, Nelly

Torres. Row 2 Martn Herrera (instructor), Alfonso Martnez,

Luis Gmez, Andrs Acevedo, Ral Romero, Rafael Abarca, Eric

Mendoza, Julin Silva, Jorge Garca, Ivan Mar. Row 3 Luis

Vasquez Collado, Hctor Baldazo, Carlos Garca, Jos Vazquez,

Ernesto Jimnez, Pauxides Martnez, Hctor Flores.

WB Florence, from left to right Eric Hand, Mohamed Kandil,

Tony Rose, Chesley Thomas, Adam Vance, Chris Barker

(instructor), Len Prokopchak, Mike Pierce, Barry Simpson,

Carrie Lai, Armel Moukoula, Kevin Walsh, Cathleen Yanco,

Richard Hawk, Cheryl Cook (instructor).

WB Aberdeen Gordon Ross, Ian Matheson, Roger Berntsen,

Willie Heron, Justin Green, Jenna Tallis, Stan Morgan, Sarah

Malone, Fiona Colquhoun, Paul Young, Kat Spriggs, Lisa

Stephen (instructor), Mike Rousseau (instructor).

WB Dubai Arseniy Iyevlev, Hope Ovie-Thompson, Ahmed

Younes, Nashat Hamed, Tawheed Elwadia, Hani Bakkar,

Sitaram Shirodkar, Ali Iqbal, Geejo Raghavan, Ahmed Khatar,

Ashutosh Patani, Jerry Duncan (instructor), Mark Hughes

(instructor), Max Yeh (instructor).

Currently, there are 30 Black Belts, 85 Orange Belts and 702 White Belts.

During the past quarter, four White Belt Classes were held with 58 people being trained. Classes were

held in Mexico, Aberdeen, Florence, KY and Dubai. An Orange Belt class was held in Edinburgh with ve

people trained.

Continuous Improvement 17

CI Belts continued from page 16

Orange Belt Edinburgh participants: Ian Roger, Lisa Stephen

(instructor), Marianne Slater, Carla Vera, Gary Hewitt,

Anastasia Vilarskaya, Paul Ward (instructor).

Mike Rousseau is presented his Orange Belt Certication.

Pictured are Alan McLean VP QHSE, Mike Rousseau Senior

Operations Mgr. Minerals QHSE, Bob Bailey VP Global

Minerals, Kathryn Friar VP Product Delivery, Frosty

Copenhaver Regional Operations Managed Minerals.

Dave Sorter discusses details of polishing butt weld joints. From right

to left are Selva Prakash, assistant plant manager; G Gurusamy,

director of operations; Rick Ball, global manufacturing engineer; Dave

Sorter, president SWECO; the polishing vendor.

Orange Belts

Everyone is smiling about SWECO India

By Dave Sorter, SWECO President

O

ver the years we have

struggled with grow-

ing SWECO India at a

double digit rate. Continuous

Improvement has been slow to

take hold and HSE standards

did not match that of our other

locations.

But several things happened

that have changed everything

at our India facility. First, we

hired Rick Ball to be our Global

Manufacturing Engineer.

Second, Rick spent many

hours training the employ-

ees at SWECO India and soon

adopted them as his fam-

ily. He demanded all QHSE rules be followed and made

Continuous Improvement a way of life. Third, we hired

G. Gurusamy as Director of Operations and he has taken

over right where Rick

left off. The future

of SWECO India is

brighter than ever.

During my recent

visit to SWECO India

I witnessed all the

changes; the progress

made has been tre-

mendous. The HSE and

CI improvements were

remarkable. But the

thing that struck me

the most was some-

thing I have never seen

before at the factory:

Everyone was smiling.

Why? Because everyone realized that the company actu-

ally does care about their safety and wellbeing.

C

o

n

t

i

n

u

o

u

s

I

m

p

r

o

v

e

m

e

n

t

Demand Planning and a Tool to support the process

FORECAST 2.0

D

emand Planning is the process of forecasting

our business needs in terms of materials and

resources that are necessary to satisfy our cur-

rent and future customer requirements. It is about more

than just a forecast of these requirements, however. It

is also about the process of planning our procurement

and necessary resources for the medium and long term

to satisfy the forecasted requirements, resulting in the

following benets to our business:

stable and reduced product lead times

increased product availability

increased customer service levels and satisfaction

product cost reduction

increased inventory turns

reduced total logistics cost

reduced total cost to the business

The major business process steps were agreed by the

area representatives and a detailed process map was

developed. This process map was crucial to the next key

step of evaluating and selecting an appropriate Demand

Planning supporting tool. An Oracle-based tool was

identied as having the potential to support our busi-

ness process in late 2011, and after some trials in January

of this year, the tool was selected. The project was then

proposed and approved by senior management and

the implementation project commenced in February. A

core team was created consisting of Mark Stoller, Paul

Ward, Marc Eigner and Chuck Berta to develop the new

application in a collaborative way by asking operations

for their input.

Pilot Testing FORECAST 2.0

The initial implementation of the new Demand

Planning tool, FORECAST 2.0, is being piloted in two

locationsNorth Gulf Coast (NAM) and Germany (EAF).

Pilot testing consists of three main phases, the rst

of which took place in the NGC region, Lafayette, LA,

in May with representatives from Germany actively

participating. Pilot testing is a very involved process,

where the tool is congured to our requirements and

M-I SWACO data is used to develop the process and con-

rm the tool conguration and process steps.

The rst stage of pilot testing was concerned with the

forecast collection and consolidation as well as some

initial correlation to business nancials. It is vitally

important that this tool is simple to use for the people

who will be inputting a forecast and for anyone review-

ing the consolidated forecast to be able to drill to the

more detailed input levels.

Operational feedback was captured during Pilot 1.

For the last 12 months or so, the process has been

supported by a spreadsheet-based toolalbeit with

some sophisticated macros and additional program-

ming added. It was important to begin our process

this way, in order to understand the business process

rst, rather than implement an IT solution with no

predeveloped process. It has long been recognized,

however, that the spreadsheet-based supporting tool

has been too limiting for our business needs.

The Way Forward

A Continuous Improvement (CI) event was held in

September 2011 with operational participants repre-

senting ve of our six business areas involved. The

goal of the event was to understand how each of the

areas was managing their Demand Planning process

and try to determine a common approach and process

that could subsequently be supported by an appropri-

ate Demand Planning tool.

18 Momentum

The rst pilot phase was a resounding success as exhib-

ited by some very positive feedback from the people that

will be actively using this tool going forward:

The tool is easy to use. It is exible and provides the

opportunity to use various worksheets for alternative

views of the forecast data. Henning Soeker, project

engineer, Germany.

The Demand Planning tool will make the process more

efcient for Project Engineers. Jody Richards, project

engineer, NGC.

This tool automates what we are doing today in Excel

and makes the process much easier. Holly McNaughton,

project engineering support manager, NGC.

It is so user-friendly and has the capability to correlate

the forecast to business nancials. I also believe this tool

will help with increasing our forecast accuracy. Audi Paz

De Lara, Demand Planning NAM.

Next Steps

There are two further pilot testing phases with the

next one planned for July. This second phase of pilot test-

ing will be more focused on the inventory management

aspects of the processtaking what is called the Gross

Forecast, which has been collected from the eld forecast

entered and then netting it off against current inventory

and orders to generate a Net Need Forecast. Supply Chain

and Manufacturing will use the net need forecast to help

plan their supply in the medium and long term.

The nal pilot phase will be concerned with the whole

process from forecast entry and consolidation, nancial

correlation and forecast approval, through to netted

demand, projected inventory and supply plans being

developed for the medium and long term to support our

business needs and customer requirements.

Continuous Improvement 19

The full rollout of FORECAST 2.0, the Demand Planning

support tool, will begin later this year after the initial

pilot locations are live and fully functioning. The rollout

will be phased across the areas starting later this year

with each area developing a specic training and imple-

mentation plan.

It is expected to be live worldwide within the next

12 months.

Regular articles and webcasts will be delivered to ensure

everyone is updated with the project progress and to

provide the opportunity for feedback and input.

This is a very exciting project with signicant future

benets to the M-I SWACO segment, operations, supply

chain and ultimately ensuring Customer Focused,

Solutions Driven approach. We, as the core team, continue

to look forward with great enthusiasm closely working

with Operations to a joint collaborative demand

planning solution.

Above: Scenario data entry by

Henning Soeker during Pilot 1.

Right: Scenario data entry by

Wayne Matlock during Pilot 1.

Above: Participants CRP-I, from left to right, Mark Graham (Inspirage),

Chuck Berta, Ankur Bhatia (Inspirage), Paul Ward, Henning Soeker,

Sambit Misra (Inspirage), Bernie Kolb, Gilbert Huang (Inspirage), Jody

Richards, Marc Eigner, Mark Stoller, Zack Kelsey, Wayne Matlock, Holly

McNaughton, Audi Paz De Lara, Jerry Duncan.

20 Momentum

Up Close

Momentum:

What is the Standard

Equipment Maintenance

Program or STEM program,

and why are we imple-

menting it throughout

M-I SWACO?

Tony Clarke:

STEM is a global

Environmental Solutions

(ES) initiative introducing

a standard maintenance

program for our ES facilities

globally. So, its an initiative

that is for every area within

M-I SWACO; every ES facil-

ity has to comply. We are

introducing standard work

for maintaining our equip-

ment in the eld, whether

its being overhauled or

maintained in a facility,

or whether it is in storage.

So, STEM provides global

standards for ES equipment

maintenance. At the same

time, we are developing our

workshops in such a way

that the maintenance can

be carried out correctly and

prociently rst time every

time no matter where in

the world it is performed.

A standard by which we

ensure all of our shops

have all of the right tools in

the right place at the right

time to enable our mechan-

ics to carry out repair and

maintenance duties in a

professional, consistent

and standard manner. It

will take commitment and

a signicant change in our

culture if we are to do busi-

ness this way.

Eric Heath:

Its laying a foundation for

where we want to be in the

next few years in terms of

predictive maintenance.

We want to evolve from

a maintenance program

thats based on days, weeks

and months to developing

predictive methods that

allow us to maximize value.

A predictive maintenance

program where were

looking at trends with our

hardware and targeting

the maintenance based on

operational hours not just

time intervals.

Thats what I mean by

predictive. Were looking

at when our failures are

occurring, the wear on

units as they return to the

shop, trending the data

from our sensors installed

on the equipment and

using this to determine

how much use we can get

out of these assets before

they need to be serviced

rather than saying I need

to service it because I do it

every thirty days. Do I need

to do it? How many hours

can I run the equipment

before I need overhaul it?

What is my data telling

me?

Its a program where

youre looking at the data

youre collecting and using

that to tailor your plan to

get the most benet.

Momentum:

Is that time period for a

piece of equipment the

same whether its here in

the U.S. or whether its in

Africa or Asia?

E.H.:

No, it will be different

based on the area youre in.

In each issue, Momentum sits down with one of the many experts within the

M-I SWACO organization for a candid look at their area of expertise and how it

impacts not only our company, but the industry as well.

UP CLOSE recently visited with Tony Clarke, Global STEM Implementation

Manager, and Eric Heath, Product Support and Verication Manager, to talk

about the Standard Equipment Maintenance Program (STEM). Initiated in 2011,

the program is focusing on introducing global standards for our maintenance

facilities worldwide. The primary goal is to improve quality assurance levels,

reduce downtime and improve the overall return on our assets. The objective

is to have two Tier 1 ES maintenance workshops in each of the six areas and all

others at Tier 2 by the end of the year.

Left: Tony Clarke, Global STEM Implementation

Manager Right: Eric Heath, Product Support and

Verication Manager

Standard Equipment Maintenance Program providing a global

standard for ES Equipment maintenance

Up Close 21

So, if youre in Africa youre

not going to necessarily

have the same predictive

maintenance schedule as

the North Slope of Alaska.

Your operating environ-

ments are a contributing

factor that must be con-

sidered. Thats why its so

important that the areas

track KPIs so decisions

can be based on data and

the effectiveness of the

program can be accurately

measured. We want to

avoid just having a central-

ized maintenance plan

without any feedback,

without any measurement,

without any tailoring,

without any adapting.

Momentum:

Why is the STEM program

vital to M-I SWACO now?

T.C.:

Were just approaching a

year since we created the

material, developed the

approach and then the

initial rollout across all the

areas. Weve been rolling

out and implementing it

for ten months, so why is it

important? For me its

important because we

currently have 82 ES

facilities globally, and as

Eric said, weve got differ-

ent maintenance practices

and expectations in

different countries, yet we

have standard equipment.

However, our facilities

dont work to the same

standards. For example, we

have different methods of

controlling standard and

critical spares yet we have

standard ES equipment. So

to me its really important

that we get these 82

facilities to maintain the

equipment to the same

standard, the same way,

using the same tools and

techniques. Get

everybody the right

tools to do the

standard repair,

and get all

the facilities

to that same

standard

such that the

equipment ows through

the facility and can be

inspected, overhauled and

tested in an efcient

manner. We need to have

better control of our assets

and a reliable product for

our customers, one which

is t for purpose every

time, no matter where in

the world it is maintained,

one we are proud to release

to a customer.

Right now, weve got

more or less 82 different

standards just because we

have 82 shops. Theres no

one standard or best

practice being shared

across any of our ES

facilities. We have six

specic areas in the

business; each area is doing

the best they possibly can

every day to manage the

assets, but were using

A screenshot of the STEM Tier Progression dashboard.

22 Momentum

different standards and

practices, different levels of

training, different methods

of communication, often

resulting in higher than

necessary maintenance

costs and in some instances

poor quality products,

which, if they fail in service,

affect our business and

customer relationships.

Momentum:

How do you take all of

those 82 ways of doing it,

or best case scenario six

ways of doing it, and make

it one?

T.C.:

Weve introduced a global

standard, with standard-

ized methods of commu-

nication and maintenance

practices across all of our

workshops, from equip-

ment ow through the

workshop, visual com-

munication techniques,

best practices and stan-

dard work. We created a

SharePoint^ site where all

of those best practices are

shared and progress to the

standard is demonstrated.

The site is available for

everybody to access at all

levels in our business. So, it

doesnt matter if youre an

ES facility manager in Baku

or whether youre an ES

maintenance mechanic in

Cabinda. If you have access

to a company computer,

you have access to the

standards.

We created a compre-

hensive two-day training

program, which was a

train-the-trainer program,

whereby we went out to

the areas, trained the train-

ers in an area and then left

them with the material.

But, again, that training

wasnt just classroom

training; we gave them

one days worth of theory

or academic training. Day

two was a hands-on exer-

cise on the ES equipment,

going through the STEM

documentation. This was

done in a safe environment

ensuring that the trainers

didnt just have an appre-

ciation or idea of how it

should be, but rather they

left with a comprehensive

understanding of the pro-

cess and also a method and

approach as to how they

were going to train their

colleagues.

While we have a program

for training people how

to operate equipment, up

until now weve never had

standard work and stan-

dard processes that enable

our people to maintain,

document and control our

maintenance process.

E.H.:

It is important to mention

the overall HSE benet

that a sound maintenance

program provides. Ensuring

our equipment is t for

purpose and identifying

issues at the earliest oppor-

tunity reduces

risk. In addition,

the STEM program

is important to

M-I SWACO for

two more reasons.

First, to make sure

that our equip-

ment is available

for our customers

where they need

it and when they

need it, and the

second is to maxi-

mize our return

on our assets.

Weve seen many

examples of assets

in various stages

of disrepair. Weve

seen 20-year-old

assets in better

condition than

some with only

one year of use.

So, the objective is

to bring a process

that can be measured and

improved to ensure we

deliver products that are

safe and operate reliably.

When we rst started

talking about this, if you

asked how you determine

the cost of ownership of

a particular asset, you

would have received many

different answers. This pro-

gram will help operations

calculate the true cost of

ownership for critical assets

to ensure we maximize our

returns.

T.C.:

We talk a lot about asset

utilization. Weve got new

U

p

C

l

o

s

e

The STEM team won a Schlumberger award for their video explaining what the STEM program is all about. From left to

right are Joe Bacho, M-I SWACO president; Eric Heath; Brian Hunter, VP of ES Drilling; Tony Clarke; David Paterson, VP of

Marketing and Technologies.

Up Close 23

equipment in certain parts

of the world where theyre

doing minimal mainte-

nance. Weve got other

parts of the world where

weve got older equipment

and theyre really invested

in the maintenance and

looking after that equip-

ment. Facilities are appre-

hensive to transfer assets

because they feel theyre

going to be giving away

a lot of hard effort, time

and money which theyve

invested in that piece of

equipment. Yet, they might

get back in return a pile of

junk. Im a bit strong, but

theres that fear and idea

that they will not receive

assets maintained to the

same standards as they are

using in their facility. So

they hang on to underuti-

lized equipment when we

could transfer those assets

to other parts of the world

to meet business demands.

Theres a bigger picture:

We must improve our

utilization and get better at

maintaining and transfer-

ring our assets to meet our

customers needs and at the

same time managing our

costs in an effective man-

ner and truly understand-

ing our asset utilization.

Momentum:

What was the basic

rollout process for getting

the program out to the

82 ES shops?

T.C.:

Both Eric and I looked at

how previous initiatives

have been rolled out to the

business. Some programs

are introduced by saying,

Heres a new process;

just go out and do it, and

people are expected to

understand, perceive it,

and implement it without

any further guidance. We

approached the end-users

of this program in Global

Operations and determined

how best to roll out the

material. Operations was

involved in this process

from reviewing the mainte-

nance material to provid-

ing input and feedback on

how to best communicate

every level could access the

standard documentation

and the global metrics.

One key to the SharePoint

site is that all informa-

tion is transparent. So, for

example, you look on North

America, you see a photo-

graph of Wynn Fontenot,

then you see a photograph

of Wynns three champions:

Mike Huval, James Gharst,

and Tim Richardson. Then

you see all of his 18 shops,

and you see the photograph

of all of the ES managers,

those ops managers, and

you see their performance,

and their KPIs to the

program. But they can all

see Asia and every aspect

of our facilities there, and

they can all compare each

other to the same stan-

dards. Everybody knows

who is accountable for each

shop, at each level, in each

area. Its one program with

100 percent visibility, and

100 percent accountability.

E.H.:

One of the reasons we

were able to roll it out so

quickly and effectively is

that we used the concept of

train-the-trainer. We could

provide the training at a

shop in a particular area

and bring in all the train-

ers from other facilities

allowing them to go back to

their location and train the

operators and mechanics in

the STEM process.

Momentum:

What are some of your

goals for 2012 and 2013?

T.C.:

When we rst put it out,

the goal was every facil-

ity in 2011 had to be Tier II.

We achieved just under 40

percent by the end of 2011.

So we sat down and with

our management team,

David Patterson and Brian

Hunter, we looked at what

would be required for 2012.

We determined that every

area had to have two major

facilities at Tier I by the end

of 2012. All other facilities

in those areas had to be

Tier II by the end of 2012

with all personnel trained

in the STEM program. We

dened a facility as any

location that overhauls and

maintains ES equipment

for a customer.

By default, the target

for 2013 is to have every

facility at Tier I. If you are

already a Tier I facility then

you have to maintain that

standard. So, its sustaining

the program.

Momentum:

How are you measuring

that standard for the

workshops?

E.H.:

We have four tier levels

to measure progress at

an ES facility from a basic

Tier IV meeting the PPE,

tooling and safety require-

ments up to the Tier I

facility thats demonstrat-

ing full compliance with

the STEM Program and KPI

reporting. Initially, it is an

audit performed by the ES

Operations Manager at the

facility in conjunction with

the area champion up to

and including Tier II. We

provided a tier progression

template following the

completion of the initial

audit. The tier progression

plan allowed the facilities

to identify the resources,

actions and timeframe

Theres been a

huge cultural shift,

at least in terms

of the way people

are thinking about

maintenance

and the benets

associated with

good practices.

Eric Heath, Product Support and

Verication Manager

the program throughout

their local workforce. This

allowed us to develop the

best approach for rolling

out this initiative with the

least disruption to their

existing business.

It wasnt just developing

the STEM material and put-