Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

44 viewsDesign of One Way Slab

Design of One Way Slab

Uploaded by

faisalkalathilThis document summarizes the design of a one-way continuous slab that is 12m x 7.5m supported by T-beams spaced at 3m. It calculates the required design parameters like effective depth, bending moments, reinforcement, shear capacity, and stiffness. The effective depth is determined as 80mm. Main reinforcement of 8mm diameter bars is designed with a spacing of 180mm to resist the maximum bending moment of 7781944.8 Nmm. Shear and stiffness checks confirm the design is adequate.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You might also like

- Jack Well - Well FoundationDocument3 pagesJack Well - Well FoundationRamakanth PuttyNo ratings yet

- Design of Cantilever BeamDocument23 pagesDesign of Cantilever Beamjs kalyana rama85% (13)

- Design of Pedestal For Seismological Stations: Slenderness Ratio of The ColumnDocument2 pagesDesign of Pedestal For Seismological Stations: Slenderness Ratio of The ColumnAdarsh Kumar SNo ratings yet

- Design of Wall Like ColumnDocument4 pagesDesign of Wall Like Columnvishnumani3011No ratings yet

- Earthquake Load Calculations As Per IS1893-2002.-: Building Xyz at Mumbai. Rev - Mar2003 HSVDocument9 pagesEarthquake Load Calculations As Per IS1893-2002.-: Building Xyz at Mumbai. Rev - Mar2003 HSVEr Rakesh SharmaNo ratings yet

- Design of Column: Section ClassificationDocument4 pagesDesign of Column: Section Classificationvenkatesh19701No ratings yet

- Slab DesignDocument1 pageSlab DesignFarshad perouzNo ratings yet

- Nabin 2 WayslabDocument22 pagesNabin 2 WayslabNabin joshiNo ratings yet

- Design of Two-Way Restrained Slab (IS456:2000)Document3 pagesDesign of Two-Way Restrained Slab (IS456:2000)BasandharaAdhikariNo ratings yet

- Strap Beam FootingDocument4 pagesStrap Beam Footingrukesh104No ratings yet

- Design of Roof (Pratt) TrussDocument19 pagesDesign of Roof (Pratt) TrussKyle ForemanNo ratings yet

- Staircase Design FinalDocument10 pagesStaircase Design Finalpepe wosNo ratings yet

- 4.1 Walk Way SlabDocument12 pages4.1 Walk Way SlabSeph RjyNo ratings yet

- Super PassageDocument5 pagesSuper PassageSamir Rawat0% (1)

- Design of Cantilever Slab:: Area of The Footing RDocument4 pagesDesign of Cantilever Slab:: Area of The Footing RNarayan WNo ratings yet

- Design of Slab As Per IS:456-2000: Input DataDocument6 pagesDesign of Slab As Per IS:456-2000: Input DataMainali IshuNo ratings yet

- Staircase Design Dog Legged 2 LandingDocument5 pagesStaircase Design Dog Legged 2 LandingSuman Resolved NeupaneNo ratings yet

- Retaining Wall V 0.6 With K&CDocument59 pagesRetaining Wall V 0.6 With K&Cmayank007aggarwalNo ratings yet

- ZPurlinR1 OdsDocument21 pagesZPurlinR1 OdsRamachandra SahuNo ratings yet

- Project by Location: Girting Design ADocument10 pagesProject by Location: Girting Design AJurie_sk3608No ratings yet

- Composite Beam-Stilt FloorDocument9 pagesComposite Beam-Stilt FloorjatinNo ratings yet

- 1 456:2000 Clause 25.2) Annex E of The Code With The Assumption That The Frame IsDocument5 pages1 456:2000 Clause 25.2) Annex E of The Code With The Assumption That The Frame IsBejil ShresthaNo ratings yet

- Rectangular Tank Design-Bluetax ETP-1Document23 pagesRectangular Tank Design-Bluetax ETP-1monaliNo ratings yet

- Strap FootingDocument30 pagesStrap Footinganon_140586866No ratings yet

- Design of Ring Girder SupportDocument3 pagesDesign of Ring Girder Supportvishal guptaNo ratings yet

- Design of Flash Mixer at Kurawar - 1ADocument13 pagesDesign of Flash Mixer at Kurawar - 1AAnonymous RREG0QJWNo ratings yet

- Water TankDocument26 pagesWater Tankabhi aroteNo ratings yet

- Lacing DesignDocument4 pagesLacing DesignVenkat PalliNo ratings yet

- Footing DesignDocument2 pagesFooting DesignRathinavel VenkateshwaranNo ratings yet

- Water Tank Wall FootingDocument4 pagesWater Tank Wall FootingAbhishekKumarNo ratings yet

- Combined Footing SalinDocument30 pagesCombined Footing SalinSujan SinghNo ratings yet

- One Way Slab DesignDocument5 pagesOne Way Slab DesignharshNo ratings yet

- DistributionTheory RevBDocument102 pagesDistributionTheory RevBNasser AmmariNo ratings yet

- Beam Design With Deflection CheckDocument2 pagesBeam Design With Deflection Checkbhavin_civilNo ratings yet

- Column Is800Document4 pagesColumn Is800rammohanNo ratings yet

- VPRPL 600KL 24 M PDFDocument28 pagesVPRPL 600KL 24 M PDFAjayvidyanand SharmaNo ratings yet

- P PDFDocument49 pagesP PDFaanchaljasujaNo ratings yet

- Column Load Calculation Dt25.3.14Document4 pagesColumn Load Calculation Dt25.3.14VMRAJANNo ratings yet

- Isolated Footing DesignDocument24 pagesIsolated Footing DesignSANJEEV GANDOTRANo ratings yet

- Design of ColumnDocument46 pagesDesign of ColumnAnissah ManialaNo ratings yet

- PIle FoundationDocument6 pagesPIle FoundationsaravananNo ratings yet

- Angles - Truss DesignDocument109 pagesAngles - Truss DesignSamia H. Bhuiyan100% (2)

- Built - Up Column Design ("Effectiveness of Various Built-Up Columns") Section PropertiesDocument2 pagesBuilt - Up Column Design ("Effectiveness of Various Built-Up Columns") Section PropertiesAnandNo ratings yet

- Isolated Footing Design: Forces DetailsDocument10 pagesIsolated Footing Design: Forces DetailsJagadish_2No ratings yet

- Reinforcement: V, F: Project: Staircase Design - STC 1Document4 pagesReinforcement: V, F: Project: Staircase Design - STC 1zzweirdozzNo ratings yet

- 1 Dimensions of Tank Proper:: Design of 50 KL OhsrDocument30 pages1 Dimensions of Tank Proper:: Design of 50 KL OhsrMegatech Engineering ConsultantsNo ratings yet

- Column Rolled Section (Rev.2.00)Document3 pagesColumn Rolled Section (Rev.2.00)Harjasa AdhiNo ratings yet

- Design of Column Excel SheetDocument2 pagesDesign of Column Excel SheetAnand K RajNo ratings yet

- Sump .XLS (2.00 Lakhs)Document35 pagesSump .XLS (2.00 Lakhs)subramanyam kumarNo ratings yet

- Combine FootingsDocument1 pageCombine FootingsKherwin-j Sangalang100% (1)

- Design of Two Way Slab and ETABS Column Reaction.Document9 pagesDesign of Two Way Slab and ETABS Column Reaction.tuansteelsNo ratings yet

- Isolated Footing DesignDocument3 pagesIsolated Footing DesignSunil GuptaNo ratings yet

- RR Masonary Retaing Wall DesignDocument41 pagesRR Masonary Retaing Wall DesignAbhay KumarNo ratings yet

- Thursday, June 20, 2019, 07:28 AM: Page 1 of 226 E:/Kuliah/Semester IV/PBTS/Tugas Besar/YI - AnlDocument3 pagesThursday, June 20, 2019, 07:28 AM: Page 1 of 226 E:/Kuliah/Semester IV/PBTS/Tugas Besar/YI - AnlRyandhon GyandhaniNo ratings yet

- Design of Two Way Slab: 1) Trial DepthDocument3 pagesDesign of Two Way Slab: 1) Trial DepthDhananjay JoshiNo ratings yet

- Manual Beam DesignDocument14 pagesManual Beam DesignRonald Kaaku50% (2)

- Unit 5Document31 pagesUnit 5Nirina ArimananaNo ratings yet

- Design SectionDocument19 pagesDesign SectionKrishna KumarNo ratings yet

- T Beam Roof SlabDocument22 pagesT Beam Roof SlabRohit Khandelwal100% (1)

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- Project Report StructuralDocument70 pagesProject Report StructuralfaisalkalathilNo ratings yet

- 24-D15 - Grading - Excavation - Backfilling PDFDocument19 pages24-D15 - Grading - Excavation - Backfilling PDFfaisalkalathilNo ratings yet

- 24-D15 - Grading - Excavation - Backfilling PDFDocument19 pages24-D15 - Grading - Excavation - Backfilling PDFfaisalkalathilNo ratings yet

- TRAFFIC ACCIDENT ANALYSIS (Seminar)Document13 pagesTRAFFIC ACCIDENT ANALYSIS (Seminar)faisalkalathilNo ratings yet

- Bis Code of PracticeDocument23 pagesBis Code of PracticefaisalkalathilNo ratings yet

Design of One Way Slab

Design of One Way Slab

Uploaded by

faisalkalathil0 ratings0% found this document useful (0 votes)

44 views6 pagesThis document summarizes the design of a one-way continuous slab that is 12m x 7.5m supported by T-beams spaced at 3m. It calculates the required design parameters like effective depth, bending moments, reinforcement, shear capacity, and stiffness. The effective depth is determined as 80mm. Main reinforcement of 8mm diameter bars is designed with a spacing of 180mm to resist the maximum bending moment of 7781944.8 Nmm. Shear and stiffness checks confirm the design is adequate.

Original Description:

excel sheet

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document summarizes the design of a one-way continuous slab that is 12m x 7.5m supported by T-beams spaced at 3m. It calculates the required design parameters like effective depth, bending moments, reinforcement, shear capacity, and stiffness. The effective depth is determined as 80mm. Main reinforcement of 8mm diameter bars is designed with a spacing of 180mm to resist the maximum bending moment of 7781944.8 Nmm. Shear and stiffness checks confirm the design is adequate.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

0 ratings0% found this document useful (0 votes)

44 views6 pagesDesign of One Way Slab

Design of One Way Slab

Uploaded by

faisalkalathilThis document summarizes the design of a one-way continuous slab that is 12m x 7.5m supported by T-beams spaced at 3m. It calculates the required design parameters like effective depth, bending moments, reinforcement, shear capacity, and stiffness. The effective depth is determined as 80mm. Main reinforcement of 8mm diameter bars is designed with a spacing of 180mm to resist the maximum bending moment of 7781944.8 Nmm. Shear and stiffness checks confirm the design is adequate.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

You are on page 1of 6

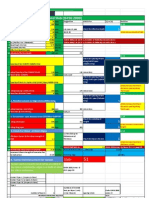

GIVEN DATA:

Area of slab 12m x 7.5 m supported by T-beams as 3 m centres

LX = 7.5 fck 20

LY = 3 fy 415

SIDE RATIO = LY/LX

2.5 is more than 2 so one way slab

it can be design using bending moment and shear force coefficient given in Table 12

and 12 of IS : 456-2000

Depth required for stiffness:

c/c of supports = 3000

basic value of l/d = 26

assume modification factor as 1.5

d = Span /(bv * mf)

76.923077

provide a total thickness of 100 mm eith effective depth of 80 mm d =

D =

efective span

width of the suports = 300 0.3 m

clear span = 2.7 m

clear span/12 = 225 mm

width of the supports > clear span/12

as per clause 22.2 (b)(1) and (2) of IS :456 - 2000

effective span of the interior panels = 2.7

effective span of the end panels = clear span + 1/2 effective depth

= 2.89 m

load claculation

consider 1 m width of slab

from (ii) j (3)of table 1 of IS : 875 (part 2 ) - 1987

inposed load , W

s =

1 * 1 * span

= 3000 n/m

dead load

self wt of slab

1 * 1 * 0.1 *25000 = 2500 n/m

wt of floor finish = 800 n/m

so W

d

3300 n/m

load factor = 1.5

design load W

ud =

4950 n/m

design load W

us =

4500 n/m

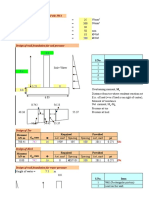

MaximumBM @ support next to end support (section 3)

from Table 112 of IS : 456 - 2000

M

max

= W

ud

l

2

/10 - W

us

l

2

/9

since the length of spans are not equal so average BM is to be calculated

M

max

= 15563.89

7781.9448 nm

= 7781944.8 nmm

depth req for strength

for balanced section of M 20 and fe 415 MR = Qubd

2

Qu = 2.079

Effective drpth req , d = 3743.1192

DESING OF ONE WAY CONTINOUS SLAB

d = 61.181036 < than 80 mm

Design BM

BM near middle of end span,

M1 = W

ud

l

2

/12 + W

us

l

2

/10

3445.2413 + 3758.445

= 7203.6863 N.m

BM near middle of interior span,

M2 = W

ud

l

2

/16 + W

us

l

2

/12

2255.3438 + 2733.75

4989.0938

BM @ support next to end support, span,

M3= W

ud

l

2

/10 - W

us

l

2

/9

-3645 + -4009.5

= -7654.5 nm

BM interior support,

M4 = = -(W

ud

l

2

/12 - W

us

l

2

/9)

-3007.125 + -3645

-6652.125 N.m

BM @end support

M5 = = -(W

ud

+W

us

)*L2/24

= -3288.639 N.m

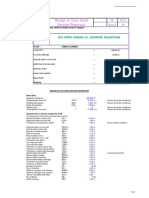

Main reinforcement - Area of steel

minimum area of styeel to be provided @ section 1, 2, 3, and 4

Ast

min

= 0.12/100 * 1000 * D

120 mm

2

Area of tensile steel required , @ section 1:

A

1

= o.5 fck/fy*1-1-(4.6m1/(fck bd2))+bd

= 268.18 mm

2

similarly

A1 = 268.18

A2 =

A3 =

A4 =

A5 =

Spacing of main bars

maximum permitted spacing aaat sections 1,2,3 and 4

= 3 x d mm

240 mm

Spacing of 8mm dia bars

S1 = as x 1000/A1 as = 3.14 x d

2

/4 dia = 8

187.33714 50.24

say 180 mm

similarly

S2 =

S3 =

S4 =

S5 =

Distributors

Area of tensile steel required (0.12%) = 120 mm

2

dia =

S = 418.66667 as =

say 415 mm

max permitted spacing = least of 5d and 450mm

= 450 mm

check for shear

from table 13 of IS : 456-2000

Maximum SF @ outer side of support next to end support

v

u =

0.6w

ud

l+0.6w

us

l

= 1.734

= 16386.3 n

Nominal shear stress

v

= v

u

/bd

= 0.2048288 n/mm

2

k > 1

Max shear stress

c =

0.28

n/mm

2

v <

k c and 0.5

c

max

hence safe against shear

check for stiffness

consider the end span

A1 = 268.18

% of reinforcement = A1/bd*100

0.34 %

taking f

s

= 0.58 fy

= 240.7 n/mm

2

from fig 4 of IS : 456-2000 mf = 1.39

d = clear span/ (basic value * MF)

79.966796 < 80

hence safe against stiffness

it can be design using bending moment and shear force coefficient given in Table 12

80 0.08 m

100 0.1 m

DESING OF ONE WAY CONTINOUS SLAB

33136956.75

128000000

0.258882475

0.741117525

0.86088183

0.13911817

268.1796046

8

50.24

You might also like

- Jack Well - Well FoundationDocument3 pagesJack Well - Well FoundationRamakanth PuttyNo ratings yet

- Design of Cantilever BeamDocument23 pagesDesign of Cantilever Beamjs kalyana rama85% (13)

- Design of Pedestal For Seismological Stations: Slenderness Ratio of The ColumnDocument2 pagesDesign of Pedestal For Seismological Stations: Slenderness Ratio of The ColumnAdarsh Kumar SNo ratings yet

- Design of Wall Like ColumnDocument4 pagesDesign of Wall Like Columnvishnumani3011No ratings yet

- Earthquake Load Calculations As Per IS1893-2002.-: Building Xyz at Mumbai. Rev - Mar2003 HSVDocument9 pagesEarthquake Load Calculations As Per IS1893-2002.-: Building Xyz at Mumbai. Rev - Mar2003 HSVEr Rakesh SharmaNo ratings yet

- Design of Column: Section ClassificationDocument4 pagesDesign of Column: Section Classificationvenkatesh19701No ratings yet

- Slab DesignDocument1 pageSlab DesignFarshad perouzNo ratings yet

- Nabin 2 WayslabDocument22 pagesNabin 2 WayslabNabin joshiNo ratings yet

- Design of Two-Way Restrained Slab (IS456:2000)Document3 pagesDesign of Two-Way Restrained Slab (IS456:2000)BasandharaAdhikariNo ratings yet

- Strap Beam FootingDocument4 pagesStrap Beam Footingrukesh104No ratings yet

- Design of Roof (Pratt) TrussDocument19 pagesDesign of Roof (Pratt) TrussKyle ForemanNo ratings yet

- Staircase Design FinalDocument10 pagesStaircase Design Finalpepe wosNo ratings yet

- 4.1 Walk Way SlabDocument12 pages4.1 Walk Way SlabSeph RjyNo ratings yet

- Super PassageDocument5 pagesSuper PassageSamir Rawat0% (1)

- Design of Cantilever Slab:: Area of The Footing RDocument4 pagesDesign of Cantilever Slab:: Area of The Footing RNarayan WNo ratings yet

- Design of Slab As Per IS:456-2000: Input DataDocument6 pagesDesign of Slab As Per IS:456-2000: Input DataMainali IshuNo ratings yet

- Staircase Design Dog Legged 2 LandingDocument5 pagesStaircase Design Dog Legged 2 LandingSuman Resolved NeupaneNo ratings yet

- Retaining Wall V 0.6 With K&CDocument59 pagesRetaining Wall V 0.6 With K&Cmayank007aggarwalNo ratings yet

- ZPurlinR1 OdsDocument21 pagesZPurlinR1 OdsRamachandra SahuNo ratings yet

- Project by Location: Girting Design ADocument10 pagesProject by Location: Girting Design AJurie_sk3608No ratings yet

- Composite Beam-Stilt FloorDocument9 pagesComposite Beam-Stilt FloorjatinNo ratings yet

- 1 456:2000 Clause 25.2) Annex E of The Code With The Assumption That The Frame IsDocument5 pages1 456:2000 Clause 25.2) Annex E of The Code With The Assumption That The Frame IsBejil ShresthaNo ratings yet

- Rectangular Tank Design-Bluetax ETP-1Document23 pagesRectangular Tank Design-Bluetax ETP-1monaliNo ratings yet

- Strap FootingDocument30 pagesStrap Footinganon_140586866No ratings yet

- Design of Ring Girder SupportDocument3 pagesDesign of Ring Girder Supportvishal guptaNo ratings yet

- Design of Flash Mixer at Kurawar - 1ADocument13 pagesDesign of Flash Mixer at Kurawar - 1AAnonymous RREG0QJWNo ratings yet

- Water TankDocument26 pagesWater Tankabhi aroteNo ratings yet

- Lacing DesignDocument4 pagesLacing DesignVenkat PalliNo ratings yet

- Footing DesignDocument2 pagesFooting DesignRathinavel VenkateshwaranNo ratings yet

- Water Tank Wall FootingDocument4 pagesWater Tank Wall FootingAbhishekKumarNo ratings yet

- Combined Footing SalinDocument30 pagesCombined Footing SalinSujan SinghNo ratings yet

- One Way Slab DesignDocument5 pagesOne Way Slab DesignharshNo ratings yet

- DistributionTheory RevBDocument102 pagesDistributionTheory RevBNasser AmmariNo ratings yet

- Beam Design With Deflection CheckDocument2 pagesBeam Design With Deflection Checkbhavin_civilNo ratings yet

- Column Is800Document4 pagesColumn Is800rammohanNo ratings yet

- VPRPL 600KL 24 M PDFDocument28 pagesVPRPL 600KL 24 M PDFAjayvidyanand SharmaNo ratings yet

- P PDFDocument49 pagesP PDFaanchaljasujaNo ratings yet

- Column Load Calculation Dt25.3.14Document4 pagesColumn Load Calculation Dt25.3.14VMRAJANNo ratings yet

- Isolated Footing DesignDocument24 pagesIsolated Footing DesignSANJEEV GANDOTRANo ratings yet

- Design of ColumnDocument46 pagesDesign of ColumnAnissah ManialaNo ratings yet

- PIle FoundationDocument6 pagesPIle FoundationsaravananNo ratings yet

- Angles - Truss DesignDocument109 pagesAngles - Truss DesignSamia H. Bhuiyan100% (2)

- Built - Up Column Design ("Effectiveness of Various Built-Up Columns") Section PropertiesDocument2 pagesBuilt - Up Column Design ("Effectiveness of Various Built-Up Columns") Section PropertiesAnandNo ratings yet

- Isolated Footing Design: Forces DetailsDocument10 pagesIsolated Footing Design: Forces DetailsJagadish_2No ratings yet

- Reinforcement: V, F: Project: Staircase Design - STC 1Document4 pagesReinforcement: V, F: Project: Staircase Design - STC 1zzweirdozzNo ratings yet

- 1 Dimensions of Tank Proper:: Design of 50 KL OhsrDocument30 pages1 Dimensions of Tank Proper:: Design of 50 KL OhsrMegatech Engineering ConsultantsNo ratings yet

- Column Rolled Section (Rev.2.00)Document3 pagesColumn Rolled Section (Rev.2.00)Harjasa AdhiNo ratings yet

- Design of Column Excel SheetDocument2 pagesDesign of Column Excel SheetAnand K RajNo ratings yet

- Sump .XLS (2.00 Lakhs)Document35 pagesSump .XLS (2.00 Lakhs)subramanyam kumarNo ratings yet

- Combine FootingsDocument1 pageCombine FootingsKherwin-j Sangalang100% (1)

- Design of Two Way Slab and ETABS Column Reaction.Document9 pagesDesign of Two Way Slab and ETABS Column Reaction.tuansteelsNo ratings yet

- Isolated Footing DesignDocument3 pagesIsolated Footing DesignSunil GuptaNo ratings yet

- RR Masonary Retaing Wall DesignDocument41 pagesRR Masonary Retaing Wall DesignAbhay KumarNo ratings yet

- Thursday, June 20, 2019, 07:28 AM: Page 1 of 226 E:/Kuliah/Semester IV/PBTS/Tugas Besar/YI - AnlDocument3 pagesThursday, June 20, 2019, 07:28 AM: Page 1 of 226 E:/Kuliah/Semester IV/PBTS/Tugas Besar/YI - AnlRyandhon GyandhaniNo ratings yet

- Design of Two Way Slab: 1) Trial DepthDocument3 pagesDesign of Two Way Slab: 1) Trial DepthDhananjay JoshiNo ratings yet

- Manual Beam DesignDocument14 pagesManual Beam DesignRonald Kaaku50% (2)

- Unit 5Document31 pagesUnit 5Nirina ArimananaNo ratings yet

- Design SectionDocument19 pagesDesign SectionKrishna KumarNo ratings yet

- T Beam Roof SlabDocument22 pagesT Beam Roof SlabRohit Khandelwal100% (1)

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- Project Report StructuralDocument70 pagesProject Report StructuralfaisalkalathilNo ratings yet

- 24-D15 - Grading - Excavation - Backfilling PDFDocument19 pages24-D15 - Grading - Excavation - Backfilling PDFfaisalkalathilNo ratings yet

- 24-D15 - Grading - Excavation - Backfilling PDFDocument19 pages24-D15 - Grading - Excavation - Backfilling PDFfaisalkalathilNo ratings yet

- TRAFFIC ACCIDENT ANALYSIS (Seminar)Document13 pagesTRAFFIC ACCIDENT ANALYSIS (Seminar)faisalkalathilNo ratings yet

- Bis Code of PracticeDocument23 pagesBis Code of PracticefaisalkalathilNo ratings yet