Professional Documents

Culture Documents

Shell: Working Pressure of Shell (As Per Ibr 270 & 271 New Amendment)

Shell: Working Pressure of Shell (As Per Ibr 270 & 271 New Amendment)

Uploaded by

Karthic KeyanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shell: Working Pressure of Shell (As Per Ibr 270 & 271 New Amendment)

Shell: Working Pressure of Shell (As Per Ibr 270 & 271 New Amendment)

Uploaded by

Karthic KeyanCopyright:

Available Formats

Sheet 3 of 25

2.

Where,

20000 psi

= 1

= 0.709 inch

= 122.05 inch

27160.00

122.73

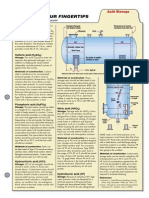

SHELL :

WP =

D = Inner Dia of shell ( 3100 / 25.4 )

2 f E ( T - 0.03 )

D + ( T - 0.03 )

WORKING PRESSURE OF SHELL ( AS PER IBR 270 & 271 NEW AMENDMENT ) :

122.05 + ( 0.71 - 0.03 )

=

(As per ASME Section-II Part D)

WP = Working pressure in PSIG

2 x 20000 x 1 x ( 0.709 - 0.03 )

f = Allowable stress (matl.SA 515 GR 70 / 516 GR 70) =

=

E = Ligament Efficiency

T = Shell Thickness ( 18 / 25.4 )

= 221.3 PSIG

T =

=

= 0.64 inch

= 16.26 mm

Result:

1.0 As per calculation required shell thickness 16.26 mm

Provided shell thickness = 18.00 mm

2.0 The calculated working pressure is greater than Design working pressure.

i.e Wp = 221.3 PSIG > 199 PSIG

[ ( D x WP ) / ( 2 f E - WP ) ]+ 0.03

[ ( 122.05 x 199 ) / ( 2 x 20000 x 1 - 199 ) ] + 0.03

HENCE DESIGN IS SAFE

Wp = 221.3 PSIG > 199 PSIG

You might also like

- Thickness Calculation of Pressure Vessel ShellDocument22 pagesThickness Calculation of Pressure Vessel ShellAkshat Jain89% (27)

- IBR CalculationDocument1 pageIBR CalculationKarthic Keyan100% (1)

- Design of Tooth Locked Quick Open Die Pressure VesselDocument4 pagesDesign of Tooth Locked Quick Open Die Pressure VesselSEP-PublisherNo ratings yet

- Pressure VesselDocument46 pagesPressure VesselHaftamu HilufNo ratings yet

- Xcalcs: Circular Flat Flanges Without Hubs: 2.7:+looseDocument2 pagesXcalcs: Circular Flat Flanges Without Hubs: 2.7:+looseayushNo ratings yet

- Datasheet of The HeaterDocument2 pagesDatasheet of The HeaterMubarik AliNo ratings yet

- 1289-Hari Prastowo-#2 Pipes Class & Thickness (Rev) Hand-OutDocument17 pages1289-Hari Prastowo-#2 Pipes Class & Thickness (Rev) Hand-OutSupriadi TansiNo ratings yet

- Design of Horizontal Flat Headed PressurDocument60 pagesDesign of Horizontal Flat Headed PressurKumarNo ratings yet

- And Dipstick Chart: Scroll Down For InstructionsDocument2 pagesAnd Dipstick Chart: Scroll Down For Instructionspowder18No ratings yet

- Fe Report of Base SkidDocument16 pagesFe Report of Base SkidpawanNo ratings yet

- 300 - F&D Head Design Tool Ver E4.01Document1 page300 - F&D Head Design Tool Ver E4.01Honey TiwariNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolssierroNo ratings yet

- Well Stimulation VesselDocument8 pagesWell Stimulation VesselHossein ramezaniNo ratings yet

- API 650 Tank Nozzle Load Allowable For Tank DiaDocument1 pageAPI 650 Tank Nozzle Load Allowable For Tank Diasemin prsesNo ratings yet

- Acid StorageDocument1 pageAcid StorageChelsea SkinnerNo ratings yet

- External PressureDocument22 pagesExternal PressureAbhijeet SahuNo ratings yet

- WRC 107 WRC 297 Co MP PDFDocument11 pagesWRC 107 WRC 297 Co MP PDFIqbal Muhammad100% (1)

- Stress RelievingDocument1 pageStress RelievingCruz Gabriel Rosetti100% (1)

- Pressure VesselDocument4 pagesPressure VesselDeaz AmbrsNo ratings yet

- E4.5.1 6 PTB 4 2015 PDFDocument50 pagesE4.5.1 6 PTB 4 2015 PDFKingston RivingtonNo ratings yet

- 2400 Tema DCDocument7 pages2400 Tema DCMasoodMiyanNo ratings yet

- Beam Design CalculationDocument33 pagesBeam Design CalculationsmijusNo ratings yet

- Openings Reinforced by Elliptical or Obround Nozzles Normal To The Shell Wall (For Cylindrical and Conical Shells) EN13445-3 - 9.4.4.2-1Document1 pageOpenings Reinforced by Elliptical or Obround Nozzles Normal To The Shell Wall (For Cylindrical and Conical Shells) EN13445-3 - 9.4.4.2-1met-calcNo ratings yet

- Eqn Reference ASME BPVC r1sDocument5 pagesEqn Reference ASME BPVC r1sagarcia654127No ratings yet

- SP-2069 Specification For Pressure VesselsDocument68 pagesSP-2069 Specification For Pressure Vesselsarjunprasannan7No ratings yet

- Stress Analysis and Design Optimization of A Pressure Vessel Using Ansys PackageDocument12 pagesStress Analysis and Design Optimization of A Pressure Vessel Using Ansys Packageanthony zegarra ochoaNo ratings yet

- 181-F Secondary Reformer Jacket Cooling Water Pit - R0 (1) - 12082018 PDFDocument17 pages181-F Secondary Reformer Jacket Cooling Water Pit - R0 (1) - 12082018 PDFManish542No ratings yet

- Project of Pressure VesselDocument25 pagesProject of Pressure VesselKalkidan DanielNo ratings yet

- Nozzle Calculations 01Document32 pagesNozzle Calculations 01Rohith V VNo ratings yet

- Calculation BS 31.3Document1 pageCalculation BS 31.3prabhjot123No ratings yet

- What Is Design Interpretation?Document17 pagesWhat Is Design Interpretation?Qaisir MehmoodNo ratings yet

- Design Note For Air Reciever TankDocument6 pagesDesign Note For Air Reciever TankJoshua Balaram RaoNo ratings yet

- NozzleDocument11 pagesNozzleharyfadlyNo ratings yet

- Pressure VesselprojectDocument26 pagesPressure VesselprojectMuhammadAli100% (1)

- 03 Metal Packing Support PlatesDocument3 pages03 Metal Packing Support PlatesypatelsNo ratings yet

- 10inch Inlet DiffuserDocument1 page10inch Inlet DiffuserJulian Vega DiazNo ratings yet

- PV Newsletter - Skirt Connections PDFDocument5 pagesPV Newsletter - Skirt Connections PDFDivyesh Patel100% (1)

- External Pressure Calculation ResultsDocument8 pagesExternal Pressure Calculation ResultsAndika DearsonNo ratings yet

- Calculation Samples - Pressure Vessel EngineeringDocument7 pagesCalculation Samples - Pressure Vessel EngineeringMarcel MrcNo ratings yet

- WI06-0260 Calculations For Obround Nozzle ConnectionsDocument4 pagesWI06-0260 Calculations For Obround Nozzle ConnectionskumarNo ratings yet

- Acum#2 RoladoDocument1 pageAcum#2 RoladoJuan PabloNo ratings yet

- Yale & Sentry 2010 Closure Catalog - R&MDocument16 pagesYale & Sentry 2010 Closure Catalog - R&MAlfredo OrellanaNo ratings yet

- Cone To Shell ReinforcementDocument4 pagesCone To Shell ReinforcementSajal KulshresthaNo ratings yet

- Comparative Research Into The Load-Bearing Capacity of Horizontal Pressure Vessels Supported by SaddlesDocument13 pagesComparative Research Into The Load-Bearing Capacity of Horizontal Pressure Vessels Supported by SaddlesMarek AdamczykNo ratings yet

- Rectangular Tanks:: Rectangle Tank DesignDocument23 pagesRectangular Tanks:: Rectangle Tank Designshna jabarNo ratings yet

- Tank Flush Simulation TutorialDocument23 pagesTank Flush Simulation TutorialPranav TripathiNo ratings yet

- Hemispherical Head Design Tool: Pressure Vessel Engineering LTDDocument1 pageHemispherical Head Design Tool: Pressure Vessel Engineering LTDExsan OthmanNo ratings yet

- Tubesheet As Per ASME Sec. VIII-Div.1 UHXDocument1 pageTubesheet As Per ASME Sec. VIII-Div.1 UHXruponline1No ratings yet

- PO BOX:41027, Dammam-31521 Kingdom of Saudi Arabia. Petronash Arabia Co. LTDDocument18 pagesPO BOX:41027, Dammam-31521 Kingdom of Saudi Arabia. Petronash Arabia Co. LTDUmair RazaNo ratings yet

- 4 - TEMA StandardDocument16 pages4 - TEMA StandardM.H vafaeiNo ratings yet

- Sealing Compounds From Project Sales CorpDocument34 pagesSealing Compounds From Project Sales CorpProject Sales CorpNo ratings yet

- TUBESHEETDocument5 pagesTUBESHEETMehta MehulNo ratings yet

- Final Weld Strength CalnsDocument5 pagesFinal Weld Strength CalnsamachmouchiNo ratings yet

- Top Pipe MomentDocument2 pagesTop Pipe Momentrsubramani100% (1)

- News Letter For Expansion Bellow PDFDocument4 pagesNews Letter For Expansion Bellow PDFAsma Khan100% (1)

- Steam Drum, Water Wall & Evaporator - VWHA054Document36 pagesSteam Drum, Water Wall & Evaporator - VWHA054Mani SunNo ratings yet

- E4.5 Flange Cover CalcDocument10 pagesE4.5 Flange Cover CalcTanCM100% (1)

- Pressure Vessel Engineering LTD.: Design ConditionsDocument30 pagesPressure Vessel Engineering LTD.: Design ConditionsTrishul Nath PallayNo ratings yet

- Design Calculations - 1Document3 pagesDesign Calculations - 1Engineering1 SaraNo ratings yet

- Company Name: Input DataDocument4 pagesCompany Name: Input Dataagb71c2478No ratings yet

- Ab1 - Anchor Bolt-ModelDocument1 pageAb1 - Anchor Bolt-ModelKarthic KeyanNo ratings yet

- AISC Bolt Standard SizeDocument1 pageAISC Bolt Standard SizeKarthic KeyanNo ratings yet

- Customer Feed Back and Handling of Customer ComplaintDocument2 pagesCustomer Feed Back and Handling of Customer ComplaintKarthic KeyanNo ratings yet

- Handling of Customer RFQ and Quotation: ProcedureDocument2 pagesHandling of Customer RFQ and Quotation: ProcedureKarthic KeyanNo ratings yet

- East Shelter Ee1 Walls SL - No Profile Take Off Length in Mtrs Qty KG/MTR Weight in KG RemarksDocument1 pageEast Shelter Ee1 Walls SL - No Profile Take Off Length in Mtrs Qty KG/MTR Weight in KG RemarksKarthic KeyanNo ratings yet

- Work Order and Contract ReviewDocument2 pagesWork Order and Contract ReviewKarthic KeyanNo ratings yet

- Engineering: Doc No: MJE-ENGG-004 Issue No: 1 Rev No: 0 Date 15 May 2018Document2 pagesEngineering: Doc No: MJE-ENGG-004 Issue No: 1 Rev No: 0 Date 15 May 2018Karthic KeyanNo ratings yet

- Design Structural Steel Design and Construction PDFDocument59 pagesDesign Structural Steel Design and Construction PDFdkaviti100% (2)

- US Steel CalculatorDocument10 pagesUS Steel CalculatorKarthic KeyanNo ratings yet

- 1 Acre 100 Cents 4840 Square Yards 1 Cent 48.4 Square Yards 1 Square Yard 9 Square Feet 1 Cent 48.4 9 435.6 Square FeetDocument1 page1 Acre 100 Cents 4840 Square Yards 1 Cent 48.4 Square Yards 1 Square Yard 9 Square Feet 1 Cent 48.4 9 435.6 Square FeetKarthic KeyanNo ratings yet

- Plate Material SpecificationDocument8 pagesPlate Material SpecificationKarthic KeyanNo ratings yet

- Public Provident Fund (PPF) Scheme 1968Document1 pagePublic Provident Fund (PPF) Scheme 1968Karthic KeyanNo ratings yet

- Turbine Inlet Condition As BelowDocument1 pageTurbine Inlet Condition As BelowKarthic KeyanNo ratings yet

- Excess Air CalculationDocument11 pagesExcess Air CalculationKarthic Keyan50% (2)

- Power (KW) Energy Efficiency Standard (Percentage) Open Enclosed 2 Pole 4 Pole 6 Pole 2 Pole 4 Pole 6 PoleDocument1 pagePower (KW) Energy Efficiency Standard (Percentage) Open Enclosed 2 Pole 4 Pole 6 Pole 2 Pole 4 Pole 6 PoleKarthic KeyanNo ratings yet

- Enquiry For Erection of BoilerDocument1 pageEnquiry For Erection of BoilerKarthic KeyanNo ratings yet

- Performance Data For Various Fuels: Composition Rice Husk Julia Flora Wood Chips Subabul Wood Maize Stalk Cotton StalkDocument1 pagePerformance Data For Various Fuels: Composition Rice Husk Julia Flora Wood Chips Subabul Wood Maize Stalk Cotton StalkKarthic KeyanNo ratings yet