Professional Documents

Culture Documents

Defect Picture: Cause: Tact Switch Not Properly Pressing When Clinching

Defect Picture: Cause: Tact Switch Not Properly Pressing When Clinching

Uploaded by

Mohd Isa HarunOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Defect Picture: Cause: Tact Switch Not Properly Pressing When Clinching

Defect Picture: Cause: Tact Switch Not Properly Pressing When Clinching

Uploaded by

Mohd Isa HarunCopyright:

Available Formats

SHINKA Evolve, Intensify, and True Value

BBGG

Harmonization

Temporary Action Permanent Countermeasure

Sorting at SOEM:-

Plan Lot: 10246004

Lot size: 2100

Result : 0/360

Detail Investigation + Findings

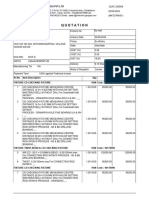

DEFECT S701 FLOATING SYMPTOM BUTTON NOT FUNCTION

BOARD/MODEL B1303 / BDP 9G PLAN LOT/ LOT SIZE 10246004 / 2100

DEFECT DATE & TIME 16/06/2014 7:00 PM P. CODE 5831

GA LINE B15 QTY / CAVITY 1PCS / 8

SUSPECTED CAUSE UNDER INVESTIGATE CLASS DEFECT AMT KAGA

DETECT BY GA CPC/ICT DETECTION UNDER INVESTIGATE

SORTING RESULTS 0/207 DM CODE 5831090614Y08704

Sorting at PARTNERS:-

Plan Lot:

Lot size:

Result :

Defect Picture

FR1303 S701 FLOATING

Tooling footprint

Pusher

Cause: Tact switch not properly pressing when clinching.

1. Increase the pusher high pressing timer before perform

lead clinching

Pusher high pressing start

Pusher high pressing start

Before

After

SHINKA Evolve, Intensify, and True Value

BBGG

Harmonization

FR1303 S701 FLOATING

AFTER BEFORE

290 degree

280 degree

SHINKA Evolve, Intensify, and True Value

BBGG

Harmonization

FR1303 S701 FLOATING

Tooling footprint

Pusher

Q1 > Why this timer had been changed from 280

o

to 290

o

Ans : We suspect

the machine did lead clinching more early than pusher pressing tact switch

to the surface of PWB.

The setting change to make pusher pressing more early than lead cutting timing

Q2> The pusher had been push down

a) push height setting (No change pusher is spring type)

b) possible pattern cut or pwb broken (No)

c) impact other component (No)

You might also like

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- CS 533E Cat Manual de Peças e ServiçosDocument824 pagesCS 533E Cat Manual de Peças e ServiçosMarco Olivetto0% (1)

- PR 9000 E - Inst Manual (E) (SG14 SE001B - Rev 20170608)Document50 pagesPR 9000 E - Inst Manual (E) (SG14 SE001B - Rev 20170608)Mooi Pang Ng100% (2)

- Frick-Rotary Screw Comp Models SGC 193 233 283 SGCB SGCH 355 Service Parts ListDocument44 pagesFrick-Rotary Screw Comp Models SGC 193 233 283 SGCB SGCH 355 Service Parts ListHugo Rodriguez83% (6)

- C2 G 20 Max 3080000 Btu Output 10 To 1 TurndownDocument8 pagesC2 G 20 Max 3080000 Btu Output 10 To 1 TurndownBülent KabadayiNo ratings yet

- Q277 027706122023 Octagon International Services Co.,ltdDocument1 pageQ277 027706122023 Octagon International Services Co.,ltdmyathsulwin83No ratings yet

- viewNitPdf 4391531Document21 pagesviewNitPdf 4391531yogesh yogeNo ratings yet

- Est N1522CDocument1 pageEst N1522CPrastyo TyoNo ratings yet

- Component Code ZZ: Printed in Japan (02) 1Document15 pagesComponent Code ZZ: Printed in Japan (02) 1Jose A. Basanta H.No ratings yet

- Pump Data Sheet - 0410-PPC-0069 - 0070Document3 pagesPump Data Sheet - 0410-PPC-0069 - 0070Jorge Jesus Nayhua GamarraNo ratings yet

- Pasela Jaya Batu PayungDocument17 pagesPasela Jaya Batu Payungariy yuli styawanNo ratings yet

- Boom Barrier ..Document1 pageBoom Barrier ..Sudhanshu ShrivastavaNo ratings yet

- Coti GIW Rep 26x28LSA PDFDocument3 pagesCoti GIW Rep 26x28LSA PDFjohan diazNo ratings yet

- 2YR Spare Parts - TAG TemplateDocument39 pages2YR Spare Parts - TAG TemplateCleevan Kayne AlegresNo ratings yet

- Bom Material MHG 5-8 PT - DssDocument40 pagesBom Material MHG 5-8 PT - DssAdeImanudinNo ratings yet

- Quotation: M/S Dalhia Energy Service LTDDocument3 pagesQuotation: M/S Dalhia Energy Service LTDPawan MouryaNo ratings yet

- Se 150-60 - 2015Document849 pagesSe 150-60 - 2015helijunior67151No ratings yet

- DS85 002Document21 pagesDS85 002Patrick ByronNo ratings yet

- Agency: Jps Construction Bill No:Ra 01 Erection BillDocument9 pagesAgency: Jps Construction Bill No:Ra 01 Erection Billvinod_eicsNo ratings yet

- Manual Honda ActuadorDocument11 pagesManual Honda ActuadorLuis MurrietaNo ratings yet

- MGA1400BDocument3 pagesMGA1400BelabedaNo ratings yet

- Agency: Jps Construction Bill No:Ra 01 Erection BillDocument9 pagesAgency: Jps Construction Bill No:Ra 01 Erection Billvinod_eicsNo ratings yet

- Ivar Aasen Field Development Project - PDQ: Dn02-S09011-E-Xk-3436-00 01EDocument3 pagesIvar Aasen Field Development Project - PDQ: Dn02-S09011-E-Xk-3436-00 01EayemyothantNo ratings yet

- 0186 MOM DSP 025 062 0030 Valvulas de Control 2Document266 pages0186 MOM DSP 025 062 0030 Valvulas de Control 2Lukas Ramírez SchiaffinoNo ratings yet

- Running Test GearboxDocument4 pagesRunning Test GearboxBayu PrasongkoNo ratings yet

- Condition/Concern: Bulletin No.: PI0631H Date: Apr-2013Document5 pagesCondition/Concern: Bulletin No.: PI0631H Date: Apr-2013Erik CruzNo ratings yet

- Prominent S.A.C.: Mina Justa ProjectDocument4 pagesProminent S.A.C.: Mina Justa ProjectWilson MamaniNo ratings yet

- Notes: Foundation Plan Sheet 3: Notas: Cimentacion Planta Hoja 3Document1 pageNotes: Foundation Plan Sheet 3: Notas: Cimentacion Planta Hoja 3Leo Unocc YauriNo ratings yet

- Company Profile Spring SCDocument27 pagesCompany Profile Spring SCRich PrayerNo ratings yet

- 0944 Service Report - Ultrajaya - Service Elmo Abb 3kw Sn. 14610po602 005 1Document1 page0944 Service Report - Ultrajaya - Service Elmo Abb 3kw Sn. 14610po602 005 1multisolusindoniagaNo ratings yet

- Shock Absorber Specification CardDocument1 pageShock Absorber Specification Cardanna mannaNo ratings yet

- Aligment Report EFPDocument6 pagesAligment Report EFPReza Beni PratamaNo ratings yet

- Epcc/kch400/wo8630 0Document7 pagesEpcc/kch400/wo8630 0spnaikNo ratings yet

- Engine-Stage 1 HPT Duct Segment: Export ControlDocument4 pagesEngine-Stage 1 HPT Duct Segment: Export ControlMassood ShNo ratings yet

- Den So 080927 Sub Panel For Injection 1Document16 pagesDen So 080927 Sub Panel For Injection 1eirNo ratings yet

- CPS6 Chokes Severn DatasheetsDocument18 pagesCPS6 Chokes Severn DatasheetskarthikNo ratings yet

- Woosu PTC & PMCDocument15 pagesWoosu PTC & PMCMani VannanNo ratings yet

- Aa16020a Replacement of Damaged Rocker Switch Actuators - NP Actuadores de CabinaDocument3 pagesAa16020a Replacement of Damaged Rocker Switch Actuators - NP Actuadores de CabinaLudwin Alex Gutierrez TintaNo ratings yet

- 009 Mam Etr Mks Att Saga Vii 2023Document33 pages009 Mam Etr Mks Att Saga Vii 2023M. Anggoro MustikoNo ratings yet

- Den So 080922 Revise-1 Sub Panel For Injection 11Document16 pagesDen So 080922 Revise-1 Sub Panel For Injection 11eirNo ratings yet

- Min1244a12 - Tag 130-Pu-029Document7 pagesMin1244a12 - Tag 130-Pu-029Monty MathewsNo ratings yet

- PO 20130916-01 For InvestaDocument10 pagesPO 20130916-01 For Investavinodkhare2007No ratings yet

- Rotomac Industries PVT LimitedDocument3 pagesRotomac Industries PVT Limitedcia sin kwangNo ratings yet

- Ver Tanky BeforeDocument3 pagesVer Tanky Beforedendi hidayatNo ratings yet

- Item Codigo Descricao Uni Quantidade EntregaDocument1 pageItem Codigo Descricao Uni Quantidade EntregaJanaina MarianoNo ratings yet

- Valve Rocker ArmDocument3 pagesValve Rocker Armsulistyo enginedieselNo ratings yet

- Vetting & Approval Form For Purchase Request PR No:10003624Document7 pagesVetting & Approval Form For Purchase Request PR No:10003624LONG ZHANGNo ratings yet

- Turbine Rtoer Assy GEDocument4 pagesTurbine Rtoer Assy GEMaricelaCrisMJNo ratings yet

- CD1116-20-25 TechnicalBulletin 20101018Document123 pagesCD1116-20-25 TechnicalBulletin 20101018dtolind smtpNo ratings yet

- 19685-Air Compressor PartsDocument1 page19685-Air Compressor PartsLin LeninNo ratings yet

- Ignition Cables and Igniter Installation PDFDocument6 pagesIgnition Cables and Igniter Installation PDFMark Evan SalutinNo ratings yet

- MTC Pipa Kotak 60x2, 50x2Document1 pageMTC Pipa Kotak 60x2, 50x2Pahala LumbantoruanNo ratings yet

- Sulzer Pumps Solutions in Product SpecificationDocument6 pagesSulzer Pumps Solutions in Product SpecificationAdriánNo ratings yet

- QuotationDocument2 pagesQuotationNPD TEAM HosurNo ratings yet

- Cylinder Head: Shutdown SIS Previous ScreenDocument5 pagesCylinder Head: Shutdown SIS Previous ScreenEric LedesmaNo ratings yet

- 07.1-8300 Adjusting Start of Delivery (After Testing)Document6 pages07.1-8300 Adjusting Start of Delivery (After Testing)asdNo ratings yet

- QuotationDocument3 pagesQuotationNPD TEAM HosurNo ratings yet

- Ministry of Electricity and Renewable Energy Cairo Electricity Production Company (Cepc)Document9 pagesMinistry of Electricity and Renewable Energy Cairo Electricity Production Company (Cepc)mohamed abourayaNo ratings yet

- Amend 2Document1 pageAmend 2Mohd Isa HarunNo ratings yet

- KL Tec 9G 12032012Document9 pagesKL Tec 9G 12032012Mohd Isa HarunNo ratings yet

- USB Pin One Leg Not Insert (8G) : BeforeDocument3 pagesUSB Pin One Leg Not Insert (8G) : BeforeMohd Isa HarunNo ratings yet

- B6452 Connector Solder Blocking-IsaDocument3 pagesB6452 Connector Solder Blocking-IsaMohd Isa HarunNo ratings yet

- PHOTO Bare Board 1-734-376-21Document3 pagesPHOTO Bare Board 1-734-376-21Mohd Isa HarunNo ratings yet

- Film Modification Proposal: Make Accurate Circle (Not Uneven)Document1 pageFilm Modification Proposal: Make Accurate Circle (Not Uneven)Mohd Isa HarunNo ratings yet

- TLP560J: Triac Driver Programmable Controllers AC Output Module Solid State RelayDocument6 pagesTLP560J: Triac Driver Programmable Controllers AC Output Module Solid State RelayMohd Isa HarunNo ratings yet

- Poor Performance Improvement ProgramDocument4 pagesPoor Performance Improvement ProgramMohd Isa HarunNo ratings yet

- Salary AppraisalDocument5 pagesSalary AppraisalMohd Isa HarunNo ratings yet

- No Model QTY/day Panel Qty / Rack Rack Qty/ Day Checking Time/panel (3 Panel Per Rack) Common ProblemsDocument1 pageNo Model QTY/day Panel Qty / Rack Rack Qty/ Day Checking Time/panel (3 Panel Per Rack) Common ProblemsMohd Isa HarunNo ratings yet

- X-Ray Check:: Potential Failure AreaDocument1 pageX-Ray Check:: Potential Failure AreaMohd Isa HarunNo ratings yet

- These People Really Want OT Monday Tuesday Manoj Manoj Manoj Ram Ram Ram Raj Raj Namuna Namuna Mohd Mohd Manju ManjuDocument2 pagesThese People Really Want OT Monday Tuesday Manoj Manoj Manoj Ram Ram Ram Raj Raj Namuna Namuna Mohd Mohd Manju ManjuMohd Isa HarunNo ratings yet

- All Cavity Capability Analysis: LSL 1.5 Nominal 2Document14 pagesAll Cavity Capability Analysis: LSL 1.5 Nominal 2Mohd Isa HarunNo ratings yet

- LDR Kaga Jan.'14Document1 pageLDR Kaga Jan.'14Mohd Isa HarunNo ratings yet

- KQP 16 Inspection & Testing Rev 04Document11 pagesKQP 16 Inspection & Testing Rev 04Mohd Isa HarunNo ratings yet

- Paramit 15 - 8 - 2014Document2 pagesParamit 15 - 8 - 2014Mohd Isa HarunNo ratings yet

- HQ Meeting Jan3Document3 pagesHQ Meeting Jan3Mohd Isa HarunNo ratings yet

- Dipping Change Model Quality Checksheet (5 Panels Confirmation)Document2 pagesDipping Change Model Quality Checksheet (5 Panels Confirmation)Mohd Isa HarunNo ratings yet

- 2013 06 13 Iso9001 Qms Team IsaDocument1 page2013 06 13 Iso9001 Qms Team IsaMohd Isa HarunNo ratings yet

- HQ Meeting 4Document4 pagesHQ Meeting 4Mohd Isa HarunNo ratings yet