Professional Documents

Culture Documents

Untitled Extract Pages

Untitled Extract Pages

Uploaded by

solidworm0 ratings0% found this document useful (0 votes)

4 views1 pageThe document summarizes the effects of different post-weld heat treatments on the hardness of aluminum alloys. It shows that post-weld artificial aging after welding leads to higher hardness values than natural aging. Welding heat-treatable aluminum alloys in the T6 condition can cause overaging and loss of strength, so welding in the T4 condition is preferred. The welding process, heat input, and speed can also impact the loss of hardness in the heat-affected zone.

Original Description:

PW

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document summarizes the effects of different post-weld heat treatments on the hardness of aluminum alloys. It shows that post-weld artificial aging after welding leads to higher hardness values than natural aging. Welding heat-treatable aluminum alloys in the T6 condition can cause overaging and loss of strength, so welding in the T4 condition is preferred. The welding process, heat input, and speed can also impact the loss of hardness in the heat-affected zone.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

4 views1 pageUntitled Extract Pages

Untitled Extract Pages

Uploaded by

solidwormThe document summarizes the effects of different post-weld heat treatments on the hardness of aluminum alloys. It shows that post-weld artificial aging after welding leads to higher hardness values than natural aging. Welding heat-treatable aluminum alloys in the T6 condition can cause overaging and loss of strength, so welding in the T4 condition is preferred. The welding process, heat input, and speed can also impact the loss of hardness in the heat-affected zone.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Knoop hardness (500g)

AlCuMg AND AlMgSi ALLOYS

100

365

Postweld artificial

aging (155oC, 18

hours)

Postweld natural

aging (7 days)

Right after welding

50

0

15

30

Distance from fusion line, mm

Figure 15.14 HAZ hardness profiles in a 6061 aluminum gastungsten arc welded in

T4 condition. From Kou and Le (11).

Hardness, DPH (500g)

Distance from fusion line, in

0

0.2 0.4 0.6 0.8 1.0

110

100

90

T4, Postweld AA

T6, Postweld AA

T6, Postweld NA

80

T4, Postweld NA

70

60

0

0.5 1.0 1.5 2.0 2.5

Distance from fusion line, cm

Figure 15.15 HAZ hardness profiles in 6061 aluminum welded in T4 or T6 and

postweld naturally or artificially aged. Reprinted from Metzger (20). Courtesy of

American Welding Society.

Figure 15.15 shows the results of hardness measurements in a 6061

aluminum (20). It suggests that welding a heat-treatable 6000- or 2000-series

alloy in the T6 (artificially aged) condition can result in severe loss of strength

(hardness) due to overaging. For this reason, welding in the T4 condition is

often preferred to welding in the T6 condition (19, 20).

15.2.3 Effect of Welding Processes and Parameters

The loss of strength in the HAZ can be significantly affected by the welding

process and by the heat input and welding speed. Figure 15.16 shows that as

You might also like

- A 447Document27 pagesA 447superman3kNo ratings yet

- En-485-4 AlMg3 H22Document20 pagesEn-485-4 AlMg3 H22Atul FalduNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Leaded Tin Bronze C54400Document3 pagesLeaded Tin Bronze C54400nfcastingsNo ratings yet

- Technical DataDocument17 pagesTechnical Datat_syamprasadNo ratings yet

- HardfacingDocument15 pagesHardfacingYahya IsiedNo ratings yet

- Cosmos Alminium-Technical SpecificationsDocument2 pagesCosmos Alminium-Technical SpecificationsmindsopenNo ratings yet

- Metals HandbookDocument33 pagesMetals HandbookAlexandre Sp50% (4)

- Nitro Nic 60 BookDocument36 pagesNitro Nic 60 BookGerman ToledoNo ratings yet

- How To Weld Fully Austenitic Stainless SteelsDocument20 pagesHow To Weld Fully Austenitic Stainless SteelsCarlos Bermejo AlvarezNo ratings yet

- STEELDocument6 pagesSTEELRico BelledoNo ratings yet

- Data SAF2205 04Document8 pagesData SAF2205 04il_yoo_1No ratings yet

- Stainless AISI 3XXDocument3 pagesStainless AISI 3XXThitaphol HuyananNo ratings yet

- 468 PDFDocument4 pages468 PDFJoshua WalkerNo ratings yet

- AISI 1035 Carbon SteelDocument3 pagesAISI 1035 Carbon SteelJESUS AVILA MTZNo ratings yet

- Microsoft Power Point - Deloro Stellite Advances in Wear Resistant Alloys and ProductsDocument56 pagesMicrosoft Power Point - Deloro Stellite Advances in Wear Resistant Alloys and ProductsMilanWaNo ratings yet

- Macsteel VRN - Wear Abrasion Steels - Creusabro 8000Document4 pagesMacsteel VRN - Wear Abrasion Steels - Creusabro 8000jonodo89No ratings yet

- Alloy List HitchinerDocument8 pagesAlloy List Hitchineratfrost4638No ratings yet

- CRGO Strips India, CRGO Transformer Laminations, CRGO Core IndiaDocument4 pagesCRGO Strips India, CRGO Transformer Laminations, CRGO Core IndiarajfabNo ratings yet

- Sail-Jyoti e Book 17-6-23Document16 pagesSail-Jyoti e Book 17-6-23heplblrNo ratings yet

- CDA110 Specifaction SheetDocument5 pagesCDA110 Specifaction SheetGendakensNo ratings yet

- Alloy 7075 Tech SheetDocument4 pagesAlloy 7075 Tech SheetRaees SwatiNo ratings yet

- Wire RoadDocument16 pagesWire Road02081987No ratings yet

- Weldeability Offshore SteelDocument12 pagesWeldeability Offshore Steelcarrotiron100% (1)

- E76 Ac510 - 520uDocument4 pagesE76 Ac510 - 520uFabianoKovalechenNo ratings yet

- Bus Conductor Design and ApplicationsDocument70 pagesBus Conductor Design and ApplicationsJithinNo ratings yet

- European Steel and Alloy GradesDocument3 pagesEuropean Steel and Alloy Gradesfarshid KarpasandNo ratings yet

- T 6061Document5 pagesT 6061Zoran DanilovNo ratings yet

- Tubular Products From Special MetalsDocument26 pagesTubular Products From Special Metalskaveh-bahiraeeNo ratings yet

- Tugas 10 - Chapter 15Document6 pagesTugas 10 - Chapter 15hana haddadNo ratings yet

- AVESTA How To Weld Duplex SteelDocument20 pagesAVESTA How To Weld Duplex SteelGMacella100% (1)

- Hot Rolling ProductsDocument17 pagesHot Rolling ProductsKrishna VamsiNo ratings yet

- KISWEL Mag Welding ConsumableDocument4 pagesKISWEL Mag Welding Consumablekhwanta-btaNo ratings yet

- 380.1 PropiedadesDocument3 pages380.1 PropiedadesNini CortesNo ratings yet

- Nitronic 60Document2 pagesNitronic 60Lalit SharmaNo ratings yet

- 3coated SteelDocument20 pages3coated Steelalifakash1605No ratings yet

- Duplex Stainless Steel AL 2205™ Alloy: (UNS S31803 and S32205)Document6 pagesDuplex Stainless Steel AL 2205™ Alloy: (UNS S31803 and S32205)Dell_RevanNo ratings yet

- CR StandardsDocument6 pagesCR Standardsalpha_beta48No ratings yet

- 6061 Aluminium Alloy - WikipediaDocument33 pages6061 Aluminium Alloy - WikipediaMangesh MishraNo ratings yet

- Die Casting Heat Treatment Process To Increase Strength Part 1Document4 pagesDie Casting Heat Treatment Process To Increase Strength Part 1itslowNo ratings yet

- GP20110327Document36 pagesGP20110327Artem KuznetsovNo ratings yet

- HandBook Stuctural SteelDocument267 pagesHandBook Stuctural SteelOnn Lajer100% (9)

- NLMK in Hot Rolled ProductsDocument7 pagesNLMK in Hot Rolled Productsafraz_xecNo ratings yet

- Alloy 800H Material and Fabrication Challenges Associated With The Mitigation of Stress Relaxation CrackingDocument11 pagesAlloy 800H Material and Fabrication Challenges Associated With The Mitigation of Stress Relaxation CrackingGeorge SalsburyNo ratings yet

- Flexible Metal HosesDocument16 pagesFlexible Metal Hosesyoonchankim0911No ratings yet

- Union S2 Si & Union S3NiMo1Document1 pageUnion S2 Si & Union S3NiMo1Kara WhiteNo ratings yet

- Carbone 2191 ISO Graphite Spec SheetDocument6 pagesCarbone 2191 ISO Graphite Spec Sheetmichaelstarr1969No ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- Forging Operations - Machine Forging, Forging Dies and Special Forging OperationsFrom EverandForging Operations - Machine Forging, Forging Dies and Special Forging OperationsNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- Ceramics for Environmental SystemsFrom EverandCeramics for Environmental SystemsLianzhou WangNo ratings yet

- 11.8.2.3 Opening The Calculation File: 11 I-235 3D InterfacesDocument14 pages11.8.2.3 Opening The Calculation File: 11 I-235 3D InterfacessolidwormNo ratings yet

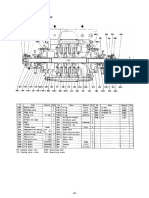

- Sectional Drawings and Lists of Components: Size MMK 40, 50, 65 Stuffing Box Housing: Type NDocument1 pageSectional Drawings and Lists of Components: Size MMK 40, 50, 65 Stuffing Box Housing: Type NsolidwormNo ratings yet

- 11.2 Generation of 3D GearsDocument10 pages11.2 Generation of 3D GearssolidwormNo ratings yet

- S Pare PartsDocument1 pageS Pare PartssolidwormNo ratings yet

- Stub Shaft Dimensions, Packing Details, Cooling Water and Oil Requirements, Bearings, Seals, O-Rings and GasketsDocument1 pageStub Shaft Dimensions, Packing Details, Cooling Water and Oil Requirements, Bearings, Seals, O-Rings and GasketssolidwormNo ratings yet

- Size MMK 40, 50, 65 Tuffing Box Housing: Type HW SDocument1 pageSize MMK 40, 50, 65 Tuffing Box Housing: Type HW SsolidwormNo ratings yet

- Buoyancy: Basic EquationsDocument1 pageBuoyancy: Basic EquationssolidwormNo ratings yet

- Fluid Statics: Manometers and Pressure MeasurementsDocument1 pageFluid Statics: Manometers and Pressure MeasurementssolidwormNo ratings yet

- 4.2.3. Re-Assembly of Pumps With End Suction NozzleDocument2 pages4.2.3. Re-Assembly of Pumps With End Suction NozzlesolidwormNo ratings yet

- And Liquid Viscosity: Stress ZDocument1 pageAnd Liquid Viscosity: Stress ZsolidwormNo ratings yet

- General Requirements:: 1062 16 Pump TestingDocument1 pageGeneral Requirements:: 1062 16 Pump TestingsolidwormNo ratings yet

- Fluid Properties: Density, Specific Volume, Specific Weight, Specific Gravity, and PressureDocument1 pageFluid Properties: Density, Specific Volume, Specific Weight, Specific Gravity, and PressuresolidwormNo ratings yet

- 1 5736Document2 pages1 5736solidwormNo ratings yet

- Fluid Prope Pipe Flow: Bhabani P Mohanty. PH.D., Development Engineer. Allison Engine Company 2 7Document1 pageFluid Prope Pipe Flow: Bhabani P Mohanty. PH.D., Development Engineer. Allison Engine Company 2 7solidwormNo ratings yet

- Essentials of Turbo Machinery in CFD: Ideen SadrehaghighiDocument9 pagesEssentials of Turbo Machinery in CFD: Ideen SadrehaghighisolidwormNo ratings yet

- 16.2.1 Types and Layout of Closed Test LoopsDocument1 page16.2.1 Types and Layout of Closed Test LoopssolidwormNo ratings yet

- Untitled Extract PagesDocument1 pageUntitled Extract PagessolidwormNo ratings yet

- Near Net ShapeDocument30 pagesNear Net ShapesolidwormNo ratings yet

- 669 IndexDocument1 page669 IndexsolidwormNo ratings yet