Professional Documents

Culture Documents

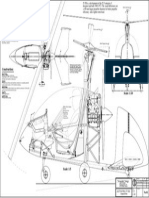

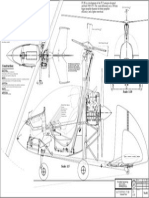

Autogyro Jt-5B: Fuselage and Tail Parts

Autogyro Jt-5B: Fuselage and Tail Parts

Uploaded by

Andone Anutu0 ratings0% found this document useful (0 votes)

87 views1 pageVacuum bag molding was used to fabricate most of the fuselage parts for an autogyro. A temporary female mold made of sheet metal and plastic tape was used to make the integral fuel tank. Two layers of fabric were added to the outside of the fuel tank after removing the metal sheets. The wings and tail parts were constructed using layers of glass fabric and foam cores, with edges rounded using an epoxy and microballoon mix. Joints between parts were bonded with a glass powder filled epoxy resin.

Original Description:

Original Title

JT-58.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentVacuum bag molding was used to fabricate most of the fuselage parts for an autogyro. A temporary female mold made of sheet metal and plastic tape was used to make the integral fuel tank. Two layers of fabric were added to the outside of the fuel tank after removing the metal sheets. The wings and tail parts were constructed using layers of glass fabric and foam cores, with edges rounded using an epoxy and microballoon mix. Joints between parts were bonded with a glass powder filled epoxy resin.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

87 views1 pageAutogyro Jt-5B: Fuselage and Tail Parts

Autogyro Jt-5B: Fuselage and Tail Parts

Uploaded by

Andone AnutuVacuum bag molding was used to fabricate most of the fuselage parts for an autogyro. A temporary female mold made of sheet metal and plastic tape was used to make the integral fuel tank. Two layers of fabric were added to the outside of the fuel tank after removing the metal sheets. The wings and tail parts were constructed using layers of glass fabric and foam cores, with edges rounded using an epoxy and microballoon mix. Joints between parts were bonded with a glass powder filled epoxy resin.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

100

3rd layer of

fabric, 90

758

Spar rowings

PVC or Urethane

foam core

Two layers of glass fabric

300 gr/sqm, 45 and 90

510

Engine cowling of

Aluminium alloy sheet

Vacuumbag molding used to fabricate most

fuselage parts. Sheet metal and plastic tape

used to make a temporary female mold for

the integral fuel tank. After removing the

metal sheets, two layers of fabric added on

the outside of fuel tank.

One layer of 300 gr/sqm

glass fabric on each side.

Honeycomb or plastic

foam core, thickness 7 mm.

Edges rounded with

microballoon/epoxy mix.

353

575

631

311

Two layers of glass fabric

300 gr/sqm, 45 and 90

B

PVC or Urethane

foam core

1879

B-B

5 mm plywood edge stiffener

2 fabrics on each side, 45 and 90

5 mm plastic foam or honeycomb core

3rd layer of

fabric, 45

1056

Main spar unidirectional roving

Joints bonded with glass powder

filled epoxy resin.

4th layer of

fabric, 45

3 Fabrics

B

658

A-A

902

20

1465

Signature

Tervamki Engineering

Jukka Tervamki

Harmaapaadentie 12A

00930 Helsinki, Finland

Fuselage and Tail Parts

Version

Feb.10,99

02

Tervamki

Engineering

Scale

AUTOGYRO JT-5B

Date

1:5

Projection

Drawing

No:08

You might also like

- Pasquali Service Manual PDFDocument65 pagesPasquali Service Manual PDFAndone Anutu100% (5)

- Ysm Ydm B Ahu Catalogue 01 2007Document9 pagesYsm Ydm B Ahu Catalogue 01 2007Hafiz Muhammad Muneeb50% (2)

- A Comprehensive Guide to Composites: Processes & Procedures from the ProfessionalsFrom EverandA Comprehensive Guide to Composites: Processes & Procedures from the ProfessionalsRating: 5 out of 5 stars5/5 (2)

- 2016 Warman CompetitionDocument19 pages2016 Warman CompetitionAndrew WalleyNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- GTB Guitar Chord Secrets PDFDocument65 pagesGTB Guitar Chord Secrets PDFAndone Anutu100% (1)

- Galene Gti Technical Information /PUIGMETAL®Document1 pageGalene Gti Technical Information /PUIGMETAL®PUIGMETAL®No ratings yet

- Fiberglass Design GuideDocument4 pagesFiberglass Design Guide0410636No ratings yet

- 03 en PSI Kebu Anti Corrosion TapesDocument13 pages03 en PSI Kebu Anti Corrosion Tapesmechanical_engineer11No ratings yet

- Epcc Total Proyek Panas Bumi Kamojang 1X35 MWDocument3 pagesEpcc Total Proyek Panas Bumi Kamojang 1X35 MWYu AnNo ratings yet

- Mcquay Dmahu Catalogue - 1.0Document55 pagesMcquay Dmahu Catalogue - 1.0Vishal Mohite100% (2)

- AA 2013 BrochureDocument24 pagesAA 2013 BrochureChaw Su LwelNo ratings yet

- You Chang CatalougDocument25 pagesYou Chang Catalougscribd4uallNo ratings yet

- Fiberglass and Composite Material Design GuideDocument4 pagesFiberglass and Composite Material Design GuideSteven PentonNo ratings yet

- Lexan Polycarbonate 9030 Technical Properties Data SheetDocument6 pagesLexan Polycarbonate 9030 Technical Properties Data Sheetenki95823100% (1)

- Laminate SelectionDocument1 pageLaminate SelectionARNOUXNo ratings yet

- Pool Covers PDF Document Aqua Middle East FZCDocument10 pagesPool Covers PDF Document Aqua Middle East FZCAdolfsmith69No ratings yet

- SUNPAL Architectural System-BrochureDocument20 pagesSUNPAL Architectural System-BrochureGirish Dhawan0% (1)

- Arc Insulations BrochureDocument5 pagesArc Insulations BrochureacompositesNo ratings yet

- Chilled Water Pipe Application Indoor 1Document2 pagesChilled Water Pipe Application Indoor 1SujithJosephNo ratings yet

- Design For Manufacture & Environment: Function Structure - BlenderDocument10 pagesDesign For Manufacture & Environment: Function Structure - Blender1prathamNo ratings yet

- SOPORTERIADocument28 pagesSOPORTERIAWilliamsh1aNo ratings yet

- Fuse Tube Cutting TemplatesDocument1 pageFuse Tube Cutting TemplatesdanielmelorNo ratings yet

- GRP TanksDocument8 pagesGRP Tanksshi_salbe_15838No ratings yet

- Al Shams BOQ For ValuationDocument191 pagesAl Shams BOQ For ValuationcostemaraNo ratings yet

- Developmental E Glass FiberDocument8 pagesDevelopmental E Glass FiberWidya Puspita SariNo ratings yet

- 01 SR 01 CRG PipesDocument1 page01 SR 01 CRG Pipesmilan_popovic_2No ratings yet

- Meercedes W100 CrashproofDocument1 pageMeercedes W100 CrashproofKedves SzabolcsNo ratings yet

- PlumberDocument31 pagesPlumberAydaLeeNo ratings yet

- Polymeric Automobiles: Materials inDocument12 pagesPolymeric Automobiles: Materials inArmando BeltránNo ratings yet

- Fit Tolerance For Plastic PartsDocument16 pagesFit Tolerance For Plastic PartsA_JANNESNo ratings yet

- TrayMfg ESD Catalog 2015Document12 pagesTrayMfg ESD Catalog 2015Nicholas FlandinNo ratings yet

- BartecDocument6 pagesBartecmilovacs6720No ratings yet

- LHB Coaches DetailsDocument5 pagesLHB Coaches Detailsabhimanyutiwari1234No ratings yet

- Neolon Profile - Duct & PIPE Insulation (Updated)Document15 pagesNeolon Profile - Duct & PIPE Insulation (Updated)ntt_121987100% (1)

- Su 35 Sukhoi 2Document26 pagesSu 35 Sukhoi 2Juan Carlos AlvaradoNo ratings yet

- PHASA Design GuideDocument16 pagesPHASA Design Guidejhlec054850No ratings yet

- Effect of Rubber Forming Process Parameters On Micro Patterning of Thin Metallic PlatesDocument6 pagesEffect of Rubber Forming Process Parameters On Micro Patterning of Thin Metallic PlatesRui MatiasNo ratings yet

- VEM - GRE TechnologyDocument2 pagesVEM - GRE Technologyim4uim4uim4uNo ratings yet

- Shaping Processes For PlasticsDocument92 pagesShaping Processes For PlasticsmindmaczaNo ratings yet

- Laminated Properties: Roll Specifications Fiber Architecture DataDocument10 pagesLaminated Properties: Roll Specifications Fiber Architecture DatakkalimenioNo ratings yet

- Fane EN21802 Enclosure PDFDocument6 pagesFane EN21802 Enclosure PDFFernando José PeixotoNo ratings yet

- Water Takjjks 3Document2 pagesWater Takjjks 3Anam Bahrul UlumNo ratings yet

- Conveyor Maintenance 1Document13 pagesConveyor Maintenance 1it4ujonlyNo ratings yet

- Metal Spray Moulds in The Shoe IndustryDocument3 pagesMetal Spray Moulds in The Shoe IndustrySiméon ANDRIAMANDROSONo ratings yet

- Total Wall NER-646Document13 pagesTotal Wall NER-646m0172No ratings yet

- Cryogel Z Specification Guidelines 3-0Document15 pagesCryogel Z Specification Guidelines 3-0Joseph Van LooNo ratings yet

- WireMesh Gunung GarudaDocument1 pageWireMesh Gunung GarudaAndy YuliantoNo ratings yet

- 3G Metric A4 Overview PDFDocument8 pages3G Metric A4 Overview PDFDiadam SharmaNo ratings yet

- Term Paper Project Final Presentation: Ice Hockey StickDocument25 pagesTerm Paper Project Final Presentation: Ice Hockey Stickhzstorm11No ratings yet

- Formability of AA5052/polyethylene/AA5052 Sandwich SheetsDocument6 pagesFormability of AA5052/polyethylene/AA5052 Sandwich SheetsYogesh DewangNo ratings yet

- TP Progress S4G2 IceHockeyStick 1Document18 pagesTP Progress S4G2 IceHockeyStick 1hzstorm11No ratings yet

- Impressive On ConcreteDocument2 pagesImpressive On ConcretemutazsalihNo ratings yet

- Nat 4+5 DM - PlasticsDocument12 pagesNat 4+5 DM - PlasticsShaheen ArihaNo ratings yet

- BluCub2 Full PDFDocument3 pagesBluCub2 Full PDFFilipe GonçalvesNo ratings yet

- ASME Class 150 and 300Document12 pagesASME Class 150 and 300pca97No ratings yet

- Plastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3From EverandPlastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3No ratings yet

- How to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityFrom EverandHow to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityNo ratings yet

- An Illustrated Guide to Making Mobile Toys - Scooter, Tricycle, Two Utility Carts and Wooden Land RoverFrom EverandAn Illustrated Guide to Making Mobile Toys - Scooter, Tricycle, Two Utility Carts and Wooden Land RoverNo ratings yet

- The Boy Mechanic: Volume 1 700 Things for Boys to DoFrom EverandThe Boy Mechanic: Volume 1 700 Things for Boys to DoNo ratings yet

- 1kw Sine Wave Inverter Circuit Diagram PDFDocument10 pages1kw Sine Wave Inverter Circuit Diagram PDFAndone Anutu100% (1)

- Prosp EN AX PDFDocument6 pagesProsp EN AX PDFAndone AnutuNo ratings yet

- Huayi Compressor MP12TG 230 60 PDFDocument5 pagesHuayi Compressor MP12TG 230 60 PDFAndone AnutuNo ratings yet

- FlightManual Cavalon 1-3 ENG PDFDocument124 pagesFlightManual Cavalon 1-3 ENG PDFAndone AnutuNo ratings yet

- Eng Manual Effekta VX M PDocument34 pagesEng Manual Effekta VX M PLuis RitaNo ratings yet

- Autogiro JW PDFDocument160 pagesAutogiro JW PDFAndone AnutuNo ratings yet

- Effekta AX PDFDocument4 pagesEffekta AX PDFAndone AnutuNo ratings yet

- Techn - Data 447 PDFDocument1 pageTechn - Data 447 PDFAndone AnutuNo ratings yet

- Scale 1:1: 1:1 1:2 Autogyro Jt-5BDocument1 pageScale 1:1: 1:1 1:2 Autogyro Jt-5BAndone AnutuNo ratings yet

- 1:1 Autogyro Jt-5B: Rotor Head PartsDocument1 page1:1 Autogyro Jt-5B: Rotor Head PartsAndone AnutuNo ratings yet

- Autogyro Jt-5B: SAE 4130 SteelDocument1 pageAutogyro Jt-5B: SAE 4130 SteelAndone AnutuNo ratings yet

- JT 59 PDFDocument2 pagesJT 59 PDFAndone AnutuNo ratings yet

- Engine:: Type: 582 Ul DcdiDocument1 pageEngine:: Type: 582 Ul DcdiAndone AnutuNo ratings yet

- Engine:: Type: 503 Ul Dcdi - 1V 503 Ul Dcdi - 2VDocument1 pageEngine:: Type: 503 Ul Dcdi - 1V 503 Ul Dcdi - 2VAndone AnutuNo ratings yet

- JT 51 PDFDocument1 pageJT 51 PDFAndone AnutuNo ratings yet

- JT 5 PDFDocument1 pageJT 5 PDFAndone AnutuNo ratings yet

- Autogiro JW PDFDocument160 pagesAutogiro JW PDFAndone AnutuNo ratings yet

- 503installationmanual PDFDocument68 pages503installationmanual PDFAndone AnutuNo ratings yet