Professional Documents

Culture Documents

Lampiran Tangki Bleacher Tangki Bleacher New

Lampiran Tangki Bleacher Tangki Bleacher New

Uploaded by

Wyda Novayanti SaragiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lampiran Tangki Bleacher Tangki Bleacher New

Lampiran Tangki Bleacher Tangki Bleacher New

Uploaded by

Wyda Novayanti SaragiCopyright:

Available Formats

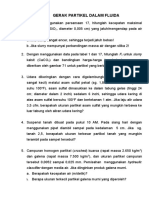

Tangki Bleacher

Fungsi :Untuk memisahkan air yang masih terkandung didalam minyak dan untuk

memucatkan warna CPO

Tipe : Tangki Silinder Vertikal Tutup Torisperikal

Data Perhitungan

Tekanan,(P)

Temperatur, (T)

Laju alir massa

Densitas Campuran

Laju Alir CPO

: 0,4 bar = 0,39476 atm = 5,802972 psi

: 110 oC = 383 K

: 58.759,2081 kg/jam = 129.540,6 lb/jam

Fraksi

: Laju Alir CPO / Laju Alir Total

:57.608,19521 kg /jam

: 57.608,19521 kg/jam / 58.759,2081 kg/jam

: 0,980411

Densitas CPO

: 847,1 kg/m3 = 0,8471 g/ml

Laju Alir Kaolin

: 1.151,012891 kg/jam

Fraksi

: Laju Alir Kaolin / Laju Alir Total

: 1.151,012891 kg/jam/58.759,2081 kg/jam

:0,019586

Densitas Kaolin

Densitas Campuran

: 2,6 g/cm3=2,6 g/ml

: (Fraksi CPO x Densitas CPO) + (Fraksi Kaolin x Densitas

Kaolin )

: (0,980411x 0,8471 g/ml) + (0,019586+2,6 g/ml)

: 0,881436925 g/ml = 881,4369246 kg/m3= 55,0210315

lb/ft3

Viskositas Campuran

Laju Alir CPO

: 57.508,19521 kg/jam

Fraksi

: Laju Alir CPO / Laju Alir Total

: 57.608,19521 kg/jam / 58.759,2081 kg/jam

: 0,980411

Viskositas CPO : 5,709 mPas = 5,709 cp = 0,003836 lb/ft.s

Laju Alir Kaolin

: 1.151,012891 kg/jam

Fraksi

: Laju Alir Kaolin / Laju Alir Total

: 1.151,012891 kg/jam/58.759,2081 kg/jam

:0,019586

Viskositas Kaolin

: 5 poise = 500 cp = 0,335985 lb/ft.s

Viskositas Campuran : (Fraksi CPO x Viskositas CPO) + (Fraksi Kaolin x Viskositas

Kaolin )

: (0,980411x 0,003836 lb/ft.s)+( 0,019586+0,335985

lb/ft.s)

: 0,010342618 lb/ft.s

Waktu Tinggal

: 30 Menit : 0,5 Jam

Dimensi Tangki

58.759,2081 /

Volume Cairan = campuran = 881,4369246 /3 0,5 = 33,33148775 m3

=1.177,191 ft3

Faktor Keamanan = 10%

Digunakan faktor keamanan 10%, maka volume tangki :

(Perry, 1997)

Volume Tangki = 1,1 x 1.177,191 ft3 = 1.294,91034 ft3

Perbandingan H/D= 1,5

H : Tinggi Tangki

D : Diameter Tangki

Volume Silinder =

33,33149

33,33149

D3

= 33,33149 / 1,1775 m3 = 28,30699596 m3

D

in

= 28,30699596 = 2,961158839 m = 9,71496619 ft = 116,5796

=3m

r

= 10 ft

= 2,961158839 m/2 = 1,480579 m

= 9,71496619 ft/2

= 4,857485 ft

= 116,5796 in/2

= 58,282982 in

= 1,5 D

= 1,5 (2,961158839 m) = 4,441738259 m

= 1,5( 9,71496619 ft) = 14,57245488 ft

= 1,5(116,5796 in) = 174,8694585 in

Tinggi Cairan (HL)

Volume Cairan = Volume Cairan dalam Shell + Volume Head

1.177,19

1.177,19

HL

HL

= 14,92609 ft

Tekanan Hidrostatik (Ph)

g = 32,174 ft/s2 gc = 32,174 lbm/lbf s2

Ph

=

= 55,02120315 lb/ft3 (32,174 ft/s2 /32,174 lbm/lbf s2) 14,92609 ft

= 821,2488 lb/ft2=5,703116 lb/in2=5,703116 Psi

Tekanan Desain (P)

Tekanan Operasi ( Pop)

= 5,802972 Psi

Tekanan Desain (P)

= Ph + Pop

= 5,703116 Psi + 5,802972 Psi

= 11,508608844 Psi

Perhitungan Tebal Shell

Jenis Plate

: Carbon Stell SA 283 Grade C

Jenis Sambungan

: Double-Welded bult joint

Efisiensi Sambungan (E)

: 80%

Faktor Korosi

:0,125 in

Tegangan yang diizinkan (F) :12.650 Psi

ts

=

= (11,50608844 Psi x 58,28982 in)/{(12.650 Psi x 0,8)

(0,6 x 11,50608844 Psi)}+ 0,125

= 0,191319 in

(diambil tebal standar 3/16)

Perhitungan Tebal Head

OD

= ID +2 ts

OD

= 116,9623 maka diambil 120 in

Brownell and Young (tabel, 5.7) hal 89

r

= 114 in

icr

= 7,25 in

Head yang digunakan adalah Torisperical

th

=

= (0,885 x 11,50608844 Psi x 114 in)/{( 12.650 x 0,8)(0,1x11,50608844 Psi)} + 0,125

= 0,239721 in = 0,25 in

(diambil tebal head standar yaitu )

Tinggi Head , OA = th + b + sf

a

= ID/2

= 58,28982

AB

= a-icr

= 58,28982 7,25 in = 51,03982 in

BC

= r-icr

=114 7,25 in = 106,75 in

AC

= 2 + 2

= 51,039822 + 106,752

= 106,5107 in

= r-AC

= 114 106,5107 in

= 7,489331 in

sf

=2

OA

= th +b + sf

= 0,25 + 7,489331 + 2 in

= 9,739331

Maka Total Tinggi Tangki = Tinggi Shell +( 2 x Tinggi Head)

= (174,86945 + (2 x 9,739331 ) = 194,3481 = 4,936452

m

Perhitungan Rancangan Pengaduk

Jenis Pengaduk

: Vertikal Blade Turbine Impeller

d/D

: 0,4

Diameter Impeller (d)

: 10 ft x 0,4 = 4 ft

Lebar Impeller (w) = d/5

: 4 ft/ 5

Tinggi Impeller dari dasar tangki=HL/6

: 14,92609 ft /6 = 2,487681 ft

Jumlah Buffle

:4

Lebar Buffle (L); D/12

: 10/12 = 0,83333 ft

Tinggi Buffle dari dasar tangku=d/2

: 4/2 = 2 ft

Kecepatan Pengadukan (v)

: 0,6 ft/s

Nre

(Walas, 1990) hal 287

= 0,8 ft

(Wallas, 1990.T.10.2)

=

= (4 ft x 0,6 ft/s x 55,0210315 lb/ft3)/0,010342618 lb/ft.s

= 12.767,60635

= (12.767,60635 x 0,010342618)/(42 x 55,0210315)

= 0,15 rps = 9 rpm

Nre

=

= ( 0,15 x 42 x 55,0210315) / 0,010342618

= 12.767,60635

Dari fig.10.6 Wallas, 1990 di dapat Np = 2,75

Np

= 2,75

=

= ( 2,75 x 0,153 x 45 x 55,0210315)/ 32,174

= 16,25287137 lb.ft/s

= 16,25287137 lb.ft/s / 550 = 0,029550675 hp

= 0,029550675 hp x 0,7457 = 0,022035939 KW

Efesiensi motor pengaduk

= 80%

Daya Motor

= 0,036938 hp

You might also like

- Produkmui Asli (Daerah)Document231 pagesProdukmui Asli (Daerah)Farhan Untung BeringinNo ratings yet

- Modul Ko15Document187 pagesModul Ko15Syambada Dzuhrizal Fadhly RNo ratings yet

- Perancangan TangkiDocument106 pagesPerancangan TangkiRyrynArianyNo ratings yet

- Efek Panas TermodinamikaDocument28 pagesEfek Panas TermodinamikaHabib Maulana Yasminto0% (1)

- RumusDocument49 pagesRumussusanto0% (1)

- PerhitunganDocument5 pagesPerhitunganRifqi ZuhdiNo ratings yet

- Appendix Lengkap - BaruDocument993 pagesAppendix Lengkap - BaruAlfauziNo ratings yet

- Tga Nitrogen Rejection Siap PrintDocument8 pagesTga Nitrogen Rejection Siap PrintAdam RizkyNo ratings yet

- 1 Diagram Alir UtilitasDocument1 page1 Diagram Alir Utilitasrika umamiNo ratings yet

- Ipal Rsud CicalengkaDocument19 pagesIpal Rsud CicalengkaTaufik RamadhanNo ratings yet

- Absorpsi Kujang 1BDocument18 pagesAbsorpsi Kujang 1Bb_dragonsNo ratings yet

- Buku HougenDocument1 pageBuku HougenMesa Sigala GalaNo ratings yet

- Documents - Tips - Pengolahan Dan Analisis Sir Sisa Kilang Sawit Lecture 10Document72 pagesDocuments - Tips - Pengolahan Dan Analisis Sir Sisa Kilang Sawit Lecture 10Lai Mei EeNo ratings yet

- DekstrinDocument8 pagesDekstrinSheila ArdinabilahNo ratings yet

- Laporan Umum Kerja Praktek PT Tunas Baru LampungDocument94 pagesLaporan Umum Kerja Praktek PT Tunas Baru LampungItachi UchihaNo ratings yet

- Perhitungan ICUMSADocument2 pagesPerhitungan ICUMSASandra Megantara100% (1)

- (#05) - Kuliah IV&v - Contoh Soal 4 & Packed ColumnDocument27 pages(#05) - Kuliah IV&v - Contoh Soal 4 & Packed ColumnMarcel MrcNo ratings yet

- KKW Singgihy 48bpskeu2007Document29 pagesKKW Singgihy 48bpskeu2007Keyblade VortexNo ratings yet

- Materi KPR 1 Reaktor 1 2023Document40 pagesMateri KPR 1 Reaktor 1 2023Ridha RahmawatiNo ratings yet

- Kuliah 4. SentrifugasiDocument21 pagesKuliah 4. Sentrifugasidedi saputraNo ratings yet

- Laporan Kerja PraktikDocument93 pagesLaporan Kerja PraktikMutiara Monica100% (1)

- Penentuan Jumlah Sel MikroorganismeDocument14 pagesPenentuan Jumlah Sel MikroorganismeBelli Martha Judika SilabanNo ratings yet

- Resume Perancangan Vessel - Kelas Pap-01 PDFDocument74 pagesResume Perancangan Vessel - Kelas Pap-01 PDFAliNo ratings yet

- UtilitasDocument14 pagesUtilitasAhmad AfifNo ratings yet

- Distilasi - McCabe Thiele-Mustain ZamhariDocument32 pagesDistilasi - McCabe Thiele-Mustain ZamhariamaliaNo ratings yet

- Laporan KP Pt. Rapp Almost DonedocxDocument69 pagesLaporan KP Pt. Rapp Almost Donedocxraynanda pratamaNo ratings yet

- Formulir Pengecekan Peralatan Yang TelahDocument1 pageFormulir Pengecekan Peralatan Yang TelahbambangNo ratings yet

- Isi LaporanDocument240 pagesIsi LaporanFaisal AriefNo ratings yet

- Data Material Bahan KimiaDocument3 pagesData Material Bahan KimiaEHSS Head OfficeNo ratings yet

- ExtruderDocument10 pagesExtruderKhairilHidayahNo ratings yet

- Mochamad Faizal AmirDocument4 pagesMochamad Faizal AmirHikmah Fatwa Nurodin100% (1)

- ReologiDocument20 pagesReologisepteriodelNo ratings yet

- Perhitungan Neraca Panas Evaporator1Document3 pagesPerhitungan Neraca Panas Evaporator1panzurliNo ratings yet

- Laporan KP Detta RevisiDocument182 pagesLaporan KP Detta RevisiBernadetta Catelya ChristiantiNo ratings yet

- Persamaan Fenske Untuk Menghitung N MinDocument1 pagePersamaan Fenske Untuk Menghitung N MinanisaNo ratings yet

- Kontrak Kuliah Rekayasa Sistem AgroindustriDocument3 pagesKontrak Kuliah Rekayasa Sistem Agroindustrinanda yudhistiraNo ratings yet

- Pemilihan ImpellerDocument20 pagesPemilihan ImpellerLaila SyafitriNo ratings yet

- Laporan Praktikum 9Document23 pagesLaporan Praktikum 9elfhatrNo ratings yet

- Sni Bakso Daging Sapi 01-3818-1995 PDFDocument7 pagesSni Bakso Daging Sapi 01-3818-1995 PDFMike Amalia0% (1)

- Sifat Dan Kegunaan Karet AlamDocument6 pagesSifat Dan Kegunaan Karet Alamwidia trisnantiNo ratings yet

- Praktikum Perisa Alami Limbah UdangDocument14 pagesPraktikum Perisa Alami Limbah UdangNadella SafitriNo ratings yet

- RMJ Jalan Nasional 2014 PDFDocument1 pageRMJ Jalan Nasional 2014 PDFArdhBlackNo ratings yet

- Sni Sari Buah Dan AirDocument2 pagesSni Sari Buah Dan AirBunga Tyas RahayuNo ratings yet

- Aldehid Keton Cureo TsDocument83 pagesAldehid Keton Cureo TsArie TampubolonNo ratings yet

- Proses Manufaktur Tang PegasDocument9 pagesProses Manufaktur Tang PegasRendy WibisonoNo ratings yet

- Sni Jagung HibridaDocument18 pagesSni Jagung Hibridasandi_prawira_yudhaNo ratings yet

- KkkguguDocument2 pagesKkkgugumutiana zain0% (1)

- Siklus Pembangkit PLTU Dan Heat & Mass Balance - 27982Document18 pagesSiklus Pembangkit PLTU Dan Heat & Mass Balance - 27982Janter Roy Agus Naibaho100% (1)

- Minyak BumiDocument3 pagesMinyak BumiSicomo Full VideosNo ratings yet

- Dalam Angka 2019-2020 Kecamatan Di Kab SlemanDocument3 pagesDalam Angka 2019-2020 Kecamatan Di Kab SlemanBhima DhewantaraNo ratings yet

- PKL WilmarDocument88 pagesPKL WilmarAgus SusantoNo ratings yet

- SOP Kalorimeter BomDocument2 pagesSOP Kalorimeter BomRizkiDIahKusumaningrumNo ratings yet

- Laporan Rev 3Document70 pagesLaporan Rev 3Dwi RiyantoNo ratings yet

- KKW Paicada Fasai L.Document85 pagesKKW Paicada Fasai L.abdul0rohiminNo ratings yet

- Perancangan Tangki AtmosferisDocument7 pagesPerancangan Tangki AtmosferisvalianamgrhyNo ratings yet

- Spek Penglihan BahanDocument91 pagesSpek Penglihan BahanwillianNo ratings yet

- Laporan Perkal He (Fix)Document14 pagesLaporan Perkal He (Fix)Mohammad Nurifki FilinoNo ratings yet

- BAB IV - Trial 1Document10 pagesBAB IV - Trial 1Katon KosukeNo ratings yet

- Perencanaan Silinder PneumatikDocument8 pagesPerencanaan Silinder PneumatikMonica AprlNo ratings yet