Professional Documents

Culture Documents

Example Risk Assessment For A Pub: Setting The Scene How Was The Risk Assessment Done?

Example Risk Assessment For A Pub: Setting The Scene How Was The Risk Assessment Done?

Uploaded by

Blas de LezoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Example Risk Assessment For A Pub: Setting The Scene How Was The Risk Assessment Done?

Example Risk Assessment For A Pub: Setting The Scene How Was The Risk Assessment Done?

Uploaded by

Blas de LezoCopyright:

Available Formats

Health and Safety

Executive

Example risk assessment for a pub

Setting the scene

How was the risk assessment done?

The manager carried out the risk assessment in this

pub, which is located in a suburban, residential area.

The manager followed the guidance in Five steps to risk

assessment (www.hse.gov.uk/pubns/indg163.pdf).

This risk assessment only addresses liquid sales; a

separate example covers the occupational health and

safety aspects for food preparation: www.hse.gov.uk/

risk/casestudies/foodprep.htm. (Also see www.hse.

gov.uk/catering/index.htm.)

1 To identify the hazards, the manager:

The manager and his partner live on the premises,

they also employ eight other bar staff, four full-time

who work lunchtime and evening shifts, five-days

every week and four part-time staff at weekends and

providing absence cover for the full-time staff.

The pub has a function room with dance floor for

live-music events and discos with a bar. It is cleaned

every morning by a cleaner, the manager and his

partner cover when the cleaner is on holiday. The

manager buys cleaning products from the wholesaler

or from a rep who visits once a month.

The premises were built before 2000; the pub building

was surveyed for asbestos when it was acquired

by the owner. Asbestos-containing materials found

in the survey have been recorded, a copy of the

survey is kept at the pub and the owner holds a

duplicate copy. A further, more detailed, survey can

be arranged to send out to contractors when building

works need to be done.

Example risk assessment: Pub

looked at HSEs web pages for small businesses

www.hse.gov.uk/smallbusinesses/index.htm, and for

the hospitality and catering industry www.hse.gov.uk/

catering/index.htm, to learn where hazards can occur;

made clear who was responsible for what under the

terms of the tenancy agreement. This was especially

important for issues such as asbestos management, gas

safety, pressurised equipment, replacement of carpets;

walked around the pub, noting things that might be

dangerous and taking HSEs guidance into

consideration;

talked to the staff (including the cleaner) about their work

to learn from their knowledge and experience of areas

and activities, and to listen to their opinions about health

and safety issues in the workplace;

talked to his preferred suppliers of maintenance work,

to ensure that their activities did not pose a risk to pub

staff, and vice versa;

observed deliveries by his food and drink suppliers; and

looked at the accident book, to gain an understanding of

previous incidents.

2 The manager then wrote down who could be harmed by

the hazards and how.

Important reminder

This example risk assessment shows the kind

of approach a pub might take. Use it as a guide

to think through some of the hazards in your

business and the steps you need to take to control

the risks. Please note that it is not a generic risk

assessment that you can just put your company

name on and adopt wholesale without any thought.

This would not satisfy the law and would not be

effective in protecting people.

Every business is different you need to think

through the hazards and controls required in your

business for yourself.

3 For each hazard, the manager wrote down what

controls, if any, were in place to manage these hazards.

He then compared these controls to the good practice

guidance provided on the HSE website. Where existing

controls were not considered good enough, the

manager wrote down what else needed to be done to

control the risk.

4 Putting the risk assessment into practice, the manager

decided and recorded who was responsible for

implementing the actions identified as necessary and

when they should be done. When each action was

done, he ticked it off and noted the date. He also made

it part of the induction process for new staff.

5 At the staff meeting, the manager discussed the findings

of the risk assessment with staff and pinned up a copy

in the staffroom. He decided to review and update the

risk assessment every year, or straightaway if any major

changes in the workplace happened.

1 of 6 pages

Health and Safety

Executive

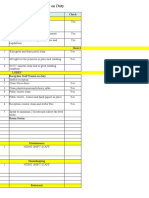

Company name: The Smiths Pub

Date of risk assessment: 28/11/08

What are the Who might be harmed What are you already doing?

hazards?

and how?

Slips, trips

and falls

Staff and customers

slipping/tripping/falling

suffering fractures and

bruising etc

Falls from

height

Staff may suffer

serious, possibly fatal,

injuries if they fall from

any height.

For example staff doing

cleaning/maintenance,

might fall from ladders.

Example risk assessment: Pub

What further action is necessary?

Action by whom?

Action by when?

Staff clean up spillages immediately using suitable methods and

leave the floor dry.

Bar floor areas only washed out of hours staff know about proper

use of detergents, correct detergent rates to avoid residue

wash, leave, rinse etc.

Good housekeeping work areas kept tidy, goods stored suitably

etc.

Drainage channels and drip trays provided where spills likely.

Equipment maintained to prevent leaks onto floor.

Good lighting in all areas including steps outside or access to

cellar areas.

Ensure door to cellar is kept locked and key controlled so only

authorised staff can get access.

Ensure stairways are not obstructed.

Carpets firmly secured.

Doormats for wet weather.

No trailing cables or obstructions in walkways.

Cable covers used for all electrical cables, especially when

hosting bands or DJs.

Repair damaged floor covering and

check carpet grips.

Manager with

landlord/Pub

managing company

12/12/08

(before Christmas

custom increases)

Ensure suitable footwear with good grip

worn by staff

Manager with

landlord/Pub

managing company

Before each shift

Put up Authorised Persons Only sign

on cellar door.

Manager with

landlord/Pub

managing company

5/12/08

Reiterate message to staff that cellar

door is to be locked when not needed

for access by authorised staff, staff to

report if cellar door left unlocked.

Manager with

landlord/Pub

managing company

Before next shift

Cellar hatches:

Check they have been closed after delivery.

Ensure other people are excluded from area while hatch open

and in use.

Ladders to be suitable, regularly inspected, and used only for light

work of short duration by trained staff.

All other work at height, such as above the roof light, is done by

contractors under a permit to work system and using trained staff

and appropriate equipment.

Speak with brewery about any

problems with pedestrians walking by

when pavement cellar hatches open

and agree if signs, barriers or staff

needed to direct pedestrians away from

danger area.

Manager

Immediately

Done

2 of 6 pages

Health and Safety

Executive

What are the Who might be harmed What are you already doing?

hazards?

and how?

Violence

Staff and customers

may suffer stress and/

or physical injuries

from aggressive

customers.

What further action is necessary?

Action by whom?

Action by when?

Keep good liaison with local police and

check latest advice.

Manager

Ongoing items

Manager to give talk to re-emphasise

coping with disputes training.

Manager

Training to be

carried out before

Christmas busy

period

Ensure all incidents promptly

investigated.

Manager

Staff adhere to legal requirement not to sell alcohol to intoxicated

customers.

Staff trained in good, polite behaviour and how to avoid

confrontation following violence policy when to call police etc.

Incident log kept and filled out as soon as possible after incident

Staff made aware of barred customers.

Information sharing scheme with police and other licensed

premises in the area member of local Pubwatch.

Regular glass collection glass policy implemented for very

busy events or as appropriate.

Gaming machines emptied after closing.

Cashing up done after hours/out of customers sight.

Consider if fitting panic alarm is

practicable and will be of benefit.

Manager to seek

advice of police/pub

company on best

panic alarm.

8/12/08

Transport

Staff may suffer serious

injuries if struck by

a vehicle, eg during

deliveries.

Reversing of vehicles to be supervised if other people in the area.

High-visibility waistcoat available.

Talk to the brewery, wholesaler and

other suppliers about agreeing safe

procedures for deliveries, to try to

eliminate reversing, or ensuring staff

available.

Manager

3/1/09

Manual

handling

Staff receiving back,

neck and limb injuries

from lifting heavy loads

(eg barrels), crates of

bottles etc

Behind the bar kegs/casks barrels rolled onto trolley and wheeled

around.

Staff training in rolling and stillaging casks.

Sack trucks and trolleys available for beer and bottle crates etc.

Staff training in lifting techniques and posture for items behind

the bar.

Consider siting and design of shelving

for items behind bar to eliminate

bending and reaching at next

refurbishment.

Manager

Next

refurbishment due

2010

Example risk assessment: Pub

Done

3 of 6 pages

Health and Safety

Executive

What are the Who might be harmed What are you already doing?

hazards?

and how?

Gas

C02 leakage

Pressurised

equipment

Staff and others risk

injury from fire and

explosion if equipment

not properly maintained

and used.

Staff may be overcome

when charging CO2

while changing

barrels and soft drinks

dispenser in cellar

Risk of explosion from

over-pressurisation of

beer pump systems,

or faulty or damaged

cylinders.

Pressurised systems:

designed, installed and maintained in line with BBPAs Code

of Practice 2006, installation certificate obtained (copy at pub,

owner holds original);

only trained staff manager, partner and named member of staff

who have undergone training to use the system;

cleaning containers suitable to accept systems maximum

pressure and labelled to avoid confusion over detergents and

flushing water;

system inspected by competent engineer every five years or to

schedule produced by the competent engineer;

certificate displayed stating date of next inspection; and

any damage reported immediately.

What further action is necessary?

Action by whom?

Action by when?

Boiler checked and serviced annually by a Gas Safe registered

engineer, see www.hse.gov.uk/gas/index.htm.

Staff trained to recognise and report defects.

No further action at this stage.

Only staff trained by the brewery or pub company, manager,

partner and named staff member, change barrels.

Safe working practice, in line with BBPA guidance.

Cellar well ventilated with adequate, low-level, ventilation.

Put forward another full-time member

of staff for training to cover absences

and weekends.

Manager

3/1/09

Put forward another full-time member

of staff for training to cover absences.

Manager

3/1/09

Done

Gas cylinders:

only obtained from reputable suppliers;

numbers kept to absolute minimum;

moved and stored properly to prevent damage;

stored in cages, chained up or laid flat and chocked (with

suppliers agreement) away from heat sources, in a dry area with

the valves closed; and

used in an upright position in a safe, secure, dry place.

Example risk assessment: Pub

4 of 6 pages

Health and Safety

Executive

What are the Who might be harmed What are you already doing?

hazards?

and how?

Noise

Electricity

Staff suffering hearing

damage from live and

recorded music

Staff and customers

could get electric

shocks from faulty/

damaged wiring or

electrical equipment

Example risk assessment: Pub

Bands and DJs speakers located in function room and focused

on dance floor, away from seating areas and bars.

Staff allowed to take regular rest breaks in designated quiet area

to reduce noise exposure.

Wiring checked every five years by a qualified electrician.

Regular PAT done by electrician.

Staff trained to spot damaged equipment, plugs, cable and

fittings and take out of service.

Staff told where fuse box is to turn off electricity in the event of an

emergency.

Fuse box/consumer unit kept accessible at all times.

What further action is necessary?

Action by whom?

Action by when?

Educate staff about noise

and damage to hearing and

assess whether health surveillance

needed, establish if staff exposed

to high noise levels in personal life, eg

do they go clubbing?

Manager

Ongoing.

First talk by

8/12/08

Check volume levels and

consider need for volume

limiters.

Manager

8/12/08

Consider acoustic screening for

exposed bar areas.

Manager

Within 2 weeks of

establishing noise

levels

Make suitable ear plugs available for

staff collecting glasses and serving in

dance area, eg will staff still be able to

hear drinks orders at bar.

Manager

3/12/08

Check to see if fuse box has 30 mA

RCD protection.

Manager

8/12/08

RCD sockets and plugs to be fitted if

protection not at consumer unit.

Manager

1/6/09

Ensure induction talk for any new staff

or temporary staff includes how to turn

off the electricity.

Manager

8/12/08 (new

Christmas staff)

Speak to contractors to ensure that

they will only use low-voltage (yellow)

equipment.

Manager

By next work

planned for 2009

Done

5 of 6 pages

Health and Safety

Executive

What are the Who might be harmed What are you already doing?

hazards?

and how?

Hazardous

substances

Staff can suffer

chemical burns or

develop dermatitis from

contact with, or use of,

cleaning chemicals

Asbestoscontaining

materials

(ACMs)

found in

building

Staff and others

carrying out normal

activities at very low

risk as asbestos

only poses a risk if

fibres are released

into air and inhaled.

Maintenance workers

most at risk.

Fire

If trapped staff could

suffer from smoke

inhalation/burns

What further action is necessary?

Action by whom?

Action by when?

All products safety data sheets checked to see what gloves, eye

protection is necessary for use with the chemicals.

Chemicals used reviewed with reps/supplier every six months to

see if safer alternative available.

Staff told about skin care when washing glasses, handling

dishwasher chemicals etc.

Chemicals always kept in original labelled containers, any

containers for decanted chemicals clearly marked.

PPE gloves and eye protection available when using, decanting

or diluting chemicals.

Tell cleaning product rep they should

check for safer alternatives before next

visit.

Manager

3/1/09

Position of all ACMs surveyed Type 1 survey by professional as

no building works planned.

Position and condition of all ACMs marked, recorded and

explained to manager and staff.

Manager and deputy given advice/training by surveyor or

other provider about identifying ACMs and spotting signs of

deterioration.

Arrangements made with pub company for:

Type 2 survey, for when non-major, routine building

maintenance work; or

Type 3 survey when intrusive work planned.

Staff told to report any accidental damage immediately.

Reiterate to staff and contractors when

they visit that asbestos must not be

disturbed and to report immediately

any accidental damage to the insulating

boards.

Manager

Ongoing.

Next meeting

3/12/08

Fire risk assessment done, see www.communities.gov.uk/fire and

necessary action taken.

Manager/senior staff member checks fire exits are clear.

Staff to check outside smoking

area to check all smoking materials

extinguished after closing

Manager

Done

When contractors

confirm date for

February 2009

work

Immediately

Assessment review date: 28/11/09

Example risk assessment: Pub

Published by the Health and Safety Executive

6 of 6 pages

11/10

You might also like

- Example Risk Assessment For A Butcher's Shop: Setting The SceneDocument4 pagesExample Risk Assessment For A Butcher's Shop: Setting The SceneSrikanth BammhideNo ratings yet

- Form Cleaning ScheduleDocument1 pageForm Cleaning SchedulefisherkiddNo ratings yet

- A Journey Not A Destination PDFDocument47 pagesA Journey Not A Destination PDFBlas de Lezo0% (1)

- 6S (5S+1) Audit Check Sheet AdaptiveBMSDocument5 pages6S (5S+1) Audit Check Sheet AdaptiveBMSSara SunriseNo ratings yet

- Example Risk Assessment For Cold Storage Warehousing: Setting The SceneDocument6 pagesExample Risk Assessment For Cold Storage Warehousing: Setting The Sceneʞǝǝs Uǝ ƎpıɥNo ratings yet

- Maintenance of Flats: Example Risk Assessment ForDocument5 pagesMaintenance of Flats: Example Risk Assessment FordwayjayNo ratings yet

- General Office Cleaning: Example Risk Assessment ForDocument3 pagesGeneral Office Cleaning: Example Risk Assessment Forisak23No ratings yet

- Covid 19 Secure ToolkitDocument44 pagesCovid 19 Secure ToolkitDianNo ratings yet

- 2016 Food Control Plan Diary Full Colour PDFDocument18 pages2016 Food Control Plan Diary Full Colour PDFAnonymous OuY6oAMggxNo ratings yet

- Kitchen Inspection CKLST JULY 2014Document13 pagesKitchen Inspection CKLST JULY 2014Andrew AdamsNo ratings yet

- All Department Training TopicsDocument302 pagesAll Department Training TopicsMacario Roy Jr AmoresNo ratings yet

- Prof. V. B. Shah Institute of ManagementDocument69 pagesProf. V. B. Shah Institute of ManagementFaidz FuadNo ratings yet

- Hotel MuseFood Safety Monitoring Record Version 1Document13 pagesHotel MuseFood Safety Monitoring Record Version 1Aditya SharmaNo ratings yet

- Comply With Workplace Hygiene Procedures: Unit Code: D1.HRS - CL1.05 D1.HOT - CL1.04 D2.TTO - CL4.10Document187 pagesComply With Workplace Hygiene Procedures: Unit Code: D1.HRS - CL1.05 D1.HOT - CL1.04 D2.TTO - CL4.10irneil H. PepitoNo ratings yet

- Manager On Duty: S.no Checklist Check StaffDocument4 pagesManager On Duty: S.no Checklist Check StaffJagannath DashNo ratings yet

- Basic and Common Competencies ExamDocument2 pagesBasic and Common Competencies ExamNoreen Cañaveral NochefrancaNo ratings yet

- Assgnmnt Sheet Wa 01 DTRDocument5 pagesAssgnmnt Sheet Wa 01 DTRNana TanNo ratings yet

- How To Use This Kitchen Inspection Checklist: Safetyunit@gre - Ac.uk October 2010 Page 1 of 8Document8 pagesHow To Use This Kitchen Inspection Checklist: Safetyunit@gre - Ac.uk October 2010 Page 1 of 8tzryadNo ratings yet

- TG - Apply Safety Proc Handling Food - FN - 020114Document198 pagesTG - Apply Safety Proc Handling Food - FN - 020114Hershell ContaNo ratings yet

- EFMK-CLN-CL-12 - Supervisor Daily Toilet Cleaning ChecklistDocument1 pageEFMK-CLN-CL-12 - Supervisor Daily Toilet Cleaning ChecklistFULL,HALF AND QUARTERNo ratings yet

- Waste Managment NKA UPES Mar 2-2k11Document64 pagesWaste Managment NKA UPES Mar 2-2k11Nk AgarwalNo ratings yet

- F&B - Kitchen Check ListDocument1 pageF&B - Kitchen Check ListdamianuskrowinNo ratings yet

- Microsoft Word - Checklist For Cafeteria Inspection - LatestDocument1 pageMicrosoft Word - Checklist For Cafeteria Inspection - LatestAyong EntilyNo ratings yet

- Kitchen Equipmemt ListDocument4 pagesKitchen Equipmemt ListMartinsNo ratings yet

- Kitchen Equipment SelectionDocument21 pagesKitchen Equipment Selectioncucucucucu72No ratings yet

- How To Use This Pack: Welcome To Safer Food, Better Business For CaterersDocument99 pagesHow To Use This Pack: Welcome To Safer Food, Better Business For CaterersRicardo SalcedoNo ratings yet

- Kitchen Station Task ListDocument9 pagesKitchen Station Task ListJason BrownNo ratings yet

- 2017 Food Safety For PantriesDocument55 pages2017 Food Safety For Pantriessoniaditia_chemistNo ratings yet

- Calculations in The Catering Industry: 8065-02 Unit 219: Catering Operations, Costs and Menu PlanningDocument12 pagesCalculations in The Catering Industry: 8065-02 Unit 219: Catering Operations, Costs and Menu PlanningSZA100% (1)

- Ohs in The Hospitality Industry 4133Document72 pagesOhs in The Hospitality Industry 4133Stephanie Lee100% (1)

- Food Courts Food Malls Banquet Halls Set Up ConsultancyDocument28 pagesFood Courts Food Malls Banquet Halls Set Up ConsultancymohamadNo ratings yet

- Kitchen Session 1d Wokplan Assessment DoneDocument40 pagesKitchen Session 1d Wokplan Assessment DoneAMAN MIGLANINo ratings yet

- Presupuesto FamiliarbDocument10 pagesPresupuesto FamiliarbmmauryfgNo ratings yet

- First Aid Box Fill ListDocument34 pagesFirst Aid Box Fill Listzam110No ratings yet

- Kitchen Station Task ListDocument9 pagesKitchen Station Task ListbibindevNo ratings yet

- SP Session1Document72 pagesSP Session1Abood Abood100% (1)

- Working in Tourism: ReadingDocument65 pagesWorking in Tourism: ReadingMarcus VoNo ratings yet

- Safety KitchenDocument4 pagesSafety KitchenHamo SaadNo ratings yet

- Fire Safety Model-A Restaurant Kitchen FireDocument9 pagesFire Safety Model-A Restaurant Kitchen FireSean BuckNo ratings yet

- Sample Weekly Cleaning Schedule For Shop FloorDocument13 pagesSample Weekly Cleaning Schedule For Shop FloorBalaje RajNo ratings yet

- Mapping of Cookery SkillsDocument2 pagesMapping of Cookery Skillszoltan2014No ratings yet

- Deep Cleaning ScheduleDocument3 pagesDeep Cleaning ScheduleTemet NoscheNo ratings yet

- Hse United Industrial Services Co Rev 02Document69 pagesHse United Industrial Services Co Rev 02Ahmad Zaid100% (1)

- Копия Restaurant Site ReviewDocument14 pagesКопия Restaurant Site ReviewАнастасия КруминаNo ratings yet

- Cleaning of BathroomDocument24 pagesCleaning of BathroomNakul MohindraNo ratings yet

- Basic Food SafetyDocument3 pagesBasic Food SafetyJessa RosalesNo ratings yet

- Building: Environmental Cleaning Standard Operating ProceduresDocument56 pagesBuilding: Environmental Cleaning Standard Operating ProceduresJoey CadanoNo ratings yet

- Blood Spill Clean-Up Procedure: WWW - Epa.govDocument1 pageBlood Spill Clean-Up Procedure: WWW - Epa.govAlexandru SeciuNo ratings yet

- HIRARC Update - HR CanteenDocument6 pagesHIRARC Update - HR CanteenDon McleanNo ratings yet

- Fire Safety Audit - Zeeshan RestaurantDocument6 pagesFire Safety Audit - Zeeshan RestaurantAbdurNo ratings yet

- HOTEL LaundryDocument46 pagesHOTEL LaundrykomalNo ratings yet

- Working Safer and Easier For Janitors, Custodians, and HousekeepersDocument86 pagesWorking Safer and Easier For Janitors, Custodians, and Housekeepersdoc_ona100% (1)

- SC Restaurant Reopening Guidelines For RestaurantsDocument18 pagesSC Restaurant Reopening Guidelines For RestaurantsWLTXNo ratings yet

- Modified TrainingDocument55 pagesModified Trainingapi-415110604No ratings yet

- Food StocktakeeDocument51 pagesFood StocktakeenkosieNo ratings yet

- Best Housekeeping PracticesDocument41 pagesBest Housekeeping PracticesJohn Kurong100% (1)

- Hotels & MotelsDocument47 pagesHotels & MotelsJomar Rudolph CabesasNo ratings yet

- Presenter: Dilani Rasanayagam: Preparing Competitive Cover Letters and ResumesDocument22 pagesPresenter: Dilani Rasanayagam: Preparing Competitive Cover Letters and ResumesThorNo ratings yet

- Food & Beverage Service: Prepared By: Nickalyn M. SalanapDocument38 pagesFood & Beverage Service: Prepared By: Nickalyn M. SalanapNickalyn SalanapNo ratings yet

- School Visitors Policy: VisionDocument2 pagesSchool Visitors Policy: Visionfahad siddiquiNo ratings yet

- A002 C NightclubDocument6 pagesA002 C NightclubBlas de LezoNo ratings yet

- Firstaid ManualDocument144 pagesFirstaid Manualabdul samadNo ratings yet

- British Standard Bs 8848:2014Document2 pagesBritish Standard Bs 8848:2014Blas de LezoNo ratings yet

- Standard HeDocument2 pagesStandard HeBlas de LezoNo ratings yet

- KeithPattinson Marketing Particular Approved Particulars 300672Document4 pagesKeithPattinson Marketing Particular Approved Particulars 300672Blas de LezoNo ratings yet

- PDF Analysis On Human Security and Its ChallengesDocument6 pagesPDF Analysis On Human Security and Its ChallengesBlas de LezoNo ratings yet

- Chubb2205 International TripsDocument32 pagesChubb2205 International TripsBlas de LezoNo ratings yet

- Adult Course Guide 2015Document28 pagesAdult Course Guide 2015Blas de LezoNo ratings yet

- Themes in Sustainable Development The Global Commons and Tragedy of Commons Antonio BlancoDocument14 pagesThemes in Sustainable Development The Global Commons and Tragedy of Commons Antonio BlancoBlas de LezoNo ratings yet

- Appendix 1: IGC3 - The Health and Safety Practical ApplicationDocument3 pagesAppendix 1: IGC3 - The Health and Safety Practical ApplicationBlas de LezoNo ratings yet

- Course Provider Declarations 1Document3 pagesCourse Provider Declarations 1Blas de LezoNo ratings yet

- A002 C NightclubDocument6 pagesA002 C NightclubBlas de LezoNo ratings yet

- Appendix 1: IGC3 - The Health and Safety Practical ApplicationDocument3 pagesAppendix 1: IGC3 - The Health and Safety Practical ApplicationBlas de LezoNo ratings yet