Professional Documents

Culture Documents

Ba Sar1!07!16 Norm en

Ba Sar1!07!16 Norm en

Uploaded by

Alonso CoradoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ba Sar1!07!16 Norm en

Ba Sar1!07!16 Norm en

Uploaded by

Alonso CoradoCopyright:

Available Formats

Multi-turn actuator

SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

(without actuator controls)

Operation instructions

Assembly, operation, commissioning

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

..

..

Operation instructions

Read the operation instructions first

Observe safety instructions.

These operation instructions are part of the product.

Store operation instructions during product life.

Pass on instructions to any subsequent user or owner of the product.

Table of contents

Page

1.

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1.

1.2.

1.3.

1.4.

1.5.

General notes regarding safety

Range of application

Applications in Ex zone 22 (option)

Warnings and notes

Further references and symbols

2.

Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1.

2.2.

Name plate

Short description

3.

Transport, storage and packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1.

3.2.

3.3.

Transport

Storage

Packaging

4.

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1.

4.2.

4.2.1

4.2.2

4.3.

4.3.1

Handwheel fitting

Multi-turn actuator mounting to valve/gearbox

Output drive types B1, B2, B3, B4, B, and E

Output drive type A

Accessories (option)

Protection tube for rising valve stem

5.

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1.

5.2.

5.3.

5.3.1

5.3.2

5.3.3

5.3.4

General notes

Connection with AUMA plug/socket connector (S, SH, SE)

Accessories for electrical connection (option)

Parking frame

Protection cover

Double sealed intermediate frame

Ground connection, external

6.

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.1.

6.2.

Manual operation

Motor operation

7.

Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.1.

Mechanical position indicator/running indication (option)

8.

Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.1.

Feedback signals from actuator

9.

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9.1.

9.2.

9.3.

Switch compartment: open

Torque switching: set

Limit switching: set

4

5

6

7

7

8

9

9

9

9

10

11

11

12

14

14

15

17

20

20

20

20

20

21

22

23

24

25

26

27

Operation instructions

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

Page

27

27

28

28

28

29

29

30

30

31

32

33

9.3.1

9.3.2

9.4.

9.4.1

9.4.2

9.5.

9.5.1

9.5.2

9.6.

9.7.

9.8.

9.9.

End position CLOSED (black section): set

End position OPEN (white section): set

Intermediate positions (option): set

Running direction CLOSE (black section): set

Running direction OPEN (white section): set

Test run

Rotational direction check

Limit switching check

Potentiometer (option) setting

Electronic position transmitter RWG setting (option)

Mechanical position indicator setting (option)

Switch compartment: close

10.

Corrective action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.1. Faults during commissioning

10.1.1

Mechanical position indicator

10.1.2

Position transmitter RWG

10.1.3

Limit and torque switches

10.1.4

Fault in end position (overrun not considered)

10.2. Motor protection (thermal monitoring)

34

34

34

34

35

35

11.

Servicing and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

11.1.

11.2.

11.3.

Preventive measures for servicing and safe operation

Maintenance

Disposal and recycling

12.

Spare parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

12.1.

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

13.

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

14.

Certificates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

14.1.

Declaration of Conformity and Declaration of Incorporation

36

37

37

38

44

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

1.

Safety instructions

1.1.

General notes regarding safety

Standards/directives

Operation instructions

AUMA products are designed and manufactured in compliance with recognised standards and directives. This is certified in a declaration of incorporation and a declaration of conformity.

The end user or the contractor must ensure that all requirements with

respect to assembly, electrical connection, and commissioning at the place

of installation are met. They include among others:

National regulations, laws, and prescriptions.

.

Safety instructions/

warnings

Qualification of staff

Assembly, electrical connection, commissioning, operation, and maintenance must be carried out exclusively by suitably qualified personnel having

been authorised by the end user or contractor of the plant.

Prior to working on this product, the staff must have thoroughly read and

understood these instructions and, furthermore, know and observe officially

recognised rules regarding occupational health and safety.

Commissioning

Prior to commissioning, it is important to check that all settings are in compliance with the requirements of the application. Incorrect settings might

present a danger to the application, e.g. cause damage to the valve or the

installation.

The manufacturer will not be held liable for any consequential damage. Such

risk lies entirely with the user.

Operation

Protective measures

Maintenance

All personnel working with this device must be familiar with the safety and

warning instructions in this manual and observe the instructions given.

Safety instructions and warning signs on the device must be observed to

avoid personal injury or property damage.

.

.

.

..

.

Prerequisites for safe and smooth operation:

Correct transport, proper storage, mounting and installation, as well as

careful commissioning.

Only operate the device if it is in perfect condition while observing these

instructions.

Immediately notify any faults and damage and allow for corrective measures.

Observe recognised rules for occupational health and safety.

Observe the national regulations.

During operation, the housing warms up and surface temperatures > 60 C

may occur. To prevent possible burns, we recommend to the check surface

temperature with an appropriate thermometer prior to working with the device.

The end user or the contractor are responsible for implementing required

protective measures on site, such as enclosures, barriers, or personal

safety equipment for the staff.

To ensure safe device operation, the maintenance instructions included in

this manual must be observed.

Any device modification requires the consent of the manufacturer.

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

Operation instructions

1.2.

Range of application

AUMA multi-turn actuators are designed for the operation of industrial

valves, e.g. globe valves, gate valves, butterfly valves, and ball valves.

Other applications require explicit (written) confirmation by the manufacturer.

..

..

..

..

..

The following applications are not permitted, e.g.:

Industrial trucks according to EN ISO 3691

Lifting appliances according to EN 14502

Passenger lifts according to DIN 15306 and 15309

Service lifts according to EN 81-1/A1

Roller conveyors according to Standard EN 14673 (draft)

Permanent operation

Buried service

Permanent submersion (observe enclosure protection)

Potentially explosive areas, with the exception of zone 22

Radiation exposed areas in nuclear power plants

No liability can be assumed for inappropriate or unintended use.

Observance of these operation instructions is considered as part of the

devices designated use.

Information

These operation instructions are only valid for the clockwise closing standard version, i.e. driven shaft turns clockwise to close the valve. Separate

instructions are available for the counterclockwise closing special version.

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

1.3.

Operation instructions

Applications in Ex zone 22 (option)

SA 07.1 SA 16.1/SAR 07.1 SAR 16.1 actuators basically meet the

requirements for applications in dust hazardous locations of ZONE 22, in

compliance with the ATEX directive 94/9/EC.

The actuators are designed to meet enclosure protection IP 67 or IP 68 and

fulfil the requirements of EN 50281-1-1:1998 section 6 Electrical apparatus for use in presence of combustible dust hazards, requirements for category 3 electrical equipment protected by enclosures.

To comply with all requirements of EN 50281-1-1: 1998, the following points

must imperatively be observed:

.

.

.

.

.

.

.

.

In compliance with the ATEX directive 94/9/EC, the actuators must be

equipped with an additional identification II3D IP6X T150 C.

The maximum surface temperature of the actuators, based on an ambient temperature of +40 C in accordance with EN 50281-1-1 section

10.4, is +150 C. In accordance with section 10.4, an increased dust

deposit on the equipment was not considered for the determination of

the max. surface temperature.

The correct connection of the thermoswitches or the PTC thermistors as

well as fulfilling the requirements of the duty type and the technical data

are prerequisites for compliance with the maximum surface temperature

of devices.

The connection plug may only be plugged in or pulled out when device is

disconnected from the mains.

The cable glands used also have to meet the requirements of category

II3 D and must at least comply with enclosure protection IP 67.

The actuators must be connected by means of an external ground connection (accessory part) to the potential equaliser or integrated into a

grounded piping system.

The screw plug (part no. 511.0) or the stem protection tube with protection cap (part nos. 568.1 and 568.2) for sealing the hollow shaft must

imperatively be mounted to guarantee the combustible dust hazard

protection.

As a general rule, the requirements of EN 50281-1-1 must be respected

in dust hazardous locations. During commissioning, service, and maintenance, special care as well as qualified and trained personnel are

required for the safe operation of actuators.

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

Operation instructions

1.4.

Warnings and notes

The following warnings draw special attention to safety-relevant procedures

in these operation instructions, each marked by the appropriate signal word

(DANGER, WARNING, CAUTION, NOTICE).

DANGER

Indicates an imminently hazardous situation with a high level of risk

Failure to observe this warning will result in death or serious injury.

WARNING

Indicates a potentially hazardous situation with a medium level of risk

Failure to observe this warning could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation with a low level of risk

Failure to observe this warning may result in minor or moderate injury. May

also be used with property damage.

NOTICE

Potentially hazardous situation.

Failure to observe this warning may result in property damage. Is not used

for personal injury.

Arrangement and typographic structure of the warnings

Safety alert symbol (warns of a potential personal injury hazard).

Signal word (DANGER, WARNING, CAUTION, NOTE)

DANGER

1.5.

Type of hazard and respective source!

Possible consequence(s) in case of non-observance (option)

Measures to avoid the danger

Further measure(s)

Further references and symbols

The following references and symbols are used in these instructions:

Information

The term Information preceding the text indicates important notes and

information.

Symbol for CLOSED.

Symbol for OPEN.

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

2.

Identification

2.1.

Name plate

Operation instructions

Each device component (actuator, motor) is equipped with a name plate.

Figure 1 shows the arrangement of name plates on the device.

Figure 1

1

2

Motor name plate

Actuator name plate

Additional plate, e.g. KKS plate

Identification data on the actuator name plate:

Figure 2

1

2

Type and size

Commission number

a CC

1

2

AUMA Riester GmbH&Co.KG

D-79379 Mllheim

SA 07.1-F10

Com No: 1309533

No : 3302MD 19302

Type and size of actuator

Commission number

These instructions are valid for the following actuators:

Type: SA = Multi-turn actuator for open-close duty

Type: SAR = Multi-turn actuator for modulating duty

Size: 07.1 16.1

Version: NORM (without actuator controls)

An order-specific commission number is assigned to each device. You can

use this number to download the wiring diagram, inspection records and further information from the Internet (http://www.auma.com).

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

Operation instructions

2.2.

Short description

Definition in compliance with EN ISO 5210

A multi-turn actuator is an actuator which transmits to the valve a torque for

at least one full revolution. It is capable of withstanding thrust.

AUMA multi-turn actuators are driven by an electric motor. A handwheel is

provided for manual operation.

Switching off in end positions may be either by limit or torque seating.

Controls are required to operate or process the actuator signals.

3.

Transport, storage and packaging

3.1.

Transport

For transport to place of installation, use sturdy packaging.

DANGER

3.2.

Storage

NOTICE

Long-term storage:

3.3.

Hovering load!

Death or serious injury possible.

Do not place below hovering load.

Attach ropes or hooks for the purpose of lifting by hoist only to housing

and not to handwheel.

Actuators mounted on valves:

Attach ropes or hooks for the purpose of lifting by hoist to valve and not

to multi-turn actuator.

Actuators mounted to gearboxes:

Attach ropes or hooks for the purpose of lifting by hoist only to the gearbox using eyebolts and not to the actuator

Actuators mounted to controls:

Attach ropes or hooks for the purpose of lifting by hoist only to actuator

and not to controls.

Danger of corrosion due to inappropriate storage!

Store in a well-ventilated, dry room.

Protect against floor dampness by storage on a shelf or on a wooden

pallet.

Cover to protect against dust and dirt.

Apply suitable corrosion protection agent to uncoated surfaces.

If the device must be stored for a long period (more than 6 months) the following points must be observed in addition:

1. Prior to storage:

Protect uncoated surfaces, in particular the output drive parts and

mounting surface, with long-term corrosion protection agent.

2. At an interval of approx. 6 months:

Check for corrosion. If first signs of corrosion show, apply new corrosion

protection.

Packaging

Our products are protected by special packaging for the transport ex works.

The packaging consists of environmentally friendly materials which can easily be separated and recycled.

We use the following packaging materials: wood, cardboard, paper, and PE

foil. For the disposal of the packaging material, we recommend recycling

and collection centres.

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

4.

Assembly

4.1.

Handwheel fitting

Information

NOTICE

Operation instructions

For transport purposes, handwheels from a diameter of 400 mm are supplied separately.

Damage at the change-over mechanism due to incorrect assembly!

Only pivot the change-over lever manually.

Using extensions as a lever for operation is not permitted.

First engage manual operation correctly, then mount handwheel.

1. Manually lift the red change-over lever while slightly turning the shaft

back and forth until manual operation engages.

The manual operation is correctly engaged if the change-over lever can

be lifted by approx. 85.

85

2. Attach handwheel over the red change-over lever then on to the shaft.

3. Secure handwheel using the circlip supplied.

10

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

Operation instructions

4.2.

Multi-turn actuator mounting to valve/gearbox

4.2.1 Output drive types B1, B2, B3, B4, B, and E

Application

Design

For rotating, non-rising valve stem.

Output drive type bore with keyway:

Type B1 B4 with bore according to ISO 5210.

Type B and E with bore according to DIN 3210.

Later change from B1 to B3, B4, or E is possible.

Figure 3

2

4

1

2

Information

Output drive type B1/B2 and B

Hollow shaft with keyway

3

4

Output drive B3/B4 and E

Plug sleeve

with bore and keyway

Spigot at flanges should be loose fit.

Mounting the multi-turn actuator

1.

2.

3.

4.

5.

Check if mounting flanges fit together.

Check whether bore and keyway match the input shaft.

Thoroughly degrease mounting faces of the mounting flanges.

Apply a small quantity of grease to the input shaft.

Mount multi-turn actuator and ensure that the spigot mates uniformly in

the recess and that the mounting faces are in complete contact.

6. Fasten multi-turn actuator with screws according to table 1.

7. Fasten screws crosswise with a torque according to table 1.

Table 1

NOTICE

Mounting flange

Screws

Thread

Fastening torque TA [Nm]

F07

F10

F14

F16

M8

M10

M12

M16

25

51

87

214

Strength class 8.8

Danger of corrosion due to damage to paint finish and condensation!

Touch up damage to paint finish after working on the device.

After mounting, connect the device immediately to electrical mains to

ensure that heater reduces condensation.

11

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

4.2.2 Output drive type A

Application

Design

..

Operation instructions

For rising, non-rotating valve stem.

Capable of withstanding thrust

Output drive type A as separate unit (figure 4):

Figure 4

1

2

3

1

2

.

.

Stem nut

3

Axial needle roller and cage assembly 4

Spigot ring

Axial bearing washer

The internal thread of the stem nut must match the thread of the valve

stem.

If not ordered explicitly with thread, the stem nut is supplied unbored or

with a pilot bore.

Finish machining the stem nut

Only required for stem nut if supplied unbored or with a pilot bore.

1. Remove spigot ring (3) from output drive type.

2. Take off stem nut (1) together with axial needle roller and cage assembly

(2) and axial bearing washers (4).

3. Remove axial needle roller and cage assembly and axial bearing washers from stem nut.

4. Drill and bore stem nut and cut thread.

When fixing in the chuck, make sure stem nut runs true!

5. Clean the machined stem nut.

6. Apply Lithium soap EP multi-purpose grease to axial needle roller and

cage assembly and axial bearing washers, then place them on stem nut.

7. Re-insert stem nut with axial bearings into output drive type. Ensure that

dogs or toothing are placed correctly in the slots of the hollow shaft.

8. Screw in spigot ring until it is firm against the shoulder.

9. Press in Lithium soap EP multi-purpose grease on mineral oil base at the

grease nipple with a grease gun (for quantities, please refer to table 2).

Grease quantities for bearing of output drive A:

Table 2

A 07.2

A 10.2

Output drive

1.5 g

2g

Qty1)

1) For grease with density = 0.9 kg/dm

12

A 14.2

3g

A 16.2

5g

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

Operation instructions

Mounting the multi-turn actuator (with output drive A) to valve

Figure 5

1

2

3

Valve stem

Output drive type A

Screw to actuator

4

5

Valve flange

Screws to output drive

1. Remove screws (3) and take off output drive type A (2) from multi-turn

actuator.

2. Check if the flange of output drive type A matches the valve flange (4).

3. Thoroughly degrease mounting faces of the mounting flanges.

4. Apply a small quantity of grease to the valve stem (1).

5. Place output drive type A on valve stem and fasten until it is seated solidly on the valve flange.

6. Turn output drive type A until alignment of the fastening holes.

7. Screw in fastening screws (5), however do not completely fasten.

8. Fit multi-turn actuator on the valve stem so that the hollow shaft pinions

engage into the stem nut. The flanges are flush with each other if properly engaged.

9. Turn multi-turn actuator until alignment of the fastening holes.

10 Fasten multi-turn actuator with screws (3) according to table 1, page 11.

11. Fasten screws crosswise with a torque according to table 1.

12. Engage manual operation at multi-turn actuator and turn handwheel in

direction OPEN until valve flange and output drive type A are firmly

placed together.

13. Tighten fastening screws (5) between valve and output drive type A

crosswise with a torque according to table 1, page 11.

NOTICE

Danger of corrosion due to damage to paint finish and condensation!

Touch up damage to paint finish after working on the device.

After mounting, connect the device immediately to electrical mains to

ensure that heater reduces condensation.

13

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

4.3.

Operation instructions

Accessories (option)

4.3.1 Protection tube for rising valve stem

Figure 6

1

2

3

1

2

1.

2.

3.

4.

14

Cap for stem protection tube

Stem protection tube

Sealing ring

Seal thread with hemp, Teflon tape, or thread sealing material.

Screw protection tube (2) into thread and tighten it firmly.

Push down the sealing ring (3) into the housing.

Check whether cap (1) is available and in perfect condition.

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

Operation instructions

5.

Electrical connection

5.1.

General notes

WARNING

Wiring diagram/terminal plan

NOTICE

Danger due to incorrect electrical connection!

Failure to observe this warning can result in death, serious injury, or property damage.

The electrical connection must be carried out exclusively by suitably

qualified personnel.

Prior to connection, observe general references contained in this clause.

After connection but prior to applying the voltage, observe the Commissioning and Test run clauses.

The wiring diagram/terminal plan is attached to the device in a

weather-proof bag, together with these operation instructions. It can also be

obtained from AUMA (state commission no., refer to name plate) or downloaded directly from the Internet (www.auma.com).

Valve damage for connection without controls!

NORM actuators require controls:

Connect motor via controls only (reversing contactor circuit).

Observe the type of seating specified by the valve manufacturer.

Observe wiring diagram.

Controls by AUMA

In case the required reversing contactors are not to be installed in the control cabinet, the AUMA MATIC or AUMATIC controls an easily be mounted to

the actuator at a later date.

For enquiries and more information, please state our commission no.

(refer to actuator name plate).

Delay time

The delay time is the time from the tripping of the limit or torque switches to

the motor power being switched off. To protect the valve and the actuator,

we recommend a delay time < 50 ms. Longer delay times are possible provided the operating time, output drive type, valve type, and the type of installation are considered. We recommend to switch off the corresponding

contactor directly by limit or torque switch.

Protection on site

For short-circuit protection and for disconnecting the actuator from the

mains, fuses and disconnect switches have to be provided on site.

The current values for respective sizing can be derived from the current

consumption of the motor (refer to name plate on motor: nominal current)

plus the current consumption of the controls.

15

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

Limit and torque switches

Information

Operation instructions

Limit and torque switches can be provided as single, tandem, or triple

switches.

Only the same potential can be switched on the two circuits (NC/NO contact) of each single switch. If different potentials are to be switched simultaneously, tandem switches are required.

When using tandem switches:

For signalling, use the leading contacts:

TSC1, TSO1, LSC1, LSO1

For switching off, use the lagging contacts:

TSC, TSO, LSC, LSO

Technical data for limit and torque switches:

Table 3

Mechanical lifetime

Silver plated contacts

U min.

U max.

I min.

I max. AC

I max. DC

Gold plated contacts

U min.

U max.

I min.

I max.

16

2 x 106 starts

30 V AC/DC

250 V AC/DC

20 mA

5 A (cos phi = 0,8)

0.5 A at 250 V (2 A at 30 V)

5V

50 V

4 mA

400 mA

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

Operation instructions

Connection with AUMA plug/socket connector (S, SH, SE)

a CC

Before mains connection

Check whether type of current, supply voltage, and frequency comply

with motor data (refer to name plate at motor).

VD00 63-4/45

Art No: Z006.413

3 ~ 400 V 50 Hz

0.090 kW

Y 0.60 A

Opening the terminal compartment

DANGER

Hazardous voltage!

Electric shock possible.

Disconnect device from the mains before opening.

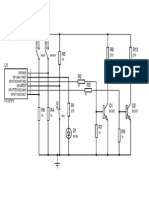

Figure 7 shows the connection using the example of version S:

Figure 7

1

8

7

6

3

5

4

1

2

3

4

Cover

Screws for cover

O-ring

Screws for socket carrier

5

6

7

8

Socket carrier

Cable entry

Screw plug

Cable gland (not included in delivery)

1. Loosen screws (2) and remove cover (1).

2. Loosen screws (4) and remove socket carrier (5) from cover (1).

3. Insert cable glands (8) suitable for connecting cables.

The enclosure protection IP stated on the name plate is only ensured

if suitable cable glands are used.

au

5.2.

IP 67 1680 rpm

Temp.Protection: Th

Insulation Class: F

4. Seal cable entries (6) which are not used with suitable screw plugs (7).

5. Insert the wires into the cable glands (8).

17

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

Operation instructions

Connecting the cables

1. Remove cable sheathing.

2. Strip wires.

3. For stranded wires: use end-sleeves according to DIN 46228.

4. Connect cables according to order-related wiring diagram.

Cable cross sections:

Power terminals (U1, V1, W1, U2, V2, W2) and

protective earth (symbol: ) =

max. 6 mm flexible, max. 10 mm rigid

Control contacts (1 to 50) = max. 2.5 mm

WARNING

In case of failure: Hazardous voltage while protective conductor is not

connected!

Electric shock possible.

Connect all protective conductors.

Connect PE connection with external protective conductor of connecting

cables.

Start running the device only after having connected the protective conductor.

5. Tighten PE conductors (symbol:

) firmly to PE connection using ring

lugs (flexible cables) or loops (rigid cables) .

Figure 8

2

3

4

5

1

6

1

2

3

Socket carrier

Screw

Washer

4

5

6

Spring lock washer

Protective earth with ring lugs/loops

PE connection

Connecting the heater

The heater prevents condensation in the actuator.

NOTICE

Danger of corrosion: damage due to condensation!

Connect heater R1 according to terminal plan.

After mounting, immediately put device into operation.

Connecting the motor protection

In order to protect against overheating and impermissibly high temperatures

at the actuator, PTC thermistors or thermoswitches are embedded in the

motor winding.

NOTICE

18

Danger of motor damage if PTC thermistor or thermoswitch are not

connected!

Connect PTC thermistor R3 or thermoswitch F1 to external controls

(refer to terminal plan).

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

Operation instructions

Connecting the motor heater (option)

Some actuators are equipped with an additional motor heater. The motor

heater improves the start-up behaviour for extremely low temperatures.

Connect motor heater R4, if available, according to terminal plan.

Closing the terminal compartment

Refer to figure 9.

1. Insert the socket carrier (5) into the plug cover (1) and fasten it with

screws (4).

2. Clean sealing faces of housing and cover.

3. Apply a thin film of non-acidic grease (e.g. Vaseline) to the sealing faces.

4. Check whether O-ring (3) is in good condition, correctly place O-ring.

5. Replace cover (1) and fasten screws (2) evenly crosswise.

6. Fasten cable glands (8) applying the specified torque to ensure the

required enclosure protection.

Figure 9

1

8

7

6

3

5

4

1

2

3

4

Cover

Screws for cover

O-ring

Screws for socket carrier

5

6

7

8

Socket carrier

Cable entry

Screw plugs

Cable gland (not included in delivery)

19

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

5.3.

Operation instructions

Accessories for electrical connection (option)

5.3.1 Parking frame

Parking frame for safe storage of a disconnected plug.

For protection against touching the bare contacts and against environmental

influences.

Figure 10

5.3.2 Protection cover

Protection cover for plug compartment when plug is removed.

The open terminal compartment can be closed using a protective cover (not

illustrated).

5.3.3 Double sealed intermediate frame

When removing the plug/socket connector or due to leaky cable glands,

ingress of dust and water into the housing is possible. This is prevented by

inserting the double sealed intermediate frame (2) between the plug/socket

connector (1) and the actuator housing. The enclosure protection of the

device, IP 67 or IP 68, will not be affected, even if the electrical connection

is removed.

Figure 11

5.3.4 Ground connection, external

As an option, an external ground connection (U-bracket) on the housing is

available.

Figure 12

20

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

Operation instructions

6.

Operation

6.1.

Manual operation

In case of motor failure or power failure, the actuator may be operated manually for purposes of setting and commissioning.

Manual operation is engaged by an internal change-over mechanism.

Engaging manual operation

NOTICE

Damage at the change-over mechanism due to faulty operation!

Engage manual operation only during motor standstill.

Only pivot change-over lever manually.

Using extensions as a lever for operation is not permitted.

1. Pivot change-over lever manually to approx. 85 while slightly turning the

handwheel back and forth until manual operation engages.

2. Release change-over lever (should snap back into initial position by

spring action), if necessary, push it back manually.

3. Turn handwheel into desired direction, in doing so the following applies:

To close the valve, turn handwheel clockwise;

drive shaft (valve) turns clockwise in direction CLOSE.

Disengaging manual operation

Manual operation is automatically disengaged when motor is started again.

The handwheel does not rotate during motor operation.

21

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

6.2.

Operation instructions

Motor operation

Controls are required to operate an actuator during motor operation.

If the actuator is to be operated locally, additional local controls are required.

Actuators without controls can be equipped with AUMA controls at a later

date. The local controls are included in the AUMA controls.

For enquiries and more information, please state our commission no. (refer

to actuator name plate).

Perform all commissioning settings and the test run prior to motor operation.

1. Switch on the power supply.

2. To close the valve, switch motor in direction CLOSE:

Drive shaft (valve) turns clockwise in direction CLOSE.

22

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

Operation instructions

7.

Indications

7.1.

Mechanical position indicator/running indication (option)

.

..

Mechanical position indicator

continuously indicates the valve position

(Indicator disc rotates approximately 180 to 230 at full travel from

OPEN to CLOSED or vice versa.)

indicates whether the actuator is running (running indication)

indicates that the end positions (via indication mark) have been reached

Figure 13

auma

4

1

2

5

3

1

2

3

Cover

Indicator disc

Indicator mark

4

5

Symbol for position OPEN

Symbol for position CLOSED

23

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

8.

Signals

8.1.

Feedback signals from actuator

End position OPEN/CLOSED reached

Intermediate position reached

Torque OPEN/CLOSED reached

Motor protection tripped

Running indication

Valve position

Operation instructions

Switching contact: 1 NC and 1 NO (standard)

Setting:

Via limit switching (page 27)

Designation in terminal plan:

WSR

Limit switch, closing, clockwise rotation

WL

Limit switch, opening, counterclockwise rotation

Switching contact: 1 NC and 1 NO

Setting:

Via DUO limit switching (page 28)

Designation in terminal plan:

WDR

DUO limit switch, clockwise rotation

WDL

DUO limit switch, counterclockwise rotation

Switching contact: 1 NC and 1 NO (standard)

Setting:

Via torque switching (page 26)

Designation in terminal plan:

DSR

Torque switch, closing, clockwise rotation

DL

Torque switch, opening, counterclockwise rotation

Thermoswitches or PTC thermistors (page 35)

Designation in terminal plan:

F1, Th

Thermoswitches

R3

Thermistor (motor protection)

Switching contact: 1 NC

Designation in terminal plan:

S5, BL

Blinker transmitter

Depending on the version, the valve position can be transmitted by various

position transmitters:

Electronic position transmitter RWG (page 31)

Potentiometer (page 30)

..

Signal:

Potentiometer or 0/4 20 mA (RWG)

Designation in terminal plan:

B1/B2, RWG, 3- or 4-wire system.

B3/B4, RWG, 2-wire system.

R2

Potentiometer

R2/2

Potentiometer in tandem arrangement (option)

Information

24

The switches can be provided as tandem switches (2 NC and 2 NO) or as

triple switches (3 NC and 3 NO). The version is indicated in the terminal

plan or on the order-related technical data sheet.

Operation instructions

9.

Commissioning

9.1.

Switch compartment: open

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

The switch compartment must be opened to perform the following settings.

1. Loosen screws (2) and remove cover (1) from the switch compartment.

2. If indicator disc (3) is available:

Remove indicator disc (3) using a wrench (as lever).

25

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

9.2.

Operation instructions

Torque switching: set

NOTICE

Valve damage due to excessive torque setting!

The torque must suit the valve.

Only change the setting with the consent of the valve manufacturer.

Figure 14

1

3

Switching head black for

torque in direction CLOSE

Lock screws

2

4

Switching head white for

torque in direction OPEN

Torque dial

1. Loosen both lock screws (3) at the indicator disc (figure 14).

2. Turn torque dial (4) for setting the required torque (1 da Nm = 10 Nm).

Example:

Figure 14 shows the following setting:

3.5 da Nm = 35 Nm for direction CLOSE

4.5 da Nm = 45 Nm for direction OPEN

3. Fasten lock screws (3) again.

The torque switches setting is complete.

Information

26

..

The torque switches may also trip in manual operation.

The torque switching acts as overload protection over full travel, also

when stopping in the end positions by limit switching.

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

Operation instructions

9.3.

Limit switching: set

Figure 15

1

2

3

Black section

Setting spindle for end position

CLOSED

Pointer for end position CLOSED

End position CLOSED correctly set

to mark

4

5

6

White section

Setting spindle for end position

OPEN

Pointer for end position OPEN

End position OPEN correctly set to

mark

9.3.1 End position CLOSED (black section): set

1. Engage manual operation.

2. Turn handwheel clockwise until valve is closed.

3. Turn handwheel back by approximately half a turn (overrun).

4. Press down and turn setting spindle (1) (figure 15) using a screw driver

in direction of the arrow, thereby observe pointer (2):

While a ratchet is felt and heard, the pointer (2) moves 90 every time.

5. If the pointer (2) is 90 from mark (3): continue turning slowly.

6. If the pointer (2) moves to mark (3): stop turning and release setting

spindle.

The end position CLOSED setting is complete.

7. If you override the tripping point inadvertently (ratchet is heard after the

pointer has snapped): continue turning the setting spindle in the same

direction and repeat setting process.

9.3.2 End position OPEN (white section): set

1. Engage manual operation.

2. Turn handwheel counterclockwise until valve is open.

3. Turn handwheel back by approximately half a turn (overrun).

4. Press down and turn setting spindle (4) (figure 15) using a screw driver

in direction of the arrow, thereby observe pointer (5):

While a ratchet is felt and heard, the pointer (5) moves 90 every time.

5. When pointer (5) is 90 from mark (6): continue turning slowly.

6. When pointer (5) moves to mark (6): stop turning and release setting

spindle.

The end position OPEN setting is complete.

7. If you override the tripping point inadvertently (ratchet is heard after the

pointer has snapped): continue turning the setting spindle in the same

direction and repeat setting process.

27

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

9.4.

Operation instructions

Intermediate positions (option): set

Actuators equipped with DUO limit switching contain two intermediate position switches. One intermediate position may be set for each running direction.

Figure 16

1

2

3

Black section

Setting spindle running direction

CLOSE

Pointer running direction CLOSE

Intermediate position CLOSED

correctly set to mark

4

5

6

White section

Setting spindle running direction

OPEN

Pointer running direction OPEN

Intermediate position OPEN

correctly set to mark

9.4.1 Running direction CLOSE (black section): set

1. Move valve in direction CLOSE until desired intermediate position.

When overriding the desired point, turn valve back and approach again

the intermediate position in direction CLOSE. (Always approach the

intermediate position in the same direction as in later electrical

operation).

2. Press down and turn setting spindle (1) (figure 16) using a screw driver

in direction of the arrow, thereby observe pointer (2):

While a ratchet is felt and heard, the pointer (2) moves 90 every time.

3. If the pointer (2) is 90 from mark (3): continue turning slowly.

4. If the pointer (2) moves to mark (3): stop turning and release setting

spindle.

The intermediate position setting in running direction CLOSE is complete.

5. If you override the tripping point inadvertently (ratchet is heard after the

pointer has snapped): continue turning the setting spindle in the same

direction and repeat setting process.

9.4.2 Running direction OPEN (white section): set

1. Move valve in OPEN direction until desired intermediate position.

When overriding the desired point, turn valve back and approach again

the intermediate position in OPEN direction. (Always approach the intermediate position in the same direction as in later electrical operation).

2. Press down and turn setting spindle (4) (figure 16) using a screw driver

in direction of the arrow, thereby observe pointer (5):

While a ratchet is felt and heard, the pointer (5) moves 90 every time.

3. If the pointer (5) is 90 from mark (6): continue turning slowly.

4. If the pointer (5) moves to mark (6): stop turning and release setting spindle:

The intermediate position setting in running direction OPEN is complete.

5. If you override the tripping point inadvertently (ratchet is heard after the

pointer has snapped): continue turning the setting spindle in the same

direction and repeat setting process.

28

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

Operation instructions

9.5.

Test run

Perform test run only once all settings previously described in the Commissioning clause have been performed.

9.5.1 Rotational direction check

NOTICE

Valve damage due to incorrect direction of rotation!

If the direction of rotation is wrong, switch off immediately.

Correct phase sequence.

Repeat test run.

1. Move actuator manually to intermediate position or to sufficient distance

from end position.

2. Switch on actuator in direction CLOSE and observe the direction of rotation.

3. Switch off before reaching the end position.

For actuators equipped with indicator disc

Fit indicator disc and observe direction of rotation on the indicator disc.

The direction of rotation is correct if the actuator moves in direction

CLOSE while the indicator disc turns counterclockwise.

auma

For actuators without indicator disc

Unscrew screw plug (1) and seal (2) or tube cap (4) and observe direction of rotation at hollow shaft (3) or the stem (5).

The direction of rotation is correct if the actuator moves in direction

CLOSE while the hollow shaft or the stem turn clockwise.

Figure 17

4

5

2

3

1

2

3

Screw plug

Seal

Hollow shaft

4

5

6

Cap for stem protection tube

Stem

Protection tube

29

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

Operation instructions

9.5.2 Limit switching check

1. Move actuator manually into both end positions of the valve.

The limit switching is set correctly if:

LSC switch trips in end position CLOSED

LSO switch trips in end position OPEN

the switches are released after turning back the handwheel.

2. If the end position setting is incorrect: Set limit switching again

(page 27).

3. If the end position setting is correct and no options (e.g. potentiometer,

position transmitter) are available: Close switch compartment

(see page 33).

9.6.

Potentiometer (option) setting

The potentiometer as travel monitor records the valve position.

This setting is only required if the potentiometer is directly wired to the customer connection XK (refer to wiring diagram).

Figure 18

Potentiometer

1. Move valve to end position CLOSED.

2. Turn potentiometer (1) clockwise to the stop.

End position CLOSED corresponds to 0 %

End position OPEN corresponds to 100 %.

3. Turn potentiometer (1) slightly back.

4. Perform fine-tuning of the zero point at external setting potentiometer

(for remote indication).

Information

30

Due to the ratio of the reduction gearing the complete resistance

range/stroke is not always passed. Therefore, external adjustment (setting

potentiometer) must be provided.

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

Operation instructions

9.7.

Electronic position transmitter RWG setting (option)

The electronic position transmitter RWG records the valve position. On the

basis of the nominal position value measured by the potentiometer (travel

monitoring), it generates a current signal between 0 20 mA or 4 20 mA.

Technical data RWG 4020

Table 4

3- or 4- wire system

KMS TP_ _ 4 / _ _ _

Terminal plan

Output current

Power

supply

max.

current consumption

max. load

Ia

Uv

I

0 20 mA, 4 20 mA

24 V DC, 15 %

smoothed

2-wire system

KMS TP_ _ 4 / _ _ _

KMS TP_ _ 5 / _ _ _

0 20 mA

14 V DC + (I x RB),

max. 30 V

24 mA

for 20 mA output current

20 mA

600

(UV 14 V) / 20 mA

RB

Figure 19

1

2

3

Potentiometer (travel monitor)

Potentiometer min. (0/4 mA)

Potentiometer max. (20 mA)

4

5

Measurement point (+) 0/4 20 mA

Measurement point () 0/4 20 mA

1. Connect voltage to electronic position transmitter.

2. Move valve to end position CLOSED.

3. Connect ammeter for 0 20 mA to measuring points (4 and 5).

No value can be measured:

Check, whether external load is connected to customer connection XK

(terminals 23/24) (observe max. load RB), or

Lay bridge across customer connection XK (terminals 23/24).

4. Turn potentiometer (1) clockwise to the stop.

5. Turn potentiometer (1) slightly back.

6. Turn potentiometer (2) clockwise until output current starts to increase.

7. Turn potentiometer (2) back until the following value is reached:

for 0 20 mA approx. 0.1 mA

for 4 20 mA approx. 4.1 mA

This ensures that the signal remains above the dead and live zero point.

8. Move valve to end position OPEN.

9. Set potentiometer max. (3) to end value 20 mA.

10. Approach end position CLOSED again and check minimum value (0.1

mA or 4.1 mA). If necessary, correct the setting.

Information

If the maximum value cannot be reached, the selection of the reduction

gearing must be checked. (The max. possible turns/stroke are indicated on

the order-related technical data sheet for the actuator).

31

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

9.8.

Operation instructions

Mechanical position indicator setting (option)

1. Place indicator disc on shaft.

2. Move valve to end position CLOSED.

3. Turn lower indicator disc until

symbol (CLOSED) is in alignment with

the p mark on the cover.

4. Move actuator to end position OPEN.

5. Hold lower indicator disc CLOSED in position and turn upper disc with

symbol (OPEN) until it is in alignment with the p mark on the cover.

6. Move valve to end position CLOSED again.

7. Check settings:

If the

symbol (CLOSED) is no longer in alignment with the p

mark on the cover:

Repeat setting procedure.

Check whether the appropriate reduction gearing has been selected, if

required.

(The maximum possible turns/stroke are indicated on the order-related

technical data sheet for the actuator).

32

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

Operation instructions

9.9.

Switch compartment: close

1. Clean sealing faces of housing and cover.

2. Apply a thin film of non-acidic grease (e.g. Vaseline) to the sealing faces.

3. Check whether O-ring (3) is in good condition, insert O-ring correctly.

4. Place cover (1) on switch compartment.

5. Fasten screws (2) evenly crosswise.

NOTICE

Danger of corrosion due to damage to paint finish!

Touch up damage to paint finish after work on the device.

33

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

10.

Operation instructions

Corrective action

10.1. Faults during commissioning

10.1.1 Mechanical position indicator

Fault description

Possible cause

Remedy

Mechanical position indicator cannot be set.

Actuator turns/stroke have been modified at a later date.

Exchange reduction gearing.

10.1.2 Position transmitter RWG

Fault description

Possible cause

Remedy

Fault description

Possible cause

Remedy

No value can be measured at measurement points.

Current loop via RWG is open.

(Position feedback 0/4 20 mA only functions if the current loop is closed

across the RWG.)

..

.

Lay bridge to XK across RWG.

Connect external load to XK, e.g. remote indication.

Observe max. load RB.

Measurement range 4 20 mA or maximum value 20 mA cannot be set.

Incorrect reduction gearing (turns/stroke).

Check reduction gearing selection (the max. possible turns/stroke are indicated on the order-related technical data sheet for the actuator).

10.1.3 Limit and torque switches

Fault description

Possible cause

Remedy

Switch does not trip.

..

Switch is defective or switch setting is incorrect.

Check setting, if required perform the end position setting again.

Check switches and replace if required.

Figure 20

Information

34

The red test buttons (1) and (2) are used for manual operation of the limit

switches:

Turn test button (1) in direction of the TSC arrow:

Torque switch CLOSED trips.

Turn test button (2) in direction of the TSO arrow:

Torque switch OPEN trips.

If the actuator is equipped with a DUO limit switching (option), the intermediate position switches will be operated at the same time.

Turn test button (1) in direction of the LSC arrow:

Limit switch CLOSED trips.

Turn test button (2) in direction of the LSO arrow:

Limit switch OPEN trips.

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

Operation instructions

10.1.4 Fault in end position (overrun not considered)

Fault description

Possible cause

Remedy

Actuator runs to end stop although the limit switches work properly.

The overrun was not considered during limit switch setting.

The overrun is generated by the inertia of both the actuator and the valve

and the delay time of the controls.

1. Determine overrun:

Overrun = travel covered from switching off until complete standstill.

2. Set limit switching again (page 27) considering the overrun (turn

handwheel back by the amount of the overrun).

10.2. Motor protection (thermal monitoring)

In order to protect against overheating and impermissibly high temperatures

at the actuator, PTC thermistors or thermoswitches are embedded in the

motor winding. The thermoswitch is tripped as soon as the max. permissible

winding temperature has been reached.

If the signals are processed accordingly in the controls, the actuator will be

stopped.

The motor has to cool down before the operation can be resumed.

35

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

11.

Operation instructions

Servicing and maintenance

CAUTION

Service

Damage caused by inappropriate maintenance!

Servicing and maintenance tasks must be carried out exclusively by suitably qualified personnel authorised by the end user or contractor of the

plant only.

Only perform servicing and maintenance tasks when the device is

switched off.

AUMA offers extensive service such as maintenance and inspection as well

as customer product training. For the relevant contact addresses, please

refer to page 46 et seqq. and on the Internet (www.auma.com).

11.1. Preventive measures for servicing and safe operation

The following measures are required to ensure safe device operation:

Every 6 months after commissioning

Carry out visual inspection:

For electrical devices: cable entries, cable glands, screw plugs, etc.

have to be checked for correct tightness and sealing.

Consider torques according to manufacturers details.

If rarely operated: perform test run.

For devices with output drive A, press in Lithium soap EP multi-purpose

grease on mineral oil base at the grease nipple with the grease gun

(quantities see 12, table 2). This procedure does not grease the valve

stem. Lubrication of the valve stem must be done separately.

..

Figure 21

Output drive type A

Grease nipple

6 months after commissioning and then once a year

Check screws between multi-turn actuator and valve for tightness. If

required, tighten by applying the torques given in table 1, page 11.

For enclosure protection IP 68 (option)

After submersion:

Check multi-turn actuator.

In case of ingress of water, dry device correctly and check for proper

function.

..

36

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

Operation instructions

11.2. Maintenance

Maintenance intervals

Lubricant change

.

..

.

Refer to lubricant change.

In the factory, the gear housing is filled with grease.

Grease change is performed during maintenance.

Generally after 4 to 6 years for modulating duty.

Generally after 6 to 8 years if operated frequently (open-close duty).

Generally after 10 to 12 years if operated rarely (open-close duty).

No additional lubrication is required during operation.

11.3. Disposal and recycling

AUMA devices have a long lifetime. However, they have to be replaced at

one point in time.

The devices have a modular design and may, therefore, easily be separated

and sorted according to materials used, i.e.:

..

..

electronic scrap

various metals

plastics

greases and oils

The following generally applies:

.

.

.

Collect greases and oils during disassembly. Generally, these substances are hazardous to water and must not be released into the environment.

Arrange for controlled waste disposal of the disassembled material or for

separate recycling according to materials.

Observe the national regulations for waste disposal.

37

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

12.

Spare parts list

12.1. Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

38

Operation instructions

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

Operation instructions

Note:

Please state type and commission no. of the device (see name plate) when ordering spare parts. Only original AUMA

spare parts should be used. Failure to use original spare parts voids the warranty and exempts AUMA from any liability. Delivered spare parts may slightly vary from the representation.

No.

001.0

002.0

003.0

005.0

005.1

005.2

005.3

005.4

006.0

009.0

010.0

017.0

018.0

019.0

020.0

022.0

023.0

024.0

025.0

058.0

061.0

070.0

079.0

080.0

155.0

500.0

501.0

502.0

503.0

504.0

505.0

506.0

507.0

511.0

514.0

514.1

516.1

535.1

539.0

542.0

549.1

551.1

553.0

554.0

556.0

556.1

557.0

558.0

559.0-1

559.0-2

560.0-1

560.0-2

560.1

560.2

566.0

566.1

Designation

Housing

Bearing flange

Hollow shaft without worm wheel

Worm shaft

Motor coupling

Coupling pin

Manual drive coupling

Pull rod

Worm wheel

Planetary gear for manual drive

Retaining flange

Torque lever

Gear segment

Crown wheel

Swing lever

Drive pinion II for torque switching

Output drive wheel for limit switching

Intermediate wheel for limit switching

Locking plate

Wire for protective earth (pin)

Torque switching head

Motor (VD motor incl. no. 079.0)

Planetary gear for motor drive (SA/SAR

07.1 14.1 for VD motor)

Planetary gear for motor drive (SA/SAR

16.1 for AD90 motor)

Reduction gearing

Cover for switch compartment

Socket carrier (complete with sockets)

Pin carrier without pins

Socket for controls

Socket for motor

Pin for controls

Pin for motor

Plug cover

Screw plug

Output drive form A (without stem nut)

Axial needle roller bearing

Output drive shaft D

Snap ring

Screw plug

Handwheel with ball handle

Output socket B3/B4/E

Parallel key

Mechanical position indicator

Socket carrier with motor cable harness

Potentiometer for position transmitter

Potentiometer without slip clutch

Heater

Blinker transmitter including pins at wires

(without impulse disc and insulation plate)

Control unit without torque head, without

switches

Control unit with magnetic limit and torque

transmitter (MWG) for Non-intrusive version in combination with AUMATIC integral controls

Switch stack for OPEN direction

Switch stack for CLOSE direction

Switch for limit/torque switching

Switch case

Position transmitter RWG

Potentiometer for RWG without slip clutch

Type

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

No.

566.2

566.3

567.1

568.1

568.2

568.3

569.0

569.1

569.2

574.1

575.1

S1

S2

Designation

Electronic board RWG

Wire harness for RWG

Slip clutch for potentiometer/RWG

Stem protection tube

(without cap)

Cap for stem protection tube

V-seal

Change-over lever assly.

Change-over lever

Notched pin

Radial seal output drive A for ISO flange

Stem nut type A

Seal kit, small

Seal kit, large

Type

Sub-assembly

Sub-assembly

Sub-assembly

Set

Set

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

Sub-assembly

39

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

13.

Operation instructions

Technical data

Features and functions

Type of duty 1)

Torque range

Output speed

Motors

Insulation class

Motor protection

Self-locking

Limit switching

Torque switching

Position feedback signal,

analogue (options)

Mechanical position indicator

(option)

Running indication

Heater in switch compartment

Motor heater (option)

Manual operation

Electrical connection

Threads for cable glands

Terminal plan

Output drive types

Standard:

SA

SAR

SA

SAR

Short time duty S2 - 15 min

Intermittent duty S4 - 25 %

Option:

Short time duty S2 - 30 min

Intermittent duty S4 - 50 %

Intermittent duty S5 25 %

Refer to actuator name plate

Refer to actuator name plate

Standard:

3-ph AC asynchronous motor, type IM B9 according to IEC 34

Options:

1-ph AC motor, type IM B14 according to IEC 34

DC shunt motor, type IM B14 according to IEC 34

DC compound motor, type IM B14 according to IEC 34

Special motors

Standard:

F, tropicalized

Option:

H, tropicalized

Standard:

Thermoswitches (NC)

Option:

PTC thermistors (according to DIN 44082)

Yes, for output speeds 4 to 90

Counter gear mechanism for end positions CLOSED and OPEN

for 1 to 500 turns per stroke (optional for 1 to 5,000 turns per stroke)

Standard:

Single switch (1 NC and 1 NO) for each end position (not galvanically isolated)

Options:

Tandem switches (2 NC and 2 NO) for each end position, switches galvanically isolated

Triple switch (3 NC and 3 NO) for each end position, switches galvanically isolated

Intermediate position switch (DUO limit switching)

Torque switching for directions OPEN and CLOSE adjustable

Standard:

Single switch (1 NC and 1 NO) for each direction (not galvanically isolated)

Options:

Tandem switches (2 NC and 2 NO) for each direction, switches galvanically isolated

Potentiometer or 0/4 20 mA (RWG)

For further details see separate data sheet

Continuous indication, adjustable indicator disc with symbols OPEN and CLOSED

Blinker transmitter (standard for SA, option for SAR)

Standard:

Self-regulating PTC heater, 5 20 W, 110 250 V AC/DC

Options:

24 48 V AC/DC or 380 400 V AC

A resistance type heater (5 W, 24 V DC) is installed in the actuator in combination with the

AUMA MATIC actuator controls.

SA/SAR 07.1 10.1: 12.5 W

SA/SAR 14.1 16.1: 25 W

Manual drive for setting and emergency operation, handwheel does not rotate during

electrical operation.

Option:

Handwheel lockable

Standard:

AUMA plug/socket connector with screw type connection,

For special motors:

Control connections on AUMA plug/socket connector

Motor connection on terminals

Standard:

Metric threads

Options:

Pg-threads, NPT-threads, G-threads

Terminal plan according to commission number included in delivery

A, B1, B2, B3, B4 according to EN ISO 5210

A, B, D, E according to DIN 3210

C according to DIN 3338

Special output drives: AF, AK, AG, IB1, IB3

1) For nominal voltage and 20 C ambient temperature and at an average load with running torque or modulating torque according to Technical data SA or SAR.

40

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

Operation instructions

Service conditions

Mounting position

Enclosure protection according

to EN 60 5292)

Any position

Standard:

IP 67

Options:

IP 68

Corrosion protection

Standard:

Options:

Max. 6 m head of water, submersible for max. 72 hours

Up to 10 operations during flooding

IP 67-DS (Double Sealed)

IP 68-DS (Double Sealed)

(Double Sealed = Electrical connection compartment

additionally sealed against interior)

KN Suitable for installation in industrial units, in water or power plants with a

low pollutant concentration

KS Suitable for installation in occasionally or permanently aggressive

atmosphere with a moderate pollutant concentration (e.g. in wastewater

treatment plants, chemical industry)

KX Suitable for installation in extremely aggressive atmosphere with high

humidity and high pollutant concentration

KX-G same as KX, however aluminium-free version (outer parts)

2,000 m above sea level

2,000 m above sea level, please contact AUMA

Installation altitude

Standard:

Option:

Pollution degree

Finish coating

Pollution degree 2 inside and outside the controls/the actuator

Standard:

Two-component iron-mica combination

Option:

Special primer/special finish coat (customers choice)

Standard:

Silver-grey (similar to RAL 7037)

Other colours are possible on request

Standard:

SA

25 C to + 80 C

SAR 25 C to + 60 C

Options:

SA

40 C to + 60 C (low temperature)

50 C to + 60 C (extreme low temperature)

60 C to + 60 C (extreme low temperature)

0 C to + 120 C (high temperature)

SAR 40 C to + 60 C (low temperature)

2 g, from 10 Hz to 200 Hz

Resistant to vibrations during start-up or for failures of the plant. However, a fatigue

strength may not be derived from this.

Applies to actuator without actuator controls only, not valid in combination with gearboxes.

Category III

Open-close duty:

Operating cycles (OPEN - CLOSE - OPEN)

SA 07.1 SA 10.1:

20,000

SA 14.1 SA 16.1:

15,000

Modulating duty:4)

SAR 07.1 SAR 10.1:

min. 5.0 million modulating steps

SAR 14.1 SAR 16.1:

min. 3.5 million modulating steps

Refer to Technical data SA/SAR

Colour

Ambient temperature 3)

Vibration resistance

according to IEC 60068-2-6

Overvoltage category

Lifetime

Weight

Further information

EU Directives

Reference documents

Electromagnetic Compatibility (EMC): (2004/108/EC)

Low Voltage Directive: (2006/95/EC)

Machinery Directive: (98/37/EC)

Product description Electric multi-turn actuators SA

Dimension sheets SA/SAR

Technical data sheets SA/SAR

Electrical data sheets SA/SAR

2) The enclosure protection according to name plate applies.

Other enclosure protections apply to single phase AC motors, DC motors, or special motors (refer to separate technical data sheets).

Enclosure protection IP 68 refers to the interior of the actuators (motor, gearing, switch compartment, and terminal compartment).

For 3-phase asynchronous motors in enclosure protection IP 68, higher corrosion protection KS or KX is strongly recommended. Additionally, for enclosure

protection IP 68, we recommend to use the double sealed terminal compartment DS.

3) Versions with RWG up to + 80 C max.

4) The lifetime depends on the load and the number of starts. A high starting frequency will rarely improve the modulating accuracy. To reach the longest possible

maintenance and fault-free operation time, the number of starts per hour chosen should be as low as permissible for the process

41

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

Notes

42

Operation instructions

Operation instructions

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

Notes

43

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

14.

Certificates

14.1. Declaration of Conformity and Declaration of Incorporation

44

Operation instructions

Multi-turn actuator SA 07.1 SA 16.1/SAR 07.1 SAR 16.1

AUMA NORM

Operation instructions

Index

A

Accessories for mounting

Assembly

14

10

C

Commission number

Commissioning

Controls made by AUMA

Corrective action

Corrosion protection

Cross sections

Current consumption

8

25

15

34

9

18

15

D

Declaration of Conformity

Declaration of Incorporation

Delay time

Disconnect switches

Disposal and recycling

Double sealed

intermediate frame

DUO limit switching

E

Electrical connection

Electronic position

transmitter RWG

44

44

15

15

37

20

28

15

31

F

Faults during commissioning

34

Feedback signals from actuator 24

Fuses on site

15

G

Ground connection, external

20

H

Handwheel

Handwheel fitting

Heater

21

10

18

I

Indication

Indicator disc

Intermediate positions

Internet

L

Limit switches

Limit switching

Long-term storage

Lubricant change

23

25,32

28

8

16

27

9

37

M

Maintenance intervals

37

Manual operation

21

Mechanical position indicator

32

Motor heater

19

Motor operation

22

Motor protection

18,35

Mounting

11

O

Operation

Output drive type A

Output drive types

B1, B2, B3, B4, B, and E

Overvoltage category

21

12

11

41

P

Packaging

Parking frame

Plug/socket connector

Position feedback signals

Position indicator

Position transmitter RWG

Potentiometer

Protection cover

Protection on site

Protection tube

Protective earth

PTC thermistors

9

20

17

24

32

31

30

20

15

14

18

18,35

S

Safety instructions

Service

Short-circuit protection

Signals

Size

Spare parts list

Multi-turn actuator

Stem nut

Storage

4

36

15

24

8

38

38

12

9

T

Technical data

Terminal plan

Test run

thermoswitches

Thermoswitches

Torque switches

Torque switching setting

Transport

Tripping torque

Type

40

15

29

35

18

16

26

9

26

8

W

Wiring diagram locating

15

45

AUMA worldwide

Europe

AUMA Riester GmbH & Co. KG

Plant Mllheim

DE-79373 Mllheim

Tel +49 7631 809 - 0

Fax +49 7631 809 - 1250

riester@auma.com

www.auma.com

Plant Ostfildern-Nellingen

DE-73747 Ostfildern

Tel +49 711 34803 - 0

Fax +49 711 34803 - 3034

riester@wof.auma.com

Service Center Cologne

DE-50858 Kln

Tel +49 2234 2037 - 9000

Fax +49 2234 2037 - 9099

Service@sck.auma.com

Service Center Magdeburg

DE-39167 Niederndodeleben

Tel +49 39204 759 - 0

Fax +49 39204 759 - 9429

Service@scm.auma.com

Service Center Bavaria

DE-85386 Eching

Tel +49 81 65 9017- 0

Fax +49 81 65 9017- 2018

Riester@scb.auma.com

AUMA Armaturenantriebe GmbH

AT-2512 Tribuswinkel

Tel +43 2252 82540

Fax +43 2252 8254050

office@auma.at

www.auma.at

AUMA Polska Sp. z o.o.

PL-41-310 Dabrowa Grnicza

Tel +48 32 261 56 68

Fax +48 32 261 48 23

R.Ludzien@auma.com.pl

www.auma.com.pl

OOO Priwody AUMA

RU-141400 Moscow region for mail:

124365 Moscow a/ya 11

Tel +7 495 221 64 28

Fax +7 495 221 64 38

aumarussia@auma.ru

www.auma.ru

ERICHS ARMATUR AB

SE-20039 Malm

Tel +46 40 311550

Fax +46 40 945515

info@erichsarmatur.se

www.erichsarmatur.se

GRNBECH & SNNER A/S

DK-2450 Kbenhavn SV

Tel +45 33 26 63 00

Fax +45 33 26 63 21

GS@g-s.dk

www.g-s.dk

IBEROPLAN S.A.

ES-28027 Madrid

Tel +34 91 3717130

Fax +34 91 7427126

iberoplan@iberoplan.com

D. G. Bellos & Co. O.E.

GR-13671 Acharnai Athens

Tel +30 210 2409485

Fax +30 210 2409486

info@dgbellos.gr

AUMA (Schweiz) AG

CH-8965 Berikon

Tel +41 566 400945

Fax +41 566 400948

RettichP.ch@auma.com

SIGURD SRUM A. S.

NO-1300 Sandvika

Tel +47 67572600

Fax +47 67572610

post@sigurd-sorum.no

AUMA Servopohony spol. s.r.o.

CZ-10200 Praha 10

Tel +420 272 700056 / 704125

Fax +420 272 704125

auma-s@auma.cz

www.auma.cz

INDUSTRA

PT-2710-297 Sintra

Tel +351 2 1910 95 00

Fax +351 2 1910 95 99

jpalhares@tyco-valves.com

OY AUMATOR AB

FI-02230 Espoo

Tel +35 895 84022