Professional Documents

Culture Documents

Metalshield MC - 110 SUITE

Metalshield MC - 110 SUITE

Uploaded by

H_DEBIANEOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Metalshield MC - 110 SUITE

Metalshield MC - 110 SUITE

Uploaded by

H_DEBIANECopyright:

Available Formats

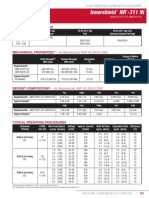

METAL-CORED WIRE

Metalshield MC -110

(AWS E110C-K4 H4)

MECHANICAL PROPERTIES(1) As Required per AWS A5.28/A5.28M: 2005

Yield Strength(2)

MPa (ksi)

Tensile Strength

MPa (ksi)

Requirements

AWS E110C-K4 H4

680 (98) min.

760 (110) min.

Typical Performance(3)

As-Welded with 75% Argon / 25% CO2 690-795 (100-115) 760-825 (110-120)

As-Welded with 90% Argon / 10% CO2 725-825 (105-120) 790-895 (115-130)

Elongation

%

Charpy V-Notch

J (ftlbf)

@ -40C (-40F) @ -51C (-60F)

15 min.

Not Specified

27 (20) min.

20-24

18-23

60-88 (44-65)

66-95 (48-70)

45-80 (34-59)

59-82 (44-61)

DEPOSIT COMPOSITION(1) As Required per AWS A5.28/A5.28M: 2005

Requirements

AWS E110C-K4 H4

Typical Performance(3)

As-Welded with 75% Argon / 25% CO2

As-Welded with 90% Argon / 10% CO2

Requirements

AWS E110C-K4 H4

Typical Performance(3)

As-Welded with 75% Argon / 25% CO2

As-Welded with 90% Argon / 10% CO2

%C

%Cr

%Ni

%Mo

%Mn

%Si

0.15 max.

0.15-0.65

0.50-2.50

0.25-0.65

0.75-2.25

0.80 max.

0.05-0.08

0.05-0.08

0.20-0.35

0.20-0.35

2.00-2.20

2.00-2.20

0.45-0.55

0.45-0.55

1.45-1.75

1.45-1.75

0.45-0.65

0.45-0.65

%P

%S

%Cu

%V

Diffusible Hydrogen

(mL/100g weld deposit)

0.025 max.

0.025 max.

0.35 max.

0.03 max.

0.01-0.02

0.01-0.02

0.01-0.02

0.01-0.02

0.02-0.06

0.02-0.06

0.01-0.02

0.01-0.02

2.5-4

Approx.

Current

(amps)

170

190

240

290

330

370

225

255

295

350

400

270

320

385

465

Melt-Off Rate

kg/hr (lb/hr)

2.4 (5.3)

3.0 (6.7)

4.2 (9.2)

5.4 (11.8)

6.5 (14.4)

7.8 (17.1)

3.2 (7.0)

4.0 (8.8)

5.5 (12.2)

7.2 (15.8)

8.7 (19.1)

4.4 (9.6)

5.4 (12.1)

7.7 (16.9)

9.8 (21.6)

TYPICAL OPERATING PROCEDURES

Diameter, Polarity

Shielding Gas(4)

CTWD(5)

mm (in)

0.045 in (1.1 mm),

DC+

90% Argon / 10% CO2

19-25

(3/4-1)

0.052 in (1.3 mm),

DC+

90% Argon / 10% CO2

19-25

(3/4-1)

1/16 in (1.6 mm),

DC+

90% Argon / 10% CO2

25-32

(1-1 1/4)

Wire Feed Speed

m/min (in/min)

5.1 (200)

6.4 (250)

8.9 (350)

11.4 (450)

14.0 (550)

16.6 (650)

5.1 (200)

6.4 (250)

8.9 (350)

11.4 (450)

14.0 (550)

5.1 (200)

6.4 (250)

8.9 (350)

11.4 (450)

Voltage

(volts)

22-24

24-26

26-28

28-30

30-32

31-33

23-25

25-27

27-29

29-31

31-33

24-26

26-28

28-30

30-32

Deposition Rate

kg/hr (lb/hr)

2.1 (4.7)

2.8 (6.1)

3.8 (8.4)

5.1 (11.3)

6.3 (13.9)

7.6 (16.7)

2.8 (6.2)

3.7 (8.1)

5.3 (11.6)

7.0 (15.4)

8.5 (18.8)

3.9 (8.6)

5.1 (11.3)

7.4 (16.4)

9.6 (21.2)

Efficiency

(%)

88

91

91

95

97

97

89

92

95

98

98

89

94

97

98

Typical all weld metal. (2) Measured with 0.2% offset. (3) See test results disclaimer on pg. 18. (4) For greater percentage of CO2 shielding gas, increase voltage by 1-2 volts. (5) To estimate ESO, subtract 3/16 in. (4.8 mm) from CTWD.

NOTE: Consult steel manufacturers recommendations regarding minimum and maximum pre-heat temperature, interpass temperature, and heat input.

(1)

W E L D I N G C O N S U M A B L E S C ATA L O G

83

You might also like

- V6001 Service ManualDocument29 pagesV6001 Service Manuallondon335100% (1)

- Esab, Dual Shield T-115 (24!02!17, 266-En - US-FactSheet - Main-01)Document2 pagesEsab, Dual Shield T-115 (24!02!17, 266-En - US-FactSheet - Main-01)RodrigoNo ratings yet

- E 399Document31 pagesE 399H_DEBIANENo ratings yet

- Metalshield MC - 90 SuiteDocument1 pageMetalshield MC - 90 SuiteH_DEBIANENo ratings yet

- Metal-Cored: Gmaw-CDocument16 pagesMetal-Cored: Gmaw-CChandrajeet ShelkeNo ratings yet

- Superarc La-75: Diameters / PackagingDocument1 pageSuperarc La-75: Diameters / PackagingH_DEBIANENo ratings yet

- Esab, Dual Shield II 110 (265-En - US-FactSheet - Main-01) (26.10.16)Document2 pagesEsab, Dual Shield II 110 (265-En - US-FactSheet - Main-01) (26.10.16)RodrigoNo ratings yet

- Dual Shield 7100 Ultra: Typical Tensile PropertiesDocument3 pagesDual Shield 7100 Ultra: Typical Tensile PropertiesDino Paul Castro HidalgoNo ratings yet

- SuperArc LA-100 SuiteDocument1 pageSuperArc LA-100 SuiteH_DEBIANENo ratings yet

- Dual Shiel Ii 101Document2 pagesDual Shiel Ii 101Robin carcamoNo ratings yet

- Dual Shield II 80-Ni1 h4 Data SheetDocument3 pagesDual Shield II 80-Ni1 h4 Data SheetNicolas MaximilianoNo ratings yet

- Dual Shield T-75: Typical Tensile PropertiesDocument2 pagesDual Shield T-75: Typical Tensile PropertiescfloresNo ratings yet

- Dual Shield T-115: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy WiresDocument2 pagesDual Shield T-115: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy WiresPEPITO GRILLO2No ratings yet

- SuperArc L 50NDocument1 pageSuperArc L 50NH_DEBIANENo ratings yet

- Innershield NS-3M: Welding Positions Conformances Key FeaturesDocument1 pageInnershield NS-3M: Welding Positions Conformances Key FeaturesH_DEBIANENo ratings yet

- Innershield NR 203 MP SuiteDocument1 pageInnershield NR 203 MP SuiteH_DEBIANENo ratings yet

- KSB EtaBlocDocument4 pagesKSB EtaBlocdokundotNo ratings yet

- Contact orDocument13 pagesContact orVictor ToledanoNo ratings yet

- Superglide S6: Diameters / PackagingDocument1 pageSuperglide S6: Diameters / PackagingH_DEBIANENo ratings yet

- Innershield NR-311 Ni SuiteDocument1 pageInnershield NR-311 Ni SuiteH_DEBIANENo ratings yet

- UltraCore SR-12 SuiteDocument1 pageUltraCore SR-12 SuiteH_DEBIANENo ratings yet

- AUT-1023 A2 Multitrac PEKDocument1 pageAUT-1023 A2 Multitrac PEKcarlosNo ratings yet

- Datasheet Cella CaricoDocument2 pagesDatasheet Cella Caricodon-donnolaNo ratings yet

- SF 71MCDocument1 pageSF 71MCGESTION Y CONTROL DE PROYECTOS IngeminNo ratings yet

- Chain: Grade 10 - Grade 8 - Short Link - Mid-Link - Long-LinkDocument8 pagesChain: Grade 10 - Grade 8 - Short Link - Mid-Link - Long-LinkQuan TranNo ratings yet

- 70ksi Grade MIG Solid Wire: Code DataDocument2 pages70ksi Grade MIG Solid Wire: Code Datarahman2007No ratings yet

- Dyadic Systems SCN6 40kgfDocument1 pageDyadic Systems SCN6 40kgfServo2GoNo ratings yet

- AMF601NTV1 1 9 A4 en PDFDocument4 pagesAMF601NTV1 1 9 A4 en PDFtruongNo ratings yet

- Atom Arc 8018: Features Typical Mechanical PropertiesDocument2 pagesAtom Arc 8018: Features Typical Mechanical PropertiesFranklin Aranda ChacónNo ratings yet

- ESB 255051815 SpecSheetDocument2 pagesESB 255051815 SpecSheetanupmenon menonNo ratings yet

- Esab, Dual Shield 810X Ni1 (248 en - US FactSheet - Main 01)Document2 pagesEsab, Dual Shield 810X Ni1 (248 en - US FactSheet - Main 01)RodrigoNo ratings yet

- Desiccant Dehumidifier Price List-Conloon-MayDocument2 pagesDesiccant Dehumidifier Price List-Conloon-MaySufiyan KhanNo ratings yet

- N2XBYDocument5 pagesN2XBYcyuenkNo ratings yet

- 278 en US FactSheet Main 01Document1 page278 en US FactSheet Main 01Jorge Manuel GuillermoNo ratings yet

- Outershield 71 Elite SuiteDocument1 pageOutershield 71 Elite SuiteH_DEBIANENo ratings yet

- ESAB Dual Shield 7100 UltraDocument3 pagesESAB Dual Shield 7100 UltrahaldunNo ratings yet

- Report Eni MX 5114 ClearedDocument17 pagesReport Eni MX 5114 Clearedshussain23.5.87No ratings yet

- Enhanced P L A P: Olyimide Aminate ND RepregDocument4 pagesEnhanced P L A P: Olyimide Aminate ND Repregoutra_pessoaNo ratings yet

- Technology To The Fore: Product RangeDocument8 pagesTechnology To The Fore: Product RangeLinh VănNo ratings yet

- Compacted Graphite Iron Material Data Sheet PDFDocument2 pagesCompacted Graphite Iron Material Data Sheet PDFDewang KambreNo ratings yet

- Typical Mechanical Properties (As Welded) : Do Not Breathe Fumes!Document20 pagesTypical Mechanical Properties (As Welded) : Do Not Breathe Fumes!Samuel LatumahinaNo ratings yet

- HoseguideDocument2 pagesHoseguideAref WidhiNo ratings yet

- 6A05 THRU 6A10: Axial Silastic Guard Junction Standard RectifierDocument2 pages6A05 THRU 6A10: Axial Silastic Guard Junction Standard RectifiercuickNo ratings yet

- Fabcor 86 RDocument2 pagesFabcor 86 RAnonymous fj4iRr1No ratings yet

- Catalogo Er70s3Document3 pagesCatalogo Er70s3upedro26No ratings yet

- Fire Retardant Cable Tie 1576222614 1Document1 pageFire Retardant Cable Tie 1576222614 1pratik jainNo ratings yet

- Shield Bright 309L-1Document1 pageShield Bright 309L-1adanmeneses1No ratings yet

- Metalshield MC - 80NI1 SUITEDocument1 pageMetalshield MC - 80NI1 SUITEH_DEBIANENo ratings yet

- Lubricants HANDBOOK PDFDocument214 pagesLubricants HANDBOOK PDFeng13100% (16)

- OKFlux 1062Document1 pageOKFlux 1062jpvtvNo ratings yet

- Horizontal Mounting Clamp-Top Type With Stud Base: (2" Trunnion Bolt and Locknut)Document4 pagesHorizontal Mounting Clamp-Top Type With Stud Base: (2" Trunnion Bolt and Locknut)jdrojasaNo ratings yet

- Dual Shield II 70T-12H4: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresDocument2 pagesDual Shield II 70T-12H4: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresPhilippe TrudelNo ratings yet

- SuperGlide S3 ER70S3Document1 pageSuperGlide S3 ER70S3H_DEBIANENo ratings yet

- Ficha Tecnica U - UTP PVC - LSZH JetLAN6 Eca - Dca GENERAL CABLEDocument1 pageFicha Tecnica U - UTP PVC - LSZH JetLAN6 Eca - Dca GENERAL CABLEBakama Okavango KajandaNo ratings yet

- Innershield NR - 305: Typical Applications Key FeaturesDocument1 pageInnershield NR - 305: Typical Applications Key FeaturesH_DEBIANENo ratings yet

- SF-71 en EngDocument2 pagesSF-71 en EngbvbarcNo ratings yet

- Calculos ElectricosDocument4 pagesCalculos Electricosjacantillo19No ratings yet

- UltraCore SR 12M SuiteDocument1 pageUltraCore SR 12M SuiteH_DEBIANENo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Advances in Solid Oxide Fuel Cells and Electronic Ceramics IIFrom EverandAdvances in Solid Oxide Fuel Cells and Electronic Ceramics IIMihails KusnezoffNo ratings yet

- WPS 904a-3857-R1-1Document3 pagesWPS 904a-3857-R1-1H_DEBIANENo ratings yet

- Ultracore Sr-12M: Typical Applications Key FeaturesDocument1 pageUltracore Sr-12M: Typical Applications Key FeaturesH_DEBIANENo ratings yet

- Outershield 71 Elite: Conformances Key FeaturesDocument1 pageOutershield 71 Elite: Conformances Key FeaturesH_DEBIANENo ratings yet

- Outershield 71 SupremeDocument1 pageOutershield 71 SupremeH_DEBIANENo ratings yet

- Ultracore Sr-12C: Applications Key FeaturesDocument1 pageUltracore Sr-12C: Applications Key FeaturesH_DEBIANENo ratings yet

- Outershield 71 Elite SuiteDocument1 pageOutershield 71 Elite SuiteH_DEBIANENo ratings yet

- UltraCore SR-12 SuiteDocument1 pageUltraCore SR-12 SuiteH_DEBIANENo ratings yet

- UltraCore SR 12M SuiteDocument1 pageUltraCore SR 12M SuiteH_DEBIANENo ratings yet

- UltraCore SR-12C SuiteDocument1 pageUltraCore SR-12C SuiteH_DEBIANENo ratings yet

- Ultracore Sr-12: Conformances Key FeaturesDocument1 pageUltracore Sr-12: Conformances Key FeaturesH_DEBIANENo ratings yet

- Ultracore 712A80: Conformances Key FeaturesDocument1 pageUltracore 712A80: Conformances Key FeaturesH_DEBIANENo ratings yet

- Ultracore HD-C: Conformances Key FeaturesDocument1 pageUltracore HD-C: Conformances Key FeaturesH_DEBIANENo ratings yet

- UltraCore HD-12M SuiteDocument1 pageUltraCore HD-12M SuiteH_DEBIANENo ratings yet

- UltraCore HD-12C SuiteDocument1 pageUltraCore HD-12C SuiteH_DEBIANENo ratings yet

- UltraCore 71A75 DualDocument1 pageUltraCore 71A75 DualH_DEBIANENo ratings yet

- UltraCore712A80 H SuiteDocument1 pageUltraCore712A80 H SuiteH_DEBIANENo ratings yet

- UltraCore 71A75 Dual SuiteDocument1 pageUltraCore 71A75 Dual SuiteH_DEBIANENo ratings yet

- UltraCore 712C SuiteDocument1 pageUltraCore 712C SuiteH_DEBIANENo ratings yet

- UltraCore HD-M SuiteDocument1 pageUltraCore HD-M SuiteH_DEBIANENo ratings yet

- Ultracore HD-M: Conformances Key FeaturesDocument1 pageUltracore HD-M: Conformances Key FeaturesH_DEBIANENo ratings yet

- Ultracore 71c SuiteDocument1 pageUltracore 71c SuiteH_DEBIANENo ratings yet