Professional Documents

Culture Documents

Innershield NR-212 Suite

Innershield NR-212 Suite

Uploaded by

H_DEBIANEOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Innershield NR-212 Suite

Innershield NR-212 Suite

Uploaded by

H_DEBIANECopyright:

Available Formats

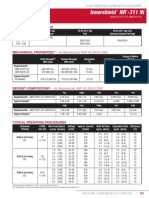

FLUX-CORED SELF-SHIELDED (FCAW-S) WIRE

Innershield NR -212

(AWS E71TG-G)

MECHANICAL PROPERTIES (1) As Required per AWS A5.29/A5.29M

Requirements - AWS E71TG-G

Typical Results

(3)

Yield Strength(2)

MPa (ksi)

Tensile Strength

MPa (ksi)

Elongation

%

Hardness

Rockwell B

400 (58) min.

480-655 (70-95)

20 min.

440-505 (64-74)

575-605 (84-88)

24-28

89-92

DEPOSIT COMPOSITION(1) As Required per AWS A5.29/A5.29M

Requirements - AWS E71TG-G

Typical Results

(3)

%C

%Mn(4)

%Si

%S

%P

Not Specified

0.50 min.

1.00 max.

0.030 max.

0.030 max.

0.06-0.11

0.84-1.55

0.20-0.33

0.003

0.006-0.009

%Ni

%Cr

(4)

%Mo

(4)

%V

(4)

%Al

(4)

Requirements - AWS E71TG-G

0.50 min.

0.30 min.

0.20 min.

0.10 min.

1.8 max.

Typical Results(3)

1.02-1.15

0.02-0.04

0.02

1.3-1.6

TYPICAL OPERATING PROCEDURES

Diameter,

Polarity

0.045 in (1.1 mm),

DC-

0.068 in (1.7 mm),

DC-

5/64 in (2.0 mm),

DC-

CTWD Wire Feed Speed

mm (in) m/min (in/min)

16 (5/8)

25 (1)

25 (1)

Voltage

(volts)

Approx. Current

(amps)

Melt-Off Rate

kg/hr (lb/hr)

Deposition Rate Efficiency

kg/hr (lb/hr)

(%)

1.4

1.8

2.3

2.8

3.3

4.1

(55)

(70)

(90)

(110)

(130)

(160)

14-15

15-16

16-17

17-18

18-19

19-20

75

90

115

135

155

170

0.5

0.7

1.0

1.2

1.4

1.6

(1.3)

(1.6)

(2.1)

(2.6)

(3.1)

(3.5)

0.5

0.6

0.8

1.0

1.2

1.4

(1.1)

(1.4)

(1.8)

(2.2)

(2.6)

(3.0)

84

87

85

84

83

85

1.5

1.9

2.3

3.0

3.8

4.4

(60)

(75)

(90)

(120)

(150)

(175)

16-17

17-18

18-19

19-20

20-21

22-23

145

180

200

230

255

275

1.4

1.7

2.0

2.7

3.3

3.9

(3.1)

(3.8)

(4.5)

(6.0)

(7.4)

(8.7)

1.1

1.4

1.7

2.3

2.9

3.4

(2.4)

(3.2)

(3.8)

(5.2)

(6.4)

(7.5)

77

84

84

86

86

86

1.5

1.9

2.3

2.8

3.3

3.8

(60)

(75)

(90)

(110)

(130)

(150)

16-17

18-19

19-20

20-21

21-23

22-23

200

225

245

275

300

325

1.7

2.1

2.6

3.2

3.7

4.3

(3.8)

(4.7)

(5.7)

(7.1)

(8.3)

(9.6)

1.5

1.8

2.3

2.8

3.3

3.8

(3.3)

(4.1)

(5.0)

(6.2)

(7.3)

(8.4)

86

87

87

87

87

87

Typical all weld metal. (2)Measured with 0.2% offset. (3)See test results disclaimer on pg. 18. (4)In order to meet the alloy AWS requirements of the G group, the weld deposit needs to have the minimum, as specified in the table, of only one of these elements.

(1)

W E L D I N G C O N S U M A B L E S C ATA L O G

105

You might also like

- Esab, Dual Shield T-115 (24!02!17, 266-En - US-FactSheet - Main-01)Document2 pagesEsab, Dual Shield T-115 (24!02!17, 266-En - US-FactSheet - Main-01)RodrigoNo ratings yet

- E 399Document31 pagesE 399H_DEBIANENo ratings yet

- Innershield NR 211 MP SuiteDocument1 pageInnershield NR 211 MP SuiteH_DEBIANENo ratings yet

- Innershield NR 203 MP SuiteDocument1 pageInnershield NR 203 MP SuiteH_DEBIANENo ratings yet

- UltraCore SR-12 SuiteDocument1 pageUltraCore SR-12 SuiteH_DEBIANENo ratings yet

- UltraCore SR 12M SuiteDocument1 pageUltraCore SR 12M SuiteH_DEBIANENo ratings yet

- Outershield 71 Elite SuiteDocument1 pageOutershield 71 Elite SuiteH_DEBIANENo ratings yet

- Superglide S6: Diameters / PackagingDocument1 pageSuperglide S6: Diameters / PackagingH_DEBIANENo ratings yet

- UltraCore SR-12C SuiteDocument1 pageUltraCore SR-12C SuiteH_DEBIANENo ratings yet

- Metal-Cored: Gmaw-CDocument16 pagesMetal-Cored: Gmaw-CChandrajeet ShelkeNo ratings yet

- SuperGlide S3 ER70S3Document1 pageSuperGlide S3 ER70S3H_DEBIANENo ratings yet

- Metalshield MC - 90 SuiteDocument1 pageMetalshield MC - 90 SuiteH_DEBIANENo ratings yet

- Superarc LA-75: Conformances Key FeaturesDocument2 pagesSuperarc LA-75: Conformances Key Featuressattar12345No ratings yet

- Innershield NR - 305: Typical Applications Key FeaturesDocument1 pageInnershield NR - 305: Typical Applications Key FeaturesH_DEBIANENo ratings yet

- METALSHIEDL MC-80Ni1Document2 pagesMETALSHIEDL MC-80Ni1ledystNo ratings yet

- Innershield NR-311 Ni SuiteDocument1 pageInnershield NR-311 Ni SuiteH_DEBIANENo ratings yet

- API Casing Color CodesDocument2 pagesAPI Casing Color CodesRajmohan BabuNo ratings yet

- Metalshield MC - 110 SUITEDocument1 pageMetalshield MC - 110 SUITEH_DEBIANENo ratings yet

- Metalshield MC - 706: Conformances Key FeaturesDocument3 pagesMetalshield MC - 706: Conformances Key FeaturesGerson HenriquesNo ratings yet

- API 2H Grade 50 Plates - Arrow Pipes & Plate IndustriesDocument5 pagesAPI 2H Grade 50 Plates - Arrow Pipes & Plate IndustriesYash MehtaNo ratings yet

- Innershield NS-3M: Welding Positions Key FeaturesDocument2 pagesInnershield NS-3M: Welding Positions Key FeaturesGiancarlo BlandinoNo ratings yet

- E9018 M Specifications PDFDocument2 pagesE9018 M Specifications PDFMohamed MostafaNo ratings yet

- OKFlux 1062Document1 pageOKFlux 1062jpvtvNo ratings yet

- UltraCore 71A75 Dual SuiteDocument1 pageUltraCore 71A75 Dual SuiteH_DEBIANENo ratings yet

- Superarc La-75: Diameters / PackagingDocument1 pageSuperarc La-75: Diameters / PackagingH_DEBIANENo ratings yet

- Esab, OK Flux 10.71 (30.06.16), 420014-En - US-FactSheet - Main-01Document2 pagesEsab, OK Flux 10.71 (30.06.16), 420014-En - US-FactSheet - Main-01RodrigoNo ratings yet

- Pipeliner 7P+: Conformances Key FeaturesDocument2 pagesPipeliner 7P+: Conformances Key FeaturesAnand GNo ratings yet

- Ultracore 360 C71: Conformances Key FeaturesDocument3 pagesUltracore 360 C71: Conformances Key FeaturesYousab CreatorNo ratings yet

- Metalshield Clarity MC - 707: Conformances Key FeaturesDocument2 pagesMetalshield Clarity MC - 707: Conformances Key FeaturesRumman Ul AhsanNo ratings yet

- AISC-360-10 Example 001 PDFDocument9 pagesAISC-360-10 Example 001 PDFMohamed Abo-ZaidNo ratings yet

- Software Verification: AISC-360-10 Example 001Document9 pagesSoftware Verification: AISC-360-10 Example 001Davico HernandezNo ratings yet

- AISC-360-05 Example 001 PDFDocument8 pagesAISC-360-05 Example 001 PDFMohamed Abo-ZaidNo ratings yet

- Semiconductor Protection Fuses: Amp-Trap - Form 101Document4 pagesSemiconductor Protection Fuses: Amp-Trap - Form 101EEH870321No ratings yet

- Pipeliner 70S-G: Conformances Key FeaturesDocument2 pagesPipeliner 70S-G: Conformances Key FeaturesZanuardi YahyaNo ratings yet

- Electrodes SelectarcDocument138 pagesElectrodes Selectarcfediss2014100% (2)

- Key Features Conformances: Low Alloy Steel - AWS E9018-D1Document2 pagesKey Features Conformances: Low Alloy Steel - AWS E9018-D1Aliakbar GhaderiNo ratings yet

- Reinforcement Steel Bars SpecificationsDocument3 pagesReinforcement Steel Bars SpecificationsCostin CezarNo ratings yet

- ATV900 Getting Started Annex NHA61583 01Document2 pagesATV900 Getting Started Annex NHA61583 01Daniel BravoNo ratings yet

- ESB 255051815 SpecSheetDocument2 pagesESB 255051815 SpecSheetanupmenon menonNo ratings yet

- MS 264Document15 pagesMS 264Felipe De la cruzNo ratings yet

- UltraCore 712C SuiteDocument1 pageUltraCore 712C SuiteH_DEBIANENo ratings yet

- Atv630 - Fusiveis e DisjuntoresDocument2 pagesAtv630 - Fusiveis e DisjuntoresKym VincentNo ratings yet

- Metalshield MC-710XL: Conformances Key FeaturesDocument3 pagesMetalshield MC-710XL: Conformances Key FeaturesRumman Ul AhsanNo ratings yet

- I74E EN 01+sigma5 Motors+DatasheetDocument26 pagesI74E EN 01+sigma5 Motors+DatasheetJosé Andrés Toro BelmarNo ratings yet

- Metalshield MC - 80NI1 SUITEDocument1 pageMetalshield MC - 80NI1 SUITEH_DEBIANENo ratings yet

- Mechanical Properties ZA-8 ZA-27: Respectively. ZAPDocument1 pageMechanical Properties ZA-8 ZA-27: Respectively. ZAPs_padu3003@yahoo.comNo ratings yet

- Dilli Max 690Document4 pagesDilli Max 690Fernando Alonso Troncos MendivesNo ratings yet

- AISC-360-16 Example 001 PDFDocument8 pagesAISC-360-16 Example 001 PDFMohamed Abo-ZaidNo ratings yet

- Se UL1741 Short Circuit Currents Three Phase Inverters Tech NoteDocument2 pagesSe UL1741 Short Circuit Currents Three Phase Inverters Tech NoteoespanaNo ratings yet

- F-Cem-021 - Cptch-012-19a-Fcaw - Aws D1.1 - Plana-HorizontalDocument7 pagesF-Cem-021 - Cptch-012-19a-Fcaw - Aws D1.1 - Plana-Horizontalenrique.chavezNo ratings yet

- Dorman Smith Air Circuit BreakerDocument28 pagesDorman Smith Air Circuit BreakerAshby KbNo ratings yet

- AUT-1023 A2 Multitrac PEKDocument1 pageAUT-1023 A2 Multitrac PEKcarlosNo ratings yet

- Lincoln Electric E8010p1 & E8010gDocument7 pagesLincoln Electric E8010p1 & E8010gsaravanabhavaNo ratings yet

- Metalshield MC - 90: Conformances Key FeaturesDocument1 pageMetalshield MC - 90: Conformances Key FeaturesH_DEBIANENo ratings yet

- UltracoreDocument3 pagesUltracorerpcampbellNo ratings yet

- UltraCore712A80 H SuiteDocument1 pageUltraCore712A80 H SuiteH_DEBIANENo ratings yet

- Techalloy 718: Conformances Key FeaturesDocument2 pagesTechalloy 718: Conformances Key FeaturesvishuNo ratings yet

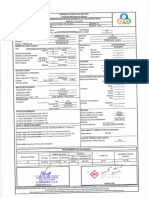

- WPS 904a-3857-R1-1Document3 pagesWPS 904a-3857-R1-1H_DEBIANENo ratings yet

- Outershield 71 SupremeDocument1 pageOutershield 71 SupremeH_DEBIANENo ratings yet

- Outershield 71 Elite SuiteDocument1 pageOutershield 71 Elite SuiteH_DEBIANENo ratings yet

- UltraCore SR 12M SuiteDocument1 pageUltraCore SR 12M SuiteH_DEBIANENo ratings yet

- Ultracore Sr-12C: Applications Key FeaturesDocument1 pageUltracore Sr-12C: Applications Key FeaturesH_DEBIANENo ratings yet

- Outershield 71 Elite: Conformances Key FeaturesDocument1 pageOutershield 71 Elite: Conformances Key FeaturesH_DEBIANENo ratings yet

- UltraCore SR-12C SuiteDocument1 pageUltraCore SR-12C SuiteH_DEBIANENo ratings yet

- Ultracore Sr-12M: Typical Applications Key FeaturesDocument1 pageUltracore Sr-12M: Typical Applications Key FeaturesH_DEBIANENo ratings yet

- UltraCore SR-12 SuiteDocument1 pageUltraCore SR-12 SuiteH_DEBIANENo ratings yet

- UltraCore HD-12M SuiteDocument1 pageUltraCore HD-12M SuiteH_DEBIANENo ratings yet

- UltraCore712A80 H SuiteDocument1 pageUltraCore712A80 H SuiteH_DEBIANENo ratings yet

- Ultracore Sr-12: Conformances Key FeaturesDocument1 pageUltracore Sr-12: Conformances Key FeaturesH_DEBIANENo ratings yet

- UltraCore 712C SuiteDocument1 pageUltraCore 712C SuiteH_DEBIANENo ratings yet

- UltraCore 71A75 DualDocument1 pageUltraCore 71A75 DualH_DEBIANENo ratings yet

- Ultracore 712A80: Conformances Key FeaturesDocument1 pageUltracore 712A80: Conformances Key FeaturesH_DEBIANENo ratings yet

- UltraCore HD-12C SuiteDocument1 pageUltraCore HD-12C SuiteH_DEBIANENo ratings yet

- UltraCore 71A75 Dual SuiteDocument1 pageUltraCore 71A75 Dual SuiteH_DEBIANENo ratings yet

- Ultracore HD-C: Conformances Key FeaturesDocument1 pageUltracore HD-C: Conformances Key FeaturesH_DEBIANENo ratings yet

- Ultracore 71c SuiteDocument1 pageUltracore 71c SuiteH_DEBIANENo ratings yet

- Ultracore HD-M: Conformances Key FeaturesDocument1 pageUltracore HD-M: Conformances Key FeaturesH_DEBIANENo ratings yet

- UltraCore HD-M SuiteDocument1 pageUltraCore HD-M SuiteH_DEBIANENo ratings yet