Professional Documents

Culture Documents

OK Tubrodur 1200i

OK Tubrodur 1200i

Uploaded by

camelod555Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OK Tubrodur 1200i

OK Tubrodur 1200i

Uploaded by

camelod555Copyright:

Available Formats

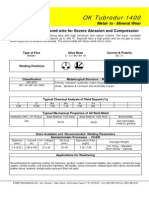

OK Tubrodur 1200

Metal-To-Mineral Wear

Self- Shielded flux cored wire for Heavy Impact and Severe Abrasion

OK Tubrodur 1200 is a hardsurfacing alloy combining compressive strength and hardness to provide excellent

resistance to wear caused by heavy impact and abrasion. Developed to use for weld surfacing and

hardfacing; it may be applied to carbon and low alloy steels; as well as of different gray cast iron parts.

Type of Flux

Alloy Base

Current & Polarity

Metallic

Fe- Cr - Mn -Si

DC ( +)

Welding Positions

Classification

Metallurgical Structure / Mechanism of wear

No AWS Class

Chromium Carbides in austenitic matrix (Hypoeutectic) / Metal -Mineral

Wear, resistant to abrasion & corrosion and heavy impact

Typical Chemical Analysis of Weld Deposit (%)

C

2,00

Cr

17,00

Mn

1,50

Si

1,50

Fe

Bal.

Typical Mechanical Properties of All Weld Metal

Hardness ( HRc ) N of layer

Base Material: 1010 Steel

Base Material: 1045 Steel

Machinability

2da.

45-54

50-54

Non machinable

Finish by grinding

Sizes Available and Recommended Welding Parameters

Semiautomatic Processes - FCAW

Diameter

(mm)

Current

(A)

Arc Voltage

(V)

Stickout

(mm)

Deposition Rate

(kg/h)

1,2 (.045)

1,6 (1/16)

170-230

180-300

26 a 29

26 a 30

35-40

2,50 3,80

2,80 4,70

Package Weight

Spool 12.5 / 16 kg Standard

Applications for Wearfacing

Hardsurfacing of parts subject to heavy impact and severe abrasin, as encountered on earthmoving and crushing

equipments. The Sugar Cane Industry; to protect lateral of teeth of milling cylinders, this alternative allows reducing the

times of maintenance. Recommended usage for power shovel, dragline bucket parts and hammermill parts.

ESAB Centroamrica SA Ave. Ricardo J. Alfaro Street Edif.Century Tower / F: 16 Off: 16/18 - Fone: (507) 302-7410 Fax: (507) 260-1810

You might also like

- Stoody - Hardfacing GuideDocument3 pagesStoody - Hardfacing GuideDayanaNo ratings yet

- The Essentials of Material Science and Technology for EngineersFrom EverandThe Essentials of Material Science and Technology for EngineersRating: 5 out of 5 stars5/5 (1)

- Welding TrainingDocument87 pagesWelding Trainingeswar100% (1)

- 3.1 3.2Document32 pages3.1 3.2camelod555No ratings yet

- OK Tubrodur 1400iDocument1 pageOK Tubrodur 1400icamelod555No ratings yet

- Hard Facing Welding ElectrodesDocument3 pagesHard Facing Welding ElectrodesValli RajuNo ratings yet

- Hard Surface Overlay Welding Crack E - Weldone-Letter - FEBRUARY-2017 - Ver - 1Document1 pageHard Surface Overlay Welding Crack E - Weldone-Letter - FEBRUARY-2017 - Ver - 1convmech enggNo ratings yet

- Ch.3 Ferrous AlloysDocument19 pagesCh.3 Ferrous AlloysMothana RawashdehNo ratings yet

- Sea Water Corrosion Resisting SteelDocument8 pagesSea Water Corrosion Resisting SteelCarlos PadillaNo ratings yet

- LH 106Document1 pageLH 106Sandeep gangulyNo ratings yet

- UTP 655 32 SpecSheetDocument1 pageUTP 655 32 SpecSheetFadi HasnNo ratings yet

- Böhler Fox CN 29/9-A: DescriptionDocument1 pageBöhler Fox CN 29/9-A: DescriptionKadir Koray BozyelNo ratings yet

- Austenitic Manganese Steels 1Document12 pagesAustenitic Manganese Steels 1gabisaNo ratings yet

- Hard - Facing Welding - Electrodes PDFDocument3 pagesHard - Facing Welding - Electrodes PDFreeet87No ratings yet

- FC580 LeafletDocument1 pageFC580 Leafletkewatanil49No ratings yet

- Coremax H333-ODocument1 pageCoremax H333-OLIM hoon boonNo ratings yet

- Propiedades AISI 410Document25 pagesPropiedades AISI 410alvaroyepezNo ratings yet

- Ferrous Alloys - 13th August2021 (1) (3 Files Merged)Document56 pagesFerrous Alloys - 13th August2021 (1) (3 Files Merged)jayakrishnan psNo ratings yet

- Ferrous Alloys - Group 05Document36 pagesFerrous Alloys - Group 05Nipun Harsha100% (1)

- Metals: Types of Metals AlloysDocument9 pagesMetals: Types of Metals AlloysIslam ElhabsheNo ratings yet

- D-Met 04 Welding of Stainless Steels, CI and Dissimilar WeldDocument42 pagesD-Met 04 Welding of Stainless Steels, CI and Dissimilar WeldTrepend Simplifying BusinessNo ratings yet

- Technical Data: ApplicationsDocument3 pagesTechnical Data: ApplicationssushmaxNo ratings yet

- FsafsaDocument45 pagesFsafsapvmssonNo ratings yet

- Soldadura de Hierro ColadoDocument10 pagesSoldadura de Hierro ColadoclnNo ratings yet

- Dr. Madhusudhan ReddyDocument57 pagesDr. Madhusudhan ReddysivakgpulNo ratings yet

- Comparison Chart ElectrodeDocument2 pagesComparison Chart ElectrodeAsaad Mohamed67% (3)

- Concept of Transition Layer During CladdingDocument11 pagesConcept of Transition Layer During CladdingUjjawal PathakNo ratings yet

- S S S S - 11018.M 11018.M 11018.M 11018.M: Hyundai Welding Co., LTDDocument6 pagesS S S S - 11018.M 11018.M 11018.M 11018.M: Hyundai Welding Co., LTDfaridshabaniNo ratings yet

- Mild Steel Welding Electrodes: Salient FeaturesDocument16 pagesMild Steel Welding Electrodes: Salient FeaturesHandrea Hadi SaputraNo ratings yet

- L1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENDocument1 pageL1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENkamals55No ratings yet

- Lastek 90 Ceweld - Croni 29-9 S - 2013-06-27Document1 pageLastek 90 Ceweld - Croni 29-9 S - 2013-06-27Niksa ZekicNo ratings yet

- CHR707Document1 pageCHR707ImmalatulhusnaNo ratings yet

- Welding Cast IronDocument10 pagesWelding Cast IronRoberto CordovaNo ratings yet

- LH 1106Document1 pageLH 1106rm539969No ratings yet

- European Steel and Alloy Grades: X6Crniti18-10 (1.4541)Document3 pagesEuropean Steel and Alloy Grades: X6Crniti18-10 (1.4541)farshid KarpasandNo ratings yet

- Welding Electrodes Types and Application Procedures Welding DefectsDocument77 pagesWelding Electrodes Types and Application Procedures Welding DefectsmkpqNo ratings yet

- Alloy Steels: Dr. Indika de SilvaDocument25 pagesAlloy Steels: Dr. Indika de SilvaChandima K Priyamal100% (1)

- Lecture On Material of ConstructionDocument19 pagesLecture On Material of Constructiondeepankar kumarNo ratings yet

- ASTM A36/A36M Standard Specification For Carbon Structural SteelDocument4 pagesASTM A36/A36M Standard Specification For Carbon Structural SteeliuliamicutNo ratings yet

- Utp BMCDocument1 pageUtp BMCSamanthaPereraNo ratings yet

- E Book On SS WeldingDocument71 pagesE Book On SS WeldingNiranjan Rajavel TigerNo ratings yet

- Raex 500Document4 pagesRaex 500Daniel MauricioNo ratings yet

- KST 309LDocument1 pageKST 309LTharman SupramaniamNo ratings yet

- ME3251 RevisionDocument9 pagesME3251 RevisionJordan NgNo ratings yet

- Utp Af A7Document1 pageUtp Af A7VIRPOPNo ratings yet

- ERNiCrMo 14Document1 pageERNiCrMo 14bhavesh nakumNo ratings yet

- Met 03 Weldability - Welding of C-MN, LA Steels - CIDocument24 pagesMet 03 Weldability - Welding of C-MN, LA Steels - CIRaghu vamshiNo ratings yet

- Dr. Vika Rizkia, S.T., M.T Mechanical Engineering State Polytechnic of JakartaDocument31 pagesDr. Vika Rizkia, S.T., M.T Mechanical Engineering State Polytechnic of JakartaCANDRA ANDREAN Mahasiswa PNJNo ratings yet

- Thermanit 308 Mo 1SE3A00G 3407112 ENDocument1 pageThermanit 308 Mo 1SE3A00G 3407112 ENbrayanNo ratings yet

- AN ISO 9001: 2000: ProductsDocument2 pagesAN ISO 9001: 2000: ProductsKamlesh DalavadiNo ratings yet

- 7 MalDocument1 page7 Malm devaiahNo ratings yet

- Fluxes For Welding and SurfacingDocument4 pagesFluxes For Welding and SurfacingVăn Trường LêNo ratings yet

- Material Selection Stainless SteelDocument16 pagesMaterial Selection Stainless SteelmagiesekarNo ratings yet

- Maintenance and Repair Welding Training ModuleDocument59 pagesMaintenance and Repair Welding Training ModuleAtefNo ratings yet

- Effect of Multi-Pass SMAW Welding On The Surface HDocument7 pagesEffect of Multi-Pass SMAW Welding On The Surface HYousab CreatorNo ratings yet

- FCD45 Ductile Iron: Common NameDocument1 pageFCD45 Ductile Iron: Common NameHimindra ChaaubeNo ratings yet

- Lec 02Document19 pagesLec 02أمير حامد100% (1)

- Manual Metal Arc Welding (MMA, SMAW or Stick Welding)Document5 pagesManual Metal Arc Welding (MMA, SMAW or Stick Welding)Robert DelafosseNo ratings yet

- Advanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactFrom EverandAdvanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactNo ratings yet

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- Welding ParametersDocument9 pagesWelding Parametershanleduy100% (1)

- Training Curses LincolnDocument52 pagesTraining Curses Lincolncamelod555No ratings yet

- Electrode PackagingDocument1 pageElectrode Packagingcamelod555No ratings yet

- Welders, CWI Inspectors, Instructors Now You Can Design Your Inspection Tool KitDocument2 pagesWelders, CWI Inspectors, Instructors Now You Can Design Your Inspection Tool Kitcamelod555No ratings yet

- VCM 200 Portable Cutting MachineDocument1 pageVCM 200 Portable Cutting Machinecamelod555No ratings yet

- One Word Defines Select-Arc's New Electrode Line and Reputation For Quality..Document1 pageOne Word Defines Select-Arc's New Electrode Line and Reputation For Quality..camelod555No ratings yet

- Agency Approvals: Select-Arc Electrode Aws CWB Abs Lloyd'S DNV MilitaryDocument1 pageAgency Approvals: Select-Arc Electrode Aws CWB Abs Lloyd'S DNV Militarycamelod555No ratings yet

- S-A10th AdDocument1 pageS-A10th Adcamelod555No ratings yet

- Introducing The Small Spools That Deliver Big Time Welding PerformanceDocument2 pagesIntroducing The Small Spools That Deliver Big Time Welding Performancecamelod555No ratings yet

- Pipe Welding GageDocument1 pagePipe Welding Gagecamelod555No ratings yet

- Cerra Deco 2Document5 pagesCerra Deco 2camelod555No ratings yet

- Welding Cable Guide: Suggested Ampacity For Welding Cable Distance Measured in FeetDocument1 pageWelding Cable Guide: Suggested Ampacity For Welding Cable Distance Measured in Feetcamelod555No ratings yet

- MISON AR Shielding Gas135 99117Document4 pagesMISON AR Shielding Gas135 99117camelod555No ratings yet

- Welding Gage: Crown Height Fillet Weld Leg HeightDocument1 pageWelding Gage: Crown Height Fillet Weld Leg Heightcamelod555No ratings yet

- OK Tubrodur 1400iDocument1 pageOK Tubrodur 1400icamelod555No ratings yet

- Sample: Welding Stainless SteelDocument5 pagesSample: Welding Stainless Steelcamelod555No ratings yet

- Pipe Welding Gage: Pipe Wall Thickness Bevel On End PreparationDocument1 pagePipe Welding Gage: Pipe Wall Thickness Bevel On End Preparationcamelod555No ratings yet

- SF-71LF Supercored 71: KR, Abs, LR, BV, DNV, GL, NK, Tüv, CWB, Ü-Sign, Rina Abs, NK, LR, DNVDocument1 pageSF-71LF Supercored 71: KR, Abs, LR, BV, DNV, GL, NK, Tüv, CWB, Ü-Sign, Rina Abs, NK, LR, DNVcamelod555No ratings yet

- Aws Qc5-91 - Standard For Certification of Welding EducatorsDocument12 pagesAws Qc5-91 - Standard For Certification of Welding Educatorscamelod555No ratings yet

- Welding Gage: Leg Length Throat Size Crown Height Leg HeightDocument1 pageWelding Gage: Leg Length Throat Size Crown Height Leg Heightcamelod555No ratings yet

- MISON 8C Shielding GasDocument2 pagesMISON 8C Shielding Gascamelod555No ratings yet