Professional Documents

Culture Documents

4340M or 300M

4340M or 300M

Uploaded by

fedaquiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4340M or 300M

4340M or 300M

Uploaded by

fedaquiCopyright:

Available Formats

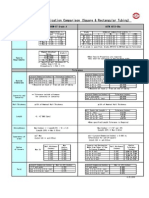

DATA SHEET

LESCALLOY 300M VAC-ARC

HIGH STRENGTH ALLOY STEEL

Typical

Composition

C

0.42

Mn

0.75

Si

1.65

Ni

1.80

Cr

0.80

Mo

0.40

V

0.07

GENERAL CHARACTERISTICS

LESCALLOY 300M VAC-ARC steel is a modified 4340 steel with added silicon allowing for use of a

higher tempering temperature. The steel has high hardenability and strength with good ductility and

toughness in heavy sections. It is used primarily in the 270/300 ksi (1862/2068) tensile strength range for

aircraft landing gears, flap tracks and other structural applications. Vacuum arc remelting (VAR) is used to

provide optimum cleanliness and preferred ingot structure.

PHYSICAL PROPERTIES

Density: 0.283 lb/in3 (7.84 g/cm3)

Thermal Conductivity: 260.0 Btuin/hrftF (37.49 W/mK)

Specific Heat: 0.107 Btu/lbF (448J/kgK)

Mean Coefficient of Thermal Expansion 0-200F (-17.8-93C): 6.3x10-6 in/inF (11.34x10-6 mm/mmC)

WORKABILITY

Forging: Forge at 1950-2250F (1066-1232C) using a minimum forging temperature of approximately

1700F (927C).

Weldability: This steel can be welded by gas or arc fusion methods.

Machinability: For optimum machinability, Lescalloy 300M Vac-Arc steel should be normalized and

tempered. Approximately 1200F (649C) is suggested for the temper. Hardness: Typically HBW 241-285.

HEAT TREATMENT

Normalize: 1700F (927C), 1 hour, air cool

Austenitize: 1600F (871C), 1 hour, oil quench

Temper: 500-600F (260-316F), four hours, air cool

COPYRIGHT 2007 by Latrobe Specialty Steel Co.

Registered Trademark of Latrobe Specialty Steel Co.

LESCALLOY 300M VAC-ARC

MECHANICAL PROPERTY DATA

TYPICAL TRANSVERSE MECHANICAL PROPERTIES WITH 575F (302C) TEMPER

Size Tested

in

mm

26 - 28

660 -711

22

559

22

559

305

12

305

12

Specimen Size

0.252

0.505

0.252

0.505

0.252

U.T.S.

ksi

MPa

286

1972

288

1986

288

1986

287

1979

288

1986

0.2% Y.S.

ksi

MPa

240

1655

245

1689

242

1669

244

1682

242

1669

Elongation

(%)

11

8.5

10

10

11

R of A

(%)

37

31

35

33

39

FRACTURE TOUGHNESS PER ASTM E 399

At nominal strength levels, the ASTM E 399 plane-strain fracture toughness is typically 60-70 ksi in. (6677 MPa m).

JOMINY END QUENCH HARDENABILITY

Rockwell C

2

59.0

4

58.5

Distance from Quenched End (1/16 inch)

6

8

10

12

14

16

58.5

58.0

58.0

57.5

57.5

57.5

SPECIFICATIONS

21

57.5

TEMPERING CURVE

The following industry specifications are

offered for general familiarization and

should not be considered a complete listing.

Austenitized 1600F (871C), Oil Quench

Tempered Twice 2+2 hours

Tempering Temperature C

204

316

427

538

649

60

Hardness Rockwell C

AMS 6257 (Replaces MIL-S-8844 Class 3)

AMS 6417

AMS 6419

BMS 7-26 (Boeing)

BE1036 (Bendix)

CE-0896 (Bendix)

C-05-1190 (Lockheed)

DMS1935 (McDonnell-Douglas)

GM1012 (Grumman)

MIL-S-83135

MTL 1201 (Messier-Dowty)

18

57.5

50

40

30

20

400

600

800

1000

Tempering Temperature F

1200

Latrobe, Pennsylvania 15650-0031 U.S.A.

Phone: (724) 537-7711 Fax: (724) 532-6316

www.latrobesteel.com

COPYRIGHT 2007 by Latrobe Specialty Steel Co.

04/07

You might also like

- .250 .031 R Collar, An876 (Proper Dash No.) Silver Solder To TubeDocument3 pages.250 .031 R Collar, An876 (Proper Dash No.) Silver Solder To TubeAnonymous 1CBdStCXUNo ratings yet

- ASTM A 514 - A 514-00. Standard Specification For High-YieldDocument3 pagesASTM A 514 - A 514-00. Standard Specification For High-YieldHo Le QuangNo ratings yet

- 17-7 PH Data SheetDocument2 pages17-7 PH Data SheetsksiddiqueNo ratings yet

- Astm A 453 Grade 660Document4 pagesAstm A 453 Grade 660Bruno_jfNo ratings yet

- AISI 4130: Incoloy Alloys, Fast QuoteDocument5 pagesAISI 4130: Incoloy Alloys, Fast QuoteSantanu SahaNo ratings yet

- AISI 1050 Steel, As RolledDocument2 pagesAISI 1050 Steel, As RolledCristobal Gutierrez CarrascoNo ratings yet

- Suhm Spring Works-Spring Materials Issue 9a en US v1Document37 pagesSuhm Spring Works-Spring Materials Issue 9a en US v1DizzixxNo ratings yet

- Astm A192 Asme Sa192Document4 pagesAstm A192 Asme Sa192Mingo EvaNo ratings yet

- 30 CR Ni Mo 8Document2 pages30 CR Ni Mo 8Amy GriffinNo ratings yet

- 13-8 MoDocument2 pages13-8 MofedaquiNo ratings yet

- BG42 Data SheetDocument0 pagesBG42 Data SheetTroy AshcraftNo ratings yet

- AISI 4340 NitridingDocument8 pagesAISI 4340 NitridingVlad Craciun100% (1)

- Astm A192 Asme Sa192 PDFDocument4 pagesAstm A192 Asme Sa192 PDFWil Vasquez C100% (1)

- Bisalloy: Bunge Industrial Steels Pty. LimitedDocument65 pagesBisalloy: Bunge Industrial Steels Pty. Limitedramaus100% (1)

- Cold Formed Carbon Structural Steel Tubing Made From Metallic Precoated Sheet SteelDocument3 pagesCold Formed Carbon Structural Steel Tubing Made From Metallic Precoated Sheet SteelDanZel DanNo ratings yet

- Filler Metal Selection GuideDocument32 pagesFiller Metal Selection GuideSamuel LatumahinaNo ratings yet

- Effect of Laser Power and Substrate On The Hastelloy C276TM Coatings Features Deposited by Laser CladdingDocument11 pagesEffect of Laser Power and Substrate On The Hastelloy C276TM Coatings Features Deposited by Laser CladdingAlex PizzattoNo ratings yet

- Bisalloy's PlatesDocument16 pagesBisalloy's PlatesMarcoNo ratings yet

- AÇO - DIN17100 St52-3Document1 pageAÇO - DIN17100 St52-3Paulo Henrique NascimentoNo ratings yet

- Corus Aerospace Spec BookletDocument14 pagesCorus Aerospace Spec BookletColinG7750% (1)

- Explosive Depth HardenedDocument1 pageExplosive Depth HardenedShipra MishraNo ratings yet

- Non Standarad Dowel PinDocument4 pagesNon Standarad Dowel Pinjaskaran singhNo ratings yet

- Din 1681-GS 60Document9 pagesDin 1681-GS 60Vishnu AgawaneNo ratings yet

- Astm 434Document3 pagesAstm 434Fabián MartínezNo ratings yet

- Astralloy-V: Abrasion and Impact Resistant, Air Hardened Wear SteelDocument2 pagesAstralloy-V: Abrasion and Impact Resistant, Air Hardened Wear SteelJRodengineerNo ratings yet

- S355J2G3 PDFDocument1 pageS355J2G3 PDFcorsini999No ratings yet

- Nitriding 4340 ADocument8 pagesNitriding 4340 AyanuarNo ratings yet

- 03.ASTM A572-15 - Eqv. A709Gr50Document4 pages03.ASTM A572-15 - Eqv. A709Gr50Mauricio_Vera_525950% (2)

- Cast Steel Guide FEB05Document6 pagesCast Steel Guide FEB05Serad AdsenNo ratings yet

- AISI 1020 Steel, Cold RolledDocument2 pagesAISI 1020 Steel, Cold RolledAnonymous ZMwWk2v50% (2)

- Interlloy 440C MartensiticDocument4 pagesInterlloy 440C MartensiticGuillaume BoyerNo ratings yet

- 440C DS CarpenterDocument5 pages440C DS CarpenterdaymonNo ratings yet

- Sae J451Document5 pagesSae J451Douglas RodriguesNo ratings yet

- Bronze SAE 64 PDFDocument1 pageBronze SAE 64 PDFIbsonhNo ratings yet

- A500 Vs A513Document2 pagesA500 Vs A513Angelo CubillosNo ratings yet

- High Tensile Steel 4340Document2 pagesHigh Tensile Steel 4340Arun KumarNo ratings yet

- C633 617621-1 PDFDocument8 pagesC633 617621-1 PDFAmy BurnsNo ratings yet

- BS3076 Na18Document4 pagesBS3076 Na18BHARGAVNo ratings yet

- Sae Ams-H-6875b-2010Document22 pagesSae Ams-H-6875b-2010dmt1905100% (1)

- Aplicación ARMDocument25 pagesAplicación ARMKjatunMayu GutierrezNo ratings yet

- ASTM A842 - Corpo de Prova OmegaDocument4 pagesASTM A842 - Corpo de Prova OmegaFabiano MonteiroNo ratings yet

- Astm A27 (2010) PDFDocument4 pagesAstm A27 (2010) PDFStuar TencioNo ratings yet

- SAE Grade SpecificationDocument1 pageSAE Grade SpecificationRamani Elampooranan K ENo ratings yet

- Transverse Rupture Strength of Metal Powder Specimens: Standard Test Method ForDocument4 pagesTransverse Rupture Strength of Metal Powder Specimens: Standard Test Method FormaldopinNo ratings yet

- ASTM A633 GR E Data Sheet 2012 04 01Document2 pagesASTM A633 GR E Data Sheet 2012 04 01FrancescoGuglielmo100% (1)

- Aerospace CustomersDocument3 pagesAerospace CustomersSinan YıldızNo ratings yet

- Aerospace Material Specification: Plating, Nickel General PurposeDocument8 pagesAerospace Material Specification: Plating, Nickel General PurposeSURYAS63No ratings yet

- AlloysDocument4 pagesAlloyslinguy007No ratings yet

- As 4964-2004 Method For The Qualitative Identification of Asbestos in Bulk SamplesDocument7 pagesAs 4964-2004 Method For The Qualitative Identification of Asbestos in Bulk SamplesSAI Global - APACNo ratings yet

- Astm A1001Document5 pagesAstm A1001zaper664100% (1)

- AISI 440 Martensit PDFDocument4 pagesAISI 440 Martensit PDFJimmyVargasNo ratings yet

- Sfa-5.7Document10 pagesSfa-5.7vannie_yundaNo ratings yet

- ShapeCUT Steel Hardness Conversion TableDocument2 pagesShapeCUT Steel Hardness Conversion TableVicente GarcíaNo ratings yet

- Astm A 278 - A 278M - 01 (2015)Document4 pagesAstm A 278 - A 278M - 01 (2015)Nguyễn Như ThếNo ratings yet

- 4340Document2 pages4340fedaquiNo ratings yet

- LSS A286Document2 pagesLSS A286anhntran4850No ratings yet

- ATA Heet: Escalloy 300M-H 300M-H L S Vac-Arc S Vac-ArcDocument2 pagesATA Heet: Escalloy 300M-H 300M-H L S Vac-Arc S Vac-ArcCristiano BeckNo ratings yet

- 17-7 PH Data BulletinDocument16 pages17-7 PH Data Bulletinmeckup123No ratings yet

- 410 Data Sheet PDFDocument2 pages410 Data Sheet PDFraviteja036No ratings yet

- Welding Newly Devel0Ped, High Strength, Seismic Grade Reinforcing BarsDocument8 pagesWelding Newly Devel0Ped, High Strength, Seismic Grade Reinforcing Barsdnageshm4n244No ratings yet

- Low Alloy Steels Part2Document1 pageLow Alloy Steels Part2fedaquiNo ratings yet

- ASM Cross Reference For NonferrousDocument17 pagesASM Cross Reference For Nonferrousfedaqui100% (2)

- 4340Document2 pages4340fedaquiNo ratings yet

- Nickel Maraging Steel PropertiesDocument30 pagesNickel Maraging Steel PropertiesRobert NatasorpNo ratings yet

- 15-5 PHDocument2 pages15-5 PHfedaquiNo ratings yet

- 17 4Document2 pages17 4fedaquiNo ratings yet

- 13-8 MoDocument2 pages13-8 MofedaquiNo ratings yet