Professional Documents

Culture Documents

503 Systems - Indirect Fired Heaters - Eng - Apr2010 PDF

503 Systems - Indirect Fired Heaters - Eng - Apr2010 PDF

Uploaded by

svnaik14Copyright:

Available Formats

You might also like

- Part A - Hvac Technical Specifications 1. Hot Water GeneratorDocument25 pagesPart A - Hvac Technical Specifications 1. Hot Water GeneratorAnand_HvacNo ratings yet

- Water Bath HeaterDocument4 pagesWater Bath HeaterBensmatNo ratings yet

- Cone Design ToolDocument1 pageCone Design ToolPramod KumarNo ratings yet

- AX5 Vaporizer Electric Water Bath Type LPG VaporizerDocument2 pagesAX5 Vaporizer Electric Water Bath Type LPG VaporizerRicky DermawanNo ratings yet

- Water Bath Heater Writeup PDFDocument2 pagesWater Bath Heater Writeup PDFJayesh SanganiNo ratings yet

- DeZURIK KCG Knife Gate ValvesDocument12 pagesDeZURIK KCG Knife Gate ValvesKithkarnonNo ratings yet

- Datasheet of The HeaterDocument2 pagesDatasheet of The HeaterMubarik AliNo ratings yet

- Standard Hook-Up Wires & Cables For ElectronicsDocument124 pagesStandard Hook-Up Wires & Cables For ElectronicsdlstoneNo ratings yet

- Norsok Electric Process Heater EDS-013 E-001 Data Sheet: Page 1 of 3Document3 pagesNorsok Electric Process Heater EDS-013 E-001 Data Sheet: Page 1 of 3Anonymous v4akjrQxKNo ratings yet

- Sok7305252 003 A 001Document107 pagesSok7305252 003 A 001muhammad nazmiNo ratings yet

- Steam HXDocument1 pageSteam HXrajachemNo ratings yet

- Sentry Tech BullDocument3 pagesSentry Tech BullFilipNo ratings yet

- Seprasol Plus: Liquid/Gas CoalescersDocument4 pagesSeprasol Plus: Liquid/Gas CoalescersSiavash YarahmadiNo ratings yet

- 23 22 00 - Steam and Condensate Piping and PumpsDocument6 pages23 22 00 - Steam and Condensate Piping and PumpsDiana SoareNo ratings yet

- Bunner ControlDocument19 pagesBunner ControlHai NguyenNo ratings yet

- Liquid Monopropellant CombustionDocument4 pagesLiquid Monopropellant Combustionherdi sutanto adigunaNo ratings yet

- EX Firetube Boiler Changed by Advances in Design TechnologyDocument7 pagesEX Firetube Boiler Changed by Advances in Design TechnologyXamir Suarez AlejandroNo ratings yet

- Horizontal Bandlock2 Manual PDFDocument23 pagesHorizontal Bandlock2 Manual PDFGigena100% (1)

- Burner Data SheetDocument6 pagesBurner Data SheetLuis Eduardo NavasNo ratings yet

- Special Closures Literature2Document2 pagesSpecial Closures Literature2ruben'sNo ratings yet

- Indirect Fired Water Bath Heater Indirect Fired Water Bath Heater Flash Point - IfwbhDocument6 pagesIndirect Fired Water Bath Heater Indirect Fired Water Bath Heater Flash Point - IfwbhMuhammad AhsanNo ratings yet

- Thermocompressor Efficiency & PerformanceDocument4 pagesThermocompressor Efficiency & PerformancerifqizafrilNo ratings yet

- Specification For Hot Water BoilersDocument1 pageSpecification For Hot Water BoilersKarthik AnandanNo ratings yet

- Domestic Gas PipingDocument2 pagesDomestic Gas Pipingvalentinlupascu33No ratings yet

- What Is Natural GasDocument7 pagesWhat Is Natural GasmohamedNo ratings yet

- Thermowell Calculation Guide V1.3Document19 pagesThermowell Calculation Guide V1.3Aymanelorbany100% (1)

- A Demister Pad Is Similar To An Air Filter Except Instead of Removing Dust ParticlesDocument1 pageA Demister Pad Is Similar To An Air Filter Except Instead of Removing Dust ParticlesyogacruiseNo ratings yet

- Modelling Performance Electric Heater PDFDocument23 pagesModelling Performance Electric Heater PDFFelipe FreitasNo ratings yet

- Filtration in HydrotreatingDocument2 pagesFiltration in Hydrotreatingck196548400% (1)

- ABO Ball ValveDocument6 pagesABO Ball ValveSunil BajpaiNo ratings yet

- Steam: Fig. 10.1.1 A Typical Basic Steam CircuitDocument47 pagesSteam: Fig. 10.1.1 A Typical Basic Steam Circuitkris_2k3No ratings yet

- Let Down StationDocument5 pagesLet Down StationSabeeh AhmedNo ratings yet

- Pressure Testing Request FormDocument1 pagePressure Testing Request FormSyed Mahmud Habibur RahmanNo ratings yet

- Sentry Sampling ComponentsDocument60 pagesSentry Sampling Componentsnagaraj108100% (3)

- 1 TPH 10.54 KG, Vapi Care PharmaDocument16 pages1 TPH 10.54 KG, Vapi Care PharmashastrysnNo ratings yet

- Pressure Control Valve Self Actuated: GeneralDocument1 pagePressure Control Valve Self Actuated: GeneralJorge RodríguezNo ratings yet

- Safety Valve Technical DetailsDocument5 pagesSafety Valve Technical DetailsvineethvskkdNo ratings yet

- Lecture 04c - Shortcut Exchanger Design ProcedureDocument47 pagesLecture 04c - Shortcut Exchanger Design Proceduresds0% (1)

- Engineering Services by KBR Technical Services, IncDocument12 pagesEngineering Services by KBR Technical Services, IncgfgfNo ratings yet

- Design of Shell & Tube HX (Unprotected For Expert Excel Users)Document31 pagesDesign of Shell & Tube HX (Unprotected For Expert Excel Users)Sameer ChaturvediNo ratings yet

- TSP0013 Steam Tracing DesignDocument23 pagesTSP0013 Steam Tracing DesignFabio TemporiniNo ratings yet

- Pipe Material Selection Chart Based On TemperatureDocument4 pagesPipe Material Selection Chart Based On TemperatureNitin KumarNo ratings yet

- Boiler Control SystemDocument30 pagesBoiler Control Systemsyahmi zainiNo ratings yet

- Expansion Vessel CalculationDocument4 pagesExpansion Vessel CalculationTsouki TsoukiNo ratings yet

- Accessen Plate Heat Exchanger Specification SheetDocument1 pageAccessen Plate Heat Exchanger Specification Sheetfakir mohammadNo ratings yet

- Block & Bleed Valve: High Technology Valve & Fitting SeriesDocument20 pagesBlock & Bleed Valve: High Technology Valve & Fitting SeriesMayur PatelNo ratings yet

- Heater: Hydrate PreventionDocument12 pagesHeater: Hydrate PreventionMahmoud Ahmed Ali AbdelrazikNo ratings yet

- Technical Standards For Insulation-Mineral Wool-RockwoolDocument2 pagesTechnical Standards For Insulation-Mineral Wool-RockwooljaganNo ratings yet

- Heat Exchanger Specification Sheet: Shell Side Tube Side Performance of One UnitDocument2 pagesHeat Exchanger Specification Sheet: Shell Side Tube Side Performance of One UnitMuthuKumar ArunachalamNo ratings yet

- Basic Ref PipingDocument28 pagesBasic Ref PipingMohammed Jassim50% (2)

- VA1 TATL 00100 M M7 DSU 0022.air Heater Drawing For Silo 18 KWDocument2 pagesVA1 TATL 00100 M M7 DSU 0022.air Heater Drawing For Silo 18 KWhoangduythanhqbNo ratings yet

- PRO 810124 12 A1-Steam-Traps enDocument30 pagesPRO 810124 12 A1-Steam-Traps enZulfadli RaniNo ratings yet

- NFPA Pipe Sizing EXAMPLEDocument4 pagesNFPA Pipe Sizing EXAMPLEMatt AndersonNo ratings yet

- 7-12-0026 Rev6 (Earthing Lug)Document1 page7-12-0026 Rev6 (Earthing Lug)sumit kumarNo ratings yet

- 2.8 Waste Heat Recovery-LibreDocument18 pages2.8 Waste Heat Recovery-Libredivyank3dNo ratings yet

- Inline Heater DatasheetDocument11 pagesInline Heater DatasheetMuhammad AhsanNo ratings yet

- Ips - Indirect Fired HeatersDocument8 pagesIps - Indirect Fired HeatersjollyNo ratings yet

- Exterran Indirect Line Heater: Standard FeaturesDocument8 pagesExterran Indirect Line Heater: Standard FeaturesFriday IjokgwungNo ratings yet

- Hot Water Supply ch.2 PDFDocument55 pagesHot Water Supply ch.2 PDFasmaaasmaaa asmaa100% (1)

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Process Courses and Seminars March 21Document1 pageProcess Courses and Seminars March 21svnaik14No ratings yet

- Lo21-21-P-Pi-04 - Rev.pDocument1 pageLo21-21-P-Pi-04 - Rev.psvnaik14No ratings yet

- Lo21-21-P-Pi-16 - Rev.pDocument1 pageLo21-21-P-Pi-16 - Rev.psvnaik14No ratings yet

- Lo21-21-P-Pi-13 - Rev.pDocument1 pageLo21-21-P-Pi-13 - Rev.psvnaik14No ratings yet

- Lo21-21-P-Pi-21 - Rev.pDocument2 pagesLo21-21-P-Pi-21 - Rev.psvnaik14100% (1)

- Reliance - Flare Gas Recovery IMPDocument6 pagesReliance - Flare Gas Recovery IMPsvnaik14No ratings yet

- Process Control Philosophy 05-01-23Document8 pagesProcess Control Philosophy 05-01-23svnaik14No ratings yet

- Summary Flare Gas Monetization ProjectsDocument2 pagesSummary Flare Gas Monetization Projectssvnaik14No ratings yet

- Gas Line Size-1Document12 pagesGas Line Size-1svnaik14No ratings yet

- 541-PC-1002 Utility Consumption Summary1Document3 pages541-PC-1002 Utility Consumption Summary1svnaik14No ratings yet

- KKS Component Coding Manual 40-0000294 - D - 002 PDFDocument18 pagesKKS Component Coding Manual 40-0000294 - D - 002 PDFsvnaik14100% (1)

503 Systems - Indirect Fired Heaters - Eng - Apr2010 PDF

503 Systems - Indirect Fired Heaters - Eng - Apr2010 PDF

Uploaded by

svnaik14Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

503 Systems - Indirect Fired Heaters - Eng - Apr2010 PDF

503 Systems - Indirect Fired Heaters - Eng - Apr2010 PDF

Uploaded by

svnaik14Copyright:

Available Formats

Indirect fired heaters

Indirect Fired Heaters

General

INDIRECT BATH HEATERS

Indirect bath heaters have a wide variety of successful applications in the oil and gas production, processing and

transmission industry. Some of the most common application include the following:

1. Gas Dew Point Heating: high-pressure natural gas heating upstream pressure regulation stations preventing

condensation phenomena due to the Joule-Thomson effect.

2. Heating of high-pressure natural gas upstream pressure regulation in order to prevent external icing formation.

3. Fuel gas super-heating upstream gas turbines (Performance haters)

4. Gas heating downstream low temperature storages

5. Hydrate prevention

6. Viscosity reduction: Crude Oil Heating upstream treatments to facilitate degassing and dewatering.

Range:

The duty of Pietro Fiorentini heaters can vary from 90Kw up to 10Mw.

Main features

Indirect bath heaters

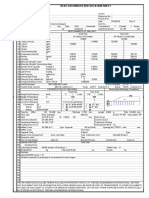

Indirect Bath Heaters are composed of the following main parts:

-

Main body

The coil or tube bundle

The water expansion tank

The fuel feed line

Burner (gas type, oil type or bi-fuel)

The fire-tube

Chimney

Burner management system panel

Skid frame and service platform

Insulation

The heater shell contains the fire-tube that

allows a rapid heat transfer (both radiant

and convective) from the flame to the hot

medium. The heat is transferred from the

bath to the coil / tube bundle and then safely

to the gas or the oil.

The expansion tank allow the hot medium to

be contained for the thermal expansion due

to the temperature increase. Level gauges

and transmitters advise when additional

water or hot medium is required and give

alarms in case of overfilling.

External insulation

Indirect bath heaters

Heaters are thermally insulated, except end sides left bare to facilitate access to the coils, burner or stack.

Insulation materials are properly selected based on operating temperature and climate conditions.

Forced draft vs natural draft

Indirect bath heaters

Forced or natural draft heater designs are available depending on working conditions and power availability

on site.

Natural draft burner relies on a stack to create negative pressure at the burner inlet, which induces as much

air as is required for combustion. These heaters are popular for remote locations and/or locations with limited

or even no power supply available.

Forced draft heaters are ideal whenever there is a low emission requirement, utilizing small bore fire-tubes

in conjunction with a combustion air fan. High velocities in the small bore fire tube reduce the dead gas film

region along the tube walls. This results in a reduced tube areas compared to their large bore counterparts,

therefore, overall heater size is minimized creating a significantly smaller footprint while offering superior burner

control compared to natural draft style heaters.

API 12K OFFICIAL MONOGRAM

Indirect bath heaters

PIETRO FIORENTINI is one of the few companies worldwide

bearing the API 12K monogram confirming the full compliance

of Indirect Heaters to API (American Petroleum Institute)

specifications.

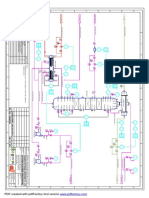

Indirect fired gas heater (water bath heaters)

Indirect bath heaters

Tailor designed according to customer specification and design conditions they can have different

configurations:

GAS PIPE INSIDE THE HEATER:

AIR DRAFTS:

BURNERS

HEAT SOURCE:

HOT MEDIUM:

Tube bundle or coil.

Natural circulation or forced flow.

Low NOx or conventional, mono-fuel or bi-fuel

Gas, oil or electricity.

De-mineralized Water, Glycol, hot oil, Thermal B

The operation of the gas heaters is completely automatic. Gas heaters are fired with natural gas which will be

supplied to the burner at a specific pressure thanks to a dedicated fuel gas pressure regulators complete of

all the required safety devices and electrical heating on a dedicated line.

HOT OIL HEATER

Indirect bath heaters

Used in order to reduce the viscosity to ease the oil stream transportation.

The hot medium can be water, hot oil, Glycol or Thermal B.

Almost every coil bundle require a tailored design in order to meet the requirements of heat duty, working

pressure, corrosion allowance, sour gas service, NACE MR-01-75 and governing specification or normative,

usually ASTM or ANSI B 31.3.

Electric heaters

Indirect bath heaters

All the previous type of heater can be constructed with Electrical heating source.

Example of electrical Gas Heating to prevent

condensate creation after the gas temperature

reducing at the pressure reducing valves for the jouleThompson effect.

On Electrical Heaters the temperature control is

operated by a Thyristor systems.

FIORENTINI can offer a full range of flameproof

heaters, immersion heaters, process flow

heaters and electric heating skids for a variety of

applications.

Typical electric process heating applications include

fuel gas heaters, fuel oil heaters, glycol reboilers,

TEG heaters, MEG heaters and water heaters.

Pietro Fiorentini Solutions

Gas treatment plants

The data are not binding. We reserve the

right to make eventual changes without

prior notice.

CT-s 568-E April 10

www.fiorentini.com

Reducing station

Ball valve

Pietro Fiorentini S.p.A.

via E.Fermi 8/10

I-36057 Arcugnano (VI) Italy

Tel. +39 0444 968.511

Fax. +39 0444 960.468

You might also like

- Part A - Hvac Technical Specifications 1. Hot Water GeneratorDocument25 pagesPart A - Hvac Technical Specifications 1. Hot Water GeneratorAnand_HvacNo ratings yet

- Water Bath HeaterDocument4 pagesWater Bath HeaterBensmatNo ratings yet

- Cone Design ToolDocument1 pageCone Design ToolPramod KumarNo ratings yet

- AX5 Vaporizer Electric Water Bath Type LPG VaporizerDocument2 pagesAX5 Vaporizer Electric Water Bath Type LPG VaporizerRicky DermawanNo ratings yet

- Water Bath Heater Writeup PDFDocument2 pagesWater Bath Heater Writeup PDFJayesh SanganiNo ratings yet

- DeZURIK KCG Knife Gate ValvesDocument12 pagesDeZURIK KCG Knife Gate ValvesKithkarnonNo ratings yet

- Datasheet of The HeaterDocument2 pagesDatasheet of The HeaterMubarik AliNo ratings yet

- Standard Hook-Up Wires & Cables For ElectronicsDocument124 pagesStandard Hook-Up Wires & Cables For ElectronicsdlstoneNo ratings yet

- Norsok Electric Process Heater EDS-013 E-001 Data Sheet: Page 1 of 3Document3 pagesNorsok Electric Process Heater EDS-013 E-001 Data Sheet: Page 1 of 3Anonymous v4akjrQxKNo ratings yet

- Sok7305252 003 A 001Document107 pagesSok7305252 003 A 001muhammad nazmiNo ratings yet

- Steam HXDocument1 pageSteam HXrajachemNo ratings yet

- Sentry Tech BullDocument3 pagesSentry Tech BullFilipNo ratings yet

- Seprasol Plus: Liquid/Gas CoalescersDocument4 pagesSeprasol Plus: Liquid/Gas CoalescersSiavash YarahmadiNo ratings yet

- 23 22 00 - Steam and Condensate Piping and PumpsDocument6 pages23 22 00 - Steam and Condensate Piping and PumpsDiana SoareNo ratings yet

- Bunner ControlDocument19 pagesBunner ControlHai NguyenNo ratings yet

- Liquid Monopropellant CombustionDocument4 pagesLiquid Monopropellant Combustionherdi sutanto adigunaNo ratings yet

- EX Firetube Boiler Changed by Advances in Design TechnologyDocument7 pagesEX Firetube Boiler Changed by Advances in Design TechnologyXamir Suarez AlejandroNo ratings yet

- Horizontal Bandlock2 Manual PDFDocument23 pagesHorizontal Bandlock2 Manual PDFGigena100% (1)

- Burner Data SheetDocument6 pagesBurner Data SheetLuis Eduardo NavasNo ratings yet

- Special Closures Literature2Document2 pagesSpecial Closures Literature2ruben'sNo ratings yet

- Indirect Fired Water Bath Heater Indirect Fired Water Bath Heater Flash Point - IfwbhDocument6 pagesIndirect Fired Water Bath Heater Indirect Fired Water Bath Heater Flash Point - IfwbhMuhammad AhsanNo ratings yet

- Thermocompressor Efficiency & PerformanceDocument4 pagesThermocompressor Efficiency & PerformancerifqizafrilNo ratings yet

- Specification For Hot Water BoilersDocument1 pageSpecification For Hot Water BoilersKarthik AnandanNo ratings yet

- Domestic Gas PipingDocument2 pagesDomestic Gas Pipingvalentinlupascu33No ratings yet

- What Is Natural GasDocument7 pagesWhat Is Natural GasmohamedNo ratings yet

- Thermowell Calculation Guide V1.3Document19 pagesThermowell Calculation Guide V1.3Aymanelorbany100% (1)

- A Demister Pad Is Similar To An Air Filter Except Instead of Removing Dust ParticlesDocument1 pageA Demister Pad Is Similar To An Air Filter Except Instead of Removing Dust ParticlesyogacruiseNo ratings yet

- Modelling Performance Electric Heater PDFDocument23 pagesModelling Performance Electric Heater PDFFelipe FreitasNo ratings yet

- Filtration in HydrotreatingDocument2 pagesFiltration in Hydrotreatingck196548400% (1)

- ABO Ball ValveDocument6 pagesABO Ball ValveSunil BajpaiNo ratings yet

- Steam: Fig. 10.1.1 A Typical Basic Steam CircuitDocument47 pagesSteam: Fig. 10.1.1 A Typical Basic Steam Circuitkris_2k3No ratings yet

- Let Down StationDocument5 pagesLet Down StationSabeeh AhmedNo ratings yet

- Pressure Testing Request FormDocument1 pagePressure Testing Request FormSyed Mahmud Habibur RahmanNo ratings yet

- Sentry Sampling ComponentsDocument60 pagesSentry Sampling Componentsnagaraj108100% (3)

- 1 TPH 10.54 KG, Vapi Care PharmaDocument16 pages1 TPH 10.54 KG, Vapi Care PharmashastrysnNo ratings yet

- Pressure Control Valve Self Actuated: GeneralDocument1 pagePressure Control Valve Self Actuated: GeneralJorge RodríguezNo ratings yet

- Safety Valve Technical DetailsDocument5 pagesSafety Valve Technical DetailsvineethvskkdNo ratings yet

- Lecture 04c - Shortcut Exchanger Design ProcedureDocument47 pagesLecture 04c - Shortcut Exchanger Design Proceduresds0% (1)

- Engineering Services by KBR Technical Services, IncDocument12 pagesEngineering Services by KBR Technical Services, IncgfgfNo ratings yet

- Design of Shell & Tube HX (Unprotected For Expert Excel Users)Document31 pagesDesign of Shell & Tube HX (Unprotected For Expert Excel Users)Sameer ChaturvediNo ratings yet

- TSP0013 Steam Tracing DesignDocument23 pagesTSP0013 Steam Tracing DesignFabio TemporiniNo ratings yet

- Pipe Material Selection Chart Based On TemperatureDocument4 pagesPipe Material Selection Chart Based On TemperatureNitin KumarNo ratings yet

- Boiler Control SystemDocument30 pagesBoiler Control Systemsyahmi zainiNo ratings yet

- Expansion Vessel CalculationDocument4 pagesExpansion Vessel CalculationTsouki TsoukiNo ratings yet

- Accessen Plate Heat Exchanger Specification SheetDocument1 pageAccessen Plate Heat Exchanger Specification Sheetfakir mohammadNo ratings yet

- Block & Bleed Valve: High Technology Valve & Fitting SeriesDocument20 pagesBlock & Bleed Valve: High Technology Valve & Fitting SeriesMayur PatelNo ratings yet

- Heater: Hydrate PreventionDocument12 pagesHeater: Hydrate PreventionMahmoud Ahmed Ali AbdelrazikNo ratings yet

- Technical Standards For Insulation-Mineral Wool-RockwoolDocument2 pagesTechnical Standards For Insulation-Mineral Wool-RockwooljaganNo ratings yet

- Heat Exchanger Specification Sheet: Shell Side Tube Side Performance of One UnitDocument2 pagesHeat Exchanger Specification Sheet: Shell Side Tube Side Performance of One UnitMuthuKumar ArunachalamNo ratings yet

- Basic Ref PipingDocument28 pagesBasic Ref PipingMohammed Jassim50% (2)

- VA1 TATL 00100 M M7 DSU 0022.air Heater Drawing For Silo 18 KWDocument2 pagesVA1 TATL 00100 M M7 DSU 0022.air Heater Drawing For Silo 18 KWhoangduythanhqbNo ratings yet

- PRO 810124 12 A1-Steam-Traps enDocument30 pagesPRO 810124 12 A1-Steam-Traps enZulfadli RaniNo ratings yet

- NFPA Pipe Sizing EXAMPLEDocument4 pagesNFPA Pipe Sizing EXAMPLEMatt AndersonNo ratings yet

- 7-12-0026 Rev6 (Earthing Lug)Document1 page7-12-0026 Rev6 (Earthing Lug)sumit kumarNo ratings yet

- 2.8 Waste Heat Recovery-LibreDocument18 pages2.8 Waste Heat Recovery-Libredivyank3dNo ratings yet

- Inline Heater DatasheetDocument11 pagesInline Heater DatasheetMuhammad AhsanNo ratings yet

- Ips - Indirect Fired HeatersDocument8 pagesIps - Indirect Fired HeatersjollyNo ratings yet

- Exterran Indirect Line Heater: Standard FeaturesDocument8 pagesExterran Indirect Line Heater: Standard FeaturesFriday IjokgwungNo ratings yet

- Hot Water Supply ch.2 PDFDocument55 pagesHot Water Supply ch.2 PDFasmaaasmaaa asmaa100% (1)

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Process Courses and Seminars March 21Document1 pageProcess Courses and Seminars March 21svnaik14No ratings yet

- Lo21-21-P-Pi-04 - Rev.pDocument1 pageLo21-21-P-Pi-04 - Rev.psvnaik14No ratings yet

- Lo21-21-P-Pi-16 - Rev.pDocument1 pageLo21-21-P-Pi-16 - Rev.psvnaik14No ratings yet

- Lo21-21-P-Pi-13 - Rev.pDocument1 pageLo21-21-P-Pi-13 - Rev.psvnaik14No ratings yet

- Lo21-21-P-Pi-21 - Rev.pDocument2 pagesLo21-21-P-Pi-21 - Rev.psvnaik14100% (1)

- Reliance - Flare Gas Recovery IMPDocument6 pagesReliance - Flare Gas Recovery IMPsvnaik14No ratings yet

- Process Control Philosophy 05-01-23Document8 pagesProcess Control Philosophy 05-01-23svnaik14No ratings yet

- Summary Flare Gas Monetization ProjectsDocument2 pagesSummary Flare Gas Monetization Projectssvnaik14No ratings yet

- Gas Line Size-1Document12 pagesGas Line Size-1svnaik14No ratings yet

- 541-PC-1002 Utility Consumption Summary1Document3 pages541-PC-1002 Utility Consumption Summary1svnaik14No ratings yet

- KKS Component Coding Manual 40-0000294 - D - 002 PDFDocument18 pagesKKS Component Coding Manual 40-0000294 - D - 002 PDFsvnaik14100% (1)