Professional Documents

Culture Documents

Methods of Welding Flanges To Pipe

Methods of Welding Flanges To Pipe

Uploaded by

rmjiran0 ratings0% found this document useful (0 votes)

18 views1 pagewelding_flanges_to_pipe

Original Title

Methods of Welding Flanges to Pipe

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentwelding_flanges_to_pipe

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

18 views1 pageMethods of Welding Flanges To Pipe

Methods of Welding Flanges To Pipe

Uploaded by

rmjiranwelding_flanges_to_pipe

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

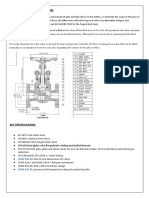

METHODS OF WELDING FLANGES TO PIPE

The methods used in welding flanges to pipe will vary

according to the type of flange and are basically the same as

those used in standard welding practices. For welding Neck

and Lap Joint Stub and Flange applications an initial root gap

spacing between pipe and flange should be 1/16 to 1/8.The

first bead must penetrate uniformly to the inside wall of the

assembly thus assuring a strong joint. The final bead should

be built up above the pipe O.D. approximately 1/16 as

shown.

LAP JOINT STUB FLANGES

WELDING NECK FLANGES

This type preferred for severe services

because it provides the greatest factor of

safety and fatigue strength. These features

make this type of flange suitable for all

pressures and temperatures for which

flanges are rated. Welding cannot cause

distortion of the flange face.

This type assembly has a lower factor of

safety in resisting pressure and fatigue than

welding neck flanges. It is available for all

pressures and temperatures for which

flanges are rated and because the flange

swivels freely on the stub, the alignment of

both holes is independent from the welding

operation. Welding cannot cause distortion of

the gasket face.

SLIP-ON FLANGES

1.4 X T

SLIP-ON FLANGES

1.4 X T

0.08 = T

MIN

SLIP-ON FLANGES

This Slip-On Flange construction necessitates refacing after welding thus reducing the

economic advantage this type flange has

over the welding neck type. It is used where

smooth bores free from pockets are desired.

Slip-On Flanges are standard in the 150 lb.

and 300 lb. classes only and because of their

lower factor of safety in resisting pressure

and fatigue, they are not recommended for

service above 750F.

1.4 X T

This Slip-On Flange is often chosen over

Welding Neck Flanges because of its lower

initial cost and is widely used because it

requires less accuracy in cutting pipe to

length and permits alignment of bolt hols

and squaring of flange faces with less

difficulty. Refacing to repair warpage or weld

spatter damage can be eliminated by the

construction shown here if care is used when

welding. Slip-On Flanges are standard in 150

lb. and 300 lb. classes only and are not

recommended for service above 750F.

T = 1/4

MAX

1.4 X T

SOCKET WELD FLANGES

52.5

1.4 X T

1.4 X T

SOCKET WELD FLANGES

For those applications in which the running

of an internal weld is particularly difficult,

this Socket Weld construction is recommended. In sizes 4 and smaller this

construction has approximately the same

resistance to internal pressure and fatigue as

the Slip-On Flanges pictured above.

SOCKET WELD FLANGES

This sock weld construction eliminates

internal pockets while avoiding warpage

from welding heat and weld spatter damage

to the flange face. It has the same resistance

to internal pressure as that of Slip-On

Flanges and better fatigue life. This

construction is recommended for all sizes in

50 lb. and 300 lb. pressure classes.

1.4 X T

1.4 X T

You might also like

- CADworx Structure Editor Users GuideDocument113 pagesCADworx Structure Editor Users GuideThiên Khánh100% (2)

- PQR - Wps - PWHT P91 To CS: Tunisian Quality EngineerDocument14 pagesPQR - Wps - PWHT P91 To CS: Tunisian Quality EngineerRajeev KhantwalNo ratings yet

- 9-Flanges & Design of Non-Standard Flange PDFDocument35 pages9-Flanges & Design of Non-Standard Flange PDFUday Gokhale75% (4)

- Flange LeakageDocument29 pagesFlange LeakageSandeep Bhatia100% (2)

- PIP P L CM0001 Pipeline Systems NomenclatureDocument18 pagesPIP P L CM0001 Pipeline Systems Nomenclatureivanov5559No ratings yet

- B.piping CodesDocument1 pageB.piping Codeskrishna_pipingNo ratings yet

- Needle ValveDocument8 pagesNeedle ValveMuhammad Chilmi100% (1)

- PmsDocument94 pagesPmssdk1978100% (1)

- PVC Pipe Making Machine 01 PDFDocument1 pagePVC Pipe Making Machine 01 PDFabdul kareeNo ratings yet

- ASTM Grades in PipingDocument1 pageASTM Grades in PipingRajkumar ANo ratings yet

- En 1092-1 PN-40 Steel Pipe FlangeDocument5 pagesEn 1092-1 PN-40 Steel Pipe FlangeHoria ZecheruNo ratings yet

- Piping Specification ChecklistDocument6 pagesPiping Specification ChecklistBinodh DanielNo ratings yet

- Vel PQCV Web Catalogo Velan Duo CheckDocument21 pagesVel PQCV Web Catalogo Velan Duo Checkel_apache10No ratings yet

- Pipes and Bends Data SheetDocument2 pagesPipes and Bends Data SheetManali PatilNo ratings yet

- Globe Valve Bs 1873 and Api 602: ASME B16.10Document7 pagesGlobe Valve Bs 1873 and Api 602: ASME B16.10swapnil PATILNo ratings yet

- DIN en Piping Code, STD by Rajesh KDocument20 pagesDIN en Piping Code, STD by Rajesh KRajesh KNo ratings yet

- Specs Chart PDFDocument1 pageSpecs Chart PDFsojeckNo ratings yet

- PD107 - Piperack For P&CDocument50 pagesPD107 - Piperack For P&C124swadeshiNo ratings yet

- Catalogo GASKET General Measurement TablesDocument20 pagesCatalogo GASKET General Measurement TablescastibraNo ratings yet

- Material Selection Chart Based On Operating TemperatureDocument1 pageMaterial Selection Chart Based On Operating TemperatureVIVEK TIWARINo ratings yet

- PIPE SpecificationDocument5 pagesPIPE SpecificationNilesh GohelNo ratings yet

- Valves Kvc07Document25 pagesValves Kvc07Dimas Anugrah MahardikaNo ratings yet

- Expansion Joints Rubber Type 40Document7 pagesExpansion Joints Rubber Type 40ductaiutcNo ratings yet

- E-F Hdpe InnogazDocument32 pagesE-F Hdpe Innogazvishnu300022No ratings yet

- SA 516 Gr60Document8 pagesSA 516 Gr60Mohammad HassanNo ratings yet

- How Do You Calculate The Width of The Pipe RackDocument3 pagesHow Do You Calculate The Width of The Pipe RackFiroz Hashmi100% (1)

- SpecificationsDocument7 pagesSpecificationsMarine SleimanNo ratings yet

- Piping Design Enginerring & Construction: Atul PatelDocument19 pagesPiping Design Enginerring & Construction: Atul Patelसरदार अतुल भाई पटेलNo ratings yet

- Piping SpecificationDocument3 pagesPiping SpecificationArun KumarNo ratings yet

- BF-PPS As Dismantling Joints - EngDocument3 pagesBF-PPS As Dismantling Joints - EngbikarexpansionjointsNo ratings yet

- Flange FacingDocument6 pagesFlange FacingDurjoy ChakrabortyNo ratings yet

- Vapor Pressure of 95% (WT) Sulfuric Acid Aqueous SolutionDocument3 pagesVapor Pressure of 95% (WT) Sulfuric Acid Aqueous SolutionJudy PerryNo ratings yet

- Eil Spec Bo16-000-80-44-Ol-S001 Rev ADocument2 pagesEil Spec Bo16-000-80-44-Ol-S001 Rev AjaganNo ratings yet

- Piping HandbookDocument17 pagesPiping HandbookangeljosNo ratings yet

- Duplex Material PDFDocument4 pagesDuplex Material PDFmengelito almonteNo ratings yet

- C 10flangesDocument11 pagesC 10flangesrajesh119100% (1)

- Valve DetailDocument5 pagesValve DetailRakesh RanjanNo ratings yet

- DOUBLE-BLADDER JOINT TESTER O & M Manual W COVER - 2018 PDFDocument17 pagesDOUBLE-BLADDER JOINT TESTER O & M Manual W COVER - 2018 PDFshafeeqm3086No ratings yet

- Ball ValveDocument14 pagesBall Valveaamer6789No ratings yet

- Swagelok Flange AdaptersDocument6 pagesSwagelok Flange AdapterstotcsabNo ratings yet

- Pipe Fittings PDFDocument164 pagesPipe Fittings PDFjlvega18No ratings yet

- ES 49BranchConnectionsDocument7 pagesES 49BranchConnectionsrodofgodNo ratings yet

- KF Check-Valves PDFDocument24 pagesKF Check-Valves PDFTaylor RamirezNo ratings yet

- DIN 2527-1972, Blank FlangesDocument6 pagesDIN 2527-1972, Blank FlangesalfredopinillosNo ratings yet

- ASTM A335 Pipe SpecificationsDocument4 pagesASTM A335 Pipe SpecificationsDhruv GohelNo ratings yet

- BS 3601Document3 pagesBS 3601nourlhudaNo ratings yet

- 23 22 13 Steam and Condensate PipingDocument15 pages23 22 13 Steam and Condensate PipingchabibNo ratings yet

- Hattersley Gate Valves 2b PDFDocument11 pagesHattersley Gate Valves 2b PDFUmmes AhmedNo ratings yet

- Catalogue-Of-Valves MSADocument52 pagesCatalogue-Of-Valves MSAJenn LozNo ratings yet

- Flange EN1092-1 TYPE 01 Flange PDFDocument4 pagesFlange EN1092-1 TYPE 01 Flange PDFVishal MistryNo ratings yet

- Lift Check Valve: Straight, Flanged EndsDocument1 pageLift Check Valve: Straight, Flanged Endsadvantage025No ratings yet

- OutoKumpu SS Pipe-2010Document124 pagesOutoKumpu SS Pipe-2010ahmedalishNo ratings yet

- Piping Codes: ASME B16 Dimensional CodesDocument9 pagesPiping Codes: ASME B16 Dimensional CodesmaxalfreNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Introduction To Flanges: Based On Pipe AttachmentDocument15 pagesIntroduction To Flanges: Based On Pipe AttachmentMohamed Al-OdatNo ratings yet

- Tipos de GasketDocument1 pageTipos de GasketOscar NietoNo ratings yet

- Reinforcing Detailing of R.C.C MembersDocument47 pagesReinforcing Detailing of R.C.C MembersAmey ShettiNo ratings yet

- FlangesDocument30 pagesFlangessbmmlaNo ratings yet

- Stock Flanges Include Socket Weld, Butt Weld, NPTF and SAE StraightDocument4 pagesStock Flanges Include Socket Weld, Butt Weld, NPTF and SAE StraightAnonymous Iev5ggSRNo ratings yet

- T C (Q 3, P 2) 1999: Y TisatangenttokatDocument4 pagesT C (Q 3, P 2) 1999: Y TisatangenttokatGraham MooreNo ratings yet

- Orddiffsolnlesson 10Document3 pagesOrddiffsolnlesson 10Graham MooreNo ratings yet

- Ordcirclesoln1998 PDFDocument3 pagesOrdcirclesoln1998 PDFGraham MooreNo ratings yet

- D & F (Q 6, 7 & 8, P 1) 2005: Ifferentiation Unctions AperDocument6 pagesD & F (Q 6, 7 & 8, P 1) 2005: Ifferentiation Unctions AperGraham MooreNo ratings yet

- Orddiffsolnlesson 13Document6 pagesOrddiffsolnlesson 13Graham MooreNo ratings yet

- Design For Manufacture and Assembly: The Boothroyd-Dewhurst ExperienceDocument22 pagesDesign For Manufacture and Assembly: The Boothroyd-Dewhurst ExperienceGraham MooreNo ratings yet

- Orddiffsolnlesson 11Document4 pagesOrddiffsolnlesson 11Graham MooreNo ratings yet

- Orddiffsolnlesson 12Document3 pagesOrddiffsolnlesson 12Graham MooreNo ratings yet

- Orddiffsolnlesson 3Document8 pagesOrddiffsolnlesson 3Graham MooreNo ratings yet

- D & F (Q 6, 7 & 8, P 1) : 7 (B) (Ii) Given That Y, 5 Find When X 2Document5 pagesD & F (Q 6, 7 & 8, P 1) : 7 (B) (Ii) Given That Y, 5 Find When X 2Graham MooreNo ratings yet

- D & F (Q 6, 7 & 8, P 1) : Ifferentiation Unctions AperDocument6 pagesD & F (Q 6, 7 & 8, P 1) : Ifferentiation Unctions AperGraham MooreNo ratings yet

- Orddiffsolnlesson 5Document5 pagesOrddiffsolnlesson 5Graham MooreNo ratings yet

- Orddiffsoln 2004Document7 pagesOrddiffsoln 2004Graham MooreNo ratings yet

- Orddiffsolnlesson 4Document3 pagesOrddiffsolnlesson 4Graham MooreNo ratings yet

- Orddiffsolnlesson 14Document10 pagesOrddiffsolnlesson 14Graham MooreNo ratings yet

- Orddiffsolnlesson 2Document9 pagesOrddiffsolnlesson 2Graham MooreNo ratings yet

- Orddiffsoln 2007Document6 pagesOrddiffsoln 2007Graham MooreNo ratings yet

- Orddiffsolnlesson 9Document12 pagesOrddiffsolnlesson 9Graham MooreNo ratings yet

- Orddiffsoln 2008Document6 pagesOrddiffsoln 2008Graham MooreNo ratings yet

- Orddiffsolnlesson 15Document7 pagesOrddiffsolnlesson 15Graham MooreNo ratings yet

- Orddiffsolnlesson 8Document7 pagesOrddiffsolnlesson 8Graham MooreNo ratings yet

- Orddiffsoln 1997Document9 pagesOrddiffsoln 1997Graham MooreNo ratings yet

- Orddiffsoln 1998Document8 pagesOrddiffsoln 1998Graham MooreNo ratings yet

- Orddiffsoln 1996Document6 pagesOrddiffsoln 1996Graham MooreNo ratings yet

- D & F (Q 6, 7 & 8, P 1) 2002: Ifferentiation Unctions AperDocument6 pagesD & F (Q 6, 7 & 8, P 1) 2002: Ifferentiation Unctions AperGraham MooreNo ratings yet

- Orddiffsoln 2000Document8 pagesOrddiffsoln 2000Graham MooreNo ratings yet

- Orddiffsoln 1999Document6 pagesOrddiffsoln 1999Graham MooreNo ratings yet

- Orddiffsolnlesson 1Document5 pagesOrddiffsolnlesson 1Graham MooreNo ratings yet

- Orddiffsoln 2006Document6 pagesOrddiffsoln 2006Graham MooreNo ratings yet

- D & F (Q 6, 7 & 8, P 1) 2001: Ifferentiation Unctions AperDocument7 pagesD & F (Q 6, 7 & 8, P 1) 2001: Ifferentiation Unctions AperGraham MooreNo ratings yet

- Engraving of Roller PrintingDocument24 pagesEngraving of Roller Printingapi-3817839100% (3)

- Plantilla WPS (SMAW) Junta TDocument1 pagePlantilla WPS (SMAW) Junta Tjhojan garciaNo ratings yet

- Vocational TrainingDocument29 pagesVocational TrainingMohammad AfzalNo ratings yet

- Auto Servis Bondowoso EMM Catalogus 2020 Colad Hamach RoninTools LRDocument104 pagesAuto Servis Bondowoso EMM Catalogus 2020 Colad Hamach RoninTools LRsupriyanto yusufNo ratings yet

- A580A580M-15 Standard Specification For Stainless Steel WireDocument5 pagesA580A580M-15 Standard Specification For Stainless Steel Wiretjt4779No ratings yet

- ME Stainless Steel Catalogue V2022Document4 pagesME Stainless Steel Catalogue V2022wqeNo ratings yet

- Material Selection For Automotive Brake Disc: Case Study 2Document39 pagesMaterial Selection For Automotive Brake Disc: Case Study 2Dhananjay ShimpiNo ratings yet

- Technical Report On Student Industrial Work Experience SchemeDocument36 pagesTechnical Report On Student Industrial Work Experience SchemeOrbital TechNo ratings yet

- Scrap-Based Steel Production and Recycling of Steel: Proizvodnja Jekla Iz Jeklenega OdpadkaDocument13 pagesScrap-Based Steel Production and Recycling of Steel: Proizvodnja Jekla Iz Jeklenega Odpadkaistanbul sörveyNo ratings yet

- (已压缩)VRF 201910V03 PDFDocument67 pages(已压缩)VRF 201910V03 PDFZeshan HaydarNo ratings yet

- Types of Pattern and Its ApplicationDocument24 pagesTypes of Pattern and Its ApplicationMitul PatelNo ratings yet

- Astm B265 (2013)Document9 pagesAstm B265 (2013)Lalit PatelNo ratings yet

- As 4291.1-2000 Mechanical Properties of Fasteners Made of Carbon Steel and Alloy Steel Bolts Screws and StudsDocument8 pagesAs 4291.1-2000 Mechanical Properties of Fasteners Made of Carbon Steel and Alloy Steel Bolts Screws and StudsSAI Global - APAC33% (3)

- Unit 3 Camilo BriñezDocument5 pagesUnit 3 Camilo BriñezJUAN CAMILO BRIEZ MONTEALEGRENo ratings yet

- L11 Mechanical FastenersDocument91 pagesL11 Mechanical FastenersSHADES 4 ALLNo ratings yet

- Standard Practice C501Document539 pagesStandard Practice C501Lucas SuarezNo ratings yet

- Olet - Complete GuideDocument8 pagesOlet - Complete GuideSanjeev KumarNo ratings yet

- KPI Card - Detailed - CSDocument6 pagesKPI Card - Detailed - CSAnilkumarGopinathanNairNo ratings yet

- Stripping Solution Section Processing Solution Immersion ElectrolyticDocument2 pagesStripping Solution Section Processing Solution Immersion ElectrolyticDavid WongNo ratings yet

- Magnetic Particle TestingDocument38 pagesMagnetic Particle Testingtbmari100% (2)

- PQR ForDocument3 pagesPQR ForAkash Singh TomarNo ratings yet

- Design and Analysis of An Industrial, Progressive Die For Cutting and FormingDocument35 pagesDesign and Analysis of An Industrial, Progressive Die For Cutting and FormingVineela ChNo ratings yet

- Non-Ferrous Metals and Alloys: Al, Cu, ZN, MG, Ti, Ni, Co, W, V and Their Alloys - All Except of Fe andDocument26 pagesNon-Ferrous Metals and Alloys: Al, Cu, ZN, MG, Ti, Ni, Co, W, V and Their Alloys - All Except of Fe andmaniNo ratings yet

- Diamondspark 52 RC: Flux Cored Wire, Seamless, Unalloyed, Rutile TypeDocument2 pagesDiamondspark 52 RC: Flux Cored Wire, Seamless, Unalloyed, Rutile TypeMahesh DeshmukhNo ratings yet

- Design and Fabrication of Drill Press MachineDocument8 pagesDesign and Fabrication of Drill Press MachineSugumar MurthyNo ratings yet

- Client Certification PackageDocument26 pagesClient Certification PackageWahyu RahmadNo ratings yet

- EDM and ECM NotesDocument25 pagesEDM and ECM NotesFRANCIS THOMASNo ratings yet

- 1SDL000192R0003 PEI - Tmax T7 - 2021Document4 pages1SDL000192R0003 PEI - Tmax T7 - 2021Jonathan LujanNo ratings yet

- 2022 Benchmade Digital CatalogDocument43 pages2022 Benchmade Digital CataloggordonsanweyNo ratings yet

- Manual Soporte Amoladora AGS 115Document4 pagesManual Soporte Amoladora AGS 115Antonino TaboadaNo ratings yet