Professional Documents

Culture Documents

Carbon Dioxide Reforming of Methane Over Niq-Al2O3 Catalysts Effect of Ni Content

Carbon Dioxide Reforming of Methane Over Niq-Al2O3 Catalysts Effect of Ni Content

Uploaded by

HVu NguyenCopyright:

Available Formats

You might also like

- Eschede Train Derailment PDFDocument18 pagesEschede Train Derailment PDFaxayjain1995100% (1)

- Temperature-Programmed Studies On Partial Oxidation of CH To Syngas Over A Ni/Al O CatalystDocument3 pagesTemperature-Programmed Studies On Partial Oxidation of CH To Syngas Over A Ni/Al O CatalystImran KhanNo ratings yet

- Cui 2007Document10 pagesCui 2007Reyner ParreirasNo ratings yet

- Hydrogen Production From Ethanol Steam Reforming Over SnO Sub 2 Sub - K Sub 2 Sub O Zeolite Y CatalystDocument9 pagesHydrogen Production From Ethanol Steam Reforming Over SnO Sub 2 Sub - K Sub 2 Sub O Zeolite Y Catalystbruno barrosNo ratings yet

- Efecto de La Calcinacion de Tio2-Al2O3Document6 pagesEfecto de La Calcinacion de Tio2-Al2O3El Aro De La CalleNo ratings yet

- Coke Formation On Pt/Zro /al O Catalysts During CH Reforming With CoDocument5 pagesCoke Formation On Pt/Zro /al O Catalysts During CH Reforming With CoWassachol SumarasinghaNo ratings yet

- 1Document7 pages1Ankit GargNo ratings yet

- Vanga Manocci ViscardiDocument6 pagesVanga Manocci Viscardieeajmal.cmdNo ratings yet

- Artikel 8 PDFDocument6 pagesArtikel 8 PDFumidwijayantiNo ratings yet

- Tri-Reforming of CH Using CO For Production of Synthesis Gas To Dimethyl EtherDocument5 pagesTri-Reforming of CH Using CO For Production of Synthesis Gas To Dimethyl EtherAnkit KumarNo ratings yet

- Methane Steam ReformingDocument8 pagesMethane Steam ReformingPanda BoyNo ratings yet

- J Ssi 2006 01 031Document9 pagesJ Ssi 2006 01 031Manoj PrakashNo ratings yet

- Calcination of Nickel-Alumina CatalystsDocument4 pagesCalcination of Nickel-Alumina CatalystsAnonymous 4PuFzAR100% (1)

- Energy Conversion and ManagementDocument43 pagesEnergy Conversion and ManagementnursyifaaNo ratings yet

- Autothermal Reforming of Simulated Gasoline and Diesel FuelsDocument8 pagesAutothermal Reforming of Simulated Gasoline and Diesel FuelsMOHAMMAD HASHIM KHANNo ratings yet

- CO2 Reforming of MethaneDocument8 pagesCO2 Reforming of Methanesorincarmen88No ratings yet

- Aromatics Hydrogenation On Silica-Alumina Supported Palladium-Nickel CatalystsDocument14 pagesAromatics Hydrogenation On Silica-Alumina Supported Palladium-Nickel Catalystsioanaandra5690No ratings yet

- Zhao 2004Document7 pagesZhao 200463011273No ratings yet

- 03po XD 3 5 PDFDocument3 pages03po XD 3 5 PDFMarcelo Varejão CasarinNo ratings yet

- Combined Steam and CO2 Reforming of CH4 Using Coke Oven Gas On Nickel-Based Catalyst - Effects of Organic Acids To Nickel Dispersion and ActivityDocument11 pagesCombined Steam and CO2 Reforming of CH4 Using Coke Oven Gas On Nickel-Based Catalyst - Effects of Organic Acids To Nickel Dispersion and ActivityWassachol SumarasinghaNo ratings yet

- Carbon Dioxide Reforming of Methane Over NiAl2O3 Treated With Glow Discharge PlasmaDocument6 pagesCarbon Dioxide Reforming of Methane Over NiAl2O3 Treated With Glow Discharge PlasmaViệtDũng TôNo ratings yet

- Carbon Dioxide Reforming of Methane Over NiAl2O3 Treated With Glow Discharge PlasmaDocument6 pagesCarbon Dioxide Reforming of Methane Over NiAl2O3 Treated With Glow Discharge PlasmaViệtDũng TôNo ratings yet

- Hydrogen Production by Steam Reforming of Commercially Available LPG in UAEDocument8 pagesHydrogen Production by Steam Reforming of Commercially Available LPG in UAEEng MohammedNo ratings yet

- Report PDFDocument10 pagesReport PDFShubham GoelNo ratings yet

- Autothermal Reforming ProcessDocument9 pagesAutothermal Reforming ProcessOliver Everett EspinoNo ratings yet

- Hydrocracking and Hydroisomerization of N-Hexadecane PT - 5Document11 pagesHydrocracking and Hydroisomerization of N-Hexadecane PT - 5ancaene99No ratings yet

- Methane Transformation Using Light Gasoline As Co-Reactant Over Zn/H-ZSM11Document6 pagesMethane Transformation Using Light Gasoline As Co-Reactant Over Zn/H-ZSM11Everyday Lentzery HogarNo ratings yet

- Mo2C-HYDocument11 pagesMo2C-HYioanaandra5690No ratings yet

- Catalytic Reforming of Methane With Carbon Dioxide Over Nickel Catalysts II. Reaction KineticsDocument26 pagesCatalytic Reforming of Methane With Carbon Dioxide Over Nickel Catalysts II. Reaction KineticsDiego LVNo ratings yet

- Production of Hydrogen by Steam Reforming of Ethanol Over A Ni/Zno CatalystDocument6 pagesProduction of Hydrogen by Steam Reforming of Ethanol Over A Ni/Zno Catalystpetro121No ratings yet

- Catalytic Oxidation of NO To NO2 For Nitric Acid Production Over A Pt-Al2O3Document5 pagesCatalytic Oxidation of NO To NO2 For Nitric Acid Production Over A Pt-Al2O3AnanthakishnanNo ratings yet

- CO2 Reforming of CH4 Over Nickel and Cobalt CatalystsDocument6 pagesCO2 Reforming of CH4 Over Nickel and Cobalt CatalystsEdwin CaceresNo ratings yet

- A Comparative Study of Water-Gas-Shift Reaction Over Ceria Supported Metallic CatalystsDocument8 pagesA Comparative Study of Water-Gas-Shift Reaction Over Ceria Supported Metallic CatalystsleonardoNo ratings yet

- Syngas Production From Methane Dry Reforming Over Ni/SBA-15 Catalyst: Effect of Operating ParametersDocument12 pagesSyngas Production From Methane Dry Reforming Over Ni/SBA-15 Catalyst: Effect of Operating ParametersWassachol SumarasinghaNo ratings yet

- Efectt of CaoDocument11 pagesEfectt of CaoAlfonso RamosNo ratings yet

- Tomishige 2000Document11 pagesTomishige 2000aminaNo ratings yet

- Production of Hydrogen Over Bimetallic Pt-Ni/d-Al O I. Indirect Partial Oxidation of PropaneDocument8 pagesProduction of Hydrogen Over Bimetallic Pt-Ni/d-Al O I. Indirect Partial Oxidation of PropaneleylaNo ratings yet

- Au-Pt/Co O Catalyst For Methane Combustion: LetterDocument4 pagesAu-Pt/Co O Catalyst For Methane Combustion: LetterfafaporkNo ratings yet

- Low Temperature Catalytic Reverse Water-Gas Shift ReactionDocument14 pagesLow Temperature Catalytic Reverse Water-Gas Shift ReactionRen FengNo ratings yet

- Ammonia Oxidation Into Nitrous Oxide Over Mn-Bi-Al Catalyst I Pokrovskaya Et Al Chem Eng J 2003 PDFDocument8 pagesAmmonia Oxidation Into Nitrous Oxide Over Mn-Bi-Al Catalyst I Pokrovskaya Et Al Chem Eng J 2003 PDFjuan davidNo ratings yet

- Hydrogen Production by Catalytic Decomposition of Methane: Naresh Shah, Devadas Panjala, and Gerald P. HuffmanDocument7 pagesHydrogen Production by Catalytic Decomposition of Methane: Naresh Shah, Devadas Panjala, and Gerald P. HuffmanMuhammad HarisNo ratings yet

- J Ijhydene 2008 02 029Document8 pagesJ Ijhydene 2008 02 029Wassachol SumarasinghaNo ratings yet

- Syngas Production Via Combined Steam and Carbon Dioxide Reforming of Methane Over Ni-Ce - MgAl2O4 Catalysts With Enhanced Coke ResistanceDocument7 pagesSyngas Production Via Combined Steam and Carbon Dioxide Reforming of Methane Over Ni-Ce - MgAl2O4 Catalysts With Enhanced Coke ResistanceWassachol SumarasinghaNo ratings yet

- Steam Reforming of Bagasse To Hydrogen and Synthesis Gas Using Ruthenium Promoted Niefe/Geal O Nano-CatalystsDocument8 pagesSteam Reforming of Bagasse To Hydrogen and Synthesis Gas Using Ruthenium Promoted Niefe/Geal O Nano-CatalystsViet Quoc DinhNo ratings yet

- Improving Sulphur Tolerance of Methane Combustion Catalysts: R. Torbati, L. Lisi, S. Cimino, G. RussoDocument6 pagesImproving Sulphur Tolerance of Methane Combustion Catalysts: R. Torbati, L. Lisi, S. Cimino, G. RussoJohnny SaavedraNo ratings yet

- Energy Source From Hydrogen Production by Methane Dry ReformingDocument8 pagesEnergy Source From Hydrogen Production by Methane Dry ReformingNguyễn Hoàng HàNo ratings yet

- SL - PAP - F.Muller O.Kleppa - 1972 - Thermodynamics of Formation of Chromite SpinelsDocument6 pagesSL - PAP - F.Muller O.Kleppa - 1972 - Thermodynamics of Formation of Chromite SpinelsEduardo CandelaNo ratings yet

- Hydrogenation of Ethyl Acetate To Ethanol Over Bimetallic Cu-Zn/Sio Catalysts Prepared by Means of CoprecipitationDocument6 pagesHydrogenation of Ethyl Acetate To Ethanol Over Bimetallic Cu-Zn/Sio Catalysts Prepared by Means of CoprecipitationAtul TripathiNo ratings yet

- MN - (Co Y-O Ce)Document8 pagesMN - (Co Y-O Ce)Karen CruzNo ratings yet

- PrecursorsDocument4 pagesPrecursorssimonwadelinNo ratings yet

- Steam Cracking of Naphtha in Packed Bed ReactorsDocument6 pagesSteam Cracking of Naphtha in Packed Bed Reactorscandidater100% (1)

- Catalytic Activation of Methane Using N-Pentane As Co-Reactant Over Zn/H-ZSM-11 ZeoliteDocument5 pagesCatalytic Activation of Methane Using N-Pentane As Co-Reactant Over Zn/H-ZSM-11 ZeoliteEveryday Lentzery HogarNo ratings yet

- AC Catalst PTDocument5 pagesAC Catalst PTJarretNo ratings yet

- 44 NOx ReductionDocument24 pages44 NOx ReductionJsueNo ratings yet

- Hydrogenation and Ring Opening of Naphthalene On Bulk and Supported Mo C CatalystsDocument11 pagesHydrogenation and Ring Opening of Naphthalene On Bulk and Supported Mo C Catalystsioanaandra5690No ratings yet

- CO2 Reforming of CH4 Over Supported Ru CatalystsDocument7 pagesCO2 Reforming of CH4 Over Supported Ru CatalystsPedro lopezNo ratings yet

- Preparation and Characterization of Sno Catalysts For Co and CH OxidationDocument13 pagesPreparation and Characterization of Sno Catalysts For Co and CH Oxidationbruno barrosNo ratings yet

- Thermochemical CO Splitting Reaction With Supported La A Fe B O (A SR, Ce, B Co, MN 0 6 X, y 6 1) Perovskite OxidesDocument13 pagesThermochemical CO Splitting Reaction With Supported La A Fe B O (A SR, Ce, B Co, MN 0 6 X, y 6 1) Perovskite OxidesRuben Montenegro BulaNo ratings yet

- Applied Surface Science 356 (2015) 181-190Document10 pagesApplied Surface Science 356 (2015) 181-190MadalinaNo ratings yet

- Activities and Selectivities Temperatures Relevant Chemical Interconversions Copper Metal-Oxide Catalysts at Heat-Pumps Based Isopropanol/ AcetoneDocument4 pagesActivities and Selectivities Temperatures Relevant Chemical Interconversions Copper Metal-Oxide Catalysts at Heat-Pumps Based Isopropanol/ AcetoneOlga ĆalasanNo ratings yet

- European Practice On Design&Construction of Concrete PavementsDocument103 pagesEuropean Practice On Design&Construction of Concrete Pavementsshakirhamid6687No ratings yet

- Bolted Connection DesignDocument25 pagesBolted Connection Designkulov1592No ratings yet

- Group 4 - Chapters 1-3Document14 pagesGroup 4 - Chapters 1-3Angel Trisha MariNo ratings yet

- Hobersal Muffle Furnaces PR SeriesDocument2 pagesHobersal Muffle Furnaces PR Seriesinna husnaNo ratings yet

- Graco Husky 3275 Diaphragm Pump Data SheetDocument8 pagesGraco Husky 3275 Diaphragm Pump Data SheetMROstop.comNo ratings yet

- Chapter 1 - Aircond & VentilationDocument54 pagesChapter 1 - Aircond & Ventilationepy87No ratings yet

- Shop Floor Management TutorialDocument45 pagesShop Floor Management TutorialDilan FernandoNo ratings yet

- SPDI Refresher Test PaperDocument12 pagesSPDI Refresher Test PaperJohn Rey PelobelloNo ratings yet

- Lantek Expert Punch 1p (EN-UK)Document2 pagesLantek Expert Punch 1p (EN-UK)LantekNo ratings yet

- Ipsen Furnace Turbo CoolingDocument8 pagesIpsen Furnace Turbo CoolingArun KrishnaNo ratings yet

- Document No. 6544-00-HH-DS-004, Rev. A Data Sheet Eot CraneDocument7 pagesDocument No. 6544-00-HH-DS-004, Rev. A Data Sheet Eot CraneSachin5586No ratings yet

- Catalytic HydrodearomatizationDocument42 pagesCatalytic Hydrodearomatizational3x4n9No ratings yet

- FSP Hydro G PRO User ManualDocument47 pagesFSP Hydro G PRO User ManualCuong TranNo ratings yet

- Tarea #1 PDFDocument2 pagesTarea #1 PDFManuel Hernández MontecilloNo ratings yet

- Itp Line PipeDocument8 pagesItp Line Pipekaml100% (1)

- TA2512 Manual PDFDocument2 pagesTA2512 Manual PDFMariaNo ratings yet

- 360 Degree Flexible Drilling MachineDocument24 pages360 Degree Flexible Drilling MachineDHINESH IT67% (3)

- XG32-130-001 - Rev 1 - REV1 - SIGNED - AG PIPING ISOMETRIC DRAWING FOR WBS 130 PDFDocument606 pagesXG32-130-001 - Rev 1 - REV1 - SIGNED - AG PIPING ISOMETRIC DRAWING FOR WBS 130 PDFjosejohn1No ratings yet

- 2.0 Daikin - Unidad Evaporadora AHU 7.5 Ton, CatalogoDocument16 pages2.0 Daikin - Unidad Evaporadora AHU 7.5 Ton, CatalogoarmandoNo ratings yet

- 6 in Ferrule 316 SS HN 150522 Cert ST160129-07 Zhejiang Stellar Pipe Industry Co., LTDDocument1 page6 in Ferrule 316 SS HN 150522 Cert ST160129-07 Zhejiang Stellar Pipe Industry Co., LTDJennifer FrenchNo ratings yet

- C10550270Document2 pagesC10550270foroNo ratings yet

- Presentation For Conference ImproveDocument33 pagesPresentation For Conference ImprovekamalNo ratings yet

- TDS - Mastertop 1210 PlusDocument2 pagesTDS - Mastertop 1210 PlusVenkata RaoNo ratings yet

- CL-NG-6460-002-027 Checklist For GIS Rev01Document6 pagesCL-NG-6460-002-027 Checklist For GIS Rev01WajahatNo ratings yet

- TELENGANA BUSINESS DIRECTORY PENEL D-PanelDocument65 pagesTELENGANA BUSINESS DIRECTORY PENEL D-Panelamandeep100% (4)

- VOSS Automotive Valve CatalogueDocument41 pagesVOSS Automotive Valve CatalogueManuel Pedro InácioNo ratings yet

- A Novel: Battery Charger Random Sound Sources Air PressureDocument30 pagesA Novel: Battery Charger Random Sound Sources Air PressureSNEHA LIZ PAULNo ratings yet

- Special Considerations in Marine Pile Design and ConstructionDocument3 pagesSpecial Considerations in Marine Pile Design and ConstructionNitinShepurNo ratings yet

- A500 Vs A513Document2 pagesA500 Vs A513Angelo CubillosNo ratings yet

Carbon Dioxide Reforming of Methane Over Niq-Al2O3 Catalysts Effect of Ni Content

Carbon Dioxide Reforming of Methane Over Niq-Al2O3 Catalysts Effect of Ni Content

Uploaded by

HVu NguyenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Carbon Dioxide Reforming of Methane Over Niq-Al2O3 Catalysts Effect of Ni Content

Carbon Dioxide Reforming of Methane Over Niq-Al2O3 Catalysts Effect of Ni Content

Uploaded by

HVu NguyenCopyright:

Available Formats

1166

Bull. Korean Chem. Soc. 2002, Vol. 23, No. 8

Notes

Carbon Dioxide Reforming of Methane over Ni/-Al2O3 Catalysts:

Effect of Ni Content

Hyun-Seog Roh, Ki-Won Jun,* Seung-Chan Baek, and Sang-Eon Park*

Catalysis Center for Molecular Engineering, Korea Research Institute of Chemical Technology,

P.O. Box 107, Yuseong, Daejeon 305-600, Korea

Received April 22, 2002

Key words : -Al2O3, CH4, CO2, Ni, Reforming

Recently, carbon dioxide reforming of methane (CDR) to

produce synthesis gas attracts many researchers for the

chemical utilization of natural gas and carbon dioxide,

which are suspected to be greenhouse gases.1 The major

interest in CDR originates from the demand of the production of liquid hydrocarbons and oxygenates, e.g. acetic acid,

formaldehyde, and oxoalcohols since this reaction gives

synthesis gas with a H2/CO ratio of about 1.2 However, this

reaction has a disadvantage of serious coking on the reforming catalyst. For this reason, a number of studies have been

focused on the development of a coke-resistant catalyst for

CDR.1-7 The catalysts based on noble metals have been

found to be less sensitive to carbon deposition.7 However,

considering the high cost and limited availability of noble

metals, it is more practical in industrial standpoint to

develop Ni-based catalysts with high performance and high

resistance to carbon deposition.

As a catalyst for CDR, Ni/-Al2O3 catalyst has been used.8

However, Ni/-Al2O3 is usually unstable at high temperature

(>1000 K) because of the thermal deterioration of the Al2O3 support as well as phase transformation into -Al2O3.

Therefore, it is necessary to modify the -Al2O3 support in

order to obtain thermally stable support. Xiong and coworkers9 modified Ni/-Al2O3 with alkali metal oxide and

rare earth metal oxide, and reported high performance with

excellent stability. We attempted to prepare a stable Ni/Al2O3 catalyst which overcomes the demerits of Ni/-Al2O3

catalyst without further modification, and successfully performed partial oxidation of methane (POM) over Ni/-Al2O3

with high activity as well as high stability.10 We also applied

Ni/-Al2O3 to steam reforming of methane (SRM) and oxySRM (OSRM) resulting in high activity and high stability.11

We report here as a note that Ni/-Al2O3 exhibited also a

good catalytic performance in CDR.

Experimental Section

Support materials employed in this study were -Al2O3

(SBET = 234 m 2/g) and -Al2O3 (SBET = 167 m2/g), which

was prepared by calcining -Al2O3 at 1173 K for 6 h. Supported Ni catalysts with various Ni loading were prepared by

impregnating appropriate amounts of Ni(NO3)26H2O onto

supports followed by drying at 373 K and calcining at 823 K

for 6 h in air. Ni/MgAl 2O4 (SBET = 18 m2/g), which has been

used as a commercial SRM catalyst, was also employed for

CDR as comparison. Activity tests were carried out using a

fixed-bed quartz reactor.10-16 Reactant gas was composed of

CH4:CO2:N2 = 1:1:3. The activity tests were carried out at

1073 K and 60,000 mL/gcath. N2 was employed as a

reference gas for calculating both CH4 and CO2 conversion.

Each catalyst was reduced in the reactor with 5% H2/N2 at

973 K for 2 h prior to each catalytic measurement. Effluent

gases from the reactor were analyzed by a gas chromatograph (Chrompack CP9001) equipped with a thermal conductivity detector (TCD). GC column used in this study was

a Fused Silica capillary column (CarboPLOT P7). The BET

specific surface areas were measured by nitrogen adsorption

at 77 K using a Micromeritics instrument (ASAP-2400). The

Ni surface area was calculated according to the reference17

by assuming the adsorption stoichiometry of one hydrogen

atom per nickel surface atom (H/Nis=1).

Results and Discussion

BET surface areas of 3-15% NiO/-Al2O3 catalysts are in

the range of 160-138 m2/g. Generally, the BET surface area

decreases with increasing Ni content. These values are

smaller than those of NiO/-Al2O3 by about 50 owing to the

heat treatment at 1173 K for 6 h. As a result, it can be

expected that Ni/-Al2O3 catalysts are more stable than Ni/

-Al2O3 catalysts during CDR. Ni surface areas of 3, 6, 12,

15% NiO/-Al2O3 catalysts are 0.25, 1.02, 2.45 and 3.35 m2/g,

respectively. Average crystallite diameters are about 20 nm

above 6% Ni loading, indicating that Ni is well dispersed

on the support. The detailed characterization results were

reported in an earlier publication.11

TPR patterns of NiO/-Al2O3 with various Ni loadings

have three distinct peaks.11 One (peak maximum = 753 K) is

the free NiO species, the second peak (peak maximum = 913

K) can be assigned to the complex NiOx species having the

strong interaction with -Al2O3, and the third peak (peak

maximum = 1073 K) is highly dispersed NiAl2O4 species.

NiO/-Al2O3 catalysts having more than 6 wt% Ni show

both NiO and NiOx species. This indicates that Ni was

deposited on the thermally stable -Al2O3, so that NiOx

species are formed rather than NiAl2O4. Comparison of TPR

patterns between NiO/-Al2O3 and NiO/-Al2O3 catalysts

revealed that the Ni-support interaction is stronger in NiO/

Notes

Bull. Korean Chem. Soc. 2002, Vol. 23, No. 8

1167

Figure 1. CH4 conversion with time on stream over Ni/-Al2O3

catalysts in CDR (Reaction conditions: P = 1 atm, T = 1073 K,

CH4/CO2/N2 = 1/1/3, GHSV = 60,000 mL/gcath).

Figure 2. Comparison of CDR activity between 12% Ni/-Al2O3

catalyst and 12% Ni/MgAl2O4 catalyst (Reaction conditions: P = 1

atm, T = 1073 K, CH4/CO2/N2 = 1/1/3, GHSV = 60,000 mL/gcath).

-Al2O3. Thus, the temperature assigned to NiOx peak of

NiO/-Al2O3 is 50 K lower than that of NiO/-Al2O3. In the

case of NiO/-Al2O3 catalysts, two peaks can be separated

and there is no free NiO species. NiOx species (peak

maximum = 963 K) and highly dispersed NiAl2O4 species

(peak maximum = 1073 K) appear. Since, it is well known

that a chemical interaction between Ni and -Al2O3 leads to

the formation of spinel NiAl2O4 having almost negligible

activity in the reforming reaction,10,11,16 it can be strongly

expected that NiOx species over Ni/-Al2O3 are more stable

and effective in CDR than those over Ni/-Al2O3.

Figure 1 describes the Ni content effect on CH4 conversion over Ni/-Al2O3 catalysts. 3% Ni catalyst deactivated

with time on stream due to the phase transformation into

inactive NiAl2O4. After the reaction, NiAl2O4 formation was

confirmed from the color change of the used catalyst from

black to blue. In the case of 6% Ni catalyst, initial CH4

conversion was 97% but it slightly decreased to 96% after

17 h. For the catalysts with 9-12% Ni loading, however, CH4

conversions were 97% without catalyst deactivation. Thus, it

is likely that optimum Ni content is about 9-12%. In the case

of 15% Ni loading, CH4 conversion was initially 96% and it

slowly decreased to 95% after 20 h. This is due to coke

formation during CDR resulting from Ni sintering. This

result is in good agreement with catalytic performances in

POM, SRM, OSRM over the same catalyst.11 According to

the TPR pattern of 15% Ni/-Al2O3 catalyst,11 this catalyst

has a considerable amount of free NiO species which

resulted in Ni sintering during the reforming reactions. Even

though, due to too small amount of the catalyst employed,

the amount of carbon deposition was not measured quantitatively over 15% Ni/-Al2O3 in CDR, carbon deposition on

the quartz reactor was clearly observed after the reaction of

20 h. Except 15% catalyst, carbon was not seen over Ni/

-Al2O3 catalysts having less than 15% Ni loading.

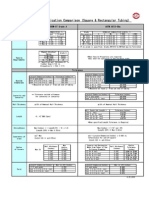

Table 1 summarizes CH4 conversion, CO2 conversion, H2

yield, CO yield and H2/CO ratio over Ni/-Al2O3 catalysts.

The trend of CO2 conversion was closely similar to that of

CH4 conversion but CO2 conversion was 1% higher than

CH4 conversion. Besides, H2 yield is slightly lower than CH4

conversion but CO yield is slightly higher than CH4 conversion. This suggests that there is reverse water gas shift

reaction (RWGS: H2 + CO2 H2O + CO) during CDR.

Thus, H2/CO ratio is usually 0.96-0.97, which is just slightly

lower than unity.

In order to evaluate catalytic activity and stability of Ni/

-Al2O3 catalyst, the performance of 12% Ni catalyst was

compared with 12% Ni/MgAl2O4, which is a commercially

available SRM catalyst. Figure 2 illustrates the comparison

result. Ni/MgAl2O4 rapidly deactivated with time on stream

owing to the carbon formation during the reaction. Ni/

-Al2O3 catalyst, however, showed stable activity during 20

h. Thus, it was confirmed that Ni/-Al2O3 catalyst is more

active and stable in CDR.

In summary, stable Ni/-Al2O3 catalyst can be prepared by

heat treatment of -Al2O3 at 1173 K for 6 h and can be used

for CDR. Low Ni loading catalysts deactivated with time on

stream due to the transformation into inactive NiAl2O4 during the reaction, high Ni loading catalyst (15%) deactivated

due to carbon formation, and 9-12% Ni loading is considered as the optimum value in CDR.

Table 1. Ni content effect on CH4 conversion, CO2 conversion, H2

yield, CO yield and H2/CO ratio over Ni/-Al2O3 catalysts in CDR

Ni content

(%)

XCH4

(%)

XCO2

(%)

YH2

(%)

YCO

(%)

H2/CO

ratio

6

9

12

15

96

97

97

95

97

98

98

96

94

96

96

94

99

100

100

97

0.96

0.96

0.96

0.97

(Reaction conditions: P = 1 atm, T = 1073 K, CH4/CO2/N2 = 1/1/3, GHSV

= 60,000 mL/gcath).

References

1. Bradford, M. C. J.; Vannice, M. A. Catal. Rev.-Sci. Eng. 1999, 41, 1.

1168

Bull. Korean Chem. Soc. 2002, Vol. 23, No. 8

2. Rostrup-Nielsen, J. R. Stud. Surf. Sci. Catal. 1993, 81, 25.

3. Ashcroft, A. T.; Cheetham, A. K.; Green, M. L. H.; Vernon, P. D.

F. Nature 1991, 352, 225.

4. Zhang, Z.; Verykios, X. E.; MacDonald, S. M.; Affrossman, S. J.

Phys. Chem. 1996, 100, 744.

5. Ruckenstein, E.; Hu, Y. H. Appl. Catal. A 1998, 51, 183.

6. Chang, J.-S.; Park, S.-E.; Chon, H. Appl. Catal. A 1996, 145, 111.

7. Nakamura, J.; Aikawa, K.; Sato, K.; Uchijima, T. Catal. Lett.

1994, 25, 265.

8. Jung, K.-S.; Coh, B.-Y.; Lee, H.-I. Bull. Korean Chem. Soc. 1999,

20, 89.

9. Miao, Q.; Xiong, G.; Sheng, S.; Cui, W.; Xu, L.; Guo, X. Appl.

Catal. A 1997, 154, 17.

10. Roh, H.-S.; Jun, K.-W.; Dong, W.-S.; Park, S.-E.; Joe, Y.-I.

Notes

Chem. Lett. 2001, 666.

11. Roh, H.-S.; Jun, K.-W.; Dong, W.-S.; Baek, S.-C.; Park, S.-E. J.

Ind. Eng. Chem. 2002, submitted.

12. Roh, H.-S.; Jun, K.-W.; Dong, W.-S.; Park, S.-E.; Baek, Y.-S.

Catal. Lett. 2001, 74, 31.

13. Roh, H.-S.; Dong, W.-S.; Jun, K.-W.; Park, S.-E. Chem. Lett.

2001, 88.

14. Dong, W.-S.; Roh, H.-S.; Liu, Z.-W.; Jun, K.-W.; Park, S.-E. Bull.

Korean Chem. Soc. 2001, 22, 1323.

15. Roh, H.-S.; Jun, K.-W.; Baek, S.-C.; Park, S.-E. Bull. Korean

Chem. Soc. 2002, 23, 793.

16. Roh, H.-S.; Dong, W.-S.; Jun, K.-W.; Liu, Z.-W.; Park, S.-E.; Oh,

Y.-S. Bull. Korean Chem. Soc. 2002, 23, 669.

17. Bartholomew, C. H.; Pannell, R. B. J. Catal. 1980, 65, 390.

You might also like

- Eschede Train Derailment PDFDocument18 pagesEschede Train Derailment PDFaxayjain1995100% (1)

- Temperature-Programmed Studies On Partial Oxidation of CH To Syngas Over A Ni/Al O CatalystDocument3 pagesTemperature-Programmed Studies On Partial Oxidation of CH To Syngas Over A Ni/Al O CatalystImran KhanNo ratings yet

- Cui 2007Document10 pagesCui 2007Reyner ParreirasNo ratings yet

- Hydrogen Production From Ethanol Steam Reforming Over SnO Sub 2 Sub - K Sub 2 Sub O Zeolite Y CatalystDocument9 pagesHydrogen Production From Ethanol Steam Reforming Over SnO Sub 2 Sub - K Sub 2 Sub O Zeolite Y Catalystbruno barrosNo ratings yet

- Efecto de La Calcinacion de Tio2-Al2O3Document6 pagesEfecto de La Calcinacion de Tio2-Al2O3El Aro De La CalleNo ratings yet

- Coke Formation On Pt/Zro /al O Catalysts During CH Reforming With CoDocument5 pagesCoke Formation On Pt/Zro /al O Catalysts During CH Reforming With CoWassachol SumarasinghaNo ratings yet

- 1Document7 pages1Ankit GargNo ratings yet

- Vanga Manocci ViscardiDocument6 pagesVanga Manocci Viscardieeajmal.cmdNo ratings yet

- Artikel 8 PDFDocument6 pagesArtikel 8 PDFumidwijayantiNo ratings yet

- Tri-Reforming of CH Using CO For Production of Synthesis Gas To Dimethyl EtherDocument5 pagesTri-Reforming of CH Using CO For Production of Synthesis Gas To Dimethyl EtherAnkit KumarNo ratings yet

- Methane Steam ReformingDocument8 pagesMethane Steam ReformingPanda BoyNo ratings yet

- J Ssi 2006 01 031Document9 pagesJ Ssi 2006 01 031Manoj PrakashNo ratings yet

- Calcination of Nickel-Alumina CatalystsDocument4 pagesCalcination of Nickel-Alumina CatalystsAnonymous 4PuFzAR100% (1)

- Energy Conversion and ManagementDocument43 pagesEnergy Conversion and ManagementnursyifaaNo ratings yet

- Autothermal Reforming of Simulated Gasoline and Diesel FuelsDocument8 pagesAutothermal Reforming of Simulated Gasoline and Diesel FuelsMOHAMMAD HASHIM KHANNo ratings yet

- CO2 Reforming of MethaneDocument8 pagesCO2 Reforming of Methanesorincarmen88No ratings yet

- Aromatics Hydrogenation On Silica-Alumina Supported Palladium-Nickel CatalystsDocument14 pagesAromatics Hydrogenation On Silica-Alumina Supported Palladium-Nickel Catalystsioanaandra5690No ratings yet

- Zhao 2004Document7 pagesZhao 200463011273No ratings yet

- 03po XD 3 5 PDFDocument3 pages03po XD 3 5 PDFMarcelo Varejão CasarinNo ratings yet

- Combined Steam and CO2 Reforming of CH4 Using Coke Oven Gas On Nickel-Based Catalyst - Effects of Organic Acids To Nickel Dispersion and ActivityDocument11 pagesCombined Steam and CO2 Reforming of CH4 Using Coke Oven Gas On Nickel-Based Catalyst - Effects of Organic Acids To Nickel Dispersion and ActivityWassachol SumarasinghaNo ratings yet

- Carbon Dioxide Reforming of Methane Over NiAl2O3 Treated With Glow Discharge PlasmaDocument6 pagesCarbon Dioxide Reforming of Methane Over NiAl2O3 Treated With Glow Discharge PlasmaViệtDũng TôNo ratings yet

- Carbon Dioxide Reforming of Methane Over NiAl2O3 Treated With Glow Discharge PlasmaDocument6 pagesCarbon Dioxide Reforming of Methane Over NiAl2O3 Treated With Glow Discharge PlasmaViệtDũng TôNo ratings yet

- Hydrogen Production by Steam Reforming of Commercially Available LPG in UAEDocument8 pagesHydrogen Production by Steam Reforming of Commercially Available LPG in UAEEng MohammedNo ratings yet

- Report PDFDocument10 pagesReport PDFShubham GoelNo ratings yet

- Autothermal Reforming ProcessDocument9 pagesAutothermal Reforming ProcessOliver Everett EspinoNo ratings yet

- Hydrocracking and Hydroisomerization of N-Hexadecane PT - 5Document11 pagesHydrocracking and Hydroisomerization of N-Hexadecane PT - 5ancaene99No ratings yet

- Methane Transformation Using Light Gasoline As Co-Reactant Over Zn/H-ZSM11Document6 pagesMethane Transformation Using Light Gasoline As Co-Reactant Over Zn/H-ZSM11Everyday Lentzery HogarNo ratings yet

- Mo2C-HYDocument11 pagesMo2C-HYioanaandra5690No ratings yet

- Catalytic Reforming of Methane With Carbon Dioxide Over Nickel Catalysts II. Reaction KineticsDocument26 pagesCatalytic Reforming of Methane With Carbon Dioxide Over Nickel Catalysts II. Reaction KineticsDiego LVNo ratings yet

- Production of Hydrogen by Steam Reforming of Ethanol Over A Ni/Zno CatalystDocument6 pagesProduction of Hydrogen by Steam Reforming of Ethanol Over A Ni/Zno Catalystpetro121No ratings yet

- Catalytic Oxidation of NO To NO2 For Nitric Acid Production Over A Pt-Al2O3Document5 pagesCatalytic Oxidation of NO To NO2 For Nitric Acid Production Over A Pt-Al2O3AnanthakishnanNo ratings yet

- CO2 Reforming of CH4 Over Nickel and Cobalt CatalystsDocument6 pagesCO2 Reforming of CH4 Over Nickel and Cobalt CatalystsEdwin CaceresNo ratings yet

- A Comparative Study of Water-Gas-Shift Reaction Over Ceria Supported Metallic CatalystsDocument8 pagesA Comparative Study of Water-Gas-Shift Reaction Over Ceria Supported Metallic CatalystsleonardoNo ratings yet

- Syngas Production From Methane Dry Reforming Over Ni/SBA-15 Catalyst: Effect of Operating ParametersDocument12 pagesSyngas Production From Methane Dry Reforming Over Ni/SBA-15 Catalyst: Effect of Operating ParametersWassachol SumarasinghaNo ratings yet

- Efectt of CaoDocument11 pagesEfectt of CaoAlfonso RamosNo ratings yet

- Tomishige 2000Document11 pagesTomishige 2000aminaNo ratings yet

- Production of Hydrogen Over Bimetallic Pt-Ni/d-Al O I. Indirect Partial Oxidation of PropaneDocument8 pagesProduction of Hydrogen Over Bimetallic Pt-Ni/d-Al O I. Indirect Partial Oxidation of PropaneleylaNo ratings yet

- Au-Pt/Co O Catalyst For Methane Combustion: LetterDocument4 pagesAu-Pt/Co O Catalyst For Methane Combustion: LetterfafaporkNo ratings yet

- Low Temperature Catalytic Reverse Water-Gas Shift ReactionDocument14 pagesLow Temperature Catalytic Reverse Water-Gas Shift ReactionRen FengNo ratings yet

- Ammonia Oxidation Into Nitrous Oxide Over Mn-Bi-Al Catalyst I Pokrovskaya Et Al Chem Eng J 2003 PDFDocument8 pagesAmmonia Oxidation Into Nitrous Oxide Over Mn-Bi-Al Catalyst I Pokrovskaya Et Al Chem Eng J 2003 PDFjuan davidNo ratings yet

- Hydrogen Production by Catalytic Decomposition of Methane: Naresh Shah, Devadas Panjala, and Gerald P. HuffmanDocument7 pagesHydrogen Production by Catalytic Decomposition of Methane: Naresh Shah, Devadas Panjala, and Gerald P. HuffmanMuhammad HarisNo ratings yet

- J Ijhydene 2008 02 029Document8 pagesJ Ijhydene 2008 02 029Wassachol SumarasinghaNo ratings yet

- Syngas Production Via Combined Steam and Carbon Dioxide Reforming of Methane Over Ni-Ce - MgAl2O4 Catalysts With Enhanced Coke ResistanceDocument7 pagesSyngas Production Via Combined Steam and Carbon Dioxide Reforming of Methane Over Ni-Ce - MgAl2O4 Catalysts With Enhanced Coke ResistanceWassachol SumarasinghaNo ratings yet

- Steam Reforming of Bagasse To Hydrogen and Synthesis Gas Using Ruthenium Promoted Niefe/Geal O Nano-CatalystsDocument8 pagesSteam Reforming of Bagasse To Hydrogen and Synthesis Gas Using Ruthenium Promoted Niefe/Geal O Nano-CatalystsViet Quoc DinhNo ratings yet

- Improving Sulphur Tolerance of Methane Combustion Catalysts: R. Torbati, L. Lisi, S. Cimino, G. RussoDocument6 pagesImproving Sulphur Tolerance of Methane Combustion Catalysts: R. Torbati, L. Lisi, S. Cimino, G. RussoJohnny SaavedraNo ratings yet

- Energy Source From Hydrogen Production by Methane Dry ReformingDocument8 pagesEnergy Source From Hydrogen Production by Methane Dry ReformingNguyễn Hoàng HàNo ratings yet

- SL - PAP - F.Muller O.Kleppa - 1972 - Thermodynamics of Formation of Chromite SpinelsDocument6 pagesSL - PAP - F.Muller O.Kleppa - 1972 - Thermodynamics of Formation of Chromite SpinelsEduardo CandelaNo ratings yet

- Hydrogenation of Ethyl Acetate To Ethanol Over Bimetallic Cu-Zn/Sio Catalysts Prepared by Means of CoprecipitationDocument6 pagesHydrogenation of Ethyl Acetate To Ethanol Over Bimetallic Cu-Zn/Sio Catalysts Prepared by Means of CoprecipitationAtul TripathiNo ratings yet

- MN - (Co Y-O Ce)Document8 pagesMN - (Co Y-O Ce)Karen CruzNo ratings yet

- PrecursorsDocument4 pagesPrecursorssimonwadelinNo ratings yet

- Steam Cracking of Naphtha in Packed Bed ReactorsDocument6 pagesSteam Cracking of Naphtha in Packed Bed Reactorscandidater100% (1)

- Catalytic Activation of Methane Using N-Pentane As Co-Reactant Over Zn/H-ZSM-11 ZeoliteDocument5 pagesCatalytic Activation of Methane Using N-Pentane As Co-Reactant Over Zn/H-ZSM-11 ZeoliteEveryday Lentzery HogarNo ratings yet

- AC Catalst PTDocument5 pagesAC Catalst PTJarretNo ratings yet

- 44 NOx ReductionDocument24 pages44 NOx ReductionJsueNo ratings yet

- Hydrogenation and Ring Opening of Naphthalene On Bulk and Supported Mo C CatalystsDocument11 pagesHydrogenation and Ring Opening of Naphthalene On Bulk and Supported Mo C Catalystsioanaandra5690No ratings yet

- CO2 Reforming of CH4 Over Supported Ru CatalystsDocument7 pagesCO2 Reforming of CH4 Over Supported Ru CatalystsPedro lopezNo ratings yet

- Preparation and Characterization of Sno Catalysts For Co and CH OxidationDocument13 pagesPreparation and Characterization of Sno Catalysts For Co and CH Oxidationbruno barrosNo ratings yet

- Thermochemical CO Splitting Reaction With Supported La A Fe B O (A SR, Ce, B Co, MN 0 6 X, y 6 1) Perovskite OxidesDocument13 pagesThermochemical CO Splitting Reaction With Supported La A Fe B O (A SR, Ce, B Co, MN 0 6 X, y 6 1) Perovskite OxidesRuben Montenegro BulaNo ratings yet

- Applied Surface Science 356 (2015) 181-190Document10 pagesApplied Surface Science 356 (2015) 181-190MadalinaNo ratings yet

- Activities and Selectivities Temperatures Relevant Chemical Interconversions Copper Metal-Oxide Catalysts at Heat-Pumps Based Isopropanol/ AcetoneDocument4 pagesActivities and Selectivities Temperatures Relevant Chemical Interconversions Copper Metal-Oxide Catalysts at Heat-Pumps Based Isopropanol/ AcetoneOlga ĆalasanNo ratings yet

- European Practice On Design&Construction of Concrete PavementsDocument103 pagesEuropean Practice On Design&Construction of Concrete Pavementsshakirhamid6687No ratings yet

- Bolted Connection DesignDocument25 pagesBolted Connection Designkulov1592No ratings yet

- Group 4 - Chapters 1-3Document14 pagesGroup 4 - Chapters 1-3Angel Trisha MariNo ratings yet

- Hobersal Muffle Furnaces PR SeriesDocument2 pagesHobersal Muffle Furnaces PR Seriesinna husnaNo ratings yet

- Graco Husky 3275 Diaphragm Pump Data SheetDocument8 pagesGraco Husky 3275 Diaphragm Pump Data SheetMROstop.comNo ratings yet

- Chapter 1 - Aircond & VentilationDocument54 pagesChapter 1 - Aircond & Ventilationepy87No ratings yet

- Shop Floor Management TutorialDocument45 pagesShop Floor Management TutorialDilan FernandoNo ratings yet

- SPDI Refresher Test PaperDocument12 pagesSPDI Refresher Test PaperJohn Rey PelobelloNo ratings yet

- Lantek Expert Punch 1p (EN-UK)Document2 pagesLantek Expert Punch 1p (EN-UK)LantekNo ratings yet

- Ipsen Furnace Turbo CoolingDocument8 pagesIpsen Furnace Turbo CoolingArun KrishnaNo ratings yet

- Document No. 6544-00-HH-DS-004, Rev. A Data Sheet Eot CraneDocument7 pagesDocument No. 6544-00-HH-DS-004, Rev. A Data Sheet Eot CraneSachin5586No ratings yet

- Catalytic HydrodearomatizationDocument42 pagesCatalytic Hydrodearomatizational3x4n9No ratings yet

- FSP Hydro G PRO User ManualDocument47 pagesFSP Hydro G PRO User ManualCuong TranNo ratings yet

- Tarea #1 PDFDocument2 pagesTarea #1 PDFManuel Hernández MontecilloNo ratings yet

- Itp Line PipeDocument8 pagesItp Line Pipekaml100% (1)

- TA2512 Manual PDFDocument2 pagesTA2512 Manual PDFMariaNo ratings yet

- 360 Degree Flexible Drilling MachineDocument24 pages360 Degree Flexible Drilling MachineDHINESH IT67% (3)

- XG32-130-001 - Rev 1 - REV1 - SIGNED - AG PIPING ISOMETRIC DRAWING FOR WBS 130 PDFDocument606 pagesXG32-130-001 - Rev 1 - REV1 - SIGNED - AG PIPING ISOMETRIC DRAWING FOR WBS 130 PDFjosejohn1No ratings yet

- 2.0 Daikin - Unidad Evaporadora AHU 7.5 Ton, CatalogoDocument16 pages2.0 Daikin - Unidad Evaporadora AHU 7.5 Ton, CatalogoarmandoNo ratings yet

- 6 in Ferrule 316 SS HN 150522 Cert ST160129-07 Zhejiang Stellar Pipe Industry Co., LTDDocument1 page6 in Ferrule 316 SS HN 150522 Cert ST160129-07 Zhejiang Stellar Pipe Industry Co., LTDJennifer FrenchNo ratings yet

- C10550270Document2 pagesC10550270foroNo ratings yet

- Presentation For Conference ImproveDocument33 pagesPresentation For Conference ImprovekamalNo ratings yet

- TDS - Mastertop 1210 PlusDocument2 pagesTDS - Mastertop 1210 PlusVenkata RaoNo ratings yet

- CL-NG-6460-002-027 Checklist For GIS Rev01Document6 pagesCL-NG-6460-002-027 Checklist For GIS Rev01WajahatNo ratings yet

- TELENGANA BUSINESS DIRECTORY PENEL D-PanelDocument65 pagesTELENGANA BUSINESS DIRECTORY PENEL D-Panelamandeep100% (4)

- VOSS Automotive Valve CatalogueDocument41 pagesVOSS Automotive Valve CatalogueManuel Pedro InácioNo ratings yet

- A Novel: Battery Charger Random Sound Sources Air PressureDocument30 pagesA Novel: Battery Charger Random Sound Sources Air PressureSNEHA LIZ PAULNo ratings yet

- Special Considerations in Marine Pile Design and ConstructionDocument3 pagesSpecial Considerations in Marine Pile Design and ConstructionNitinShepurNo ratings yet

- A500 Vs A513Document2 pagesA500 Vs A513Angelo CubillosNo ratings yet