Professional Documents

Culture Documents

Packing Installation Flowserve

Packing Installation Flowserve

Uploaded by

MachineryengOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Packing Installation Flowserve

Packing Installation Flowserve

Uploaded by

MachineryengCopyright:

Available Formats

Flow Solutions Division

Compression Packing

Installation Instructions

1.

Flush system. Lock-out motor. Close valves.

Relieve all pressure. Wear appropriate safety

clothing and eye protection.

2.

Remove all the old packing by using a Dura Hook.

Aim the hook at the bore to protect the shaft. Clean the

sleeve and box thoroughly. Use a mirror to examine for

pitting, wear and scoring. Replace sleeve if necessary.

Lift shaft to check bearings. Replace bearings if necessary.

3.

Use correct cross section

and number of rings.

B-A =

Cross Section

2

Butt Cut

B

(OD)

(ID)

D-Lantern Ring

= Number

of Rings

Cross Section

4.

Cut, do not wind. Use TFE pipe thread tape to prevent

unraveling. Cut on mandrel the same size as the sleeve.

Do not stretch. Slide rings from mandrel. Do not flatten out.

Keep clean. Pre-engineered rings require no cutting.

Diagonal Cut

5.

Install one ring at a time.

Use compatible lubricant on the

box bore, sleeve and packing.

Use "S" twist to install

ring on sleeve.

Press ring into the bottom of the box

and seat gently with tamping tool or

split bushing. Rotate shaft after each

ring is installed. Stagger joints 180.

Seat rings of foil packing very firmly.

1999 Flowserve Corporation

6.

9.

The Lantern Ring should be installed if

needed. Locate under the lantern ring tap.

Allow packing to leak freely at first and

gradually tighten gland to an allowable leakage

rate. Allow 24 hours break-in time. Do not

overtighten.

Suggested Leakage Rates

Shaft Diameter

Up to 1"

2"

3"

4"

6"

8"

10"

7.

Tighten the gland ring slightly. The

nose of the gland should insert into the

stuffing box 1/8". Rotate the shaft by hand.

Running Leakage

3 cc/min.

6 cc/min.

9 cc/min.

12 cc/min.

18 cc/min.

24 cc/min.

30 cc/min.

Break-in

Leakage Equals

2 x Running Leakage

1 cc = 15 drops

10. Replace packing when leakage can not

be controlled by further take up of the gland.

1/8"

to 3/16"

11. Dispose of used packing in accordance

with local, state, and federal regulations.

8.

Do not start up dry. Remove lock-out,

turn on seal water to the lantern ring, and open

the valves. Flood the pump and vent the air.

Valve packing is installed using the above

steps except that the gland can be tightened

to eliminate leakage. Do not over tighten so

the valve stem can not be turned. Retighten

after a day even if no leakage occurs.

Storage Procedures: Refer to Recommended Storage Procedures for Compression Packings, FTA109.

Specify original Dura Hooks

Order Hook Number

1

2

3

4

5

5

Flowserve Corporation

2100 Factory Street

Kalamazoo, Michigan 49001-4163

Telephone: (616) 381-2650

FAX: (616) 381-8368

Customer Service (616) 345-2744

Printed in U.S.A.

For Packing Sizes

1/4

- 5/16"

3/8"

7/16

- 1/2"

9/16 - 5/2"

11/16 - 1"

11/16 - 1"

Flow Solutions Division

www.flowserve.com

ISO 9000

Certified

All Flowserve Corporation, Flow Solutions Division, products must be installed in

accordance with Flowserve installation instructions. Failing to do so or attempting to

change or modify Flowserve products will void Flowserves limited warranty. Flowserves

limited warranty is described fully in Flowserves Standard Terms and Conditions of

Sale. Flowserve makes no warranty of merchantability or fitness for a particular purpose

and in no event shall Flowserve be liable for consequential or incidental damages.

FIS107

REV 5/99 USA

You might also like

- Multi Port Valve ManualDocument2 pagesMulti Port Valve ManualJithin JamesNo ratings yet

- SM Tm3989 Knott A4Document1 pageSM Tm3989 Knott A4Marc GlebNo ratings yet

- HA Series Hydraulic Amplifier Electrical - Installation Operation Manual - Rev FDocument25 pagesHA Series Hydraulic Amplifier Electrical - Installation Operation Manual - Rev FMachineryeng0% (1)

- HA Series Hydraulic Amplifier Electrical - Installation Operation Manual - Rev FDocument25 pagesHA Series Hydraulic Amplifier Electrical - Installation Operation Manual - Rev FMachineryeng0% (1)

- Dawson Downie Lamont LTDDocument2 pagesDawson Downie Lamont LTDwarehouse cikalongNo ratings yet

- Power EngineeringDocument61 pagesPower Engineeringjaguar13No ratings yet

- Atex PumpDocument31 pagesAtex PumpZMARKANOVICNo ratings yet

- Turbogrupo Pni1: Vibrotest 60 Bruel & Kjaer VibroDocument16 pagesTurbogrupo Pni1: Vibrotest 60 Bruel & Kjaer VibroNestor Lopez100% (1)

- Minex - S Permanent Magnetic Coupling: KTR-N Sheet: Edition: 46510 EN 1 of 20 5Document20 pagesMinex - S Permanent Magnetic Coupling: KTR-N Sheet: Edition: 46510 EN 1 of 20 5HyungTae JangNo ratings yet

- LN Uk Magtecta 01Document8 pagesLN Uk Magtecta 01denizarazNo ratings yet

- Goulds PSG Readers PDFDocument16 pagesGoulds PSG Readers PDFJosé Fernando TerronesNo ratings yet

- Sample Pump Rebuild Report - 0Document21 pagesSample Pump Rebuild Report - 0Trịnh Đức Hạnh100% (1)

- DONIT IG Brosura NOVO PDFDocument36 pagesDONIT IG Brosura NOVO PDFMohamed RizkNo ratings yet

- Sealweld 5050 Ball Valve SealantDocument2 pagesSealweld 5050 Ball Valve SealantMabelinha DNo ratings yet

- Labtecta 04Document10 pagesLabtecta 04sanjeevvangeNo ratings yet

- TYPE 1604/2609/3609: First Edition API 682 Type C Sealol Metal Bellows SealsDocument6 pagesTYPE 1604/2609/3609: First Edition API 682 Type C Sealol Metal Bellows SealsKapa KamalakarNo ratings yet

- Delta Fluid Systems - Notable Completed Projects Sept 2018Document27 pagesDelta Fluid Systems - Notable Completed Projects Sept 2018Diego Armando MtzNo ratings yet

- Mechanical Seal and Support System Considerations For Negative Temperature Hydrocarbon Services: NGL Processing and Ethylene Production FocusDocument21 pagesMechanical Seal and Support System Considerations For Negative Temperature Hydrocarbon Services: NGL Processing and Ethylene Production FocuspratapNo ratings yet

- Chanjot ReportDocument18 pagesChanjot ReportKumud BadoniNo ratings yet

- Chemical Engineering Progress: An PublicationDocument1 pageChemical Engineering Progress: An PublicationgoalgoalNo ratings yet

- 2020 Style 688 Split SealtekDocument8 pages2020 Style 688 Split SealtekdiamsamNo ratings yet

- Coupling PDFDocument68 pagesCoupling PDFmmkattaNo ratings yet

- Magnetic Drive Pumps Product GuideDocument32 pagesMagnetic Drive Pumps Product GuideJean-francois RosierNo ratings yet

- Torque para PrisionerosDocument3 pagesTorque para PrisionerosJulian Chia100% (1)

- Bomba FanDocument88 pagesBomba FanJA_RRY100% (1)

- API 682 Training Manual PDF - Google SearchDocument3 pagesAPI 682 Training Manual PDF - Google SearchPahe DriveNo ratings yet

- Syn Gas Compressor Oil Tank ExplosionDocument6 pagesSyn Gas Compressor Oil Tank Explosionarunanshu palNo ratings yet

- EagleBurgmann - E11061 - E1 - DF-SAF-P-I Mechanical Seals For Boiler Feed Pumps - 07.11Document2 pagesEagleBurgmann - E11061 - E1 - DF-SAF-P-I Mechanical Seals For Boiler Feed Pumps - 07.11Octama RizkyNo ratings yet

- Movitec VCF: High-Pressure In-Line Pumps 50 HZDocument40 pagesMovitec VCF: High-Pressure In-Line Pumps 50 HZHardik Vavdiya100% (1)

- CAD Designer or CAD TechnicianDocument1 pageCAD Designer or CAD Technicianapi-79041757No ratings yet

- OHH OHHL E00697 (Pump Zulzer)Document6 pagesOHH OHHL E00697 (Pump Zulzer)Jose Sosa CojNo ratings yet

- NuggetsDocument202 pagesNuggetsfazzlieNo ratings yet

- Fred K. Geitner, Ronald G. Eierman Process MachineryDocument522 pagesFred K. Geitner, Ronald G. Eierman Process Machinerynguyen.songtung9xNo ratings yet

- O-Ring Metric & Inch Groove Dimensions: Dynamic and Static Face TypeDocument3 pagesO-Ring Metric & Inch Groove Dimensions: Dynamic and Static Face TypeSomen DasNo ratings yet

- SEALDocument6 pagesSEALkishorsinghNo ratings yet

- 3.2 Atex GLRD enDocument19 pages3.2 Atex GLRD enatenciaj100% (1)

- Rod Drop Monitroing TheoryDocument10 pagesRod Drop Monitroing TheoryAvik BhaiNo ratings yet

- Troubleshooting Centrifugal Pumps July04!28!34Document7 pagesTroubleshooting Centrifugal Pumps July04!28!34ho-faNo ratings yet

- KSB RPH-V. Process Pumps. 1. Application. 3. Designation. 2. Design. 4. Operating Data. To API 610, 11 TH Ed. and ISO 13709Document20 pagesKSB RPH-V. Process Pumps. 1. Application. 3. Designation. 2. Design. 4. Operating Data. To API 610, 11 TH Ed. and ISO 13709Hazim HazimNo ratings yet

- Turbine Control Solution Parameter Reference Guide EP-DPCX18 PDFDocument352 pagesTurbine Control Solution Parameter Reference Guide EP-DPCX18 PDFMahesh DivakarNo ratings yet

- April 2016Document15 pagesApril 2016Pumper TraderNo ratings yet

- Compressors Valves Reprint eDocument8 pagesCompressors Valves Reprint eNavigator VirgoNo ratings yet

- Finder PSG Engineered Products Brochure L PDFDocument20 pagesFinder PSG Engineered Products Brochure L PDFGeorge_Wabag_2014No ratings yet

- مضخة الطرد المركزى- كتيب للتحميلDocument128 pagesمضخة الطرد المركزى- كتيب للتحميلGrundfosEgypt100% (4)

- Royal Purple BarrierDocument14 pagesRoyal Purple BarrierAnonymous H3I29yjNo ratings yet

- Liquid Ring Vacuum Pumps, Compressors and Systems: Conventional and Hermetic DesignFrom EverandLiquid Ring Vacuum Pumps, Compressors and Systems: Conventional and Hermetic DesignNo ratings yet

- Valve Operation Manula-KINKADocument30 pagesValve Operation Manula-KINKAyosNo ratings yet

- Installation Manual - Eaton Model 53BTX SizesDocument6 pagesInstallation Manual - Eaton Model 53BTX SizesGrafton MontgomeryNo ratings yet

- VAAS Fig 740 and 730 Series IOMDocument9 pagesVAAS Fig 740 and 730 Series IOMCarlos GutierrezNo ratings yet

- Owner'S Manual: Artmolds' Pressure PotDocument4 pagesOwner'S Manual: Artmolds' Pressure PotAnonymous Wyb8Y1No ratings yet

- PFI-DHDF - Single Bag Filter Housing Manual BookDocument4 pagesPFI-DHDF - Single Bag Filter Housing Manual Bookbennypartono407No ratings yet

- 2.2 Replacing Casing Oil Seal AssemblyDocument3 pages2.2 Replacing Casing Oil Seal AssemblynabiNo ratings yet

- Gland Packing InstallationDocument2 pagesGland Packing InstallationPramod Kumar GiriNo ratings yet

- Gasket Installation Instructions: The Global Leader in Static SealingDocument4 pagesGasket Installation Instructions: The Global Leader in Static SealingFarhan TalibNo ratings yet

- Dive Scubapro - Tank Valves - Maintenance ProcedureDocument4 pagesDive Scubapro - Tank Valves - Maintenance ProceduremanonpomNo ratings yet

- S, I A M P: Gate Valve "O.S." & "Y"Document6 pagesS, I A M P: Gate Valve "O.S." & "Y"Hafiz Ali AlviNo ratings yet

- Saunders HC4 Diaphragm Valves Installation and Maintenance Instructions Manual ValvesDocument6 pagesSaunders HC4 Diaphragm Valves Installation and Maintenance Instructions Manual ValvesJose Gregorio FerrerNo ratings yet

- Valve MaintenanceDocument6 pagesValve Maintenancemoorthymech1979No ratings yet

- Central Vacuum Power Unit: Household TypeDocument20 pagesCentral Vacuum Power Unit: Household Typeanilr008No ratings yet

- Installation, Operation & Maintenance ManualDocument4 pagesInstallation, Operation & Maintenance ManualgshdavidNo ratings yet

- Groupe de Filtration Manuel ENDocument20 pagesGroupe de Filtration Manuel ENJuanchettiNo ratings yet

- JC Gasket CranfoilDocument2 pagesJC Gasket CranfoilMachineryengNo ratings yet

- Lip Seal Installation PDFDocument11 pagesLip Seal Installation PDFMachineryengNo ratings yet

- Api 617 CameronDocument31 pagesApi 617 CameronMachineryengNo ratings yet

- Seal Design For High Pressure Offshore-Morton & EvansDocument10 pagesSeal Design For High Pressure Offshore-Morton & EvansMachineryengNo ratings yet

- Compressor Performance Test Procedure Shaybah Rev.2 BorsigDocument23 pagesCompressor Performance Test Procedure Shaybah Rev.2 BorsigMachineryengNo ratings yet

- Compressor MountingDocument41 pagesCompressor MountingjmacarroNo ratings yet

- Compressor Turbo-Air API a4-IRDocument12 pagesCompressor Turbo-Air API a4-IRMachineryengNo ratings yet

- Borsig BZM - 2016 - EngDocument84 pagesBorsig BZM - 2016 - EngMachineryengNo ratings yet

- BZM Centrifugal CompressorDocument16 pagesBZM Centrifugal CompressorMachineryengNo ratings yet

- Burgmann Quick Guide To Identifying Mechanical Seal FailuresDocument1 pageBurgmann Quick Guide To Identifying Mechanical Seal FailuresakabbaraNo ratings yet

- 713 SYS LubeSite-Systems BR-R5Document36 pages713 SYS LubeSite-Systems BR-R5Jas SumNo ratings yet

- Multilube Pumping Unit MLP Advantages and Features: Compact and Flexible Centralised Lubrication SystemDocument2 pagesMultilube Pumping Unit MLP Advantages and Features: Compact and Flexible Centralised Lubrication SystemMachineryengNo ratings yet

- BORSIG Valve PresentationDocument18 pagesBORSIG Valve PresentationMachineryengNo ratings yet

- SVS.435 Steam Turbine Control UpgradesDocument4 pagesSVS.435 Steam Turbine Control UpgradesMachineryeng100% (1)

- Bolting Guide LineDocument2 pagesBolting Guide LineMachineryengNo ratings yet

- Lifts and Hoists Maintenance Tasks PDFDocument19 pagesLifts and Hoists Maintenance Tasks PDFMachineryengNo ratings yet

- Recommended Radial Clearance For Cast Bronze BearingDocument1 pageRecommended Radial Clearance For Cast Bronze BearingMachineryengNo ratings yet

- Thread Terms: External Standard Thread ProfileDocument2 pagesThread Terms: External Standard Thread ProfileMachineryengNo ratings yet

- Introduction To Storage TanksDocument49 pagesIntroduction To Storage TanksMachineryeng100% (2)

- Technical Data of ThreadedDocument4 pagesTechnical Data of ThreadedMachineryengNo ratings yet

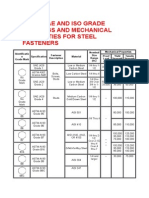

- Bolts GradesDocument9 pagesBolts GradesMachineryengNo ratings yet