Professional Documents

Culture Documents

Principal Application Fields Heat Treatable Steel:: 42crmo4

Principal Application Fields Heat Treatable Steel:: 42crmo4

Uploaded by

Ioana PopescuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Principal Application Fields Heat Treatable Steel:: 42crmo4

Principal Application Fields Heat Treatable Steel:: 42crmo4

Uploaded by

Ioana PopescuCopyright:

Available Formats

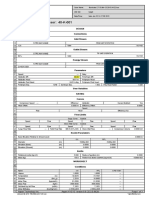

TECHNICAL CARD 42CrMo4

PRINCIPAL APPLICATION FIELDS

Heat treatable steel:

Alloyed heat treatable steel with a typical tensile strength of 900 -1200 N/mm.

Used for highly stressed components, where the combination of high strength with

tenaciousness is of utmost importance.

EX: axles, drive rods, crankshafts, pinions, gearwheels, linings, springs, saw blades, knifes

and scissors, bolt.

EUROPEAN GRADE: EN10083-3 / EN10277-5

1.7225

42CrMo4

1.7227

42CrMoS4

COMPARABLE GRADE

China

USA

Japan

Germany

India

Korea

GB

SAE -AISI

JIS

DIN

IS

KS

Russia

GOST

42CrMo

4140

SCM 440

42CrMo4

42Cr4Mo2

SCM 440

38ChM

Cr%

0.90

1.20

Mo%

0.15

0.30

CHEMICAL COMPOSITION

Element

MIN

MAX

C%

0.38

0.45

Si%

0.40

Mn%

0.60

0.90

P%

0.025

S%

0.020

0.035

MECHANICAL PROPERTIES Peeled +SH or Peeled and ground +SH+SL

Treatment

mm

16<40

40<100

100<160

160<200

Quenched and tempered +QT

Soft annealed +A

Rm (MPa)

Rp0.2 (MPa)

A5%

Z%

KV(J at 20C)

Hardness (HB)

1000-1200

> 750

> 11

>45

>35

< 241

900-1100

> 650

> 12

> 50

> 35

< 241

800-950

> 550

> 13

>50

>35

< 241

750-900

> 500

> 14

>55

>35

< 241

Different characteristics may be agreed (EX: B7 ASTM A193, EN 20898-1 class 10.9, 8.8,)

HARDENABILITY (850C - hardness HRC distance mm)

HRC-mm

MAX

MIN

HRC-mm

MAX

MIN

Type

1.5

61

53

1.5

61

56

+H

Type

+HH

3

61

53

3

61

56

6

61

52

6

61

55

7

60

51

7

60

54

9

60

49

9

60

52

11

59

43

11

59

48

13

59

40

13

59

46

15

58

37

15

58

44

20

56

34

20

56

41

25

53

32

25

53

39

30

51

31

30

51

38

35

48

30

35

48

36

40

47

30

40

47

36

45

46

29

45

46

35

50

45

29

50

45

34

HIGH TEMPERATURE YIELD STRENGHT Rp0.2 EN 10269 QT condition (for information only)

C

Rp0.2

(MPa)

50

100

150

200

250

300

350

400

450

500

720

702

677

640

602

562

5158

475

420

375

LOW TEMPERATURE IMPACT TEST EN 10269 QT condition (only for information)

C

KV (J)

+20

> 50

-40

> 40

-100

> 27

STRUCTURE Austenite grain size 5 or finer (EN ISO 643)

Degree of purity

DIN 50602 - K

Oxides

8<17

17<35

35<70

70<100

100<140

140<200

K330

K340

K435

K440

K445

K450

You might also like

- The Essentials of Material Science and Technology for EngineersFrom EverandThe Essentials of Material Science and Technology for EngineersRating: 5 out of 5 stars5/5 (1)

- 37R 06Document8 pages37R 06mirakul100% (2)

- En 19Document1 pageEn 19CharminNo ratings yet

- About En19Document1 pageAbout En19ramanamurtytv7176No ratings yet

- Lastek 90 Ceweld - Croni 29-9 S - 2013-06-27Document1 pageLastek 90 Ceweld - Croni 29-9 S - 2013-06-27Niksa ZekicNo ratings yet

- Etchant Test On CastingsDocument2 pagesEtchant Test On CastingsHarshaVeeragandhamNo ratings yet

- Uporedna Tabela Za CelikeDocument6 pagesUporedna Tabela Za Celikesnuffit11No ratings yet

- Technical Datasheet: Engineering SteelDocument1 pageTechnical Datasheet: Engineering SteelKiranNo ratings yet

- SINOXX 4116 Steel: Designation by StandardsDocument2 pagesSINOXX 4116 Steel: Designation by StandardsSamirNo ratings yet

- Mim-Material Specification and Applications: Material: Heat Treatable Steel Standards: Aisi 4140, Din 42crmo4, 1.7225Document1 pageMim-Material Specification and Applications: Material: Heat Treatable Steel Standards: Aisi 4140, Din 42crmo4, 1.7225ducthien_80No ratings yet

- Metrode 410NiMo B-11Document4 pagesMetrode 410NiMo B-11Claudia MmsNo ratings yet

- En 19Document1 pageEn 19Parvee K Nakwal100% (1)

- Aerospace Standard Materials - Mechanical Properties - Issue 12 - 2015Document6 pagesAerospace Standard Materials - Mechanical Properties - Issue 12 - 2015Leandro González De CeccoNo ratings yet

- Charla Ing. Andreas Hunger - Nuevas Tendencias en El ProcesoDocument39 pagesCharla Ing. Andreas Hunger - Nuevas Tendencias en El ProcesoWalter-uniNo ratings yet

- DH 1400modDocument1 pageDH 1400modGopiNathNo ratings yet

- Limarosta 312Document2 pagesLimarosta 312Burag HamparyanNo ratings yet

- 1.7225 Material 42CrMo4 +QT Steel Chemical Composition, Equivalent, PropertiesDocument7 pages1.7225 Material 42CrMo4 +QT Steel Chemical Composition, Equivalent, PropertiesAdrian D.RazvanNo ratings yet

- Din 1652-3 Grade 16Mncr5 Treated To Ferritic-Pearlite Structure and Cold-DrawnDocument3 pagesDin 1652-3 Grade 16Mncr5 Treated To Ferritic-Pearlite Structure and Cold-DrawnairkadNo ratings yet

- High Tensile: Nearest StandardDocument4 pagesHigh Tensile: Nearest StandardtdfsksNo ratings yet

- Our Products: About Us What We Do About Us What We Do About Us What We Do About Us What We DoDocument4 pagesOur Products: About Us What We Do About Us What We Do About Us What We Do About Us What We DoThaw Zin HtayNo ratings yet

- Duplex 1.4662 UKDocument2 pagesDuplex 1.4662 UKtienNo ratings yet

- 42CrMo4 (EN 10083 3)Document2 pages42CrMo4 (EN 10083 3)GABRIEL IORDACHINo ratings yet

- 308H Tig: Category GMAW-GTAW Solid Wires Type ApplicationsDocument1 page308H Tig: Category GMAW-GTAW Solid Wires Type ApplicationsFilipe CordeiroNo ratings yet

- Material Specification Sheet Saarstahl - 36crnimo4Document1 pageMaterial Specification Sheet Saarstahl - 36crnimo4Anonymous rYZyQQot55No ratings yet

- 25CR20NIDocument2 pages25CR20NIShariq KhanNo ratings yet

- 4340Document1 page4340ralishNo ratings yet

- Cold Rolled 2010 DUNAFER HungriaDocument12 pagesCold Rolled 2010 DUNAFER HungriaBeatriz RizzoNo ratings yet

- 3 SpringDocument66 pages3 Springall_meca_allNo ratings yet

- Kaiser Aluminum Shapes Soft Alloy PDFDocument18 pagesKaiser Aluminum Shapes Soft Alloy PDFgerrzen64No ratings yet

- 6125 Low Alloyed Steel For Casting SCM25: Scana Steel Stavanger AsDocument1 page6125 Low Alloyed Steel For Casting SCM25: Scana Steel Stavanger AsMadhu KumarNo ratings yet

- Kaiser Aluminum 6061 Pipe Tube PDFDocument2 pagesKaiser Aluminum 6061 Pipe Tube PDFgerrzen64No ratings yet

- High Tensile Alloy 4140Document1 pageHigh Tensile Alloy 4140browniezboyNo ratings yet

- SS 6mo - 1.4547Document1 pageSS 6mo - 1.4547f_riseNo ratings yet

- En 24Document1 pageEn 24V. A. TripathiNo ratings yet

- ST 12 - Echivalenta DC01Document12 pagesST 12 - Echivalenta DC01mariussinhoNo ratings yet

- Technical Data: ApplicationsDocument3 pagesTechnical Data: ApplicationssushmaxNo ratings yet

- UNS R30006 Steel GradesDocument3 pagesUNS R30006 Steel GradesRatnakar PatilNo ratings yet

- High Speed Steel PDFDocument1 pageHigh Speed Steel PDFYogesh PatelNo ratings yet

- Technical Datasheet: Engineering SteelDocument1 pageTechnical Datasheet: Engineering SteelKarimulla ShaikNo ratings yet

- 4) ASTM A29 GR 4130 PDFDocument1 page4) ASTM A29 GR 4130 PDFchandraNo ratings yet

- Stainless Steel 422 Round BarDocument2 pagesStainless Steel 422 Round BarArun KumarNo ratings yet

- 17 4 PHDocument2 pages17 4 PHzaranrajputNo ratings yet

- Cast Materials: Sulzer PumpsDocument6 pagesCast Materials: Sulzer PumpsElmey Bin JulkeplyNo ratings yet

- Diffusion Hardfacing PlatesDocument8 pagesDiffusion Hardfacing Platesbalajiprasanna.kNo ratings yet

- Category SMAW Stick Electrodes Type Applications: WC Cr3C2 Fe NBDocument1 pageCategory SMAW Stick Electrodes Type Applications: WC Cr3C2 Fe NBmohamedNo ratings yet

- Stainless Steel Durax: Data SheetDocument2 pagesStainless Steel Durax: Data SheetkdvNo ratings yet

- RATNA 7014: Medium Heavy Coated, Iron Powder & Rutile Type Welding Electrode For High Deposition Efficiency 115% MinDocument1 pageRATNA 7014: Medium Heavy Coated, Iron Powder & Rutile Type Welding Electrode For High Deposition Efficiency 115% MinIkhsani IzaNo ratings yet

- En 8Document1 pageEn 8Devendera TripathiNo ratings yet

- Stianless SteelDocument1 pageStianless SteelusefiNo ratings yet

- Technical Datasheet: Engineering SteelDocument1 pageTechnical Datasheet: Engineering SteelKiranNo ratings yet

- Tirasteel Machinery SteelDocument36 pagesTirasteel Machinery SteelAndieka Cool AndieNo ratings yet

- T Thermanit Nicro 82 Gtaw 01 01 enDocument2 pagesT Thermanit Nicro 82 Gtaw 01 01 enKathir VelNo ratings yet

- Section 2.0 Alloy SteelsDocument10 pagesSection 2.0 Alloy SteelsAloísio NascimentoNo ratings yet

- D.A.Cooper Sons Product Datasheet AISI SAE 4140 1Document1 pageD.A.Cooper Sons Product Datasheet AISI SAE 4140 1Muhamad Wahyu BudiawanNo ratings yet

- Euro 410 Ni MoDocument1 pageEuro 410 Ni MoMustafa OğuzhanNo ratings yet

- Welding Terminology: A Guide to MIG, TIG, Stick, Gas, and Spot Welding TermsFrom EverandWelding Terminology: A Guide to MIG, TIG, Stick, Gas, and Spot Welding TermsNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Air Cooled Heat ExchangersDocument6 pagesAir Cooled Heat ExchangersIoana PopescuNo ratings yet

- Ammonia TankDocument17 pagesAmmonia TankIoana PopescuNo ratings yet

- DS VFD PDFDocument2 pagesDS VFD PDFIoana PopescuNo ratings yet

- 42 - Pe-P-Roa07114227006-Me-Dwg-003-01-E - Plan LegaturiDocument1 page42 - Pe-P-Roa07114227006-Me-Dwg-003-01-E - Plan LegaturiIoana PopescuNo ratings yet

- Stress Analysis of Piping SystemsDocument108 pagesStress Analysis of Piping SystemsShijumon Kp100% (1)

- PSV 6r8 Api - 526lDocument1 pagePSV 6r8 Api - 526lIoana PopescuNo ratings yet

- Pump Sizing Calculation: Data FlowrateDocument4 pagesPump Sizing Calculation: Data FlowrateIoana PopescuNo ratings yet

- PSV Calculation Report - Liquid Relief Sizing Case: Const. VarDocument1 pagePSV Calculation Report - Liquid Relief Sizing Case: Const. VarIoana PopescuNo ratings yet

- PSV Data Sheet WettedDocument7 pagesPSV Data Sheet WettedIoana PopescuNo ratings yet

- Sala Unirii PDFDocument1 pageSala Unirii PDFIoana PopescuNo ratings yet

- Template - Hold UpDocument1 pageTemplate - Hold UpIoana PopescuNo ratings yet

- Flow1 PDFDocument1 pageFlow1 PDFIoana PopescuNo ratings yet

- PSV Data Sheet UnwettedDocument7 pagesPSV Data Sheet UnwettedIoana PopescuNo ratings yet

- Dictionar Tehnic Roman Englez A IDocument798 pagesDictionar Tehnic Roman Englez A IIoana PopescuNo ratings yet

- Cars Air France: Line 2: Etoile - Porte Maillot / Aéroport Paris-Charles de GaulleDocument5 pagesCars Air France: Line 2: Etoile - Porte Maillot / Aéroport Paris-Charles de GaulleIoana PopescuNo ratings yet

- Glycol Reboiler - Still Column PDFDocument3 pagesGlycol Reboiler - Still Column PDFIoana PopescuNo ratings yet

- TM 5 3895 358 14 and PDocument1 pageTM 5 3895 358 14 and PIoana PopescuNo ratings yet

- Compressor: 40-K-001: Stream Name 131Document3 pagesCompressor: 40-K-001: Stream Name 131Ioana PopescuNo ratings yet