Professional Documents

Culture Documents

Gtaw Smaw 6 Inch 6G CS

Gtaw Smaw 6 Inch 6G CS

Uploaded by

KentDemeterioOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gtaw Smaw 6 Inch 6G CS

Gtaw Smaw 6 Inch 6G CS

Uploaded by

KentDemeterioCopyright:

Available Formats

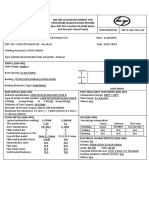

IWFAP

INDUSTRIAL WELDERS AND FITTERS

ASSOCIATION OF THE PHILIPPINES

# 2821 2nd floor Nova Star Bldg

EDSA CORNER F.B HARRISON ST. FRONT

VIOLETA COURT. PASAY CITY 1300

PROJECT

CLIENT

Mukha Mo

: PUMPING FACILITIES FOR MELUT BASIN OIL DEVELOPMENT PROJECT (DOWNSTREAM), REPUBLIC OF SUNDAN

: PETRODAR OPERATING COMPANY

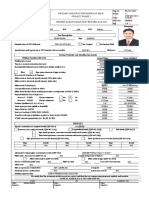

WELDER PERFORMANCE QUALIFICATIONS

CODE REF.: ASME 2004 Section IX

VIVENCIO D. MENCHAVEZ JR.

Welders Name: ______________________________

Identification No

IWFAP# VM0001

Testing Conditions and Qualification Limits

Welding Variables (QW-350)

Actual Values

GTAW/SMAW

___________________

Welding Process(es)

MANUAL

Type (ie. Manual semi-auto) used

GTAW/SMAW

___________________

MANUAL

___________________

___________________

GTAW(NONE);SMAW(YES) GTAW(NONE);SMAW(YES)

___________________

___________________

Backing (metal weld metal, double-weld, etc.)

Plate

Range Qualified

Pipe(enter diameter if is pipe or tube)

Base metal P- or S-Number

Filler metal or electrode specification(s)(SFA)(info only)

Filler metal F-Number(s)

2 7/8 ~ ABOVE

___________________

___________________

___________________

___________________

___________________

___________________

P1 TO P1

5.18/5.1

___________________

6/4

GTAW

P1 TO P11

5.18/5.1

___________________

6/4

GTAW

Consumable insert (GTAW or PAW)

___________________

___________________

Filler type(solid, metal or flux cored/powder)(GTAW or PAW)

___________________

___________________

Deposit thickness for each process

___________________

___________________

GTAW

SMAW

SOLID METAL

-

4mm

3.11mm

SOLID METAL

-

8mm

6.22mm

Process 1: __________________

Yes

No

___________________

___________________

Process 2: __________________

Yes

No

___________________

___________________

Position qualified (2G,6G,3F,etc.)

Vertical progression(uphill or downhill)

6G

___________________

UPHILL

___________________

___________________

___________________

___________________

N.A

Type of fuel gas (OFW)

Insert gas backing (GTAW,PAW,GMAW)

Transfer mode(spray/globular or pulse to short circuit-GMAW)

GTAW current type/ polarity (AC,DCEP,DCEN)

ALL

UPHILL

___________________

N.A

N.A

N.A

___________________

___________________

ARGON 99.99%(GTAW) ARGON 99.99%(GTAW)

___________________

___________________

GTAW DC-VE:SMAW DC+VE GTAW DC-VE:SMAW DC+VE

___________________

___________________

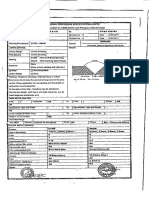

RESULTS

WELD VISUAL FOUND SATISFACTORY

Visual Examination of Completed Weld (QW-302.4)______________________________________________

Best test; Transverse root and face [QW-462.3(a)]; Longitudinal root & face [QW-462.3(b)]; Side [QW-462.2];

Pipe Bend Specimen, Corrosion-resistant overlay[QW-462.5(c)];

Plate bend specimen, corrosion-resistant overlay [QW-462.5(d)];

Macro test for fusion [QW-462.5(b)]

Macro test for fusion [QW-462.5(e)]

ACCEPTED-PS3/PIP/WQT/003

Alternative radiographic examination results (QW-191) _______________________________________

N.A

Fillet Weld fracture test (QW-180) __________ Length and percent of defect ___________

N.A

Macro examination (QW-184)______

Fillet size (in.) _____x_____ Concavity/convexity(in.)______

N.A

Other test __________________________________________________________________________________

ZOOL/REMY

SHAMIRA SDN BHD

Film or specimens evaluated by ___________________

Company __________________________________

N.A

N.A

Mechanical tests conducted by ___________________

Laboratory test no. ______________________

MR.

M.

ASHIS

BANERERJEE

(BNFE

QC)

Welding supervised by _______________________________________________________________________

We certify that the statements in this record are correct and that the test coupon were

prepared, welded, and tested in accordance with the requirements of Section IX of the ASME

Boiler and Pressure Vessel Code.

Test Conducted By

__________________________

Date __________________

Witness by _____________________

You might also like

- WPS, PQR & WPQ - Duplex 2205Document20 pagesWPS, PQR & WPQ - Duplex 2205prod41525% (4)

- WPS PQR A36.20Document5 pagesWPS PQR A36.20gchaves504100% (2)

- Welder Performance Qualification-Interactive Form QW-484ADocument1 pageWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- PQR 014 (Qualified Sa 106 GR BDocument5 pagesPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- Qw-482 Welding Procedure Specification (WPS)Document4 pagesQw-482 Welding Procedure Specification (WPS)Aldeline SungahidNo ratings yet

- WPS1Document10 pagesWPS1bhavin178No ratings yet

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Ultrasonic Testing Report For PipingDocument54 pagesUltrasonic Testing Report For Pipingeldobie3No ratings yet

- Welding Inspection in ShipbuildingDocument40 pagesWelding Inspection in ShipbuildingKentDemeterio0% (1)

- Welding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Document1 pageWelding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Mohammad Mehdi Jafari100% (2)

- Wps 1010 IfrDocument28 pagesWps 1010 IfrSyed Mahmud Habibur RahmanNo ratings yet

- 1035 03Document2 pages1035 03Anuj ShahiNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (2)

- Electrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedureDocument2 pagesElectrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedurePrashant Puri100% (2)

- Gtaw 106Document2 pagesGtaw 106ganeshkumarg_1No ratings yet

- Wqt-Visual-Mag - BS 2Document24 pagesWqt-Visual-Mag - BS 2KyNo ratings yet

- Afcons Infrastructure Limited: Procedure Qualification Record (PQR)Document21 pagesAfcons Infrastructure Limited: Procedure Qualification Record (PQR)GaapchuNo ratings yet

- PQR - PipeDocument3 pagesPQR - PipeAdvanced Quality Centre AQC100% (1)

- A 36 WPSDocument2 pagesA 36 WPSNaqqash Sajid100% (1)

- Wps Aws d1.1 NEWDocument2 pagesWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- WPQT FormatDocument176 pagesWPQT FormatRafiqKu50% (2)

- Welding Procedure Specification (WPS) : N.A N.ADocument1 pageWelding Procedure Specification (WPS) : N.A N.AMajdi Jerbi100% (1)

- WPQ Sample PrintoutDocument1 pageWPQ Sample PrintoutKannan VelNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- Juta Bumi Kapital Sdn. BHD: Doc. No. Revision NoDocument2 pagesJuta Bumi Kapital Sdn. BHD: Doc. No. Revision NoSong Kiet ChooNo ratings yet

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoNo ratings yet

- Birla Copper WPS For Tube To Tubesheet Welding MOC - CSDocument2 pagesBirla Copper WPS For Tube To Tubesheet Welding MOC - CSJitu Padhiyar PadhiyarNo ratings yet

- Iqtsz DK Uke% Vkwijs'Ku % Iqtkz La ( K% Ekmy % Vkwijs'Ku U %: Quality Check Points XQ - Kork PSD IokbzavlDocument1 pageIqtsz DK Uke% Vkwijs'Ku % Iqtkz La ( K% Ekmy % Vkwijs'Ku U %: Quality Check Points XQ - Kork PSD IokbzavlAjayNo ratings yet

- Alum 6xxx PwpsDocument1 pageAlum 6xxx PwpsAbu Zahid100% (1)

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad Pathan100% (1)

- SS WPSDocument1 pageSS WPSMOHAMEDABBASNo ratings yet

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- Val Caraig WPQTDocument1 pageVal Caraig WPQTMark Jason M. BrualNo ratings yet

- Smaw PQR FinalDocument3 pagesSmaw PQR Finalsheikmoin100% (1)

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- PQR With-PwhtDocument2 pagesPQR With-PwhtKarthikNo ratings yet

- QA-R-04 - Visual Inspection ReportDocument1 pageQA-R-04 - Visual Inspection ReportvinothNo ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Document17 pagesWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizNo ratings yet

- Welding Procedure Specification For Storage Tank & Piping SystemDocument3 pagesWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFtomj9104No ratings yet

- Approved Structural Steel-Welding Procedures - Double V-Groove With Back Gouge PDFDocument3 pagesApproved Structural Steel-Welding Procedures - Double V-Groove With Back Gouge PDFBhavani PrasadNo ratings yet

- WPSDocument3 pagesWPSKhurram Burjees100% (1)

- RF Pad Test ReportDocument1 pageRF Pad Test ReportKarthikNo ratings yet

- WPS GTAW Stainless SteelDocument4 pagesWPS GTAW Stainless SteelAnand NarayananNo ratings yet

- WPS - PQR (Sa516 GR.70)Document4 pagesWPS - PQR (Sa516 GR.70)miltonangulomorrisNo ratings yet

- Sample Welder ID As Per ASME Section IXDocument99 pagesSample Welder ID As Per ASME Section IXVivek Jadhav100% (1)

- WpsDocument2 pagesWpssamer8saifNo ratings yet

- Wps Magi Tig Exemple PDFDocument6 pagesWps Magi Tig Exemple PDFJaime PatrónNo ratings yet

- Welding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2Document2 pagesWelding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2tayyabNo ratings yet

- WPS 2014-002 006 - 6G PipeDocument3 pagesWPS 2014-002 006 - 6G PipejeswinNo ratings yet

- Equivalent ASME en MaterialsDocument3 pagesEquivalent ASME en MaterialsChee WeiNo ratings yet

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- WpsDocument3 pagesWpsPankaj KumarNo ratings yet

- GTAW SMAW 6 Inch CSDocument1 pageGTAW SMAW 6 Inch CSKentDemeterioNo ratings yet

- Procedure Qualification Record (PQR)Document2 pagesProcedure Qualification Record (PQR)Mohamed elrefaeyNo ratings yet

- Nuclear Power Corporation of India Litd.: Quality Assurance GroupDocument4 pagesNuclear Power Corporation of India Litd.: Quality Assurance GroupviswamanojNo ratings yet

- M/S SPML Infra LTDDocument6 pagesM/S SPML Infra LTDyouuuuyNo ratings yet

- Upgrading Skills For Pipe Fitters FabricatorsDocument4 pagesUpgrading Skills For Pipe Fitters FabricatorsKentDemeterio0% (1)

- Types WeldingDocument66 pagesTypes WeldingRathnakraja50% (2)

- Weld DefectsDocument38 pagesWeld DefectsJerry Man UtdNo ratings yet

- Weld-Consumable-Calculator Butt & Fillet WeldDocument7 pagesWeld-Consumable-Calculator Butt & Fillet WeldKentDemeterioNo ratings yet

- Weld Design SymbolsDocument63 pagesWeld Design Symbolspriyoc6100% (15)

- Weld Defects 2Document78 pagesWeld Defects 2HskumarReddy KarriNo ratings yet

- Weld Defects TWIDocument96 pagesWeld Defects TWISabir Shabbir100% (7)

- Welding Lecture Guide NewDocument31 pagesWelding Lecture Guide NewKentDemeterioNo ratings yet

- Welder Fitters Program NewDocument9 pagesWelder Fitters Program NewKentDemeterioNo ratings yet

- Weld Design SymbolsDocument63 pagesWeld Design Symbolspriyoc6100% (15)

- Welding PositionDocument20 pagesWelding PositionKentDemeterioNo ratings yet

- Welding XXXXXDocument25 pagesWelding XXXXXKentDemeterioNo ratings yet

- Welding Metallurgy and Weldability of MetalsDocument133 pagesWelding Metallurgy and Weldability of MetalsEfren Ibanez100% (2)

- Welding DefectsDocument77 pagesWelding DefectsBalakumar100% (1)

- Welding Super Duplex SSDocument11 pagesWelding Super Duplex SSmuarabadak100% (1)

- Welding-Training & InspectionDocument46 pagesWelding-Training & InspectionKentDemeterio100% (3)

- Non Destructive TestingDocument62 pagesNon Destructive Testingjoescribd55No ratings yet

- Welding Processes PresentationDocument101 pagesWelding Processes PresentationKentDemeterio100% (1)