Professional Documents

Culture Documents

Halliburton: Job Safety Analysis

Halliburton: Job Safety Analysis

Uploaded by

aneshse100%(1)100% found this document useful (1 vote)

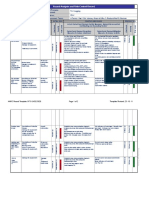

512 views2 pagesThe document provides a job safety analysis for a barite plug job at the Nilam #99 well in Southeast Asia. It lists personal protective equipment required, which includes a long sleeve coverall, safety boots, safety glasses, gloves, mask, hardhat, and earplugs. The analysis describes four steps of the job - rigging up and testing the line, mixing chemicals and barite, pumping the barite slurry, and bleeding off pressure - along with potential hazards such as pinch points, line breaks, pressure releases, and irritants from the chemicals. Recommended actions are provided to help perform each step safely.

Original Description:

Jsa BARITE Plug.doc

Original Title

Jsa BARITE Plug.doc

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides a job safety analysis for a barite plug job at the Nilam #99 well in Southeast Asia. It lists personal protective equipment required, which includes a long sleeve coverall, safety boots, safety glasses, gloves, mask, hardhat, and earplugs. The analysis describes four steps of the job - rigging up and testing the line, mixing chemicals and barite, pumping the barite slurry, and bleeding off pressure - along with potential hazards such as pinch points, line breaks, pressure releases, and irritants from the chemicals. Recommended actions are provided to help perform each step safely.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

100%(1)100% found this document useful (1 vote)

512 views2 pagesHalliburton: Job Safety Analysis

Halliburton: Job Safety Analysis

Uploaded by

aneshseThe document provides a job safety analysis for a barite plug job at the Nilam #99 well in Southeast Asia. It lists personal protective equipment required, which includes a long sleeve coverall, safety boots, safety glasses, gloves, mask, hardhat, and earplugs. The analysis describes four steps of the job - rigging up and testing the line, mixing chemicals and barite, pumping the barite slurry, and bleeding off pressure - along with potential hazards such as pinch points, line breaks, pressure releases, and irritants from the chemicals. Recommended actions are provided to help perform each step safely.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 2

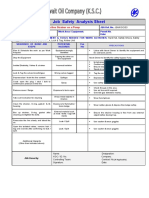

HALLIBURTON

JOB SAFETY

ANALYSIS

JOB TITLE:

DATE:

NEW

BARITE PLUG

SUPERVISOR :

OCTOBER 08, 2004

REVISED

ANALYSIS BY :

MADONG A

REGION / COUNTRY /

WELL NO. / LOCATION:

OPERATIONAL AREA

NILAM # 99

S.E. Asia/Indonesia/Badak

Required Personal Protective Equipments:

Long sleeve coverall, safety boots, safety glasses, glove,

Masker, hardhat and earplug.

SEQUENCE OF JOB STEPS

POTENTIAL HAZARDS

DEPARTMENT /

PSL

CEMENTING

1. Rig up Lo torch and Test

line with high pressure

REVIEWED BY:

BUDYANA

APPROVED:

RECOMMENDED ACTION OR

PROCEDURE

Pinch point between lo torch and elevator

Keep hands clear of danger

Break off the line

Ensure the line is secure with

Discharge line bursting and swing around

and hit people

chain

-

Remind people away from the line

during pumping job

2. Mixing chemicals and

mixing

Irritate the eyes and burn the skin,

Breath dry barite

Wearing PPE as recommended

during mixing barite

3. Pumping barite,

Break off the line while pumping job

displacement

Ensure the line is secured with

chain

4. Bleed off Pressure

Sudden release of pressure causing

Bleed off pressure slowly

Ensure the line is free of pressure

discharge line to Gas hitting personnel or

equipment

You might also like

- Jsa - Gas MonitoringDocument2 pagesJsa - Gas MonitoringaneshseNo ratings yet

- Jsa - Electrical WorksDocument2 pagesJsa - Electrical WorksaneshseNo ratings yet

- Halliburton: Mobilize Equipment Job Safety AnalysisDocument1 pageHalliburton: Mobilize Equipment Job Safety Analysisaneshse100% (2)

- JSA Clean Up TankDocument1 pageJSA Clean Up Tankaneshse100% (1)

- Job Safety Analysis Sheet: Cleaning Suction Strainer On A PumpDocument1 pageJob Safety Analysis Sheet: Cleaning Suction Strainer On A Pumpjoshua100% (1)

- JSA-012 Low-Flow Groundwater SamplingDocument3 pagesJSA-012 Low-Flow Groundwater SamplingfrancisseeNo ratings yet

- 1-Coveralls, 2-Gloves, 3-Safety Boots, 4-Safety Hard Hat 5-Safety Glasses, 6-Full Body Safety Harness & 7-Derrickman's BeltDocument3 pages1-Coveralls, 2-Gloves, 3-Safety Boots, 4-Safety Hard Hat 5-Safety Glasses, 6-Full Body Safety Harness & 7-Derrickman's BeltkhurramNo ratings yet

- JSA - T8420 Tank Cleaning - docFSPDocument3 pagesJSA - T8420 Tank Cleaning - docFSPavinash100% (2)

- SDS Alcad BDX en Aug10Document4 pagesSDS Alcad BDX en Aug10Suthep LairusameeNo ratings yet

- Job Safety Analysis - 100 Ton Hyd Press 14.8.07Document1 pageJob Safety Analysis - 100 Ton Hyd Press 14.8.07IB IsmadyNo ratings yet

- Jsa CMT BLCDocument2 pagesJsa CMT BLCaneshseNo ratings yet

- JSA Clean Up TankDocument1 pageJSA Clean Up TankMaudiAyundaAyundaNo ratings yet

- JSA CT Cement (Example)Document2 pagesJSA CT Cement (Example)aneshse100% (1)

- Procedure For Vehicle and Mobile Equipment OperationDocument18 pagesProcedure For Vehicle and Mobile Equipment OperationAtiq MoghulNo ratings yet

- Safety Drilling Rig Inspection ChecklistDocument3 pagesSafety Drilling Rig Inspection ChecklistJion MujionoNo ratings yet

- Jha Miura Z-Steam Boilers Intallation2Document8 pagesJha Miura Z-Steam Boilers Intallation2perquino oasanNo ratings yet

- Water Tank Cleaning TRADocument5 pagesWater Tank Cleaning TRAyehia sayedNo ratings yet

- JSA - 003 - Tripod Rig Erection, Operation and DismantlingDocument2 pagesJSA - 003 - Tripod Rig Erection, Operation and DismantlingAbhijit JanaNo ratings yet

- MSU Standard Operating Procedures Vehicle and Equipment Fueling Introduction and PurposeDocument2 pagesMSU Standard Operating Procedures Vehicle and Equipment Fueling Introduction and Purposesarge18100% (1)

- IDC SOP # 13 POOH With DP, DC's and BitDocument4 pagesIDC SOP # 13 POOH With DP, DC's and BitkareemNo ratings yet

- Cold Work PermitDocument11 pagesCold Work PermitMuneeb Ur Rehman100% (1)

- Category Current Month (Feb 2018) 2018 YTD (End Feb 2018) 2018 LimitDocument4 pagesCategory Current Month (Feb 2018) 2018 YTD (End Feb 2018) 2018 LimitShahzad AhmadNo ratings yet

- Harc TLC Kd-1revisiDocument2 pagesHarc TLC Kd-1revisitanjungkasri rayaNo ratings yet

- Ocm1 Confined SpaceDocument2 pagesOcm1 Confined SpacerapidsicuminteNo ratings yet

- PTW Training LV2 DraftDocument21 pagesPTW Training LV2 DraftRaulNo ratings yet

- Rig 812-A-001-Jha Prepare and Lower The Rig Floor & DerrickDocument5 pagesRig 812-A-001-Jha Prepare and Lower The Rig Floor & DerrickMalik Muhammad Nauman ZiaNo ratings yet

- Sop - FoggingDocument2 pagesSop - FoggingQS KCJNo ratings yet

- Jha Rig Up Hwu Equipment & Surface Line N-U and N-D BopDocument7 pagesJha Rig Up Hwu Equipment & Surface Line N-U and N-D BopHSE PULAI A100% (1)

- 10 Questions For Line of FireDocument2 pages10 Questions For Line of FireGary Moses100% (1)

- Jsa (Job Safety Analysis)Document2 pagesJsa (Job Safety Analysis)Ruben Mejia100% (1)

- JSA CT Drill CementDocument2 pagesJSA CT Drill Cementaneshse100% (1)

- Finlay Training Services Ad24a98430Document1 pageFinlay Training Services Ad24a98430Christian MakandeNo ratings yet

- KOC - SA.007 - Entry Into Confined SpacesDocument14 pagesKOC - SA.007 - Entry Into Confined SpacesSatya NaiduNo ratings yet

- Document Title: HSE Standard Manual Sec. C.005 Confined Space Entry COPI Doc No.: ID-G-BU-00000-00000-00372Document11 pagesDocument Title: HSE Standard Manual Sec. C.005 Confined Space Entry COPI Doc No.: ID-G-BU-00000-00000-00372riskha100% (1)

- 4 Steps To Spill Response: Prevention: The Best SolutionDocument4 pages4 Steps To Spill Response: Prevention: The Best SolutionJuan Carlos Guerrero RNo ratings yet

- Permit To Work Hseprof Com 1691465620Document36 pagesPermit To Work Hseprof Com 1691465620ajidwiyuniarsoNo ratings yet

- Personnel Transfer Procedure (PEX), RevaDocument33 pagesPersonnel Transfer Procedure (PEX), RevaHSE PULAI ANo ratings yet

- 002 - Hydro TestDocument8 pages002 - Hydro TestMohammed AdnanNo ratings yet

- IADC Gin Pole Guidelines Rig Pass.75140439Document22 pagesIADC Gin Pole Guidelines Rig Pass.75140439Hashimi Juni100% (1)

- Jsa-013 Well DevelopmentDocument2 pagesJsa-013 Well DevelopmentRehman Muzaffar100% (2)

- Safety Moment For CoP June 2006Document14 pagesSafety Moment For CoP June 2006Gagan SidhuNo ratings yet

- 1 - ERP - CrisisDocument124 pages1 - ERP - Crisisamira_zainal92No ratings yet

- 01.01. HSE ManagementDocument64 pages01.01. HSE ManagementHussainNo ratings yet

- JSA-009a Drilling and Mon Well Construction-Sonic - 2Document4 pagesJSA-009a Drilling and Mon Well Construction-Sonic - 2sudarmanNo ratings yet

- Monsoon Safety Monsoon Safety: Delivery, India RegionDocument6 pagesMonsoon Safety Monsoon Safety: Delivery, India RegionGaurav PandeyNo ratings yet

- 07.03.09 Rig Move (Working at Height)Document1 page07.03.09 Rig Move (Working at Height)Hamdi RafiekNo ratings yet

- High Potential - Dropped Pony CollarDocument2 pagesHigh Potential - Dropped Pony CollarAkshat TarateNo ratings yet

- OB Afety NalysisDocument5 pagesOB Afety NalysisNaveed WarraichNo ratings yet

- Contractor Checklist Instructions GeneralDocument3 pagesContractor Checklist Instructions GeneralleighbatesNo ratings yet

- F0810 - Pre-Post Rig Move Meetings FormsDocument18 pagesF0810 - Pre-Post Rig Move Meetings FormsPaulNo ratings yet

- Golden RulesDocument10 pagesGolden RulesSrđan NjegićNo ratings yet

- Welding, Cutting and BrazingDocument66 pagesWelding, Cutting and BrazingSohail AnjumNo ratings yet

- Hygiene and Industrial ProcedureDocument4 pagesHygiene and Industrial ProcedureNovida Rosalia Sinaga0% (1)

- Operating A Telescoping Aerial Boom LiftDocument1 pageOperating A Telescoping Aerial Boom LiftTFattahNo ratings yet

- Rig Up and Rig Down Potential HazardDocument3 pagesRig Up and Rig Down Potential HazardRizwanButtNo ratings yet

- JSA Gasket & StudboltsDocument1 pageJSA Gasket & StudboltsKarl WilliamsNo ratings yet

- 34A. Compressed Gas CylindersDocument2 pages34A. Compressed Gas CylindersSantos RexNo ratings yet

- JSA For Filter Cleaning by Steam and Water ManuallyDocument22 pagesJSA For Filter Cleaning by Steam and Water ManuallyThái Đạo Phạm LêNo ratings yet

- Lifting Plan 50tonDocument9 pagesLifting Plan 50tonViejay BalachandarNo ratings yet

- Coshh Assessment FormDocument4 pagesCoshh Assessment FormLsri MurthyNo ratings yet

- Mhs12-Boliers and Pressures VesselDocument29 pagesMhs12-Boliers and Pressures VesselWidya BungaNo ratings yet

- Hsef Report Jan 2013Document18 pagesHsef Report Jan 2013kirandevi1981No ratings yet

- Jsa Cement PackerDocument2 pagesJsa Cement PackeraneshseNo ratings yet

- Human Resources Development PT. Vico Indonesia JakartaDocument1 pageHuman Resources Development PT. Vico Indonesia JakartaaneshseNo ratings yet

- Curriculum VitaeDocument3 pagesCurriculum VitaeaneshseNo ratings yet

- CTU UnloadDocument2 pagesCTU UnloadaneshseNo ratings yet

- Msds - 016 Scotchkote-3m Electrical CoatingDocument2 pagesMsds - 016 Scotchkote-3m Electrical CoatinganeshseNo ratings yet

- Conocophillips Indonesia - Ramba: Job Description: Area/Unit: Tag No/Equipment Description: ReferencesDocument3 pagesConocophillips Indonesia - Ramba: Job Description: Area/Unit: Tag No/Equipment Description: Referencesaneshse100% (9)

- JSA Arc WeldingDocument2 pagesJSA Arc WeldinganeshseNo ratings yet

- Blank Form - JsaDocument1 pageBlank Form - JsaaneshseNo ratings yet

- JSA CT Drill CementDocument2 pagesJSA CT Drill Cementaneshse100% (1)

- Jsa Cement PackerDocument2 pagesJsa Cement PackeraneshseNo ratings yet

- Change Roller Track and Change Bolt of Shoe Track CraneDocument2 pagesChange Roller Track and Change Bolt of Shoe Track CraneaneshseNo ratings yet

- Change Track Link Crowler CraneDocument3 pagesChange Track Link Crowler CraneaneshseNo ratings yet

- JSA CT Cement (Example)Document2 pagesJSA CT Cement (Example)aneshse100% (1)

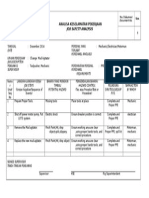

- Analisa Keselamatan Pekerjaan: Job Safety AnalysisDocument1 pageAnalisa Keselamatan Pekerjaan: Job Safety AnalysisaneshseNo ratings yet

- Analisa Keselamatan Pekerjaan: Job Safety AnalysisDocument2 pagesAnalisa Keselamatan Pekerjaan: Job Safety AnalysisaneshseNo ratings yet

- Jsa CMT BLCDocument2 pagesJsa CMT BLCaneshseNo ratings yet

- Change Rear Abrorber For Carg TruckDocument1 pageChange Rear Abrorber For Carg TruckaneshseNo ratings yet

- Change Rubber Extension Join Centifugal PumpDocument1 pageChange Rubber Extension Join Centifugal PumpaneshseNo ratings yet

- Emergency Drill Report IIDocument1 pageEmergency Drill Report IIaneshseNo ratings yet

- Accumulator Pressure Test (Offline)Document3 pagesAccumulator Pressure Test (Offline)aneshseNo ratings yet

- Change & Check Centrifugal Pump.Document2 pagesChange & Check Centrifugal Pump.aneshseNo ratings yet

- 2.03 JSA Change Rams 5 - 7Document3 pages2.03 JSA Change Rams 5 - 7aneshse100% (1)