Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

22 viewsNX650 J Section 10 Crankshaft Balancer PDF

NX650 J Section 10 Crankshaft Balancer PDF

Uploaded by

LeandroLeiteCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Diagrama Elétrico PSI GM4.3Document1 pageDiagrama Elétrico PSI GM4.3LeandroLeiteNo ratings yet

- 115135150175-OptiMax-Direct Fuel Injection Starting Model Year 2000-Starting Serial Number OG960500Document653 pages115135150175-OptiMax-Direct Fuel Injection Starting Model Year 2000-Starting Serial Number OG960500LeandroLeiteNo ratings yet

- NX650 Q Section 17 Ignition System PDFDocument5 pagesNX650 Q Section 17 Ignition System PDFLeandroLeiteNo ratings yet

- NX650 V Section 21 Troubleshooting Pages PDFDocument5 pagesNX650 V Section 21 Troubleshooting Pages PDFLeandroLeiteNo ratings yet

- NX650 P Section 16 Battery Charging PDFDocument8 pagesNX650 P Section 16 Battery Charging PDFLeandroLeiteNo ratings yet

- NX650 N Section 14 Hydraulic Brake PDFDocument12 pagesNX650 N Section 14 Hydraulic Brake PDFLeandroLeiteNo ratings yet

- NX650 M Section 13 Rear Wheel Brake Suspension PDFDocument23 pagesNX650 M Section 13 Rear Wheel Brake Suspension PDFLeandroLeiteNo ratings yet

- NX650 H Section 8 ClutchDocument11 pagesNX650 H Section 8 Clutchjurgute2000No ratings yet

NX650 J Section 10 Crankshaft Balancer PDF

NX650 J Section 10 Crankshaft Balancer PDF

Uploaded by

LeandroLeite0 ratings0% found this document useful (0 votes)

22 views13 pagesOriginal Title

NX650 J Section 10 Crankshaft balancer.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

22 views13 pagesNX650 J Section 10 Crankshaft Balancer PDF

NX650 J Section 10 Crankshaft Balancer PDF

Uploaded by

LeandroLeiteCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 13

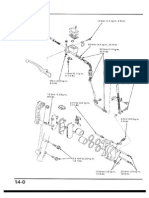

(CRANKSHAFT/BALANCER

10-0

10. CRANKSHAFT/BALANCER

SERVICE INFORMATION 10-1 CRANKCASE BEARING

‘TROUBLESHOOTING 10-2 REPLACEMENT 10-6

GRANKSHAFT/BALANCER

CRANKCASE SEPARATION 108 OA AON 10-10

BALANCER/CRANKSHAFT

ROAR 10-4 CRANKCASE ASSEMBLY 10-11

) SERVICE INFORMATION

GENERAL

Engine ‘Section 5

Ot! pamp Secton 2

Cylinder head Section 6

Cylinder/aiston Section 7

Clutch Section &

Altemeter Section 9

SPECIFICATIONS rid

rem STANDARD SERVICE LiMiT.

Connecting rod big end side clearance (0.050—0.60 mm (0.0020-0.0256 in) 0.80 mm (0.081 in)

Connecting red big end radial clearance 0.006 0.018 mm (0.0002-0.0007 in) | 0.05 mm (0.002 in)

Crancshaft runout — [0.10 mm (0.004 in)

TORQUE VALUE

Cronkesse tot 12am 142 kgm, 8)

roois

Special

Universal bearing cule 7821 ~9010000

Boring ie catch Oroat neo" 09 ,

Snoring remover 07930—MRSoIoo %eaivalent commercial

femover ange 07936—Ke10100

Remover sng weight 07741 ~9010201

Need rece remover oree—-NiKse 100

Dawn remover shat o7748 a¢60%00

Palo son 07991-Meao0000r97891 -ME4G00A

fssortly colar 7991 Kr00100

Ted adaptor 07931 400200

Attachment, 78 x 90 mm d7eab—s040101

Common

Brver 0749-0010000

Pio. 96 mm o7r46 a0r0e00

‘tachment 62 x 66 mn 97740-06t0s00

Pie, 28 mh 07748 -080600

btchmant, 42x 47 mm 07748 -o010300

Plot, 40 rm 07746 -oo40800

‘tachment, 2 x 36 mm 87746 oot0v00

Attachrnen, 62 © 38 rn 877400010800

Astachinon, 36 mo 1.0. O76 —on0400

Attachment, 72x 75mm 077460010600

Plot. 20-0 77480040800

10-1

——

CRANKSHAFT/BALANCER

TROUBLESHOOTING

Excessive Noise

rankaheft

= Worn connecting rod bearings

— Bent connecting rod

— Worn crankshaft bearings

nprope installation

— Worn balancer beatings

10-2

CRANKSHAFT/BALANCER

CRANKCASE SEPARATION FERS ITA

Ramave the following:

bolt, collar and cam chain tensioner

= carn chain

= cam chain drive sprocket

Inspect the cam chain tensioner for excessive wear or dam-

208

Loosen and remove the right crankease belts

Loosen and remove the left crankease bolts in g crisscross pat-

tein in two or more steps.

10-3

CRANKSHAFT/BALANGER

Remove the right crankcase from the left crankcase, (1) GasKeT

NOTE

* Separate the right and left crankcases from each othe:

while tapping them at saveral locations with a soft hammer

CAUTION

‘Do not pry the crankeases apart with a screwdriver.

Remove the gasket and dowel pins.

BALANCER/CRANKSHAFT REMOVAL |1) BALANCER

Remove the transmission (nage 17-2).

Insert a proper sized nail into the holes in the balancer, while

prying the scissors gears with a screwdriver.

Turn the balancer weight with the balancer weight out of she

crank weight, and paint on the balancer drive gear end driven

gear,

Romove the balancer and pull out the nail.

Using @ hydraulic press, press the crankshaft out of the left 11) CRANKSHAFT

‘cronkense,

Remove the left crankshaft beating wth a bearing puller 1

‘comes out with the crankshaft

TooL:

Universel bearing puler 07631—0010000

or equivalent commoretatly

available in U.S.A.

Bearing puller catch 07931—MK20100

valent commercially

|3} PILOT 20. mm

or EQUIVALENT

Discard the bearing.

CAUTION

+ Always replace the left bearing with a new one if t comes with

the crankshaft.

10-4

CRANKSHAFT/BALANCER

CRANKSHAFT INSPECTION

Sot the crankshaft on a ttuing stand or V blocks and measurs

the runout using a dil indicator.

SERVICE LIMIT: 0.10 mm (0.004 in}

emm

(0.24 in}

Measure the side clearance of the connecting rod big end with

2 feoler gauge

SERVICE LIMIT: 0.80 mm (0.031 In}

‘Measure the connecting rod big ond radicl cloarance.

SERVICE LIMIT: 0.05 mm (0.002 in)

BALANCER DISASSEMBLY/ASSEMBLY (1) WASHER ji

Separate the outer driven gear from the inner driven gear by re-

moving the snap ring and cone spring washer.

Remove the four springs from the inner driven gear

(3) SNAP RING

10-5

CRANKSHAFT/BALANCER

Check the gears and springs for weer, damage or fatigue, and (1) SPRINGS (2) OUTER DRIVEN GEAR

replace If necessary. sii

Ingtall the four epringe into the inner driven goar.

Install the outer driven gear onto the inner driven gear

NOTE

+ Position the punch mark on the outer gear hetwaen the

punch marks on the inner got

Install the cone spring washer and the snap ring soouroly,

CRANKCASE BEARING REPLACEMENT

INSPECTION

Turn the inner reces with your finger.

‘The beerings should turn smoothly and quietiy.

Algo check thst the outor raves of tha baaringe fit tightly in the

crankcase,

Replace the bearings if necessary.

RIGHT CRANKCASE BEARING REPLACEMENT

Romove the right balancer bearing using the following tools.

TooLs:

Bearing remover 07936—MK50100

oF oquivalont commorcilly

available in U.S.A.

Remover handle 07936—KC10100

or equivalent commercially

available in U.S.A.

077410010207

oF equivalent commoretally

available in U.S.A,

CRANKSHAFT/BALANCER

Bend down the tabs of the lock plete, and remove the bolt,

lock plate and beating stopper plate

Discard the lock plate.

Romeve each boating cut of the right erankea

Remove the oil seal and ciscard it after removing the éght

crankshaft bearing,

Apoly clean engine oil 10 the ip of the new right counter shaft

cil seal and install it securely

2) ATTACH.

Apply ell to each new bearings, and drive each bearing into the few

fight crankease,

NOTE

Drive in the bearing perpendiculerly to the right crankoasa.

Too.s:

Crankshaft beating

Driver 077490010000

Attachment, 72 x75mm 077460010600

Pilot, 35 mm. 07746-0040800

{ht mainshaft bearing

Driver 077490010000

Attechment, 52x 55mm 077460010400 ‘

Pilot, 25 mm 077460040600 (1) BALANCER (2) MAINSHAFT.

BEARING: BEARING

Right countershaft bearing

Driver 077490010000

Attachment, 42 x47 mm 07746—9010300

Puiot, 20 mm 077460040500

Right balancer bearing

Driver 077490010000

Attachment, 42x47 mm 077460010300

(4) CRANKSHAFT!

BEARING,

CRANKSHAFT/BALANCER

Install the bearing stopper plats and new lock plate, and secure

them with a bolt.

Berd up the tabs of the lock plate against the bolt

LEFT CRANKCASE BEARING REPLACEMENT (1) REMOVER HANDLE’, os. (2) BEARING

: ley iy REMOVER

Romove the left belancer bearing using the following tools.

TooLs:

Bearing remover 07936—MK60100

or equivalent commarcially

available in U.E.A.

Remover handle 07936—Kc10100

wuivelent commarotally

available in U.S.A.

Remover sliding weight 07741—0010201

oF equivalent commercially

available in U.S.A.

Romove the needle bearing and check it for wear of damage,

and replace if necessary.

Remove the bolt and bearing race stopper.

Remove the needle beating race from the right crankcase using

the following touls.

Toots:

Needla raca remover 07GMe—MK50100

Booring remover shatt 077460060100

co atiaweeme ||) remover shar

10-8

CRANKSHAFT/BALANCER

Remove the le't countershaft bearing cil seal and discard it, i) COUNTERSHAFT Ol

Be

Check the gearshift spinde oil seal for wear, damage or

fatigue, and replace it if necessary.

Romove each bearing cut of the left crankoase.

Replace the bearing plate if necessary.

Apply oil to each new beering, and drive each bearing into the (1) DRIVER

left crankease

(2) ATTACH

Nore

+ Drive in the bi

rings perpendicularly to the left crankcase.

Toots:

Loft crankshaft beering

Driver 07743—0010000

Attachment, 78x90 mm 07GAD—SD40101

Pilot, 40 mm 07746—0040900

Loft mainshaft bearing race

Driver 07749-0010000

Attachment, 32x35 mm 07746—0010100 wo

(0) COUNTERSHAET ©

“2) CRANKSHAFT

BEARING, 3

BEARING

Left countershaft booting

Driver 07749-0010000

ttachment, 62x 68mm — 07746—0010500

lot, 25 mm 07746040800

Loft balancer bearing

Driver 07748—0010000

Attachment, 42x47 mm 07746—0010300

10-9

CRANKSHAFT/BALANCER

Install a new countershaft cil seal in the left erankease, anc

apply oil to the oll seal lp,

Secure the bearing race stopper plate with the bolt

Install the nescle bearing into the bearing race.

CRANKSHAFT/BALANCER INSTALLATION

Clean the crankcase mating surfacas hafora assembling and

check for wear or damage.

NOTE

+ IF thete ® minor roughness oF imegularities on the crankcase

mating surfeces, dress them with an cil stone.

+ After cleaning, lubricate the crankshaft bearings and other

contacting surfaces

Install the special too! into the thread end of the crankshatt

Positien tho orankehatt into the loft crankea

Draw the crankshaft into the lett crankcase with the Following

tools:

NOTE

+ Draw in the crankshaft, making sure the connecting rad is

not comprossed against the crankcase edge.

TooLs:

Puller shaft 97931—Me40000

Assembly collar 07931—KF00100

Thread adaptor 07931—KF00200

Attachment |.D. 35 mm 077460030400

Insert a proper sized nail into the hole in the balencer, while

prying the scissors gears with a screw driver

Install the balancer with the paint marks aligned,

10-10

CRANKSHAFT/BALANCER

‘Turn the barencer, and meke sure the puntch marks on the ba (1) PUNCH MARKS

ancer drive geer and driven gear are aligned.

Draw the nail out of the balancer.

Inetall the transmissicn (ssction 11},

CRANKCASE ASSEMBLY UIP SASKET

Install the three dowel pins and a naw gesket

Assemble the right and left crankcases being careful to align

the dowel pins and snatts,

CAUTION

+ Don't force the crankease halves together; if there is excessive

force required, something is wrong, Remove the right crank

ease and check for msatigned parts.

Tighten the left crankcase bolts in a crisscross pattern in two

or more steps.

TORQUE: 12 Nem (1.2 kgm, 9 feb)

Tighten the right crankcase bolts.

TORQUE: 12.Nem (1.2 kgm, 8 tb)

CRANKSHAFT/BALANCER

Apply a locking egent to the threads of the tensioner bolt.

‘Secure che cam chain tensioner with the collar and bolt.

Install the cam chein drive sprocket and cam chain,

NOTE

+The cam chain drive earackat will only go on ane position

becauas of oxtr signing spline.

Reinetall the romoved parte in the reverae order of removal

(page 10-1),

10-12

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Diagrama Elétrico PSI GM4.3Document1 pageDiagrama Elétrico PSI GM4.3LeandroLeiteNo ratings yet

- 115135150175-OptiMax-Direct Fuel Injection Starting Model Year 2000-Starting Serial Number OG960500Document653 pages115135150175-OptiMax-Direct Fuel Injection Starting Model Year 2000-Starting Serial Number OG960500LeandroLeiteNo ratings yet

- NX650 Q Section 17 Ignition System PDFDocument5 pagesNX650 Q Section 17 Ignition System PDFLeandroLeiteNo ratings yet

- NX650 V Section 21 Troubleshooting Pages PDFDocument5 pagesNX650 V Section 21 Troubleshooting Pages PDFLeandroLeiteNo ratings yet

- NX650 P Section 16 Battery Charging PDFDocument8 pagesNX650 P Section 16 Battery Charging PDFLeandroLeiteNo ratings yet

- NX650 N Section 14 Hydraulic Brake PDFDocument12 pagesNX650 N Section 14 Hydraulic Brake PDFLeandroLeiteNo ratings yet

- NX650 M Section 13 Rear Wheel Brake Suspension PDFDocument23 pagesNX650 M Section 13 Rear Wheel Brake Suspension PDFLeandroLeiteNo ratings yet

- NX650 H Section 8 ClutchDocument11 pagesNX650 H Section 8 Clutchjurgute2000No ratings yet