Professional Documents

Culture Documents

NX650 N Section 14 Hydraulic Brake PDF

NX650 N Section 14 Hydraulic Brake PDF

Uploaded by

LeandroLeite0 ratings0% found this document useful (0 votes)

101 views12 pagesOriginal Title

NX650 N Section 14 Hydraulic brake.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

101 views12 pagesNX650 N Section 14 Hydraulic Brake PDF

NX650 N Section 14 Hydraulic Brake PDF

Uploaded by

LeandroLeiteCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 12

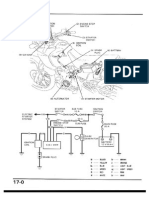

HYDRAULIC BRAKE

12.Nem (1.2 kgm, 9 feb)

ae

14 Nem (1.4 kg-m,

10 Filb)

ONsn 10.6 kgm,

4 fib

35 Nin (3.5 kgan,

25 fib)

13 Nem (1.3 ko-m,

9 feb)

23 Nem (2.3 kgm,

& 17 tetby

6 Nim 40.6 kgm

Safely

2.5 Nem (0.25 ko-m,

1.8 fb)

1ehem AB kgm, 2

Jom (2.6 kgm,

13 feb)

5

8 fel)

14. HYDRAULIC BRAKE

SERVICE INFORMATION 141 BRAKEPAD/DISC 14-4

TROUBLESHOOTING 142 MASTER CYLINDER 14-6

BRAKE FLUID REPLACEMENT/ BRAKE CALIPER 14-9

AIR BLEEDING 14-3

SERVICE INFORMATION

GENERAL

no

+ A contaminated brake aise or ped reduces stopping power. Biscard contaminated pads and clean « contaminated dise with a high

quality brake degreasing agent.

© The brake calipers can be removed without disconnecting the hydraulic system.

© Bleed the nydraulic system if it has bean disassembled or if rha brake fee's spongy.

© Do not allow foreign mats

to enter the syetem when filing the rocerveir

Avoid spilling brake fluid on painted, plastic or rubber parts, Place a fag over these parts whenever the system is serviced,

© Always check brake operation betore riding the mavoreycle.

SPECIFICATIONS

rem STANDARD SERVICE LIMIT

} om ee

[_Dise thickness 3.6 mm (0.14 inl 3.0 mm (0.12 in)

Dise runout I — 0.30 mm (0.012 in)

Master eylinder 1D. | 12.700—12.743 mm (0.5000 0.5017 in) 12.75 mm (0.502 in)

Master piston 0. 12.65— 12.684 mm (0.4983—0.4994 in} 12.64 mm (0.498 in)

Caliper eyinde> 1D. __32.030~$2.080 mm {1.2610— 1.2630 in) 32.11 mm (1.264 in) HZ

Caliper piston 9.0. 91.949 91.998 mm (1.2578—1.2698 in) 81.90 mun (1.256 in)

TORQUE VALUES

Bleed vaive 8 Nem (0.6 kgem, 4 tb)

Front broke caliper bracket bolt 2B Nem (2.8 kg-m, 20 ft-l)

Hanger pin 18 Nem (1.8 ka-m. 13 ft-lb)

Hanger pin plug 25 Nem (0.28 kgm, 1.8 ft-lb)

Brake lever pivot nut 6 Nem (0.6 kg-m, 4 fi-b) Apply oil to the threads

Brake light switch screw 12. Nem (1.2 kg-m, 9 ftp)

Master cylinder holder bolt 12 Nem (1.2 kg-m, 9 ft-lb)

Brake hose nut (master cylinder side} 35 Nem (3.6 kg-m, 25 ft-lo)

Braka hose joint nut 1A Nem (1.4 kgm, 10 ft-lb)

Brake hose bolt 39 Nem (3.5 ky-m, 25 flo}

Catiper pin bolt 23 Nem (2.3 kg-m, 17 ft-lb) Apply a locking agent to the threads

Caliper bracket pin bolt 13 Nem (1.3 ka-m, 9 ftlb| Apply alocking agent to the threads,

TOOL

Special

Shap ring pliers 07914~ 3230001

HYDRAULIC BRAKE

TROUBLESHOOTING

Brake lever soft or spongy

+ Air a hydraulic aystem

+ Lew fluid lava

+ Hydraulic system leaking

Brake lever too hard

+ Sticking piston's)

+ Clogged hydraulic eyetom

+ Peds grazed or worn excessively

Brakes drag

Hydraulic eystem leaking

+ Sticking pistonis)

Brakes grab or pull to one side

+ Pads contaminated

+ Disc or wheel misaligned

Broke chatter or squacl

+ Pads contaminated

+ Pads worn

+ Excessive dise run out

+ Calipor inetaled incorrectly

+ Dise or wheel misaligned

14-2

HYDRAULIC BRAKE

BRAKE FLUID REPLACEMENT/ (1) senews

AIR BLEEDING

WS

A contaminated brake dise or pad reduces stopping power. DIs-

‘card contaminated pads and clean a contaminated disc with a

high quaitty brake degreasing agent.

CAUTION

+ Do nor allow foreign material t0 enter ihe system when filing

the reservoir.

+ Avokd spilling uid on painted, plastic or rubber parts. Place a

rag over these parts whenever the system is serviced.

+ Use DOT 3 or DOT 4 brake fluid from a sealed conainer.

+ Do not mix brake fluid types and never reuse druined fluid.

—

BRAKE FLUID DRAINING

Connect a bleee: hose to the bleed valve

Romove the reservair cover.

NOTE

+ Be sure the fluid reservoir is parallel to the ground before 12-

‘moving the cover and diaphragm.

Loosen the caliper bleed valve end slowly pump the brake thst (2] BLEED HOSE

| blood valve, (1) UPPER LEVEL

BRAKE FLUID FILLING

Note

+ Check the fluid tevel often while bleeding the brakes to pre-

vent ait trom being pumped into the system.

+ When using the Brake Bleader, follow the manufacturor's

instructions.

+ Do not mix brake fluid types and never reuse the tluid which

hes bean pumped out during brake bleecing, becauseit may

impair the efficiency of the brake system.

Close the bleeder vaive, fll the reservoir with DOT 3 or DOT 4.

brake Fluid to the upper level

Install tho ¢iaphragm and reservoir cover.

(TT BRAKE BLEEDER

Connect a Breke Bleedar or equivalent to the bleed valve.

Pump the brake bleeder and loosen the bleed valve. Add fluid

when the fluid lovel in the master cylinder reservoir is low.

Repeat above procedures until no alr bubbies eppear in the

plastic hose.

NOTE

“If air entering the bleed from around the bieed valve

threads, seal the threads with teflon tage.

HYDRAULIC BRAKE

a brake bleecer is not avaliable, nil the system as follows:

Pump up tha aystam pressure with the lever until there aro no

tai bubbles in the fluid flowing out of the reservoir hole and

lever resistance Is felt.

AIR BLEEDING

in) LEED vatve 24

Bleed the system os follows:

1) Connect a bleed hose to the bleed vaive.

2) Squoaza the brake lever, then open the bleed valve 1/2 tura

and close the valve.

NOTE

+ Do not release the brake lever until the bleed vaive has been

closed.

3) Rolosse the brake lever slowly end weit several seconds

after it reaches the end of its travel.

Repeat steps 2 anc 3 until bubbles cease te gppeer in the Muid

at the end of the hose.

Tighten the bleed valve. 1) UPPER LeveL,

“(2) BLEED Hose

TORQUE: 6 Nem (0.6 kg-m, 4 ft1b)

Close the blood valve, fill the reservoir with DOT 3 or DOT 4

brake fluid to the upper level.

Reinstall the diaphragm and reservoir cover.

BRAKE PAD/DISC

PAD REPLACEMENT

NOTE

= Alwraye replace the brake pade in paire to acoure even dice

pressure.

+ itis unnecessary to disconnect the brake hose to replace

the brake pads,

Remove the brake hose clamp from the fork slider.

Remove the harger pin plugs and loosen the hanger pins.

Romave the caliper brecke: boks and seperate the brake ali

per and caliper bracket assembly from the brake disc

Separate the bracket from tha caliper.

14-4

ia] HANGER Pe

HYDRAULIC BRAKE

Pry one old pad against the caliper with a screwsriver 10 push

the pistons into the caliper.

Remove the hangar ping and brake pads from the brake calipar

Install new pads in the caliper.

Install the pad pins; one pad pin first, then install the other pin

by pushing the pads against the calipar te depress the pad

spring.

d (2) BRAKE PADS:

‘Mako cure that the brake pad rotainer ie installed eecurely.

Apply silicone grease to the caliper pin bol: end caliver bracket

pin bol.

Install the bracket to the c

ped retainer.

HYDRAULIC BRAKE

‘With she caliper bracket, set tho caliper onto the brake cise

with the disc between the pads.

NOTE

(4) BRACKET,

+ When installing the caliper, be careful no: to damage the pores

brake pace with the dise.

Tighten the caliper bracket belts

TORQUE: 27 Nem (2.7 kgm, 20 flb)

Tighten the hanger pin

TORQUE: 18 N-m (1.8 kgm, 13 Fb)

Intall and tighten the hanger pin plugs.

‘ToRAUE

5 Nem (0.25 kg-m, 1.8 ft-lb)

Secure the brake hose with the brake hose damp.

DISC THICKNESS

Measure the thickness of dise.

SERVICE LIMIT: 3.0 mm (0.12 in}

BRAKE DISC WARPAGE

Measure brake disc tor warpage on a surface plate,

SERVICE LIMIT: 0.30 mm (0.012 in}

MASTER CYLINDER

REMOVAL,

CAUTION

+ Avoid spitting brake fluid on painied, plastic or rubber parts.

Place a rag over (hese parts whenever the system is serviced.

NOTE

+ When removing the fluid hose, cover the end of the brake

ipe to prevent contamination

Drain the brake fluid from the breke system (page 14-3).

Loosen the brake hose joint while holding the braks hose nut

{brake pipe side) with a wrench.

Freo tha brake hose from the clamp,

Loosen the brake hose nut(master cylinder sidel and remove

the brake hose.

Remove the rear view mirror from the master cylinder.

Remove the master cylinder holder bolts. holder and master

eylindor

14-6

(3) BOLTS

HYDRAULIC BRAKE

| Remove tne front brake tight switen. (2) BRASE UGHT

> Remove the pivot nut, belt and brake lever. SWITCH

11) NUT AND. BOLT \

>

(3) BRAKE LEVER

) DISASSEMBLY (1) PISTON 2) SNAP FING

BOOT LIERS

Remove the piston boot.

Nore

Be careful not to damage the piston boot when removing it.

Fomove the snap ring frem the master eylinder body.

TOOL:

Snap ting pliers 079143230001

Remove the washer, master piston with the piston cups and (1) MASTER CYLINDER,

‘spring from the mactor oylindor.

(2) SPRING

Clean the inside of the master cylinder and reservoir with clean

brake fluid.

"i Ce (3) MASTER

wore i Beton

+ Clean the disassembled parts with brake fluid and make i

sure air car flow through the master cylinder port by apply-

ing compressed air. 5) PISTON CUPS

INSPECTION

Chace the master cylinder fo- scores, scratches or nicks.

Measure the master cylinder ILD.

SERVICE LIMIT: 12.76 mm (0.502 in}

HYDRAULIC BRAKE

Moacure the master piston 0.0. at the primary cap.

SERVICE LIMIT: 12.64 mm (0.498 in)

Before the assembly, check the primary and secondary caps

for damage or fatigue

NOTE

The masier cylinder piston, cups and spring must ve re

placed as a set.

ASSEMBLY (1) MASTER CYLINDER

Dip the piston cups in clean brake fluid before assemaly. (2) SPRING

Install the spring and primary cup tagethar. Install the master

ylindor piston, (3) MASTER

i PISTON

aut Re

We instal the eps, do 01 tow the ps 0 Fn sie te Privany MN

+_ Instat the spring with its tapered end toward the master piston.

1st hespring Pere SELON IDE GE PION. (8) SECONDARY,

CUP nt 3

(4) WASHER ——~ Y

Install the snap ring to the master cylinder body. 11) SNAP RING Ooo

PLIERS

Toot:

‘Snap ring pers 079143230001 sii

‘CAUTION

Be certain the snap ring Is frrly seated in the groove,

Install the piston beet.

Apply grease to the brake lever oivats.

Install the pivet bolt and tighten the pivot bolt to the saccifiod

torgu:

(1b PIVOT.NUT (2) SCREW 19) BRAKE LIGHT

\ SWITCH

ToROU

Nem (0.6 kgm, 4 feb)

Install the brake light switch

Tighton the screw to the specified torque.

TORQUE: 1 Nem (0.1 kg-m, 0.7 fttb)

14-8

HYDRAULIC BRAKE

Install the master cylinder and master cylinder holcer and

secure them with tio bos.

TORQUE: 12 N-m (1.2 kgm,

feb)

NOTE

+ Install the raster cylinder holder with ite “UP” mark facing

vp.

+ Align the master cylinder mating surface with the punch

rmerk on the handlebar.

“+ Tighten the uppor bolt firct thon the lower one.

‘Connact the brake hese to the master cylinder and tighten the

brake hose bolt with a new sealing wesher.

TORQUE: 35 N-m (3.5 kgm, 25 f-1b)

‘Secure the brake hose with the clamp.

Tighten tho brake hase joint nut whi

rnutibiake pive side) with a wrench,

holding the brace hose

TORQUE: 14 Nem {1.4 kg-m, 10 fb)

Connect the front drake switch wires

Fill and bleed the front brake system (page 14:9).

(Check the front brake system for leaking.

BRAKE CALIPER

REMOVAL

Place a clean container under the caliper and disconnect the

bbrake hose from brake exliper.

CAUTION

Avoiil spilling brake fluid on painted surfaces.

Loosen the hanger pins (page 14-4)

Remove the caliper bracket bolts and remove the caliper and

caliper bracket es an assembly

Remove the hanger pins and pads (page 14-5)

Romove the fellowinge ftom the broke cali

= Caliper bracket

Pad spring

— Pivot boots

DISASSEMBLY

Position the caliper with the pistons down and apply short

bursts of air pressure to the fluid inlet.

ES

+ Do notuse high pressure ar or bring the noztle too close fo the

inlet

+ Place ashop towel over the pistons to prevent them from fing

CChack the pistons and eylinders for scoring, scratches or othar

damage end replace if necessary.

(2) PUNT Manic,

MATING SURFACE

(iy MasTen

a) CLAN)

CYLINDER, 5

“ALING WASHERS

aM se

(4) HANGER PINS

(1) CALIPER BRACKET

HYDRAULIC BRAKE

Push che piston and dust seals in, ft them out and discard 1) PISTON SEALS,

them.

CAUTION

+ Be careful not to damage the pision siding su-faces when

removing the seats.

Cleen the celiner cylinders, seal grooves anc caliper pistons

with clean brake flui

(2) DUST SEALS.

INSPECTION

Chack the pistons for scoring, scratches or other damage,

‘Moscure the piston ©.D.

SERVICE LIMIT: 31.90 mm (1.256 in)

Check the caliper cylinder for scoring, scratches or other

damage. Moacure the caliper cylinder bore.

SERVICE LIMIT: 32.11 mm (1.266 In)

ASSEMBLY/INSTALLATION (1) PISTON SEALS,

The piston and dust geals must be roalaced with new ones (2) oust

whenever they are removed. SEALS sists

Coat the seals with brake fluid before assembly.

Install new seals

Inetall the pistons with the insulated ende toward the pede.

|S) FISTONS

Apply silicone grease to the ceriper bracket pin bolt and caliper ‘ty (1) CALIPER

pin bolt (2) BRACKET

Fil the inside ofthe pivot boots with scone gieese. an

Install the pivot boots, pad spring and pad retainer.

Siew

wore

~ Wako se Tha he pvt boows ao teaied ln the cla ie

grooves. :

(3) RETAINER

Assemble the caliper and caliper bracket.

Install the brake pads and hanger ain (page 14-5)

(5) SPRING” (4) PIVOT BOOT

14-10

HYDRAULIC BRAKE

INSTALLATION

Install the caliper assembly aver the brake disc go that the disc

is positioned between the pads.

CAUTION

‘Be careful not io damage the brake pads with the brake disc.

Tighten the caliper bracket bolts,

TORQUE: 27 Nem (2.7 kg-m, 20 feb)

Connect the brake hose to the caliper with the now sealing

wasters and hose belt,

Tighten the breke hose belt.

TORQUE: 35 Nem (3.5 kam. 25 ftb)

Tighten the hanger pins.

TORQUE: 18 Nem (1.8 kg-m, 13 feb)

Install the and tighten the hanger pin plugs

TORQUE: 2.5 Nl-m (0.25 kgm, 1.8 fb)

Secure the brake hose with the clamp,

Fill and bleed front brake system (page 14.3)

14-11

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Diagrama Elétrico PSI GM4.3Document1 pageDiagrama Elétrico PSI GM4.3LeandroLeiteNo ratings yet

- 115135150175-OptiMax-Direct Fuel Injection Starting Model Year 2000-Starting Serial Number OG960500Document653 pages115135150175-OptiMax-Direct Fuel Injection Starting Model Year 2000-Starting Serial Number OG960500LeandroLeiteNo ratings yet

- NX650 Q Section 17 Ignition System PDFDocument5 pagesNX650 Q Section 17 Ignition System PDFLeandroLeiteNo ratings yet

- NX650 V Section 21 Troubleshooting Pages PDFDocument5 pagesNX650 V Section 21 Troubleshooting Pages PDFLeandroLeiteNo ratings yet

- NX650 P Section 16 Battery Charging PDFDocument8 pagesNX650 P Section 16 Battery Charging PDFLeandroLeiteNo ratings yet

- NX650 M Section 13 Rear Wheel Brake Suspension PDFDocument23 pagesNX650 M Section 13 Rear Wheel Brake Suspension PDFLeandroLeiteNo ratings yet

- NX650 H Section 8 ClutchDocument11 pagesNX650 H Section 8 Clutchjurgute2000No ratings yet