Professional Documents

Culture Documents

Skin Plate

Skin Plate

Uploaded by

nasaritaCopyright:

Available Formats

You might also like

- Design of MS Pipe Wall Thickness - Guwahati C 01Document6 pagesDesign of MS Pipe Wall Thickness - Guwahati C 01rvsingh17gmailcom100% (1)

- Design Calculation 4-PadeyesDocument4 pagesDesign Calculation 4-PadeyesMuhammad Yahdiman100% (3)

- 26 Pressure Vessel.Document21 pages26 Pressure Vessel.mishtinil93% (14)

- Potable Water Tank CalculationDocument37 pagesPotable Water Tank Calculationcamycax0% (1)

- Pressure Vessel THCK CalcDocument8 pagesPressure Vessel THCK Calcmkchy12100% (1)

- Saddle Support Calculation PD 5500,2000 Annex.G)Document26 pagesSaddle Support Calculation PD 5500,2000 Annex.G)Neeraj Kumar33% (3)

- Kill Sheet HHHHHDocument5 pagesKill Sheet HHHHHRyan Llaneta67% (3)

- Compressiong SpringsDocument68 pagesCompressiong SpringsponcatoeraNo ratings yet

- Contoh Proteksi Katodik PerhitunganDocument6 pagesContoh Proteksi Katodik PerhitunganDeo Harita100% (1)

- End Plate Design As Per-Ec3Document18 pagesEnd Plate Design As Per-Ec36j7100% (1)

- 7.voltage DropDocument33 pages7.voltage Droprajpre1213No ratings yet

- Annexure - Bolt Torque CalculationDocument4 pagesAnnexure - Bolt Torque CalculationDarshan PanchalNo ratings yet

- 191201-140 Calculation of Lengths For HDPE SheathingDocument9 pages191201-140 Calculation of Lengths For HDPE Sheathingmonu yadavNo ratings yet

- RectangularDocument15 pagesRectangularaku9450% (2)

- Calculation of T-100Document14 pagesCalculation of T-100b4suki100% (1)

- 26 Pressure VesselDocument21 pages26 Pressure VesseljnmanivannanmechNo ratings yet

- CIS EVA (SideWall) 6320 SDWL 01Document29 pagesCIS EVA (SideWall) 6320 SDWL 01Nasrul AdliNo ratings yet

- Ibr Calc GSRDocument4 pagesIbr Calc GSRAniket GaikwadNo ratings yet

- 250 HP Engine For Unmanned HelicopterDocument52 pages250 HP Engine For Unmanned HelicopteryanfengzhangNo ratings yet

- PV Elite 2013 Sp3 Licensee: Isgec Filename: Pe-1668 75 - Hydro Asme Ts Calc: Case: 1 12:08P Apr 2,2014Document8 pagesPV Elite 2013 Sp3 Licensee: Isgec Filename: Pe-1668 75 - Hydro Asme Ts Calc: Case: 1 12:08P Apr 2,2014Mayank MittalNo ratings yet

- Penstock Embedded DesignDocument6 pagesPenstock Embedded Designgrahazen50% (2)

- Hfo Service Tank - ht003 Data Sheet r1 PDFDocument4 pagesHfo Service Tank - ht003 Data Sheet r1 PDFsocomenin2013No ratings yet

- Design As Per Is-456Document23 pagesDesign As Per Is-456ALOK THAKURNo ratings yet

- IS 456 Fig 4: y S T Req. T Prov. T 2 2Document8 pagesIS 456 Fig 4: y S T Req. T Prov. T 2 2Rahul AggarwalNo ratings yet

- IS 456 Fig 4: y S T Req. T Prov. T 2 2Document23 pagesIS 456 Fig 4: y S T Req. T Prov. T 2 2Rahul Aggarwal100% (1)

- Emp2 Box Pressure TransmitterDocument8 pagesEmp2 Box Pressure TransmitterAsif HameedNo ratings yet

- Line Stop Welded To Shoe CalculationDocument4 pagesLine Stop Welded To Shoe CalculationpipestressNo ratings yet

- Footing 2Document72 pagesFooting 2abdul kareeNo ratings yet

- 03 CalDocument56 pages03 Calnatarajan RavisankarNo ratings yet

- Retaining Wall 6.85m HighDocument2 pagesRetaining Wall 6.85m HighMuhammad Talha Javed SiddiquiNo ratings yet

- Tank Venting API 2000Document3 pagesTank Venting API 2000Gusfi CarsurinNo ratings yet

- Is 456 2000Document22 pagesIs 456 2000Sourav Chandra100% (1)

- Material Properties: Ref ColDocument12 pagesMaterial Properties: Ref ColnavinNo ratings yet

- Element ThicknessDocument10 pagesElement ThicknesskhairulakbarNo ratings yet

- Rectangular Tank CalculationDocument9 pagesRectangular Tank CalculationFabrício Menegassi75% (4)

- Stiffened Plate Buckling DNV-RP-C201 Rev02-December-2011Document9 pagesStiffened Plate Buckling DNV-RP-C201 Rev02-December-2011Farid TataNo ratings yet

- Perancangan Plate Adn Frame HEDocument36 pagesPerancangan Plate Adn Frame HEDavid LambertNo ratings yet

- Car Shade (Double Span) LoadsDocument1 pageCar Shade (Double Span) LoadsShaikh Muhammad Ateeq100% (1)

- Hanger Clamp DesignDocument10 pagesHanger Clamp DesignVenkat gopalakrishna P100% (1)

- End Plate ConnectionDocument12 pagesEnd Plate ConnectioncklconNo ratings yet

- Strength Calculation For ThermowellsDocument5 pagesStrength Calculation For ThermowellsNymphetamine AnhNo ratings yet

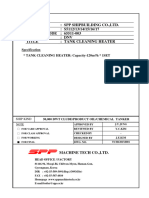

- Hm-01 Tank Cleaning HeaterDocument59 pagesHm-01 Tank Cleaning HeaterMayan De la CruzNo ratings yet

- Deflection Calculation For Over Head PipesDocument6 pagesDeflection Calculation For Over Head PipesRamachandran VenkateshNo ratings yet

- Calculation Storage Tank1000 KL PDFDocument58 pagesCalculation Storage Tank1000 KL PDFemre gedikli100% (1)

- Out of Roundnesscalculations:: Max MinDocument6 pagesOut of Roundnesscalculations:: Max MinAdekimi EmmanuelNo ratings yet

- Forces On Gantry-34Document5 pagesForces On Gantry-34vkjainabc100% (1)

- Design of Heat ExchangerDocument26 pagesDesign of Heat ExchangerSatish YadavNo ratings yet

- Final HP Heater by Kerns MethodDocument5 pagesFinal HP Heater by Kerns Methodbb84sharmaNo ratings yet

- Tank Venting Requirements (API 2000) 2Document3 pagesTank Venting Requirements (API 2000) 2RubensBoerngenNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Electricity in Fish Research and Management: Theory and PracticeFrom EverandElectricity in Fish Research and Management: Theory and PracticeNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Main Wheel ADocument1 pageMain Wheel AnasaritaNo ratings yet

- T H T B BH I: 7 Guided Frame 1 ArrangementDocument2 pagesT H T B BH I: 7 Guided Frame 1 ArrangementnasaritaNo ratings yet

- CSI Sap2000 Bridge ExamplesDocument78 pagesCSI Sap2000 Bridge ExamplesnasaritaNo ratings yet

- Water Treatment Plant Design: SedimentationDocument38 pagesWater Treatment Plant Design: SedimentationnasaritaNo ratings yet

- PR AQ 08 Aqueduct PierDocument30 pagesPR AQ 08 Aqueduct PiernasaritaNo ratings yet

- PR AQ 08 Aqueduct PierDocument30 pagesPR AQ 08 Aqueduct PiernasaritaNo ratings yet

Skin Plate

Skin Plate

Uploaded by

nasaritaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Skin Plate

Skin Plate

Uploaded by

nasaritaCopyright:

Available Formats

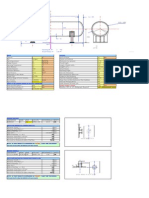

SKIN PLATE

SKIN PLATE

Bending stress due to hydraulic pressure is calculated according to the standard of

Technical Standard for Gates and Penstock

(

1

L1=

k

P .a 2

100 t 2

bending stress ,

k factor b

(

2

L2=

ratio ,

a short side of rec tan gular ,

b long side of rec tan gular ,

L 3=

P

(

3

kN

P hydraulic

pressure ,

t skin plate thickness

P4

0.0496

5.025

Hydrostatic Pressure at Main Beam

P1

0.03973

N/mm2

P2

0.04168

N/mm2

P3

0.04355

N/mm2

P4

0.04533

N/mm2

P5

0.04701

N/mm2

P6

0.04857

N/mm2

P7

0.05012

N/mm2

P8

0.05152

N/mm2

P9

0.05288

N/mm2

P10

0.05416

N/mm2

P11

0.05536

N/mm2

P12

0.05643

N/mm2

P13

0.05743

N/mm2

P14

0.05837

N/mm2

P15 dasar 0.05886

N/mm2

No. Vertikal

a (mm)

Beam

1

500

2

500

3

500

4

500

5

500

6

500

7

500

8

500

9

500

10

500

11

500

12

500

13

500

14

500

( SM 400 B ),

16 mm

2 mm

N/mm2

m

0.05886

b/a

Stresses on skin

No

1

2

a (mm)

500

500

b (mm)

87

112

b/a

5.747

4.464

k

50

50

p (N/mm2) 0.0407

0.0426

t

6

6

e

2

2

t-e

4

4

(N/mm2) 9.628

16.705

a (N/mm2)

120

OK

OK

mm

N / mm

corrosion allowance ,

Average Hydrostatic Pressure

Center point of pressure

mm

3

500

104

4.808

50

0.0444

6

2

4

15.020

4

500

132

3.788

50

0.0462

6

2

4

25.140

OK

OK

b (mm)

b/a

87

112

104

93

81

80

65

60

53

44

31

24

17.6

11

5.75

4.46

4.81

5.38

6.17

6.25

7.69

8.33

9.43

11.36

16.13

20.83

28.41

45.45

50

50

50

50

50

50

50

50

50

50

50

50

50

50

K

1

1.25

1.5

1.75

2

2.5

3

p

t (tebal

e

(N/mm2) plat) (korosi

0.0407

6

2

0.0426

6

2

0.0444

6

2

0.0462

6

2

0.0478

6

2

0.0493

6

2

0.0508

6

2

0.0522

6

2

0.0535

6

2

0.0548

6

2

0.0559

6

2

0.0569

6

2

0.0579

6

2

0.0586

6

2

t-e

4

4

4

4

4

4

4

4

4

4

4

4

4

4

(N/mm2)

9.628

16.705

15.020

12.479

9.798

9.869

6.710

5.872

4.698

3.313

1.679

1.025

0.560

0.222

30.9

40.3

45.5

48.4

49.9

50

50

ijin

(N/mm2)

120

120

120

120

120

120

120

120

120

120

120

120

120

120

4.810

50

4.464 64.68571

4.808 49.35038

Kontrol

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

You might also like

- Design of MS Pipe Wall Thickness - Guwahati C 01Document6 pagesDesign of MS Pipe Wall Thickness - Guwahati C 01rvsingh17gmailcom100% (1)

- Design Calculation 4-PadeyesDocument4 pagesDesign Calculation 4-PadeyesMuhammad Yahdiman100% (3)

- 26 Pressure Vessel.Document21 pages26 Pressure Vessel.mishtinil93% (14)

- Potable Water Tank CalculationDocument37 pagesPotable Water Tank Calculationcamycax0% (1)

- Pressure Vessel THCK CalcDocument8 pagesPressure Vessel THCK Calcmkchy12100% (1)

- Saddle Support Calculation PD 5500,2000 Annex.G)Document26 pagesSaddle Support Calculation PD 5500,2000 Annex.G)Neeraj Kumar33% (3)

- Kill Sheet HHHHHDocument5 pagesKill Sheet HHHHHRyan Llaneta67% (3)

- Compressiong SpringsDocument68 pagesCompressiong SpringsponcatoeraNo ratings yet

- Contoh Proteksi Katodik PerhitunganDocument6 pagesContoh Proteksi Katodik PerhitunganDeo Harita100% (1)

- End Plate Design As Per-Ec3Document18 pagesEnd Plate Design As Per-Ec36j7100% (1)

- 7.voltage DropDocument33 pages7.voltage Droprajpre1213No ratings yet

- Annexure - Bolt Torque CalculationDocument4 pagesAnnexure - Bolt Torque CalculationDarshan PanchalNo ratings yet

- 191201-140 Calculation of Lengths For HDPE SheathingDocument9 pages191201-140 Calculation of Lengths For HDPE Sheathingmonu yadavNo ratings yet

- RectangularDocument15 pagesRectangularaku9450% (2)

- Calculation of T-100Document14 pagesCalculation of T-100b4suki100% (1)

- 26 Pressure VesselDocument21 pages26 Pressure VesseljnmanivannanmechNo ratings yet

- CIS EVA (SideWall) 6320 SDWL 01Document29 pagesCIS EVA (SideWall) 6320 SDWL 01Nasrul AdliNo ratings yet

- Ibr Calc GSRDocument4 pagesIbr Calc GSRAniket GaikwadNo ratings yet

- 250 HP Engine For Unmanned HelicopterDocument52 pages250 HP Engine For Unmanned HelicopteryanfengzhangNo ratings yet

- PV Elite 2013 Sp3 Licensee: Isgec Filename: Pe-1668 75 - Hydro Asme Ts Calc: Case: 1 12:08P Apr 2,2014Document8 pagesPV Elite 2013 Sp3 Licensee: Isgec Filename: Pe-1668 75 - Hydro Asme Ts Calc: Case: 1 12:08P Apr 2,2014Mayank MittalNo ratings yet

- Penstock Embedded DesignDocument6 pagesPenstock Embedded Designgrahazen50% (2)

- Hfo Service Tank - ht003 Data Sheet r1 PDFDocument4 pagesHfo Service Tank - ht003 Data Sheet r1 PDFsocomenin2013No ratings yet

- Design As Per Is-456Document23 pagesDesign As Per Is-456ALOK THAKURNo ratings yet

- IS 456 Fig 4: y S T Req. T Prov. T 2 2Document8 pagesIS 456 Fig 4: y S T Req. T Prov. T 2 2Rahul AggarwalNo ratings yet

- IS 456 Fig 4: y S T Req. T Prov. T 2 2Document23 pagesIS 456 Fig 4: y S T Req. T Prov. T 2 2Rahul Aggarwal100% (1)

- Emp2 Box Pressure TransmitterDocument8 pagesEmp2 Box Pressure TransmitterAsif HameedNo ratings yet

- Line Stop Welded To Shoe CalculationDocument4 pagesLine Stop Welded To Shoe CalculationpipestressNo ratings yet

- Footing 2Document72 pagesFooting 2abdul kareeNo ratings yet

- 03 CalDocument56 pages03 Calnatarajan RavisankarNo ratings yet

- Retaining Wall 6.85m HighDocument2 pagesRetaining Wall 6.85m HighMuhammad Talha Javed SiddiquiNo ratings yet

- Tank Venting API 2000Document3 pagesTank Venting API 2000Gusfi CarsurinNo ratings yet

- Is 456 2000Document22 pagesIs 456 2000Sourav Chandra100% (1)

- Material Properties: Ref ColDocument12 pagesMaterial Properties: Ref ColnavinNo ratings yet

- Element ThicknessDocument10 pagesElement ThicknesskhairulakbarNo ratings yet

- Rectangular Tank CalculationDocument9 pagesRectangular Tank CalculationFabrício Menegassi75% (4)

- Stiffened Plate Buckling DNV-RP-C201 Rev02-December-2011Document9 pagesStiffened Plate Buckling DNV-RP-C201 Rev02-December-2011Farid TataNo ratings yet

- Perancangan Plate Adn Frame HEDocument36 pagesPerancangan Plate Adn Frame HEDavid LambertNo ratings yet

- Car Shade (Double Span) LoadsDocument1 pageCar Shade (Double Span) LoadsShaikh Muhammad Ateeq100% (1)

- Hanger Clamp DesignDocument10 pagesHanger Clamp DesignVenkat gopalakrishna P100% (1)

- End Plate ConnectionDocument12 pagesEnd Plate ConnectioncklconNo ratings yet

- Strength Calculation For ThermowellsDocument5 pagesStrength Calculation For ThermowellsNymphetamine AnhNo ratings yet

- Hm-01 Tank Cleaning HeaterDocument59 pagesHm-01 Tank Cleaning HeaterMayan De la CruzNo ratings yet

- Deflection Calculation For Over Head PipesDocument6 pagesDeflection Calculation For Over Head PipesRamachandran VenkateshNo ratings yet

- Calculation Storage Tank1000 KL PDFDocument58 pagesCalculation Storage Tank1000 KL PDFemre gedikli100% (1)

- Out of Roundnesscalculations:: Max MinDocument6 pagesOut of Roundnesscalculations:: Max MinAdekimi EmmanuelNo ratings yet

- Forces On Gantry-34Document5 pagesForces On Gantry-34vkjainabc100% (1)

- Design of Heat ExchangerDocument26 pagesDesign of Heat ExchangerSatish YadavNo ratings yet

- Final HP Heater by Kerns MethodDocument5 pagesFinal HP Heater by Kerns Methodbb84sharmaNo ratings yet

- Tank Venting Requirements (API 2000) 2Document3 pagesTank Venting Requirements (API 2000) 2RubensBoerngenNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Electricity in Fish Research and Management: Theory and PracticeFrom EverandElectricity in Fish Research and Management: Theory and PracticeNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Main Wheel ADocument1 pageMain Wheel AnasaritaNo ratings yet

- T H T B BH I: 7 Guided Frame 1 ArrangementDocument2 pagesT H T B BH I: 7 Guided Frame 1 ArrangementnasaritaNo ratings yet

- CSI Sap2000 Bridge ExamplesDocument78 pagesCSI Sap2000 Bridge ExamplesnasaritaNo ratings yet

- Water Treatment Plant Design: SedimentationDocument38 pagesWater Treatment Plant Design: SedimentationnasaritaNo ratings yet

- PR AQ 08 Aqueduct PierDocument30 pagesPR AQ 08 Aqueduct PiernasaritaNo ratings yet

- PR AQ 08 Aqueduct PierDocument30 pagesPR AQ 08 Aqueduct PiernasaritaNo ratings yet