Professional Documents

Culture Documents

Orifice

Orifice

Uploaded by

ArunRaj0 ratings0% found this document useful (0 votes)

12 views3 pagesThe orifice meter uses a flat plate with a circular hole to reduce the cross-sectional area of a flowing fluid stream. This increases velocity and decreases pressure upstream of the orifice. Pressure taps upstream and downstream measure the pressure drop, which is used to calculate flow velocity based on the orifice coefficient. The orifice coefficient depends on the location of the taps and can vary with Reynolds number. While simple and inexpensive, the orifice meter has limitations including formation of vena contracta and high viscosity effects.

Original Description:

asssaa

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe orifice meter uses a flat plate with a circular hole to reduce the cross-sectional area of a flowing fluid stream. This increases velocity and decreases pressure upstream of the orifice. Pressure taps upstream and downstream measure the pressure drop, which is used to calculate flow velocity based on the orifice coefficient. The orifice coefficient depends on the location of the taps and can vary with Reynolds number. While simple and inexpensive, the orifice meter has limitations including formation of vena contracta and high viscosity effects.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

12 views3 pagesOrifice

Orifice

Uploaded by

ArunRajThe orifice meter uses a flat plate with a circular hole to reduce the cross-sectional area of a flowing fluid stream. This increases velocity and decreases pressure upstream of the orifice. Pressure taps upstream and downstream measure the pressure drop, which is used to calculate flow velocity based on the orifice coefficient. The orifice coefficient depends on the location of the taps and can vary with Reynolds number. While simple and inexpensive, the orifice meter has limitations including formation of vena contracta and high viscosity effects.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 3

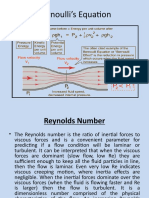

Orifice meter:

Reduction of cross-section of the flowing stream in passing

through orifice increases the velocity head at the expense of

pressure head

Reduction of pressure between taps is measured using

manometer

Complications:

Formation of Vena-contracta- Fluid stream separates from the

downstream side of the orifice plate and forms a free-flowing

jet in the downstream side.

Orifice coefficients are more empirical than those for the

Venturi meter.

Orifice coefficient, generally, is 0.61 in case of flange taps

and vena-contracta taps for NRe< 30,000.

In the process of calculating fluid velocity with a orifice

meter, the velocity of approach is not included.

Velocity through an orifice meter:

where, Co - Orifice coefficient

- Ratio of CS areas of upstream to that of down stream

Pa-Pb - Pressure gradient across the orifice

meter

- Density of fluid

The Orifice Plate

The orifice meter shown in figure (2) below, consists of a

flat orifice plate with a circular hole drilled in it. There is a

pressure tap upstream from the orifice plate and another just

downstream. There are in general three methods of placing the

taps. The coefficient of the meter depends upon the position`n

of taps.

Flange location - Tap location 1 inch upstream and 1 inch

downstream from face of orifice.

Vena contracta location - Tap location 1 pipe diameter

(actual inside) upstream and 0.3 to 0.8 pipe diameter

downstream from face of orifice.

Pipe location - Tap location 2.5 times nominal pipe diameter

upstream and 8 times nominal pipe diameter downstream

from face of orifice.

The discharge coefficient - Co - varies considerably with

changes in area ratio and the Reynolds' number. A discharge

coefficient - Co - of 0.60 may be taken as standard, but the

value varies noticeably at low values of the Reynolds number.

The pressure recovery is limited for an orifice plate and the

permanent pressure loss depends primarily on the area ratio.

For an area ratio of 0.5, the head loss is about 70 -75% of the

orifice differential.

The orifice meter is recommended for clean and dirty

liquids and some slurry services.

The pressure loss is medium

Typical accuracy is 2 to 4 of full scale

The required upstream diameter is 10 to 30

The viscosity effect is high.

The relative cost is low.

You might also like

- Field InstrumentationDocument85 pagesField InstrumentationSavana Prasanth100% (5)

- Orificemeter 1Document18 pagesOrificemeter 1Diksha GodhaneNo ratings yet

- OrificeDocument10 pagesOrificeRicha GhoshNo ratings yet

- Flow SensorsDocument57 pagesFlow Sensorsbhaihello015No ratings yet

- Orifice MeterDocument16 pagesOrifice MeterNur Dahlia100% (2)

- Flow Measurement Lecture 1Document37 pagesFlow Measurement Lecture 1Rahul KalraNo ratings yet

- Flow Meter and Orifice PlateDocument6 pagesFlow Meter and Orifice PlateOlaosebikan RoqeebNo ratings yet

- Flow MeasurementDocument88 pagesFlow MeasurementSyed Samsamuddin100% (1)

- AnandaDocument15 pagesAnandaAnkita JanaNo ratings yet

- Orifice Meter (ANANDA)Document12 pagesOrifice Meter (ANANDA)Ramit PaulNo ratings yet

- InstrumentationDocument104 pagesInstrumentationAhmed Jebreel75% (4)

- Flow Meter and Orifice PlateDocument6 pagesFlow Meter and Orifice PlateViệt Đặng XuânNo ratings yet

- FlowDocument62 pagesFlowbapita roy100% (1)

- Orifice Meter: How Does It Work?Document4 pagesOrifice Meter: How Does It Work?zubi13No ratings yet

- Title: Transportation of FluidsDocument72 pagesTitle: Transportation of FluidsRishi Gethu MassNo ratings yet

- Theory VenturiDocument7 pagesTheory VenturiMahendranath RamakrishnanNo ratings yet

- Flow SensorsDocument60 pagesFlow Sensorsbhaihello015No ratings yet

- Measrement of FlowDocument12 pagesMeasrement of FlowSushil KumarNo ratings yet

- Unit 4.1 FMDocument39 pagesUnit 4.1 FMRishi Gethu MassNo ratings yet

- Flow Measurement PDFDocument32 pagesFlow Measurement PDFmn_sundaraam100% (1)

- Measurement of Flowing FluidsDocument18 pagesMeasurement of Flowing FluidsWendell Meriel RacasaNo ratings yet

- The Orifice PlateDocument6 pagesThe Orifice PlateAli HusinNo ratings yet

- CH 5Document22 pagesCH 5Ina Marie LampitocNo ratings yet

- The Bernoulli EquationDocument7 pagesThe Bernoulli EquationRajesh N Priya GopinathanNo ratings yet

- Instrumentation Part 2omkarDocument117 pagesInstrumentation Part 2omkaromkarvadlooriNo ratings yet

- How Do You Do A Zero Check On A Differential Pressure Transmitter?Document7 pagesHow Do You Do A Zero Check On A Differential Pressure Transmitter?Qamar Hassan IqbalNo ratings yet

- Vacuum Booster Application of Bernoulli's PrincipleDocument9 pagesVacuum Booster Application of Bernoulli's PrincipleDouglas OngomNo ratings yet

- Flow Measurement Unit 4Document94 pagesFlow Measurement Unit 4Ajith AdityaNo ratings yet

- Sesion 5 FLOW MEASUREMENTDocument32 pagesSesion 5 FLOW MEASUREMENTmuh amarNo ratings yet

- Fluid Flow Lab: Experiment 4Document13 pagesFluid Flow Lab: Experiment 4shubhamNo ratings yet

- Orifice Assembly: Let The Restriction Do MeasurementDocument29 pagesOrifice Assembly: Let The Restriction Do MeasurementRajesh ViswanNo ratings yet

- Gas Flow - Pressure RestrictionDocument10 pagesGas Flow - Pressure RestrictionJovicin RadovanNo ratings yet

- Lect 15 Natural Gas Pet EngDocument9 pagesLect 15 Natural Gas Pet EngKurdish DriverNo ratings yet

- Figure1.1: U-Tube ManometerDocument5 pagesFigure1.1: U-Tube Manometeraydn_89No ratings yet

- Head Flow MetersDocument27 pagesHead Flow Metersvashu patelNo ratings yet

- Venturi Orifice Meter: Flow Measuring DevicesDocument22 pagesVenturi Orifice Meter: Flow Measuring DevicesAryan ChaurasiaNo ratings yet

- Venturimeter, OrificemeterDocument13 pagesVenturimeter, OrificemetersantaNo ratings yet

- Venturimeter ExptDocument9 pagesVenturimeter Exptatif irshadNo ratings yet

- 9878flow Measuring DeviceDocument18 pages9878flow Measuring DeviceBagadi AvinashNo ratings yet

- Aya AliDocument2 pagesAya Aliآيه علي -B-No ratings yet

- Orifice MeterDocument7 pagesOrifice MeterCeazar Justine Fulugan100% (2)

- Flow Measurement BasicDocument87 pagesFlow Measurement BasicSri100% (2)

- Orifice, Nozzle and Venturi Flow Rate Meters: Water & Air FlowmetersDocument4 pagesOrifice, Nozzle and Venturi Flow Rate Meters: Water & Air Flowmeterssiva_nagesh_2No ratings yet

- Unit I Variable Head Type FlowmetersDocument22 pagesUnit I Variable Head Type FlowmetersMs Jeevitha NNo ratings yet

- Venturimeter, Orificemeter, Notches & Weirs, Pilot TubesDocument10 pagesVenturimeter, Orificemeter, Notches & Weirs, Pilot TubesDanish LatifNo ratings yet

- Liquid Engineering: Reynolds NumbersDocument12 pagesLiquid Engineering: Reynolds NumbersajaymechengineerNo ratings yet

- 505 - Lec 01 PDFDocument33 pages505 - Lec 01 PDFUdara DissanayakeNo ratings yet

- Design of Pressure Drop Flow MeterDocument6 pagesDesign of Pressure Drop Flow Metersushant_jhawerNo ratings yet

- Venturi MeterDocument42 pagesVenturi MeterMUHAMMAD NABEEL ARIFNo ratings yet

- Measurement of Flowing FluidDocument80 pagesMeasurement of Flowing FluidHarshil BarbhayaNo ratings yet

- Orifcie Sizing CalulationDocument25 pagesOrifcie Sizing CalulationmgkvprNo ratings yet

- Elbow TapsDocument4 pagesElbow TapsSupraja SundaresanNo ratings yet

- B21ME030 Lab4 PDFDocument8 pagesB21ME030 Lab4 PDFJaydeep Prajapati (B21ME030)No ratings yet

- Chapter 5Document96 pagesChapter 5MahainiIm RuzailyNo ratings yet

- Guided By: Prof. Pratik PatelDocument25 pagesGuided By: Prof. Pratik PatelcoolmagaNo ratings yet

- Mostafa Qasim Fluid ReportDocument7 pagesMostafa Qasim Fluid ReportMostafa HamawandyNo ratings yet

- Hydraulic Tables; The Elements Of Gagings And The Friction Of Water Flowing In Pipes, Aqueducts, Sewers, Etc., As Determined By The Hazen And Williams Formula And The Flow Of Water Over The Sharp-Edged And Irregular Weirs, And The Quantity DischargedFrom EverandHydraulic Tables; The Elements Of Gagings And The Friction Of Water Flowing In Pipes, Aqueducts, Sewers, Etc., As Determined By The Hazen And Williams Formula And The Flow Of Water Over The Sharp-Edged And Irregular Weirs, And The Quantity DischargedNo ratings yet