Professional Documents

Culture Documents

Din 580-Lifting Eye Bolts PDF

Din 580-Lifting Eye Bolts PDF

Uploaded by

Antohi CatalinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Din 580-Lifting Eye Bolts PDF

Din 580-Lifting Eye Bolts PDF

Uploaded by

Antohi CatalinCopyright:

Available Formats

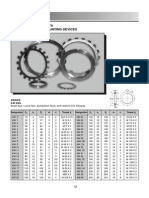

Lifting eye bolts

DIN 580

Steel / Stainless Steel

d1

d2

d3

d4

F1 max.

in N

20

36

20

36

13

10

1400 1000 700

M 10

25

45

25

45

10

17

12

2300 1700 1150

M 12

M 12

30

54

30

10

53

12

20,5

14

3400 2400 1700

M 16

M 16

M 16

35

63

35

12

62

14

27

16

7000 5000 3500

M 20

M 20

M 20

40

72

40

14

71

16

30

19

12000 8600 6000

M 24

M 24

M 24

50

90

50

18

90

20

36

24

18000 12900 9000

M 30

65

108

60

22

109

24

45

28

32000 23000 16000

M 36

75

126

70

26

128

28

54

32

46000 33000 23000

ST

NI

A4

M8

M8

M 10

M 10

M 12

Specification

F 2 max.

in N

F 3 max.

in N

Information

Steel

ST

The following guidelines of lifting eye bolts DIN 580 the have to be

observed in addition to the load values given in the above table.

-- drop-forged

-- annealed

-- contact face machined

-- zinc plated, blue passivated

Stainless Steel NI

-- A2

-- drop-forged

-- contact face machined

Stainless Steel A4

-- A4

-- drop-forged

-- contact face machined

The eye bolt must be of fully screwd in to achieve a perfect contact

between the two mating faces.

Both threads must be of a equal length and the base material of equal

strength to that of the bolt.

For more guidelines, see the enclosed operating instruction.

see also...

Lifting eye bolts (rotating) GN 581

RoHS compliant

Lifting eye bolt

1

DIN 580-M20-NI

Page 726

| 2.2 Screws and Nuts, Washers, Lifting accessories

d1

Material

You might also like

- Marco o Ring Size Chart Japanese PDFDocument12 pagesMarco o Ring Size Chart Japanese PDFraymond ngoNo ratings yet

- Radiator TTPDocument16 pagesRadiator TTPDax Xenos Arenas100% (1)

- Din 15093Document2 pagesDin 15093hadeNo ratings yet

- Basic Dimensions, American National Standard Taper Pipe Threads, NPT, (ANSI B2.1-1968)Document2 pagesBasic Dimensions, American National Standard Taper Pipe Threads, NPT, (ANSI B2.1-1968)Adrian Petrascu100% (1)

- NPT Thread Dimensions PDFDocument1 pageNPT Thread Dimensions PDFRamnandan MahtoNo ratings yet

- English Grammar Book RoundUP 4 Teachers Guide PDFDocument50 pagesEnglish Grammar Book RoundUP 4 Teachers Guide PDFAntohi Catalin100% (4)

- Din 4132Document32 pagesDin 4132Zivadin Lukic100% (2)

- Lifting Eye Bolts Steel Stainless Steel Din 580 PDFDocument1 pageLifting Eye Bolts Steel Stainless Steel Din 580 PDFheitormartNo ratings yet

- Din 580 - 582 - Maximum Permissible Loads PDFDocument9 pagesDin 580 - 582 - Maximum Permissible Loads PDFAntohi CatalinNo ratings yet

- FE410WWA - Equivalent Steel Grades QualitiesDocument6 pagesFE410WWA - Equivalent Steel Grades QualitiesbkprodhNo ratings yet

- Weight For Bolt With Nut PDFDocument1 pageWeight For Bolt With Nut PDFRam RajaramanNo ratings yet

- 08chapter6 ShaftfixingsDocument12 pages08chapter6 Shaftfixingsreinaldosidejunior100% (1)

- Rectangular Hollow Section Cold Formed..BS en 102191997Document4 pagesRectangular Hollow Section Cold Formed..BS en 102191997Jagdish ChhuganiNo ratings yet

- 1 - Ring Groove Dimensional ChartDocument2 pages1 - Ring Groove Dimensional Chartchau nguyen67% (3)

- Lock Nut WasherDocument3 pagesLock Nut WasherParmasamy SubramaniNo ratings yet

- Material EquivalentDocument88 pagesMaterial EquivalentGabriel Milicu67% (3)

- 04 Buttweldfitt Tee Din2615Document7 pages04 Buttweldfitt Tee Din2615ivanmatijevicNo ratings yet

- Tabel Material BajaDocument49 pagesTabel Material BajaAzTaurRivai100% (1)

- Contact Molded "Fiberglass" (Glass-Fiber-Reinforced Thermosetting Resin) FlangesDocument5 pagesContact Molded "Fiberglass" (Glass-Fiber-Reinforced Thermosetting Resin) FlangesJosé Luis Sierra100% (1)

- Rubber Gasket (Full Face in Flat Face Flanges) Installation & TorqueDocument4 pagesRubber Gasket (Full Face in Flat Face Flanges) Installation & Torquecavillalobosb8167No ratings yet

- TorqueDocument2 pagesTorquestaedtlerpNo ratings yet

- Attachment-5 API 6AF FLANGE - 2 Inch Node 3Document2 pagesAttachment-5 API 6AF FLANGE - 2 Inch Node 3BhaumikNo ratings yet

- Pulleys - Sole Plates - Standard Sole Plate DataDocument3 pagesPulleys - Sole Plates - Standard Sole Plate DataWaris La Joi Wakatobi0% (1)

- NS Connection For CasingDocument2 pagesNS Connection For Casingrageshmv0% (1)

- 2024 Product CatalogDocument48 pages2024 Product CatalogSastro Achmad ApriyantoNo ratings yet

- ASME B16.5 - List of Material SpecificationDocument3 pagesASME B16.5 - List of Material Specificationjr_satish6965No ratings yet

- Steels, Is and Their EquivalentsDocument2 pagesSteels, Is and Their EquivalentsVinit AhluwaliaNo ratings yet

- SM490 Ya-Yb ChemicalDocument1 pageSM490 Ya-Yb ChemicalJoko TrisnantoNo ratings yet

- Technical Specification 50 TON ALPHADocument3 pagesTechnical Specification 50 TON ALPHAMohan CharanchathNo ratings yet

- Stub EndDocument4 pagesStub EndGarfang RattanapunNo ratings yet

- Spec 7hu2 E1 en E1Document3 pagesSpec 7hu2 E1 en E1Marcos Chavarria ChNo ratings yet

- Carbon Structure Steel ComparisionDocument1 pageCarbon Structure Steel Comparisionazmatkhan30No ratings yet

- DIN 17100 ST 37-2 SteelDocument1 pageDIN 17100 ST 37-2 Steelisaaa100% (1)

- Din 6914-10.9Document2 pagesDin 6914-10.9vpjagannaathNo ratings yet

- WEP Standard For Reference OnlyDocument37 pagesWEP Standard For Reference OnlyKiran NikateNo ratings yet

- Counter Weight Drawing MCT85Document14 pagesCounter Weight Drawing MCT85Nirmalya SenNo ratings yet

- ISMC StandardDocument2 pagesISMC Standardauazar0% (1)

- Jis g3456 Grade STPT 410 Pipes PDFDocument1 pageJis g3456 Grade STPT 410 Pipes PDFMitul MehtaNo ratings yet

- Katalog Bolt & Nut PDFDocument12 pagesKatalog Bolt & Nut PDFDede SetiawanNo ratings yet

- GSW (Galvanized Steel Wire) ASTM A475Document2 pagesGSW (Galvanized Steel Wire) ASTM A475Vaza Firdaus100% (1)

- Wiggins Vents Info Wiggins VentsDocument2 pagesWiggins Vents Info Wiggins Ventsapi-3752216No ratings yet

- Material For Roll CastingDocument5 pagesMaterial For Roll CastingPankaj PandeyNo ratings yet

- Wellmark PSVDocument6 pagesWellmark PSVHomer SilvaNo ratings yet

- Flow Well Pumps For TransfomersDocument1 pageFlow Well Pumps For TransfomersAmit PatelNo ratings yet

- Mechanical - Anchoring - DynaBolt Plus PDFDocument6 pagesMechanical - Anchoring - DynaBolt Plus PDFAnonymous dSFbLxc9No ratings yet

- Wrench ClearancesDocument2 pagesWrench Clearancescamohunter71No ratings yet

- Equivalent Materials 2Document5 pagesEquivalent Materials 2lalitlbw91No ratings yet

- Din 3570-EnDocument1 pageDin 3570-EnCuong Nguyen Manh100% (1)

- Carbon Hollow Bar ST 52Document2 pagesCarbon Hollow Bar ST 52JeganeswaranNo ratings yet

- Astm A325m InnerDocument7 pagesAstm A325m InnerNgiuyen Viet TienNo ratings yet

- Din Flange Din 2627: (Dimensions in MM.)Document12 pagesDin Flange Din 2627: (Dimensions in MM.)Wisüttisäk PeäröönNo ratings yet

- Rail Welding Enclosed Arc Method PDFDocument4 pagesRail Welding Enclosed Arc Method PDFfedaretNo ratings yet

- Chemical ChartDocument6 pagesChemical ChartAnurag SarkarNo ratings yet

- Specifications Ss400Document8 pagesSpecifications Ss400Burak KececiNo ratings yet

- Din 580Document1 pageDin 580safaozhanNo ratings yet

- BRD - Klee-Datablad DIN 580Document2 pagesBRD - Klee-Datablad DIN 580ArielNo ratings yet

- Lifting Eye Nuts: Steel / Stainless SteelDocument1 pageLifting Eye Nuts: Steel / Stainless SteelMalik Uzair ZafarNo ratings yet

- Lifting Eye Bolts DIN 580 - Machine Elements - Elesa+GanterDocument2 pagesLifting Eye Bolts DIN 580 - Machine Elements - Elesa+Gantere.korkmazNo ratings yet

- 582Document2 pages582bhushansalunkeNo ratings yet

- Din 580Document1 pageDin 580kgnanavelNo ratings yet

- Lifting Male Eye Bolts: Max. Load For One Bolt With Load Direction VerticalDocument1 pageLifting Male Eye Bolts: Max. Load For One Bolt With Load Direction Verticalkumar779No ratings yet

- IMO - MODU Code - 2009 PDFDocument148 pagesIMO - MODU Code - 2009 PDFAntohi CatalinNo ratings yet

- Din 78 Thread Ends and LengthsDocument5 pagesDin 78 Thread Ends and LengthsLazarasBenny Isprithiyone100% (1)

- Atlas of The Newborn Volume 5 PDFDocument229 pagesAtlas of The Newborn Volume 5 PDFAntohi CatalinNo ratings yet

- Din 580 - 582 - Maximum Permissible Loads PDFDocument9 pagesDin 580 - 582 - Maximum Permissible Loads PDFAntohi CatalinNo ratings yet

- Din 1025-3-1994 Eng PDFDocument4 pagesDin 1025-3-1994 Eng PDFAntohi Catalin100% (1)

- Straub Catalog PDFDocument24 pagesStraub Catalog PDFAntohi CatalinNo ratings yet

- SS 2387-2 Swedish Standard: Compression SpringsDocument5 pagesSS 2387-2 Swedish Standard: Compression SpringsAntohi CatalinNo ratings yet

- Boliers and Pressure VesselsDocument33 pagesBoliers and Pressure VesselsMarcelo Chaves RestrepoNo ratings yet

- Sika Duoflex NS/SL: Two-Component, Polysulphide SealantDocument2 pagesSika Duoflex NS/SL: Two-Component, Polysulphide SealantAbu Vulkanik Al-JawiyNo ratings yet

- Section D - Proposed Methodology: Request For Proposal - Civil & Structural Consultancy ServicesDocument46 pagesSection D - Proposed Methodology: Request For Proposal - Civil & Structural Consultancy Servicesdak comeiNo ratings yet

- Basement ExcavationDocument4 pagesBasement ExcavationAnonymous U6pIEKQghNo ratings yet

- Trapezoidal FootingDocument6 pagesTrapezoidal FootingEvanrey EnriquezNo ratings yet

- Confined Space VentilationDocument31 pagesConfined Space VentilationX100% (1)

- What Are The Thermal, Electrical, and Physical Properties of The Panasonic HIPER V R-1755V MaterialDocument5 pagesWhat Are The Thermal, Electrical, and Physical Properties of The Panasonic HIPER V R-1755V MaterialjackNo ratings yet

- HvacDocument32 pagesHvacRonald Oliveria BaldiviaNo ratings yet

- Ch-3 Mix Design ProcedureDocument13 pagesCh-3 Mix Design ProcedureMuhammad ImranNo ratings yet

- Phoenix - SAFETY CABINETDocument9 pagesPhoenix - SAFETY CABINETprawinsujaNo ratings yet

- U ValueDocument35 pagesU ValuePiyush PandeyNo ratings yet

- Peikko Lifting Systems PDFDocument16 pagesPeikko Lifting Systems PDFErickzelaya2014No ratings yet

- Anchor Bolt Design Apdx D ACI318 05Document4 pagesAnchor Bolt Design Apdx D ACI318 05Mohammed HanafiNo ratings yet

- Ga Marta ViewDocument188 pagesGa Marta ViewAndes PutraNo ratings yet

- Estimation of Slab CulvertDocument31 pagesEstimation of Slab Culvertpraloy das100% (1)

- 3.1 - Analysis of Singly Reinforced Beams 1Document15 pages3.1 - Analysis of Singly Reinforced Beams 1Marcelo AbreraNo ratings yet

- Evaluation of Strut-and-Tie Modeling Applied To Dapped Beam With OpeningDocument6 pagesEvaluation of Strut-and-Tie Modeling Applied To Dapped Beam With OpeningMarcel SteoleaNo ratings yet

- Screened-In and Covered Pool Design IdeasDocument1 pageScreened-In and Covered Pool Design IdeasStefan CorneaNo ratings yet

- Essay Electrical WiringDocument1 pageEssay Electrical Wiringamalinakurniasari0% (1)

- 2-Week Look AheadDocument1 page2-Week Look AheadJOHN CARLO AZORESNo ratings yet

- Amercoat 370Document3 pagesAmercoat 370Victor Hugo Bustos Beltran100% (1)

- Doughan Clinic-Final SelectionDocument5 pagesDoughan Clinic-Final SelectionilpostinoNo ratings yet

- Asco Series 551 553 Direct Mount Inline Spool CatalogDocument4 pagesAsco Series 551 553 Direct Mount Inline Spool CatalogNaseer HydenNo ratings yet

- Mechanics of Deformable Bodies: Mapúa Institute of TechnologyDocument16 pagesMechanics of Deformable Bodies: Mapúa Institute of TechnologyAhsan AliNo ratings yet

- RLS - Medication Room STDR-10 - 3Document1 pageRLS - Medication Room STDR-10 - 3Christdel VivarNo ratings yet

- PDF On Window ConstructionDocument4 pagesPDF On Window ConstructionioginevraNo ratings yet

- API 571 DemoDocument14 pagesAPI 571 Demophan hoang diep100% (1)

- Data Teknik Out Going 6Document2 pagesData Teknik Out Going 6Murdiansyah DhianNo ratings yet