Professional Documents

Culture Documents

CH 10 Lathe As Shpaer and Index

CH 10 Lathe As Shpaer and Index

Uploaded by

Gohilakrishnan Thiagarajan0 ratings0% found this document useful (0 votes)

30 views5 pagesmanual

Original Title

Ch 10 Lathe as Shpaer and Index

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentmanual

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

30 views5 pagesCH 10 Lathe As Shpaer and Index

CH 10 Lathe As Shpaer and Index

Uploaded by

Gohilakrishnan Thiagarajanmanual

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 5

ye THE SHAPING MACHINE

CHAPTER 10

The Lathe as Shaping Machine

‘There are sometimes small jobs of a character akin to shaping

that might with advantage be carried out with the work still mounted

in the lathe, The cutting of an internal keyway is an example in point.

‘This is an operation that may be performed with a suitably shaped

tool caught in a boring bar mounted on the lathe top-slide. ‘The tool

is set on the centre line of the lathe and pulled through the work by

moving the saddle along the lathe bed, the depth of cut being con-

trolled by the cross-stide feed screw. The process is analagous to

the treatment already described when dealing with the cutting of

keyways in the shaping machine.

‘The simple set up is depicted in Fig. 1.

‘The use of the lathe saddle alone limits the operator to keyways

parallel with the axis of the lathe. It is therefore better to use the

top slide for imparting movement to the cutting tool; in this way

keyways on the taper can be formed when needed by simply turning

the slide to the desired angle. AAs before, the cross-slide feed screw

controls the depth of cut which in the interests of comfortable

‘working should be limited to some 0.00r to 0.002 in. per stroke

Fig.1 Simple set up for keyway cutting

— WORK |

/ CUTTER

DIRECTION OF

CUT

‘THE LATHE AS SHAPING MACHINE 93

Fig. 2 Shaping equipment fitted to a Winfield Lathe

‘The equipment illustrated in Fig. 2 was onee fitted to a Winfield

lathe, the forerunner of the Myford produets incidentally, and has

since been modified for use on a ML 7 lathe.

"The attachment consists of but few parts. ‘These are the fulcrum

plate A supporting the operating lever B and a conneeting rod C

attached to the lever and the top slide by suitable fitments. As

Fig. Parts of the equipment

i ass

o4 THE SHAPING MACHINE

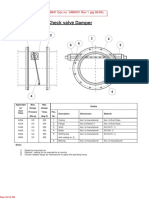

Fig. 4 Change Wheel and Detent Fitted to the ML 10 Lathe

depicted in Fig. 3, the clamp mounted on the lever is adjustable for

position and enables both the stroke and the leverage obtainable to

be varied at will

‘The connection to the top slide is by means of a fork attached to

the slide in place of the feed crow, which ie, of course, removed

when the device is used.

When the top slide is of substantial construction it may be possible

to mount improvised fittings that will allow a tool to be secured

vertically and fed to the work under controlled conditions. In this

Fig. 4A Details of the Mandrel Extension

‘aig'ow

sagan

IE LATHE AS SHAPING MACHINE 95

©)

Fig. 4B Alternative forms of Mandrel Extension

way such work as the forming of simple flat surfaces on components,

‘or the squaring of the ends of shafts, ean be carried out as required

Such operations of course call for the use of dividing equipment,

however, simple, that may be attached to the lathe and the number

of divisions required are few. ‘The easiest way to ensure accurate

Fig.7 Holder for keyway cutting tool

Fig. 5 Shaping equipment

Fig. 6 Component with

feted to a Drummond Lathe

Opposing Keyways

96 THE SHAPING MACHINE

Fig. 8 Machining a transverse slot in the Drummond Lathe

dividing in the lathe is to make use of a change wheel having a

number of tecth that can be divided equally by the number of divi

sions required As only 2, 4 and possibly 6 divisions are needed,

cither a 40-tooth or a 6o-tooth change wheel will suffice. In practice

the change wheel is mounted on an extension to the lathe mandrel

itself. A typical arrangement is depicted in the illustration Fig. 4,

MLio. Here the change wheel is mounted on an adapter having a

Fig. 9 Sct up for cutting a ring Gear in the lathe

THE LATHE AS SHAPING MAC!

INE 7

spigot that is made a push fit in the mandrel ard is expanded by a

tapered bolt that causes the adapter to grip both the bore of the

hollow mandrel and the change wheel simultaneously A detent,

attached to the change cover on the lathe, engaged the indexing

wheel which is marked off at the correct intervals for the number of

divisions required For example, let us suppose that four separate

areas of machining have to be carried out, al at right angles to one

another; then, asstiming a 40-tooth wheel is being used for indexing,

every tenth tooth space will be marked and the detent engaged with

each mark in turn as the machining proceeds.

The details of the mandrel extension are given in the drawing

Fig. 4A. The particular extension shown is one fitted by the author

to the Myford MLro lathe. However, the information given on the

drawing should enable any reader interested to work out for himself

any modifications needed to adapt the device to another make of

lathe.

‘An exploded view of a similar mandrel extension is given in the

right hand illustration of Fig. 4B. ‘The extension depicted in the

upper illustration is a rather more advanced device providing means

of expanding the seating for the change wheel as that of the extension

adapter as a whole.

‘An interesting, somewhat improvised, set up applied to a 33 in

Drummond lathe is illustrated in Fig. 5. The shaping equipment is

10. Close-up of the work

98 THE SHAPING MACHINE

depicted machining the opposing keyways in the component seen

in Fig. 6. The tool used is mounted in the holder illustrated in

Fig. 7 and is of a type referred to carlier in the chapter.

“Those readers who know the Drummond lathe well will not need

reminding of the essential sturdiness of many of its component parts.

"This is particularly true of the top slide which is a robust and well

engineered unit having in addition, a form of tool clamp, that makes

tool height adjustment a simple and rapid procedure. For this

reason the Drummond top slide has much versatility, as may be

gathered from the illustration Fig. 8.

Index

‘Acorn Tools Power Shaper, 26, 34

‘com Tools “Shaper” Too! “Stide,

2

Acom Tools Vive, 67, 68

‘Aasitions ta the Machines 43, 53,

‘Ajusting “the Ram Bos

A

Adjusting the Ram Stroke, 28, 29

‘Adjustment, Connecting Rody 48

‘Adjustment, Work Table, 32

‘American’ Pattern Clapper Box, 12,

7

American Pattern ‘Tool Holder, 19

‘Angle Pate, 15

Angles, Cleissnce and Rake, 38

Angular Rest, so-s7

‘Apron, 28

Arm, Driving, 48

‘Automatic Feed, 9,22, 24

‘Automatic Feed Detent, $3

‘Automatic Feed, Drummond, 19, 27

Automatic Feed, “Too! 'S

“40-53,

Automatic Work Table Feed, 31-32

Bed, 21

Bench Grinder, Electric, 56

Bench Shaper, Drummond, 28

Benching, Weoden, 61-63

Blocks, V, 89-00

Bolts, -Sloe, 33

Box, American Pattern Clapper, 12

Box Bed, 24

Box, Clapper, 10-11, 22,21, 42

"Hox, English Batten Clapper, 12

Bos, Locking the Clapper, ty

Bracket, Quadeune Gear, 49° 3¢

Bracket) Rack, 1-53,

Brenkage, ToS, 78,77

Checking » Second data Vice, 72

Gheulor Pitch, 87 7

Chsppes 13

Clapper ‘Box, 30-11, 13, 17, a8,

242

Clapicr Box, Lacking the, 38

Clenrance and Rake Anges, 38

Clement, Joseph, 8

Clutch, Bog, 24

Connecting Plugs Correctly, 66

Gonnectinat Rod, 47-48

Connecting Rod Adjustment, 8

(Cranis, Diss, 28

Crank, Overbang, 28

Deteng, Automatic Feed, 53

Dial Indicator, 79

ise Crank, 26

Bog Cates, 2+

Drirsmond Automate Feed, 29

Drummond Bench Shaper, #8

Brammond Machine Vice, 19

‘Belipse: Machine Vice, 77

Feipse’ Mageetie Bas, 79-80

Electric Motor Drive, 33-35

Electrical Installation, 85-86

Besttng Ga, Wonk Table 22

nigh Patter Clapper Boxy 12

English Potters Tool Holder, 9

Extension, Mandrel, 96

External Keyways, ‘Tool for, 40

Feed, Autor, 9, 23,24

eed’ Screw 13,22

rod Screw Hindle, 44-45,

erto Concrete Said, 63-64

Bed Head Shapers 18

Gear, Quadeset 47-48

Gib Binp Lact Screws, 45

Grinding ape Honing, 3-57

Grinding Swan-necked Tool, 57

Grinding Tungsten Carbide. Tools,

2

Gainding Wheels, 58-50

Ground Steel Toots

and Power Machines

Handle, Feed Seresy, 4445,

High-Speed Steel Tools, $5

Installation, Flectrical, 65°86

stalling the Machine, 61-05,

Intemal Keyway ‘Tool, 40

Jack Serew, 21

Jack, Thruse, 52

Key"way Cuttng Tools, 27-40

Kepways, Cutting 84-83, 92

ree, 8 tz, 18

Rie Tools, 36

Lanter, 12,15

athe at Shaping Machine, the 92-98

Tock Screws, Gib stip, 45

Lacking the Capper Boxy 38

Mirchine, Additions to the, 43-53

Machine, Instaling the, 61-05

Machine, Levelling the, 61-60

Machine’ Sides, Shaping. 91

Machine Viee, is

Machine Viee, Atomn ‘Tools, 67-68

INDEX

Machine Viee, Drummond, 19

Machine Vice he Eline! 9

Machine Vice, The 'Mytordy pe

Machine Vice, The ‘Oflens 6g”

Machine Vice ‘Perfecto, 869

Machine Vice. Securing the 7)

Machine View. Serting they'3g-80

Machines, Hend Bower, 15-33

‘Machines, Power Driven, 33-34

‘Machining the end of Shatle, -83

Magnets Pot

Mandrel Extension, 96

Metinis, Richard 5

Motor Déive Blectno) 33-34

Mounting the Worl 67-08

Murray, Matthew, 8

‘Mylord Machine Vice 71

‘Oflen! Machine Vice, 69-50

Operating Speeds, 26

Overhung Crank 28

Parse o¢

PauleandcMatchet System, 46

Perlccto Hand Shapers 21-32

Perfecto Machine Vice, 88-69

Perlect Power Shaper, 4-26

Poh, Citealar, 87

Plate! Ana, 1s

Bot Magnets, So

Power Driven Machines, 23-34

Power Shaper, Acorn Tools, 28-24

Quant Sess e748

Quadrant Gear Hacker, 49-1

Rees, 4749.

Rack theckes, 51-53

Ricks Curing oto

Ram, 8 9, 517,289 34,28, 32

Ra Patios Atte, 380

Ratchet, 20

Ratchet Link, 18,19

Ratchet Whedl, 95

Ret, Angular Grinding, 56-57

Robre Richerd,

Roni, Connecting” 47-48

Roughing Out Fadl $ony7

Saddle ao, 21

Bawing ‘Tools, 42

Screws Feed, ib 22

Sere Jacky 11

Sere Len ty

Seconitshand Vice, Checking a 71-74

Securing the Machine Vice, 73

Scieacs, the

Servicing the Toots, 4,60

Setting the Machine Vice, 70-80

Shafts, Machining the ends of 81-85,

Shafts, Squaring the endo of bo Se

Shaper, Fixed Head, x8

Shaping Machine, Cowell, 19-23

ping Machine, the’ Lathe a

2-08

Shiping Machine Sides, 0:

Shaping Machine Tools” 35-42

Slide, Tool org, 14, 19,31

Special Purpose Favls 39-42

Speeds, Cutng, 34

Speeds, Grinding Whee, 59

speeds, Operating, 26,

ands, Fermo Concrete, 62-64

trike, 18) 0

Surface Finishing Toot, 38

Swancneched Tools 33

Table, Work, 1112

Thrust Jack 32

Tools Ground Sts, 75

Tool Holder, American Baten, 19

‘Tool Holder Baeish Batcern 1

‘Tool, Kerway Cating

‘Tool, Knife, 36

‘Tool, Roughing Ou, 36-37

Tool'Stales 9-10, 10, Pr 3h 43

Tool "Slide, “Autoinate "Feed for,

“ss

Todke: Cran, 36,

Tools, Grindig Swan-neckes

Tools, High-Speed Stee,

Tools, Sawing 42

Tool Servicing the, 54-60

‘Tools; Shaping Machine, 35~42

‘Tools, Special Purpose 39542

Tools, Surface-Finahingy a8

‘Poole Swamcneckes, 3

TiS. 7578

[Slr bak, 95

Slot Breakage. 75,

Sor Mahi,

‘Tungsten Carbide 55

Tungsten Carbide” *Toels, Grinding

7

<0

VBlocks, 89-90

Vice, Aeoen Tools Machine, 67-68

Vice! Checking a Second-hand, 71-74

Vice, elipse™ Machine, 71

Vice, Machine, 13

Vice, ‘Myford’ Machine, 72

Vice, ‘Often’ Machine, 69-70

Wheel, Ratche, 33

Wheels, Grinding: 8-50

Wheels; Grinding Speeds, 50

Whitworth, Joseph, &

Wooden Benching, 61-62

Work, Mounting the 67-78

Work’ Table, vinra, ae

Work Table Feed, Automatic, 31-32

Work Table Adjustment, 32,

‘Work Table Blevatg Gear, 32

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Is.1976.1976 Paddy Wheader ManualDocument13 pagesIs.1976.1976 Paddy Wheader ManualGohilakrishnan ThiagarajanNo ratings yet

- 2 Check Type Damper Drawing 1555074039Document1 page2 Check Type Damper Drawing 1555074039Gohilakrishnan ThiagarajanNo ratings yet

- Cotton Waste TenderDocument2 pagesCotton Waste TenderGohilakrishnan ThiagarajanNo ratings yet

- Valve Stds AllDocument11 pagesValve Stds AllGohilakrishnan ThiagarajanNo ratings yet

- Welding Process: SMAW WGS /WPS/ SMAW/0033 Dear Sir, We Are Sending The Following PlateDocument1 pageWelding Process: SMAW WGS /WPS/ SMAW/0033 Dear Sir, We Are Sending The Following PlateGohilakrishnan ThiagarajanNo ratings yet

- Wps FormatDocument12 pagesWps FormatGohilakrishnan ThiagarajanNo ratings yet

- Bharat Heavy Electricals Limited: Tvenkat@bheltry - Co.inDocument14 pagesBharat Heavy Electricals Limited: Tvenkat@bheltry - Co.inGohilakrishnan ThiagarajanNo ratings yet

- Ball Screw AssyDocument8 pagesBall Screw AssyGohilakrishnan ThiagarajanNo ratings yet

- Bharat Heavy Electricals LimitedDocument8 pagesBharat Heavy Electricals LimitedGohilakrishnan ThiagarajanNo ratings yet

- Process Layout Status SheetDocument2 pagesProcess Layout Status SheetGohilakrishnan ThiagarajanNo ratings yet

- Inspection and Test Plan No 826 Vendor Qualification For Hardfacing Overlay of Seat Rings and DiscsDocument3 pagesInspection and Test Plan No 826 Vendor Qualification For Hardfacing Overlay of Seat Rings and DiscsGohilakrishnan ThiagarajanNo ratings yet

- Butterfly ValveDocument20 pagesButterfly Valvenazar750No ratings yet

- Valve Size & Class PO Reference:-: Qty: Drawing No: NBDN Ref:-: Description:Seat Ring:-: Invoice No. Job Code Report No Material (Base + Overlay)Document1 pageValve Size & Class PO Reference:-: Qty: Drawing No: NBDN Ref:-: Description:Seat Ring:-: Invoice No. Job Code Report No Material (Base + Overlay)Gohilakrishnan ThiagarajanNo ratings yet

- SOP - 03C Rev 1 Weld Shop PDFDocument9 pagesSOP - 03C Rev 1 Weld Shop PDFGohilakrishnan Thiagarajan100% (1)

- Astrum BrochureDocument20 pagesAstrum BrochureGohilakrishnan ThiagarajanNo ratings yet

- TDC-10B Heat Treatment For C12A Steel CastingsDocument2 pagesTDC-10B Heat Treatment For C12A Steel CastingsGohilakrishnan ThiagarajanNo ratings yet

- TDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsDocument3 pagesTDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsGohilakrishnan ThiagarajanNo ratings yet