Professional Documents

Culture Documents

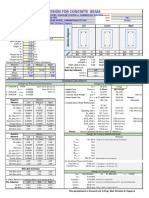

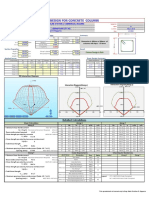

Structural Notes: Center of Moment

Structural Notes: Center of Moment

Uploaded by

Czareena DominiqueOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Structural Notes: Center of Moment

Structural Notes: Center of Moment

Uploaded by

Czareena DominiqueCopyright:

Available Formats

STRUCTURAL NOTES

ASTM- American Society for Testing and

PROPERTIES OF FORCES

ACI- American Concrete institute

According to ACI code, I the strain in concrete reaches

0.003 (conc= 0.003),

=3mm

It begins to crack

MAGNITUDE- the amount of force, N

Materials

1000

DIRECTION- refers to the orientation of its path or line of

action. It is usually described by the angle that the line of

action makes with some reference.

AISC- American Institute for steel construction

If a grade 60 steel (fy= 60ksi= 414Mpa) reaches a strain

0.0021 it begins to yield of (2.1mm)

SENSE- refers to the manner in which it acts along its line

of action

FEATURES OF A STRAIN STRESS DIAGRAM:

FORCE SYSTEM

STRESS- STRAIN DIAGRAM - a graphic representation of

the relationship between unit stress values and the

corresponding unit strains for a specific material

COPLANAR

- all acting in a single plane of a vertical wall

1. PROPORTINAL LIMIT- maximum stress which the

material springs back to the original length when the load is

released

PARALLEL

- all having the same direction

CONCURRENT

- all having their lines of action intersect at a common point.

2. ELASTIC LIMIT- maximum stress below which the

material does not return to its original length but has

incurred a permanent deformation we call permanent set

MOMENT

- force x distance

- moment can be about any point called

3.YIELD POINT- the stress wherein the deformation

increases without any increase in the load. The material at

some portion shows a decrease in its cross section

CENTER OF MOMENT

MOMENT ARM

- distance from center of moment to force

- shortest or perpendicular distance from the center of

moment to line of action of force.

KINDS OF LOADS

CONCENTRATED LOADS - example is a

supporting a column

beam

UNIFORM LOADS- a series of uniform

concentrated

loads, but for 5 or more

uniformly spaced concentrated

loads.

OTHER LOADS- varying load, moment load

TYPES OF SUPPORT

HINGED

ROLLER

FIXED/ RESTRAINED

TYPES OF BEAMS

SIMPLY SUPPORTED BEAM

SIMPLY SUPPORTED W/ OVER HANG

(OVERHANGING BEAM)

CANTILEVER BEAM

PROPPED CANTILEVER BEAM (indeterminate)

CONTINOUS BEAM

INTERNAL FORCES TYPES

TENSION- pulls away from joint

COMPRESSION-pushes towards joint

SHEAR- for connections

4. ULTIMATE STRENGTH- the maximum stress that can be

attained immediately before actual failure or rupture

RUPTURE STRENGTH- stress at which material specimen

breaks

ALLOWABLE STRESS- the maximum unit stress permitted

for a material in the design of a structural member, usually a

fraction of the materials elastic limit, yield strength, or

ultimate strength. Also called allowable unit stress, working

stress.

ELASTIC RANGE- the range of unit stresses for which a

material exhibits elastic deformation

ELASTIC DEFORMATION- a temporary change in the

dimensions or shape of a body produced by a stress less

than the elastic limit of the material

BRITLENESS- the property of material that causes it to

rupture suddenly under stress with little evident

deformation. Since brittle materials lack the plastic behavior

of ductile materials, they can give no warning of impending

material

DUCTILITY- the property of a material that enables it to

undergo plastic deformation after being stressed beyond the

elastic limit and before rupturing. Ductility is a desirable

property of a structural material since plastic behavior is an

indicator of reserve strength and can serve as a visual

warning of impending failure.

ELASTICITY- the property of a material that enables it to

deform in response to an applied force and to recover its

original size and shape upon removal of the force

MALLEABILITY- the ability of a material to regain and

rebound to original shape when the load is released

1|S t r u c t u r a l

TOUGHNESS- the property of a material that enables it to

absorb energy before rupturing, represented by the area

under the stress- strain curve derived from a tensile test of

the material. Ductile materials are tougher than brittle

materials.

MODULUS OF ELASTICITY- a coefficient of elasticity of a

material expressing the ratio between a unit stress aSd the

corresponding unit strain caused by the stress, as derived

from Hookes law and represented by the slope of he

straight line portion of the stress- strain line diagram. Also

called coefficient of elasticity, elastic modulus

PERMANENT SET- the inelastic strain remaining in a

material after complete release of the stress producing

deformation

YIELD STRENGTH- the stress necessary to produce a

specific limiting permanent set in a material, usually 0.2% of

its original length when tested in tension. Yield strength is

used to determine the limit of usefulness of a material

having a poorly defined yield point. Also called poor stress.

STRAIN- RATE EFFECT- the behavior an increased rate of

load application can cause in normally ductile material

TEMPERATURE EFFECT- the brittle behavior

temperatures can cause in a normally ductile material

AXIAL STRESS- the tensile or compressive stress that

develops to resist axial force, assumed to be normal to and

uniformly distributed over the area of the cross section. Also

called direct stress, normal stress

COMPRESSION- the act of shortening or state of being

pushed together, resulting in the reduction in size or volume

of an elastic body

COMPRESSIVE FORCE- an applied force producing or

tending to produce compression in an elastic body

ECCENTRIC FORCE- a force applied parallel to the

longitudinal axis of a structural member but not to the

centroid of the cross section, producing bending and

uneven distribution of stresses in the section. Also called

eccentric load.

STRESS- the internal resistance or reaction of an elastic

body to external forces applied to it. Equal to the ratio of

force to area and expressed in units of force per unit of

cross- sectional area. Also called unit stress.

TENSILE STRESS- the axial stress that develops at the

cross section of an elastic body to resist the collinear tensile

forces tending to elongate it.

low

STRESS RELAXATION- the time- dependent decrease in

stress in a constrained material under a constant load

CREEP- the gradual permanent deformation of a body

produced by a continued application of stress or prolonged

exposure to heat. Creep deflection in a concrete structure

continues over time and can be significantly grater than the

initial elastic deflection

FATIGUE- the weakening or failure of a material at a stress

below the elastic limit when subjected to a repeated series

of stresses

STRUCTURAL PROPERTIES

OF A36 STEEL:

Maximum allowable stress (Fv) in shear is 14.5 ksi

Maximum allowable stress (Fb) for bending is 24 ksi

Modulus of elasticity (E) is 29,000 ksi

WEIGHT:

water= 1000 kg/ m3

steel= 7850 kg/ m3

concrete= 2400 kg/ m3

weight= density x volume

volume of cylinder= pi (diameter)2 x length

4

PROPERTIES OF A MATERIAL

TENSION- the act of stretching or state of being pulled

apart, resulting in the elongation of an elastic body

TENSILE FORCE- an applied force producing or tending to

produce tension in an elastic body

AXIAL FORCE- a tensile or compressive force acting along

the longitudinal axis of a structural member and at the

centroid of the cross section, producing axial stress without

bending, torsion or shear, also called axial load

TENSILE STRAIN- the elongation of a unit length of

material produces by a tensile stress

ELONGATION- a measure of ductility of a material,

expressed as the percentage increase in length of a test

specimen after failure in tensile test

REDUCTION OF AREA- a measure of ductility of a

material, expressed as the percentage decrease in crosssectional area of a test specimen after rupturing in a tensile

test

TENSILE STRENGTH- the resistance of a material to

longitudinal stress, measured by the minimum amount of

longitudinal stress required to rupture the material

STRAIN - the deformation of a body under the action of an

applied force. Strain is a dimensionless quantity, equal to

the ratio of the change in size and shape to the original size

and shape of a stressed element.

STAIN GAUGE- an instrument for measuring minute

deformation in a test specimen caused by tension,

compression, bending or twisting. Also called extensometer

YOUNGS MODULUS- a coefficient of elasticity of material

expressing the ratio of longitudinal stress to the

corresponding longitudinal strain caused by the strain.

POISSONS RATIO- the ratio of lateral strain to the

corresponding longitudinal strain in an elastic body under

longitudinal stress

COMPRESSIVE STRESS- the axial stress that develops at

the cross section of an elastic body to resist the collinear

compressive forces tending to shorten it.

COMPRESSIVE STRAIN - the shortening of a unit length of

material produced by a compressive stress

SHEAR - the lateral deformation produced in a body by an

external force that causes one part of the body to slide

relative to an adjacent part in a direction parallel to their

plane contact.

2|S t r u c t u r a l

SHEAR FORCE - an applied force producing or tending to

produce shear in the body

SHEARING FORCE - an internal force tangenial to the

surface on which it acts, developed by a body in response

to shear, shearing in a vertical plane necessarily involves

shearing in a horizontal plane and vise versa

SHEARING STRESS- the force per unit area developed

along a section of an elastic body to resist a shear force.

Also called shear stress, tangenial stress

SHEARING STRAIN - the lateral deformation developed in

a body in response to shearing stresses, defined as the

tangent of the skew angle of the deformation.

SHEAR MODULUS OF ELASTICITY - a coefficient

elasticity of a material, expressing the ratio between

shearing stress and the corresponding shearing strain

produced by the strain. Also called modulus of rigidity,

modulus of torsion

BENDING- the bowing of an elastic body as an external

force is applied transversely to its length. Bending is the

structural mechanism that enables a load to be mechanism

that enables a load to be channeled in a direction

perpendicular to its application.

TRANSVERSE FORCE- a force applied perpendicular to

the length of a structural member, producing bending and

shear

TORQUE- the moment of a force system that causes or

tends to cause rotation or torsion

TORSION- the twisting of an elastic body about its

longitudinal axis caused by two equal and opposite torques,

producing shearing stresses in the body

REINFORCED CONCRETE

EFFECTIVE LENGTH- the depth of concrete section

measured from the compression face to the centroid of the

tension reinforcement

COVER- the amount of concrete required to protect steel

reinforcement from fire and corrosion, measured from the

surface of the reinforcement to outer surface of the concrete

section

BOND STRESS- the adhesive for per unit area of contact

between reinforcing bar and the surrounding concrete

developed at any section of a flexural member

HOOK- a bend or curve given to develop an equivalent

embedment length, used where there is insufficient room to

develop in adequate embedment length

STANDARD HOOK- a 90, 135, 180 bend made at the

end of a reinforcing bar according to standards

ANCHORAGE - any of various means, as embedment

length or hooked bars, for developing tension or

compression in a reinforcing bar on each side of critical

section in order to prevent bond failure or splitting

CRITICAL SECTION - the section of a flexural concrete

member at a point of maximum stress, a point of inflection,

or appoint within the span where tension bars are no longer

needed to resist stress

BALANCED SECTION - a concrete in which the tension

reinforcement theoretically reaches its specified yield

strength as the concrete in compression reaches its

assumed ultimate strain

OVERREINFORCED SECTION - a concrete section in

which the concrete in compression reaches its assumed

ultimate strain before the tension reinforcement reaches its

specified yield strength. This is a dangerous condition since

failure of the section could occur instantaneously without

warning

UNDERREINFORCED SECTION - a concrete section in

which the tension reinforcement reaches its specified yield

strength before the concrete in compression reaches its

assumed ultimate strain. This is desirable condition since

failure of the section would be preceded by large

deformations giving prior warning of impending collapse

BEAM

BEAM- a rigid structural member designed to carry and

transfer transverse loads across spaces supporting

elements

SPAN- the extent of space between two supports of a

structure

CLEAR SPAN- the distance between inner faces of the

support of a span

EFFECTIVE SPAN- the center to center distance between

the supports of a span

BENDING MOMENT- an external moment tending to cause

part a structure to rotate or bend, equal to the algebraic sum

of the moments about the neutral axis of the section under

consideration

RESISTING MOMENT- an internal moment equal and

opposite to a bending moment, generated by a force couple

to maintain equilibrium of the section being considered

DEFLECTION - the perpendicular distance a spanning

member deviates from a true course under transverse

loading, increasing with load and span, and decreasing with

an increase in the moment of inertia of the section of the

modulus of elasticity of the material

NEUTRAL AXIS - an imaginary line passing through the

centroid of the cross section of a beam, other ember subject

to bending, along which no bending stresses occur

BENDING STRESS - a combination of compressive and

tensile stresses developed at a cross section of structural

member to resist transverse force, having a maximum value

at the surface furthest from the neutral axis

CAMBER - a slight convex curvature intentionally built into

beam, girder, or truss to compensate for an anticipated

deflection.

How is camber treated in a steel truss 25 meters and

longer? Camber shall be approximately equal to the dead

load deflection

TRANSVERSE SHEAR- an external shear force at a cross

section of a beam or other member subject to bending,

equal to the algebraic sum of transverse forces on one side

of the section

3|S t r u c t u r a l

VERTICAL SHEARING- the shearing stress developed

along cross section of a beam to resist transverse shear,

having a maximum value at the neutral axis and decreasing

nonlinearly toward the outer faces

HORIZONTAL SHEARING- the shearing stress developed

to prevent slippage along longitudinal planes of a beam

under transverse loading, equal to any point to the vertical

shearing stress at that point. Also called longitudinal

shearing stress

FLEXURE FORMULA - a formula defining the relationship

between bending moment, bending stress, and the cross

sectional properties of a beam. Bending stress is directly

proportional to bending moment and inversely proportional

to the moment of inertia of a beam section.

MOMENT OF INERTIA - the sum of the products of each

element of an area and the square of its distance from a

coplanar axis of rotation. Moment of inertia is a geometric

property that indicates how the cross sectional area of

structural member is distributed and does not reflect the

intrinsic physical properties of a material

SECTION MODULUS- a geometric property of a cross

section, defined as the moment of inertia of the section

divided by the distance from the neutral axis to the most

remote surface.

LATERAL BUCKLING- the buckling of a structural member

induced by compressive stresses acting on slender portion

insufficiently rigid in the lateral direction

STRESS TRAJECTORIES- lines depicting the direction but

not the magnitude of the principal stresses in a beam

SHEAR DIAGRAM - a graphic representation of the

variation in magnitude of the external shears present in a

structure for a given set of transverse loads and support

conditions concentrated loads produce external shears

which are constant in magnitude between the loads

uniformly distributed loads produce linearly varying shears

MOMENT DIAGRAM - a graphic representation of the

variation in magnitude of the bending moment present in a

structure for a given set of transverse load and support

conditions. The overall deflected shape of a structure

subject to bending can often be inferred from the shape of

its moment diagram

NEGATIVE MOMENT- a bending moment that produces a

convex curvature at a section of a structure

SIMPLE BEAM - a beam resisting on simple supports at

both ends which are free to rotate and have no moment

resistance. As with any statistically determinate structure,

the values of all reactions, shears, and moments for a

simple beam are independent of its cross sectional shape

and material

CANTILEVER BEAM- a projecting beam supported at only

one fixed end

CANTILEVER- a beam or other rigid structural member

extending beyond a fulcrum and supported by a balancing

member or a downward force behind the fulcrum

OVERHANGING BEAM - a simple beam extending beyond

one of its supports. The overhanging reduces the positive

moment at midspan while developing a negative moment at

the base of the cantilever over the support

FIXED END BEAM- a beam having both ends restrained

against translation and rotation. The fixed ends transfer

bending stresses, increase the rigidity of the beam and

reduces its maximum deflection

CONTINUOUS BEAM - a beam extending over more than 2

supports in order to develop greater rigidity and smaller

moments than a series of simple beams having similar

spans and loading. Both fixed end and continuous beams

are indeterminate structures for which the values of all

reactions, shears and moments are dependent not only on

span and loading but also on cross sectional shape and

material

HAUNCH - the part of a beam that is thickened or

deepened to develop greater moment resistance. The

efficiency of a beam can be increased by shaping its length

in response to the moment and shear values which typically

vary along its longitudinal axis

SUSPENDED SPAN- a simple beam supported by the

cantilevers of two adjoining spans with pinned construction

joints at points of zero moment. Also called hung span

EFFECTIVE LENGTH- the distance between inflection

points in the span of a fixed end or continuous beam,

equivalent in nature to the actual length of simply supported

beam

CONCENTRATED LOADS- produce bending moments

which vary linearly between loads

UNIFORMLY DISTRIBUTED LOADS produce parabolically

varying moments

POSITIVE SHEAR- a net resultant of shear forces that acts

vertically upward on the left part of the structure being

considered

NEGATIVE SHEAR- a net resultant of shear forces that act

vertically downward on the left part of the structure being

considered

POSITIVE MOMENT- a bending moment that produces

moment that produces a concave curvature at a section of a

structure

INFLECTION POINT- a point at which a structure changes

curvature from convex to concave or vise versa as it

deflects under a transverse load: theoretically an internal

hinge and therefore a point of zero moment

COLUMN

COLUMN - a relatively slender structural member designed

primarily to support axial, compressive loads, applied at the

member ends.

POST - a stiff vertical support especially a wooden column

in timber framing

BUCKLING - the sudden lateral or torsional instability of a

slender structural member induced by the action of a

compressive load. Buckling can occur well before the yield

stress of the material is reached

BUCKLING- the axial load at which a column begins to

deflect laterally and becomes unsuitable.

CRITICAL BUCKLING LOAD - the maximum axial load

that can theoretically be applied to a column without

causing it to buckle. The critical buckling load for a column

4|S t r u c t u r a l

is inversely proportional to the square of its effective length

and directly proportional to the modulus of elasticity of the

material and to the moment of inertia of the cross section.

Also called Euler buckling load

BIFURCATION - the critical point at which a column

carrying its critical buckling load, may either buckle or

remain undeflected. The column is therefore in a state of

neutral equilibrium

CRITICAL BUCKLING STRESS - the critical buckling load

for a column divided by the area of its cross section

acting in the same direction and equal at any point to their

algebraic sum.

KERN The central area of any horizontal section of a

column or wall within which the resultant of all compressive

loads must pass if only compressive stresses are to be

applied beyond this area will cause tensile stresses to

develop in the section. Also called kern area.

KERN POINT A point on either side of the centroidal axis

of a horizontal column or wall section defining the limits of

the kern area.

SLENDERNESS RATIO- the ratio of the effective length of

a column to its least ratio of gyration

The higher the slenderness ratio, the lower is the critical

stress that will cause buckling. A primary objective in the

design of a column is to reduce its slenderness ratio by

minimizing its effective length or maximizing its effective

length or maximizing the radius of gyration of its cross

section

LATERAL BRACING the bracing of a column or other

compression member to reduce its effective length. Lateral

bracing is most effective when the bracing pattern occurs in

more than one plane.

RADIUS OF GYRATION - the radial distance from any axis

to a point at which the mass of a body could be

concentrated without altering the moment of inertia of the

body about that axis. For a structural section, the radius of

gyration is equal to the square root of the quotient of the

moment of inertia and the area

The higher the radius of gyration of a structural section, the

more resistant the section is to buckling. In determining the

cross- sectional shape of a column, the objective is to

provide the necessary radius of gyration about the different

axes. For an asymmetrical cross section, buckling will tend

to occur about the weaker axis or in the direction of the

least dimension

EFFECTIVE LENGTH FACTOR a coefficient for

modifying the actual length of a column according to its end

conditions in order to determine its effective length. Fixing

both ends of a long column reduces its effective length by

half and increases its load-carrying capacity by a factor of 4.

UNBRACED LENGTH the distance between the points at

which a structural member is braced against buckling in a

direction normal to its length.

TRUSS

METHOD OF SECTIONS a method of determining

member forces in a truss by considering the equilibrium of

any portion of the truss assembly.

LONG COLUMN- a slender column subject to failure by

buckling rather than by crushing

METHOD OF JOINTS a method for determining member

forces in a truss by considering the equilibrium of the

various joints idealized as points in free body diagrams

SHORT COLUMN - a thick column subject to failure by

crushing rather than by buckling. Failure occurs when the

direct stress from an axial load exceeds the compressive

strength of the material available in the cross section. An

eccentric load, however, can produce bending and result in

uneven stress distribution in the section

DEFINITION OF TERMS

INTERMEDIATE COLUMN - a column having a mode of

failure between that a short column and a long column,

often party inelastic by crushing and partly elastic by

buckling

ECCENTRICITY - The amount by which an axis deviates

from another parallel axis.

P-DELTA EFFECT An additional moment developed in a

structural member as its longitudinal axis deviates from the

line of action of a compressive force equal to the product of

the load and the member deflection at any point.

MIDDLE THIRD RULE The proposition that a

compressive load should be located within the middle third

of a horizontal section of a column or wall to prevent tensile

stresses from developing in the section.

EFFECTIVE LENGTH The distance between inflection

points in a column subject to buckling load. When this

portion of a column buckles the entire column falls.

COMBINED STRESSES A set of tensile and compressive

stresses resulting from the superposition of axial and

bending stresses at a cross section of a structural member,

ACTIVE EARTH PRESSURE - a soil pressure acting on

any structure that will tend to push the structure wherein the

structure or a wall tends to move away from the soil

ACCELEROGRAPH- is an instrument which measures the

velocity and acceleration of an earthquake in the ground

ANCHOR BOLTS - a round, steel bolt embedded in

concrete or masonry used to hold down machinery, steel

columns or beam casting, shock beam plates and engine

heads

BALANCED DESIGN - is one which both the concrete and

the steel are so proportioned as to work to their full working

stresses when the member carries its full allowable load

BATTER PILES - are piles at an inclination to resist forces

that are not critical. This is also known as brace pile or spur

pile

BEARING WALL SYSTEM- a structural system without a

complete vertical load carrying space frame

BENDING MOMENT - is the algebraic sum of the moments

of the forces acting on either side of the section of a beam

about an axis through the center of the gravity of the section

5|S t r u c t u r a l

BORED PILE (bearing pile)- a concrete pile which

concreted either with a casing or without a casing at its

permanent location. This is a cast in place pile

CAISSON - a watertight, cylindrical or rectangular chamber

used to in under water construction to protect workers from

water pressure and soil collapse

EXPANSION OR CONTRACTION - the designed break in a

structure to allow for the drying and temperature shrinkage

of concrete, brickwork of similar material, thereby

preventing the formation of harmful cracks

CEMENT GUN - is an ejector operated by compressed air

to force gunite into cavities or cracks in rocks or cement

works

FATIGUE - is a phenomenon of failure under repeated

stresses. A fact, based experience and experiments, is well

known that stresses which are applied to a body a few times

without causing apparent structure injury may, if applied

repeatedly or causing a great number of times, causes

failure

CHUTE - is an open-top through which bulk materials are

conveyed and by gravity

GUNITE - is a rich cement mortar which is applied by

spraying under high air pressure

COFFER DAM - a temporary dam- like structure

constructed which excludes water from the site of the

foundation during its excavation and construction

GRADE BEAM - a concrete beam placed directly on the

ground to provide foundation for the superstructure

CONSTRUCTION JOINT - the vertical or horizontal face in

a concrete structure where concreting has been stopped

and continued later

COLD JOINT- formed when a concrete surface hardens

before the next batch o f concrete is placed

CREEP- the tendency of most material to move or deform

over time under a constant load The amount of movement

varies enormously depending upon the material. The area

that is highly stressed will move the most. The movement

causes stresses to be redistributed.

COUNTER (inner in retaining wall)- a cantilever wall that is

reinforced with a masonry structure extending upward from

the foundation or from the inner face of the retaining wall to

provide additional resistance to thrust and are placed at

regular intervals. (buttress if outer)

COFFER DAM- a temporary watertight enclosure around an

area of water or water bearing soil, in which construction is

to take place, bearing on a stable statum at or above the

foundation level of new construction. The water is pumped

from within to permit free access to the area

DIAPHRAGM- a horizontal or nearly horizontal system

including horizontal bracing system, that act to transmit

lateral forces to the vertical resisting elements

DIAPHRAGM STRUT - a structural member of a horizontal

bracing system that takes axial tension or compression. It is

parallel to the applied load that collects and transfers shear

to the vertical resisting elements or distributive loads within

the horizontal bracing system

DIVING BELL- a watertight bell- shaped steel chamber

which can be lowered to or raised from a fresh or seawater

bed crane. It is opened at the bottom and filled with

compressed air so that men can prepare foundations and

undertake similar construction work under water.

DOWEL - a short steel bar extending from one concrete

element to another as for instance a concrete foundation to

a concrete column. It may or may not transfer direct stress

DRIFT BOLT- is a long pin of steel or wood, made with or

without the head, driven through the timber and into an

adjacent timber to hold them together and to transmit

stresses

EXPANSION OR CONTRACTION - a joint designed to take

expansion and contraction

GRANOLITHIC FINISH - a surface layer or granolithic

concrete which maybe laid on a base of either fresh or

hardened concrete

GRILLAGE - is a footing which consist of steel beams

arranged to distribute a concentrated load to the supporting

masonry or soil

DISTRIBUTION OF HORIZONTAL SHEAR - design

analysis requirement, considered as the basis for the

structural design of structures where the total lateral forces

are distributed to the various vertical elements of the lateral

force resisting system in proportion to their rigidities

considering the rigidity of the horizontal bracing system or

diaphragm

HYBRID STEEL GIRDER - is a fabricated metal beam

composed of flanges with a material of a specified minimum

yield strength different from that of the web plate

INTENSITY - the measure of the damage level of an

earthquake (subjective to visual assessment)

INFLECTION POINT- a point in the moment diagram where

it changes from positive to negative moment of vise versa

and the value of the moment at this point is zero

JETTING - a method of driving piles or well points into the

sand in the situations where a pile hammer might not be

suitable owing to the risk of damage by vibration to the piles

of adjacent buildings

LINTEL BEAM - a beam especially provided over an

opening for a door, window, to carry the wall over the

opening

MAGNITUDE - the measure of the energy released by an

earthquake (measured by instrument)

MODULUS OF ELASTICITY - is the constant which, within

the proportional limit, express ratio between the unit stress

to the unit strain. It is the measure of the relative abilities of

the different materials of construction to resist deformation

under stress within proportional limit

MODULUS OF RESILIENCE - is a measure of the capacity

of the material to absorb energy without danger of being

permanently deformed

MOMENT OF RESITANCE- is the internal resisting moment

of a beam. It is opposite in sense to the bending moment

but of the same magnitude

6|S t r u c t u r a l

MORTAR- is a mixture, composed of one part of Portland

cement and one part of clean sand, used as a filter

MULLION- is a vertical member between two portions of

window sash usually designed to resist wind load and not

vertical load. It is different from muntin, which is smaller

member which separates the panels of glass within the

whole sash.

NON- BEARING WALL - is wall that carries no load other

than its own weight

ORTHOGONAL EFFECT - the effect on the structure due to

extreme lateral (earthquake) motions acting in directions

other than parallel to the direction to the direction of

resistance under consideration

PARTY WALL- is a wall used or adopted for joint service

between two buildings

PLASTER CEMENT FINISH- a mixture of Portland cement,

with water and sand applied to surfaces such as walls

ceilings in a plastic state, later it sets to form a hard surface

POINTING - in masonry, the final treatment of joints by the

troweling of mortar or putty like filler into joints

PORTAL METHOD - method of analyzing indeterminate

modular building frames by assuming hinges at the center

of beam spans and column heights or the interior column

carries twice as much shear as the exterior column

PORTLAND CEMENT - is the product obtained by finely

pulverizing clinker produced by calcining to incipient fusion

an intimate and properly proportioned mixture of

argillaceous and calcareous materials with no additions

subsequent to calcinations except water and calcined or

uncalcined gypsum

PROPORTIONAL LIMIT - is the highest unit stress for

which the deformation of a body is proportional to the

stress. Beyond this point, permanent deformation occurs

REDUNDANT MEMBER - is any framed structure or truss,

is one which maybe omitted in the structure without affect in

the possibility of analyzing the frame or truss by ordinary

static method of computations such as the counter diagonal

truss

RIP-RAP - consist of rough stones of various placed

compactly or irregularly to prevent scour by water and

protect material which maybe washed out by the water

SAGROD- structural member in the steel truss framing that

counteracts forces in compression because of high

probability of the purlins to deflect and bend down during

purlin installation.

SAND DRAIN- it is provided to help in the compaction of

natural soil which provide channels through which water can

escape much more rapidly then through the clay itself. The

weight of the drain itself helps in the compaction.

SHEAR WALL- a wall designed to resist lateral forces

parallel to the plane of a wall

SOFFIT- is the concave surface of an arch

SPANDREL BEAM- is a beam from column to column,

carrying an exterior wall in a skeleton building

STIFFNESS RATIO (K) in moment distribution method- (as

used in analysis of indeterminate structures) is the ratio of

moment of inertia of the cross section of its length

STRESS- is the cohesive force in a body, which resists the

tendency of an external force to change the shape of the

body

STRAIN OR DEFORMATION- is the change in the shape of

any material when subjected to the action force

TIE BAR- a deformed bar, embedded in a concrete

construction at a joint and designed to hold a butting edges

together, not designed for direct load transfer

TORSION OR MOMENT OF INERTIA- is a quality which

measures the resistance of the mass to being revolved

about a line

TRANSFORMED SECTION- is one in which the flexural

steel is conceived to be replaced by large area of imaginary

concrete which can take tension. This gives a

homogeneous section of concrete to which ordinary beam

analysis may be applied

TREMIE- is a watertight pipe 300 mm to 600 mm in

diameter with a flared top used in depositing concrete under

water

UNDERPINNING- is an art of placing new foundation under

old foundation

VIBRATOR- is an oscillating power operated machine used

to agitate fresh concrete so as to eliminate gross voids

including entrapped air and to produce intimate contact with

form surfaces and embedded materials

VOID- CEMENT RATIO- is the ratio of volume of air plus

water to the volume cement

WALL FOOTING- a continuous type of spread footing the

supports vertical load, the weight of the wall itself and the

weight of the footing

WATER CEMENT RATIO- the ration of the amount of water,

to the amount of cement in a concrete or mortar mixture

WEB CRIPPLING- local failure of a thin web plate of a steel

beam or girder in the immediate vicinity of a concentrated

load

ASD- allowable stress design

LRFD- load resistance factor design

SEISMIC DESIGN PROVISION

ARTIFICIAL RIGIDITY- will cause torsion (twisting)

BASE- is the level at which the earthquake motions are

considered to be imparted to the structure

BASE SHEAR- is the total designed lateral force or shear at

the base of the structure

BEARING WALL SYSTEM (shear type)- is a structural

system without a complete vertical load carrying space

frame

BOUNDARY ELEMENT- is an element at edges of opening

or at the perimeters of shear walls or diaphragm

7|S t r u c t u r a l

BRACED FRAME- is an essentially vertical truss system of

the concentric or eccentric type which is provided to resist

lateral forces

BUILDING FRAME SYSTEM- is an essentially complete

space frame which provides supports for gravity loads

CONCENTRIC BRACED FRAME- is a braced frame in

which the members are subjected primarily to axial forces

COLLECTOR- is a member or an element provided to

transfer lateral forces from a portion of a structure to the

vertical elements of the lateral force resisting system

DIAPHRAGM- is a horizontal or nearly horizontal system

(including horizontal bracing system) acting to transmit

lateral forces to the vertical resisting elements

DIAPHRAGM STRUT - also known as tie or collector, is the

element of a diaphragm parallel to the applied load which

collects and transfer diaphragm shear to the vertical

resisting elements or distribute loads within the diaphragm.

Such members may also take axial tension or compression.

DIAPHRAGM CHORD- is the boundary element of a

diaphragm or a shear wall which is assumed to take axial

stresses analogous to the flanges of the beam

DUAL SYSTEM- is a combination of a Special or

Intermediate Moment Resisting Space Frame and Shear

walls or Braced Frame

ESSENTIAL FACILITIES- are those structures which are

necessary for emergency post- earthquake operations

FLEXIBLE ELEMENT- an element or system is one whose

deformation under lateral load significantly larger than

adjoining parts of the system

HARMONIC MOTION- the coincidence of the natural period

of structural with the dominant frequency in the ground

MOMENT RESISTING FRAME- is a space frame in which

the members and joints are capable of resisting forces

primarily by flexure

ORTHOGONAL EFFECT- is the effect of the structure due

to earthquake motions acting in directions other than

parallel to the direction of resistance under consideration

P- DELTA EFFECT- is the secondary effect on shears and

moments of frame members induced by the vertical loads

acting on the laterally displaced building frame

PERT-CPM (Program Evaluation Review Technique- Critical

Path Method) - it is a presentation of project plan by a

schematic diagram or network that depicts the sequence

and interrelation of all the component parts of the project,

and the logically analysis and manipulation of this network

in determining the best overall program of operation.

PLATFORM- is the lower rigid portion of a structure having

vertical combination of structural system

PNEUMATIC MORTAR- mortar applied to a surface with a

cement gun in the same manner as gunite, with such mortar

has a cube crushing strength of 20.68 Mpa at 28 days with

water/ cement ratio of 0.45

SOFT STOREY- is a storey whose lateral stiffness is less

than 70% of the stiffness of the storey above

SOIL- STRUCTURE RESONANCE- is the coincidence of

the natural period of structure which dominant frequency in

the ground motion

STRENGTH is the usable capacity of a structure or its

members to carry loads within the deformation limits

prescribed in the code

SOIL STABILIZATION- is the process of improving the

properties of a soil to make it more suitable for a particular

purpose

SPACE FRAME- is a three dimensional structural system

without bearing walls composed of members interconnected

so as to function as a complete self contained unit with or

without the aid of horizontal diaphragms or bracing systems

STOREY- is the space between levels. Storey x is the

storey below level x

STOREY SHEAR- is the summation of design lateral forces

above the storey under consideration

STOREY DRIFT- is the displacement of one level relative to

the level above or below

STOREY DRIFT RATIO- is the storey drift divided by the

storey height

STRUCTURE- is an assemblage of framing members

designed to support gravity loads and resist lateral forces.

They maybe categorized as building or non- building.

RAINWATER LEADER- it is another term of a downspout. It

is a vertical pipe, often of sheet metal, used to conduct

water from a roof drain or gutter to the ground.

TORSION RIGIDITY- (s used in seismic design) refers to

the relative stiffness of the structure to resist torsional stress

TOWER- is the upper flexible portion of a structure having a

vertical combination of structural system

VERTICAL LOAD CARRYING SPACE FRAME- is a space

frame designed to carry all vertical (gravity) loads

WEAK STOREY- is a storey whose strength is less than

80% of the strength of the storey

SEISMIC REQUIREMENT FOR

TRANSVERSE REINFORCEMENT

1.

2.

3.

4.

maximum spacing of hoops shall not exceed 24

times the diameter of the hoop bars

maximum spacing of hoops shall not be 8 times

the diameter of the smallest longitudinal bars

maximum spacing of hoops shall not be more than

d/4

the first hoop shall be located not more than 50

mm from the face of the supporting member

SHEAR WALL- is a wall designed to resist lateral forces

parallel to the plane of the wall (sometimes referred to or a

structural wall)

8|S t r u c t u r a l

GRADING AND EARTHWORK

AS GRADED- is the extent of surface conditions on

completion of grading

BEDROCK- is in-place solid rock

BENCH- is a relatively level step excavated into earth

material on which fill is to be placed

BURROW- is earth material acquired from an off site

location for use in grading on a site

COMPACTION- is the densification of a fill by mechanical

means

EARTH MATERIAL- is any rock, natural soil or fill or any

combination

EROSION- is the wearing away of the ground surface as a

result of the movement of the wind, water or ice

EXCAVATION- is the mechanical removal of the earth

material

FILL- is a deposit of earth material placed by artificial

means

GRADE- is the vertical location of the ground surface

EXISTING GRADE- is the grade prior to the grading

FINISH GRADE- is the final grade of the site that conforms

to the approved plan

GRADING- is any excavating or filling or combination

thereof

KEY- is a designed compacted fill placed in a trench

excavated material beneath the toe of a proposed fill slope

CONCRETE - mixture of Portland cement or any other

hydraulic cement, fine aggregate, coarse aggregate, and

water, with or without admixtures

SPECIFIED COMPRESSIVE STRENGTH OF CONCRETE

(f) - compressive strength of concrete used in design

expressed in megapascals (Mpa). Whenever the quantity

Fc is under a radical sign, square root of numerical value

only is intended, and result has units of megapascals (Mpa).

CONCRETE, STRUCTURAL LIGHT WEIGHT- concrete

containing lightweight aggregate and has an air-dry unit

weight not exceeding 1900 kg/m3. lightweight concrete

without natural sand is termed all- light weight concrete and

lightweight concrete in which of the fine aggregate consists

of normal weight sand is termed sand- lightweight concrete.

CURVATURE FRICTION- friction resulting from bends or

curves in the specified pre-stressing tendon profile

DEFORMED REINFORCEMENT - deformed reinforcing

bars, bar mats, deformed wire fabric and welded deformed

fabric.

DEVELOPMENT LENGTH - length of embedded

reinforcement required to develop the design strength of

reinforcement at a critical section

EFFECTIVE DEPTH OF SECTION (d) - distance measure

from extreme compression fiber to centroid of tension

reinforcement

EFFECTIVE PRESTRESS- stress remaining in prestressing

tendons after all losses has occurred, excluding effects of

dead load and super imposed load

EMBEDMENT

LENGTHlength

of

embedded

reinforcement provided beyond a critical section

JACKING FORCE- in prestressed concrete, temporary

force exerted into prestressing tendons

REINFORCED CONCRETE DESIGN

DEAD LOAD (DL) - dead weight supported by a member.

Loads of constant magnitude that remains in one position.

ADMIXTURE- a material used as ingredient of concrete and

added to concrete before or during its mixing to modify its

properties

LIVE LOAD (LL) loads that may change in magnitude and

position

AGGREGATE- granular material such as sand gravel stone

and iron blast furnace slag used with a cementing medium

to form a hydraulic cement concrete or mortar

AGGREGATE LIGHTWEIGHT- aggregate with a dry, loose

weight of 100 kg/m or less

ANCHORAGE- in post tensioning, a device used to anchor

tendon to concrete member, in pre-tensioning, a device

used to anchor a tendon during hardening of concrete

BONDED TENDON- pre-stressing tendon that is bonded to

concrete either directly or through grouting

COLUMN- member with a ratio to least lateral dimension of

3 or greater used primarily to support axial compressive

load

COMPOSITE CONCRETE FLEXURAL MEMBERS concrete flexural members of pre-cast and/or cast in place

concrete elements but so interconnected that all elements

respond to loads as a unit

FACTORED LOAD- load multiplied by appropriate load

factors, used to proportion a members by the strength

design method.

MODULUS OF ELASTICITY- ratio of normal stress to

corresponding strain for tensile or compressive stresses

below proportional limit of material

MODULUS, APARENT (concrete)- also known as long term

modulus, is determined by using the stress and strain

obtained after the load has been applied for a certain length

of time

MODULUS, INITIAL (concrete)- the slope of the stress

strain diagram at the origin of the curve

MODULUS, SECANT (concrete)- the slope of the line

drawn from the origin to appoint on the curve somewhere

between 25% and 50% of its ultimate compressive strength

MODULUS, TENGENT (concrete)- the slope of tangent to

the curve to some point along the curve

9|S t r u c t u r a l

PEDESTAL- an upright compression member with a ratio of

unsupported height to average least lateral dimensions of

less than 3

balanced conditioned. Failure under this condition is ductile

and will give warning to the user of thee structure to

decrease the load

PLAIN CONCRETE- concrete that does not conform to the

definition of reinforced concrete

OVERREINFORCED DESIGN- a design in which the steel

reinforcement is more than what is required for balanced

condition

PLAIN REINFORCEMENT- reinforcement that does not

conform to the definition of deformed reinforcement

POST TENSIONING- method of prestressing in which the

tendons are tensioned after concrete has hardened

PRECAST CONCRETE- plain or reinforced concrete

element cast elsewhere than its final position in the

structure

POSTENSIONING- method of prestressing concrete which

the tendons are tensioned before concrete is placed

REINFORCED CONCRETE- designed on the assumption

that two materials act together in resisting forces

SPIRAL

REINFORCEMNTcontinuously

reinforcement in the form of a cylindrical helix

wound

STIRRUP - reinforcement used to resist shear and torsion

stresses in a structural member: typically bars, wires or

welded wire fabric (smooth or deformed) either single leg or

bent into L, U or rectangular shapes and located

perpendicularly to or at angle to longitudinal reinforcement

(The term stirrups is usually applied to lateral reinforcement

in flexural members and the term ties to those in

compression members.)

DEIGN STRENGTH- nominal strength reduction factor,

NOMINAL STRENGTH- strength of a member or crosssection before application of any strength reduction factors

REQUIRED STRENGTH - strength of a member or cross

section required to resist factored loads or related internal moments

and forces in such combinations

TENDON- steel element such as wire, cable, bar, rods or

strand, or a bundle of such elements used to impart

prestress to concrete

TIE- loop or reinforcing bar or wire enclosing longitudinal

reinforcement

TRANSFER - act of transferring stress in prestressing

tendons from jacks or pretensioning bed to concrete

member

WALL - member, usually vertical, used to enclose or

separate spaces

WOBBLE FRICTION - in prestressed concrete, friction

caused by unintended deviation of prstressing sheath or

duct from its specified profile

YIELD STRENGTH - specified minimum yield strength or

yield point or reinforcing in Mpa

BALANCED DESIGN - a design so proportioned that the

maximum stress in concrete (with strain of 0.003) and steel

(with strain of Fy/Es) are reached simultaneously once the

ultimate load is reached, causing them to fall simultaneously

UNDERREINFORCED DESIGN - a design in which the

steel reinforcement is lesser than what is required for

AGGREGATES

Fine aggregates- sand

are those that passes through a No.4

(about 6mm in size)

sieve

Coarse aggregate -gravel or crushed stone

Coarse aggregate shall not be less than:

1/5 the narrowest dimension

between sides of forms

1/3 the depth of slabs

minimum clear spacing between individual reinforcing

bars or wires, bundle of bars or prestressing tendons or

ducts

CONCRETE PROTECTION FOR

REINFORCEMENT

75 mm

-for concrete cast and

permanently exposed to earth

as footings

such

40-50 mm

for concrete members exposed

to weather

40 mm

concrete cover of pipes,

conduits or fittings and exposed

to

weather

40 mm

20 mm

for beams and columns

for concrete not exposed to

weather

or in contact with

ground, such as

slabs, walls

and joists

FOR BUNDLED BARS

a.

groups of parallel reinforcing bars bundled in

contact as a unit shall be limited to 4 in any

one

bundle

b. bundled bars shall be enclosed within stirrups

ties

or

c. bars larger than 32mm shall not be bundled

beams

in

d. individual bars within a bundle terminated

within

the span of flexural members

should terminate at a

different points at least

40db stagger

The minimum concrete cover for bundled bars shall be:

Equal to the equivalent diameter of the bundle but

not exceeding 50 mm

10 | S t r u c t u r a l

75 mm- for concrete cast against and permanently

exposed to earth

STANDARD HOOKS

A.

180 bend plus 4db extension but not

STRENGTH REDUCTION FACTOR

less

than 65 mm at free end

B.

90 bend plus 12db extension, at free

end

of bar

C.

for stirrups and tie hooks:

16 mm bar and smaller, 90 bend plus 6d b

extension at free end of bar or

20 mm and 25 mm bar, 90 bend plus 6d b

extension at free end of bar or

25 mm bar and smaller, 135 bend plus 6db

extension at free end of bar

MINIMUM BEND DIAMETER

(b.)

6db for 10 mm to 25 mm bar

8db for 10 mm to 28 mm bar

(c.)

10db for 10 mm to 36 mm bar

in

diameter

ONE- WAY SLAB

A one-way slab is considered as wide shallow rectangular

beam. The reinforcing steel is usually spaced uniformly over

its width. The flexural reinforcement of a one-way slab

extends in one direction only.

Maximum flexural reinforcement spacing:

3 times the slab thickness or 450 mm

Minimum thickness of one-way slab:

Solid one-way slab

L/20 - simply supported

L/24 - one end continuous

L/28 - both end continuous

L/10 - cantilever

* Span length L is in millimeter

Ribbed one-way slab

L/16 - simply supported

L/18.5 - one end continuous

L/21 - both end continuous

L/8 - cantilever

LOAD FACTORS

REQUIRED STRENGTH, U or Pu

Required strength U to resist dead load DL and live load LL

is

U= 1.4DL + 1.7LL

Wind load W are included in design

U= 0.75 (1.4DL + 1.7LL + 1.7W)

Where structural effect T of differential settlement, creep,

shrinkage or temperature change are significant in design

U= 0.75 (1.4DL + 1.4T + 1.7LL)

but required strength U shall not be less than

U= 1.4 (DL + T)

4db minimum inside diameter of bend of

stirrups and ties for 16 mm bar and smaller

a.

Earthquake loads or forces are included in design

U= 0.75 (1.4DL + 1.7LL + 1.87E)

The diameter of bend measured on the inside of the bar

shall not be less than the following:

(a.)

Flexure w/o axial load

0.90

Axial tension & axial tension w/ flexure

0.90

Shear and torsion

0.85

Axial compression & axial compression w/ flexure

spiral reinforcement

0.75

b. tie reinforcement

0.70

Bearing on concrete

0.70

SIZES AND SPACING OF

MAIN BARS AND TIES

1.

Clear distance between longitudinal bars shall be

not less than 1.5 db nor 40 mm

2. Use 10 mm diameter ties for 32 mm bars or

smaller and at least 12 mm in size for 36 mm and

bundled longitudinal bars

3. Vertical spacing of ties shall be the smallest of the

following:

a. 16 x db (db = longitudinal bar diameter)

b. 48 x tie diameter

c. least dimension of columns

4. Ties shall be arrange such that every corner and

alternate longitudinal bar shall have lateral support

provided by the corner of the tie with an included

angle of not more than 135 and no bar shall be

farther than 150 mm clear on each side along the

tie from such a laterally supported bar. Where

longitudinal bars are located around the perimeter

of a circle tie is allowed.

MINIMUM REQUIREMENT FOR

DEVELOPMENT OF REINFORCEMNT

1.

2.

3.

not less than 12 db

not less than 1/16 clear span

not less than d

whichever is greater

dead load, DL. 1.40

live load, LL. 1.70

wind load, WL..... 1.70

earthquake, E. 1.87

earth or water pressure, H 1.70

11 | S t r u c t u r a l

CRITERION FOR CONDUITS AND PIPES

EMBEDDED IN CONCRETE

a.

Conduits and pipes embedded in slab, the wall or

beam shall not be larger in outside dimension than

1/3 the overall thickness of slab, wall or beam

b.

Reinforcement with an area not less than 0.002

times the area of cross- section shall be provided

normal to piping

c.

Conduits and pipes with their fittings, embedded

within a column shall not displace more than 4% of

the area of the cross section on which strength is

calculated

d.

Concrete cover for pipes, conduits and fittings shall

not be less than 40 mm for concrete exposed to

earth or weather

CHARACTERISTICS OF HIGH BOLTED

CONNECTION

1.

high-strength bolted parts shall fit solidly together

when assembled and shall not be separated by

gaskets or any other interposed compressive

material.

2.

Bolts tightened by means of a calibrated wrench

shall be installed with a hardened washer under

the nut or bolt head whichever is the element

turned in tightening.

3.

When assembled, all joint surfaces, including

those adjacent to the washer, shall be free of

scale, except tight mill scales, dirts and burns.

4.

Surface in contact with the bolt head and nut head

shall have slope of not more than 1:20 with respect

to a plane normal to the bolt axis.

12 | S t r u c t u r a l

You might also like

- Concrete Wall DesignDocument26 pagesConcrete Wall DesignKeelNo ratings yet

- Concrete Bridge Designer Manual - 0721010830Document171 pagesConcrete Bridge Designer Manual - 0721010830Leung Lui100% (15)

- Three Member FrameDocument72 pagesThree Member FrameSampanna 37No ratings yet

- CIVL 331 - Loads On StructuresDocument27 pagesCIVL 331 - Loads On Structuresকাফী ওয়াহিদNo ratings yet

- Manual For Structural Inspection & Appraisal For BuildingsDocument26 pagesManual For Structural Inspection & Appraisal For BuildingsNoordin Abdul MajidNo ratings yet

- Seismic AnalysisDocument13 pagesSeismic AnalysisJea Manguing-YubalNo ratings yet

- Col PedDocument1 pageCol PedMark Christian EsguerraNo ratings yet

- H D E G: Male C.R. PWD C.R. Female C.R. Pump RMDocument1 pageH D E G: Male C.R. PWD C.R. Female C.R. Pump RMMark Christian EsguerraNo ratings yet

- 2 M High Free Standing WallDocument20 pages2 M High Free Standing WallAnonymous ciKyr0tNo ratings yet

- Reinforced Concrete Pitched Roof Apex Slab Reinforcement DetailDocument5 pagesReinforced Concrete Pitched Roof Apex Slab Reinforcement DetailDauji SahaNo ratings yet

- Sample Design Detail For Bridge SupportDocument1 pageSample Design Detail For Bridge SupportJoseph Cloyd LamberteNo ratings yet

- 5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesDocument1 page5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesMark Christian EsguerraNo ratings yet

- 5417.ductile Special Beam Design As Per ACI 318MDocument4 pages5417.ductile Special Beam Design As Per ACI 318MNapoleon CarinoNo ratings yet

- MyNotes SteelDesignDocument40 pagesMyNotes SteelDesignKyle Casanguan100% (1)

- Pretest, RC Part 2 PDFDocument1 pagePretest, RC Part 2 PDFleanne DespaNo ratings yet

- Column Axial Strength Aisc 360-05Document42 pagesColumn Axial Strength Aisc 360-05Kory Estes0% (1)

- Dimension Is 300mm X 300mm of Columns With 4pcs - Ø16mmDocument1 pageDimension Is 300mm X 300mm of Columns With 4pcs - Ø16mmMark Christian EsguerraNo ratings yet

- ASCE PM All in One PDFDocument442 pagesASCE PM All in One PDFAbinashNo ratings yet

- Compressive Strength For Cast-In-Place Concrete: Table 1.7Document23 pagesCompressive Strength For Cast-In-Place Concrete: Table 1.7Dave TalabocNo ratings yet

- Strength of MaterialFormulas Short NotesDocument19 pagesStrength of MaterialFormulas Short NotesRavindra DevireddyNo ratings yet

- CE Weekend Knockout Quiz With Answer Key PDFDocument19 pagesCE Weekend Knockout Quiz With Answer Key PDFppppp100% (1)

- Technical Note - Vertical Shear in Transfer PlatesDocument12 pagesTechnical Note - Vertical Shear in Transfer PlatesHuy Nguyen VanNo ratings yet

- تصميم الكمرات بطريقة ultimate PDFDocument42 pagesتصميم الكمرات بطريقة ultimate PDFqaisalkurdyNo ratings yet

- Appendix G Elastic and Inelastic Response SpectraDocument11 pagesAppendix G Elastic and Inelastic Response SpectracedaserdnaNo ratings yet

- Trusses Are Used in A Broad Range of Buildings, Mainly Where There Is A Requirement For Very Long Spans, SuchDocument14 pagesTrusses Are Used in A Broad Range of Buildings, Mainly Where There Is A Requirement For Very Long Spans, SuchHaden MateoNo ratings yet

- Lecture 2 - Reinforced Concrete - Design of Rectangular BeamDocument44 pagesLecture 2 - Reinforced Concrete - Design of Rectangular BeamChristopher PaladioNo ratings yet

- Formwork For ColumnsDocument7 pagesFormwork For Columnsaaryandas86No ratings yet

- Self Support Tower AnalysisDocument17 pagesSelf Support Tower AnalysisAris Bagoes MaladhiNo ratings yet

- Wind Loads NSCP 2001 ProvisionsDocument22 pagesWind Loads NSCP 2001 ProvisionsMonde Nuylan75% (4)

- By: Edgar B. Manubag, Ce, PHDDocument40 pagesBy: Edgar B. Manubag, Ce, PHDRoberto Gabriel Conrado CapulongNo ratings yet

- Practice Problems in Timber Design PDFDocument9 pagesPractice Problems in Timber Design PDFRuby AsensiNo ratings yet

- RULE12 of PD1096Document16 pagesRULE12 of PD1096Caryll BuenaluzNo ratings yet

- 7) Design of One-Way SlabsDocument8 pages7) Design of One-Way SlabsVanessa Rosal PalerNo ratings yet

- Staad ExamplesDocument35 pagesStaad ExamplesvisharamNo ratings yet

- Chapter5 - Shear and Diagonal Tension in BeamsDocument9 pagesChapter5 - Shear and Diagonal Tension in BeamsYo FangirlsNo ratings yet

- Plumbing Terms: Roughing-In Floor Mounted Fixtures Flush Meter Full Bath Hose Bibb Area Drain RiserDocument12 pagesPlumbing Terms: Roughing-In Floor Mounted Fixtures Flush Meter Full Bath Hose Bibb Area Drain RiserLawrence TingNo ratings yet

- Design ProjectDocument54 pagesDesign ProjectGiemhel GeleraNo ratings yet

- Session 1 - Lateral Loads - NSCP 2015Document49 pagesSession 1 - Lateral Loads - NSCP 2015HahahahahahahahahaNo ratings yet

- Structural Calculation TemplateDocument19 pagesStructural Calculation TemplateMelecio Magbuhos IINo ratings yet

- Review Questions Structural 4Document14 pagesReview Questions Structural 4abNo ratings yet

- Structural Specifications PDFDocument15 pagesStructural Specifications PDFRenvil PedernalNo ratings yet

- The National Building Code of The Philippines 2005 - Vicente B. FozDocument390 pagesThe National Building Code of The Philippines 2005 - Vicente B. FozJean Ann D. WapelleNo ratings yet

- Arch 631Document17 pagesArch 631althea guanzonNo ratings yet

- Dimension Is 300mm X 300mm of Columns With 4pcs - Ø16mmDocument1 pageDimension Is 300mm X 300mm of Columns With 4pcs - Ø16mmMark Christian Esguerra100% (1)

- Slab Design Slab C8Document1 pageSlab Design Slab C8Mark Christian Esguerra100% (1)

- Dimension Is 300mm X 300mm of Columns With 4pcs - Ø16mmDocument1 pageDimension Is 300mm X 300mm of Columns With 4pcs - Ø16mmMark Christian EsguerraNo ratings yet

- Lecture 6 - Reinforced Concrete - Slender ColumnDocument24 pagesLecture 6 - Reinforced Concrete - Slender ColumnChristopher Paladio100% (1)

- Strength of Materials Objective and Conventional by S K MondalDocument434 pagesStrength of Materials Objective and Conventional by S K Mondalpadalakirankumar33% (3)

- Mutuobare WarehouseDocument2 pagesMutuobare WarehousePEng. Tech. Alvince KoreroNo ratings yet

- Sample Steel Connection DetailDocument1 pageSample Steel Connection DetailJoseph Cloyd LamberteNo ratings yet

- ST2 p9 Moment Distribution MethodDocument50 pagesST2 p9 Moment Distribution MethodhanzNo ratings yet

- Prepared By:: Engr. Mark Roger R Huberit Ii Civil / Structural Engineer PRC NO. 072279Document9 pagesPrepared By:: Engr. Mark Roger R Huberit Ii Civil / Structural Engineer PRC NO. 072279Mark Roger Huberit IINo ratings yet

- 01 JSB551 Introduction To Design of Multi Storey BuildingsDocument34 pages01 JSB551 Introduction To Design of Multi Storey BuildingsBarongan BsgNo ratings yet

- What Is STAAD?: Analytical ModelingDocument3 pagesWhat Is STAAD?: Analytical ModelingGodfrey EmilioNo ratings yet

- Structures 1Document186 pagesStructures 1Muwaffaq m.100% (2)

- Part 3 Calculation of Wind Loads For BuiDocument11 pagesPart 3 Calculation of Wind Loads For BuiAica M. AtendidoNo ratings yet

- E.Naldoza Design of Singly Reinforced Rectangular Section-ACI318M-14 (NSCP 2015) V2.1.2-08june2021Document2 pagesE.Naldoza Design of Singly Reinforced Rectangular Section-ACI318M-14 (NSCP 2015) V2.1.2-08june2021RL SanNo ratings yet

- Structural ReviewerDocument17 pagesStructural ReviewerJireh Grace100% (4)

- Structural ReviewerDocument18 pagesStructural ReviewerjericoNo ratings yet

- Structural DesignDocument14 pagesStructural DesignMiguel Fernando YangNo ratings yet

- Structural Notes: Center of MomentDocument14 pagesStructural Notes: Center of MomentNeochel De JesusNo ratings yet

- The Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingFrom EverandThe Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingNo ratings yet

- Lost-in-Place Formwork System - Plaswall Panel System (For Structural Applications)Document41 pagesLost-in-Place Formwork System - Plaswall Panel System (For Structural Applications)Czareena DominiqueNo ratings yet

- January 2015 Room Assignment - ArchitectsDocument56 pagesJanuary 2015 Room Assignment - ArchitectsCzareena DominiqueNo ratings yet

- Types of WCDocument1 pageTypes of WCAr JCNo ratings yet

- Bioclimatic ChartDocument4 pagesBioclimatic ChartCzareena DominiqueNo ratings yet

- Electrical NotesDocument8 pagesElectrical NotesArki TektureNo ratings yet

- Change Order: Project: Location: Project No.Document1 pageChange Order: Project: Location: Project No.Czareena DominiqueNo ratings yet

- SummaryDocument17 pagesSummaryanamontana23No ratings yet

- Prayer For Preparation To StudyDocument12 pagesPrayer For Preparation To StudyCzareena DominiqueNo ratings yet

- COMMUNITY, WEALTH AND THE ENVIRONMENT: Examining Implications of Agricultural Land Use Conversion Within The City of DasmariñasDocument16 pagesCOMMUNITY, WEALTH AND THE ENVIRONMENT: Examining Implications of Agricultural Land Use Conversion Within The City of DasmariñasCzareena DominiqueNo ratings yet

- BT NotesDocument46 pagesBT NotesCzareena DominiqueNo ratings yet

- 18 MasterBeam Concrete Beam DesignerDocument14 pages18 MasterBeam Concrete Beam Designerdalton wongNo ratings yet

- AMSM Module 4Document27 pagesAMSM Module 4Shaji EtNo ratings yet

- Mechanics of Solids: Shear Stresses in Beams and Related ProblemsDocument37 pagesMechanics of Solids: Shear Stresses in Beams and Related ProblemsrpsirNo ratings yet

- Structural Calculation - Aluminium Curtain Wall (Sample Design)Document117 pagesStructural Calculation - Aluminium Curtain Wall (Sample Design)Power PedalsNo ratings yet

- Chapter 5Document49 pagesChapter 5ISRAEL HAILUNo ratings yet

- Objectives of Composite LabDocument27 pagesObjectives of Composite LabEshwar DevaramaneNo ratings yet

- Structural Design of RCC Clear Water Reservoir (C. W. R.)Document36 pagesStructural Design of RCC Clear Water Reservoir (C. W. R.)abhishek5810100% (1)

- Unit8 Introduction To Working Stress Method and Flexural Mechanics OF Singly Reinforced Rectaygualar SectionDocument17 pagesUnit8 Introduction To Working Stress Method and Flexural Mechanics OF Singly Reinforced Rectaygualar SectionkrisNo ratings yet

- 11 Design of Steel Structures MCQs and Answers 2023Document111 pages11 Design of Steel Structures MCQs and Answers 2023trusselNo ratings yet

- Sa 1 Unit-IiiDocument15 pagesSa 1 Unit-IiiYamuna jeyaramNo ratings yet

- Design of ColumnDocument44 pagesDesign of ColumnAnissah ManialaNo ratings yet

- Steel HSC Composite Beams With Partial Shear Connection and Miniaturized Limited Slip Capacity ConnectorsDocument10 pagesSteel HSC Composite Beams With Partial Shear Connection and Miniaturized Limited Slip Capacity ConnectorsCường NguyễnNo ratings yet

- PSC Single SpanDocument99 pagesPSC Single SpanRaden Budi HermawanNo ratings yet

- PSC Single SpanDocument60 pagesPSC Single Spanthanzawtun1981No ratings yet

- ch01 Mekanik BahanDocument78 pagesch01 Mekanik BahanAzman SamerNo ratings yet

- Determinacy, Indeterminacy and Stability of StructuresDocument34 pagesDeterminacy, Indeterminacy and Stability of StructuresedenNo ratings yet

- Vdocuments - MX - Curriculum of Civil EngineeringDocument171 pagesVdocuments - MX - Curriculum of Civil EngineeringandersonvallejosfloresNo ratings yet

- Nsba Basics of Steel Bridge Design Workshop - Part 1bDocument15 pagesNsba Basics of Steel Bridge Design Workshop - Part 1bLuis CortesNo ratings yet

- Termpaper-Strength Analysis of Screw Jack-Mechanics of SolidsDocument21 pagesTermpaper-Strength Analysis of Screw Jack-Mechanics of SolidsOmkar Kumar JhaNo ratings yet

- Final Exam of Structural BehaviorDocument3 pagesFinal Exam of Structural BehaviorNeven Ahmed HassanNo ratings yet

- Structural Analysis Bab 12Document37 pagesStructural Analysis Bab 12Kara Loven0% (1)

- Determination of Distribution of Modulus of Subgrade ReactionDocument3 pagesDetermination of Distribution of Modulus of Subgrade Reactionعبد القادر جمالNo ratings yet

- Soil-Pile-Bridge Seismic Interaction KinematicDocument24 pagesSoil-Pile-Bridge Seismic Interaction KinematicJustine NewmanNo ratings yet

- Oreste 2007Document21 pagesOreste 2007Tai TienNo ratings yet

- MPSC Civil (Mes) Main Exam Subjectwise Previous Year Question Paper With Detail ExplanationDocument29 pagesMPSC Civil (Mes) Main Exam Subjectwise Previous Year Question Paper With Detail ExplanationvishalNo ratings yet