Professional Documents

Culture Documents

Piping - Nozzle Loading

Piping - Nozzle Loading

Uploaded by

aap1Copyright:

Available Formats

You might also like

- AIV Screening Per EI GuidelinesDocument26 pagesAIV Screening Per EI GuidelinesChan100% (1)

- Guidelines For Acoustic Induced Vibration (AIV), Flow Induced Vibration (FIV) AnalysisDocument8 pagesGuidelines For Acoustic Induced Vibration (AIV), Flow Induced Vibration (FIV) Analysisgpskumar22No ratings yet

- Stress Analysis of Pump PipingDocument142 pagesStress Analysis of Pump Pipingmakeencv100% (3)

- Load CasesDocument15 pagesLoad CasesVishnu Menon100% (2)

- Nozzle LoadDocument8 pagesNozzle LoadDam VoNo ratings yet

- Calgary 2011 Nozzle Loads PresentationDocument10 pagesCalgary 2011 Nozzle Loads PresentationpexyNo ratings yet

- Sustained Stress Indices (SSI) in The B31.3 2010 EditionDocument9 pagesSustained Stress Indices (SSI) in The B31.3 2010 Editiont_rajith1179100% (2)

- Nozzle StressDocument25 pagesNozzle StressvamsiNo ratings yet

- Accoustic Induced Vibration-1Document6 pagesAccoustic Induced Vibration-1cpsankarNo ratings yet

- Stress Analysis - Guide To Caesar Ii (Ver 4.10) PACKAGE: DOC No.: 29040-PI-UFR-0030 Rev.: R0Document83 pagesStress Analysis - Guide To Caesar Ii (Ver 4.10) PACKAGE: DOC No.: 29040-PI-UFR-0030 Rev.: R0FathyNo ratings yet

- b31.3 Load CasesDocument1 pageb31.3 Load CasesPedro Montes MarinNo ratings yet

- Nozzle Loads - Part 1 - Piping-EngineeringDocument5 pagesNozzle Loads - Part 1 - Piping-EngineeringShaikh Aftab100% (1)

- Piping Stress Analysis For PROCESSDocument6 pagesPiping Stress Analysis For PROCESSFredie Unabia100% (1)

- Inputs Required For FIV & AIV StudyDocument1 pageInputs Required For FIV & AIV StudyRonak MotaNo ratings yet

- CAESARII Assorted TopicsDocument21 pagesCAESARII Assorted TopicsromlibNo ratings yet

- Pip Vessp002-2014Document9 pagesPip Vessp002-2014d-fbuser-93320248No ratings yet

- Improvements in Design and Fitness Evaluation of Above Ground Steel Storage TanksDocument284 pagesImprovements in Design and Fitness Evaluation of Above Ground Steel Storage TanksrodrigoperezsimoneNo ratings yet

- Seismic AnalysisDocument4 pagesSeismic AnalysisAnkithNo ratings yet

- Ligament Pressure Vessel AnalysisDocument8 pagesLigament Pressure Vessel AnalysisAnnie HillNo ratings yet

- Surge Analysis: Mostafa Ajjawi, Jr. Engineer 16230 Mr. Barry Howe, Head of Piping StressDocument17 pagesSurge Analysis: Mostafa Ajjawi, Jr. Engineer 16230 Mr. Barry Howe, Head of Piping StressprashantNo ratings yet

- Multi Layer Pressure VesselsDocument8 pagesMulti Layer Pressure VesselsprivatehomeNo ratings yet

- Orifice Plate Showing VenaDocument6 pagesOrifice Plate Showing VenahugepotatoNo ratings yet

- WRC368Document33 pagesWRC368fahid masoodNo ratings yet

- Tech Brief Pump Curves PDFDocument5 pagesTech Brief Pump Curves PDFThomas KamongNo ratings yet

- Pulsation Suppression Device Design For Reciprocating CompressorDocument9 pagesPulsation Suppression Device Design For Reciprocating CompressorFrancis LinNo ratings yet

- Piping Spring HangersDocument2 pagesPiping Spring HangersyogacruiseNo ratings yet

- Support Arrangement Natural FrequencyDocument3 pagesSupport Arrangement Natural FrequencyrajeevfaNo ratings yet

- B31.3 Process Piping Course - 03 Materials PDFDocument19 pagesB31.3 Process Piping Course - 03 Materials PDFNguyen Anh TungNo ratings yet

- Virtual Anchor Length - KBRDocument22 pagesVirtual Anchor Length - KBRSammar Adhikari100% (2)

- Two Phase FlowDocument4 pagesTwo Phase FlowsindalvaleriNo ratings yet

- Cast - Basket Strainers - 2nd EditionDocument27 pagesCast - Basket Strainers - 2nd EditionmartinnovelNo ratings yet

- Bentley PULS XM Edition: Acoustic Mode ShapesDocument75 pagesBentley PULS XM Edition: Acoustic Mode Shapes聂lNo ratings yet

- Re-Rate Case StudyDocument4 pagesRe-Rate Case StudyA_MosbahNo ratings yet

- WRC 537 Cige Noz B Op 1Document1 pageWRC 537 Cige Noz B Op 1metroroadNo ratings yet

- Treatment of Support Friction in Pipe Stress AnalysisDocument6 pagesTreatment of Support Friction in Pipe Stress Analysissateesh chandNo ratings yet

- PSV Reaction Force - Closed SystemDocument5 pagesPSV Reaction Force - Closed SystemWayne Monnery100% (1)

- Comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2/comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2 PDFDocument13 pagesComparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2/comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2 PDFruponline1No ratings yet

- Causes, Assessment and Reduction of Piping VibrationsDocument12 pagesCauses, Assessment and Reduction of Piping VibrationsGustavo Espinosa MartinezNo ratings yet

- Water Hammer Analysis Using Caesar IIDocument4 pagesWater Hammer Analysis Using Caesar IIramesh100% (1)

- 1Document7 pages1sri9987No ratings yet

- Static Analysis of Slug FlowDocument7 pagesStatic Analysis of Slug FlowGicuNo ratings yet

- Stress Analysis of GRP-GRE-FRP PipingDocument4 pagesStress Analysis of GRP-GRE-FRP PipingHmd MokhtariNo ratings yet

- Maximum Allowable Stress: Mechanical Design of Pressure VesselsDocument17 pagesMaximum Allowable Stress: Mechanical Design of Pressure Vesselsfauzi100% (2)

- Nozzle Loads - Part 2 - Piping-EngineeringDocument3 pagesNozzle Loads - Part 2 - Piping-EngineeringShaikh AftabNo ratings yet

- 10 Dynamic AnalysisDocument113 pages10 Dynamic AnalysisThiên Khánh100% (1)

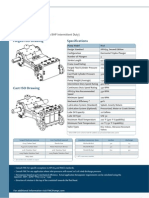

- Plunger Pump M18Document4 pagesPlunger Pump M18Pipe LopezNo ratings yet

- PIMAPPC Piping Vibration GuidelinesDocument16 pagesPIMAPPC Piping Vibration Guidelinesmika cabello100% (1)

- Acceptable External Nozzle Loads Calculation For Pressure VesseDocument7 pagesAcceptable External Nozzle Loads Calculation For Pressure Vesset_rajith1179No ratings yet

- Nozzle Loads of Equipment and Means For Reducing ThemDocument5 pagesNozzle Loads of Equipment and Means For Reducing ThemamlanfacebookNo ratings yet

- Clarifying Nozzle Load and Piping PDFDocument4 pagesClarifying Nozzle Load and Piping PDFMuhammad ImranNo ratings yet

- PIPING Engineering Interview Questions:-: Isolation, Regulation, Non-Return and Special PurposesDocument21 pagesPIPING Engineering Interview Questions:-: Isolation, Regulation, Non-Return and Special PurposesAdil KhawajaNo ratings yet

- Stress Analysis of Pump PipingDocument5 pagesStress Analysis of Pump PipingSamNo ratings yet

- Spring SelectionDocument12 pagesSpring SelectionNitesh KumarNo ratings yet

- API 521 7 Edition Ballot Item 6.1 New Work Item - Potential ASME Code ViolationsDocument14 pagesAPI 521 7 Edition Ballot Item 6.1 New Work Item - Potential ASME Code ViolationsAyadi_AymanNo ratings yet

- Nozzle Load and PipingDocument5 pagesNozzle Load and PipingJose PradoNo ratings yet

- Design Requirements For Reciprocating CompressorsDocument3 pagesDesign Requirements For Reciprocating Compressorsvsvineesh100% (1)

- Pipes Should Be Properly SupportedDocument3 pagesPipes Should Be Properly SupportedGomathyselviNo ratings yet

- Using The Dynamic Depressuring Utility To Simulate High Pressure Blowdown ScenariosDocument4 pagesUsing The Dynamic Depressuring Utility To Simulate High Pressure Blowdown Scenariosebby1No ratings yet

- Sabp L 006 PDFDocument8 pagesSabp L 006 PDFWNo ratings yet

- Technical Paper #6: Don Faust and Brian Peterson Gartner Refrigeration & Manufacturing, Inc. Plymouth, MinnesotaDocument33 pagesTechnical Paper #6: Don Faust and Brian Peterson Gartner Refrigeration & Manufacturing, Inc. Plymouth, Minnesotapalinox.refrigeracionNo ratings yet

- Factors That Influence Fatigue: - MaterialDocument3 pagesFactors That Influence Fatigue: - Materialaap1No ratings yet

- Thin Walled Pressure VesselsDocument8 pagesThin Walled Pressure Vesselsaap1No ratings yet

- KC - Crack Growth ConditionDocument3 pagesKC - Crack Growth Conditionaap1No ratings yet

- Fundamental Mechanical Properties: FatigueDocument11 pagesFundamental Mechanical Properties: Fatigueaap1No ratings yet

- AWS D1.1 Overview - 1Document7 pagesAWS D1.1 Overview - 1aap1100% (1)

- Pipe Stress and Flexibility AnalysisDocument25 pagesPipe Stress and Flexibility Analysisaap1No ratings yet

- Longitudinal Stress and Hoop StressDocument2 pagesLongitudinal Stress and Hoop Stressaap1100% (2)

- Fatigue AnalysisDocument8 pagesFatigue Analysisaap1No ratings yet

- Solidworks TutorialDocument52 pagesSolidworks TutorialAMar Ridhwan100% (1)

- Stress Analysis - FeaDocument33 pagesStress Analysis - Feaaap1100% (3)

- Introduction Fracture Mechanics 1Document15 pagesIntroduction Fracture Mechanics 1aap1No ratings yet

- Introduction To Finite Element MethodsDocument31 pagesIntroduction To Finite Element Methodsaap1No ratings yet

- Metallic FatigueDocument69 pagesMetallic Fatigueaap1No ratings yet

- Fracture ToughnessDocument20 pagesFracture Toughnessaap1100% (2)

- Failure Mechanisms FatigueDocument12 pagesFailure Mechanisms Fatigueaap1No ratings yet

- 2-D State of StressDocument7 pages2-D State of Stressaap1No ratings yet

- Fracture MechanicsDocument22 pagesFracture Mechanicsaap1No ratings yet

- Stress MohrDocument18 pagesStress Mohraap1No ratings yet

- Mohr's CircleDocument13 pagesMohr's Circleaap1No ratings yet

- Welding Residual StressDocument10 pagesWelding Residual Stressaap1No ratings yet

Piping - Nozzle Loading

Piping - Nozzle Loading

Uploaded by

aap1Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Piping - Nozzle Loading

Piping - Nozzle Loading

Uploaded by

aap1Copyright:

Available Formats

Nozzle Loading of Various Equipments

and means for reducing them

Introduction:

One of the major difficulty piping stress engineers face while analyzing any piping system is to keep

piping side loads or external loads (forces and moments are combinedly mentioned as loads) on

equipment nozzle connection within allowable limits. All equipments to which piping system is

connected is categorized in two groups. a) Static Equipments and b) Rotary Equipments.

Nozzle Loads for Static Equipments:

Most of the prevailing EPC organizations follow a project specific table as allowable values for static

equipments (made of Steel, ferrous material) like pressure vessels (Columns, Horizontal vessels, Drums,

Reactors, Filters, Scrubbers, sometimes Tanks which are not within API 650 scope, etc) and shell and

tube heat exchangers or similar equipments. The table is generated based on the following two parameter:

the nozzle diameter and flange rating. In some organizations the table value is multiplied with some

factors (normally 0.75) while checking nozzle loads for shell and tube heat exchangers.

Normally mechanical department send these load tables to the equipment manufacturer indicating that the

nozzle connections must be designed to resist at a minimum the table values. The equipment vendor

reproduces the values in the equipment general arrangement drawing to avoid any confusion at a later

stage.

For cases while the static equipment does not fall on the types mentioned in the above criteria the nozzle

loads has to be obtained from equipment vendor or from some ASME B 31.3 code specified standards.

Few of such type of equipment and nozzle connection is listed below for your reference:

Jacketed nozzles connected to Normal pressure vessels: Loads to be obtained from manufacturer,

in case the piping side load is more than allowables the loads has to be forwarded to vendor for

FEA/vendor acceptance.

Jacketed nozzles connected to Jacketed pressure vessels: Loads to be obtained from manufacturer,

in case the piping side load is more than allowables the loads has to be forwarded to vendor for

FEA/vendor acceptance.

Pressure vessels made of non ferrous (Aluminium is more common) materials: Loads to be

obtained from equipment vendor.

Nozzles connected to Air Fin Fan Cooler: Loads are mentioned in API 661, discuss with vendor

(check internal project specification) if any factor is to be used (Normally a factor of 2 or 3 is used in

some organization).

Nozzles connected to Plate Fin Heat Exchanger: Refer API 662 for nozzle loads (There are 2 tables

in the standard depending on fluid service (normal service and severe service), check carefully which

table to be used)

Tangential nozzles connected to Pressure Vessels: Loads have to be taken from manufacturer.

Nozzles whose axis is not perpendicular to Vessel axis: Obtain allowable loads from vendor.

Nozzles connected to API Tanks with diameter more than 36 meter: Refer API 650 for nozzle

loads (No standard table is provided for load values, you have to determine the loads from equations.)

Nozzles connected to Fired Heaters: Refer API 560 for allowable nozzle loads. Sometimes a factor

of 2 or 3 is used for multiplying the table values. Refer project specification for the same or discuss

with vendor.

Nozzles connected to Miscellaneous Equipments (Cold Box, Flaker system, Packaged items,

Spherical Equipments, Cooling Tower etc): Arrange limiting loads from Vendor.

Nozzle Loads for Rotary Equipments:

Normally rotary equipments are designed based on some code specified standards and accordingly the

limiting loads has to be taken from respective standards. Few of such commonly used equipments are

mentioned below:

Centrifugal Pumps: For pumps which are designed based on API standard, allowable loads has to be

taken from API 610 (If loads are more than allowable values as specified in table 5 of the standard,

perform appendix P). Allowable load values upto nozzle size 16 inch is provided in the table. For

higher sizes ANSI standard is used. If the pumps are not designed as per API standard (now a days

non API pumps are most frequently used due to its lower costs) obtain loads from vendor. Sometimes

ANSI/HI 9.6.2 is used for nozzle loads in absence of data.

Positive displacement (Screw pumps, gear pumps etc) pumps: Use API 676 for allowable nozzle

loads. Loads can be taken from vendor.

Reciprocating Pumps/Compressors: Obtain the allowable nozzle loads from vendor.

Centrifugal Compressors: Use API 617 for equipment nozzle loads. Note that combined analysis

must be performed for proper functioning of the compressor. Sometimes vendor permits more loads

so discuss with them.

Steam Turbine: Refer NEMA SM 23 or API 612 for allowable nozzle loads. Dont forget to perform

combined nozzle load checking. Sometimes vendor permits more loads so discuss with them.

Positive displacement compressors: Refer API 619 or manufacturer allowable loads.

Gas Turbine: Loads to be obtained from manufacturer.

Means for Reducing Nozzle Loads:

Now if the nozzle load on equipment is found to be more than the allowable values as specified above,

first try to get a feel of the reason of the increased load and then try to apply any of the following

alternatives to reduce the nozzle loads:

Try to reduce the nozzle load by adding additional flexibility in the piping system (Could be followed

if the load is arising because of less flexibility)

If the load is due to the weight of the piping system, provide additional support.

Try to direct the thermal expansion away from the equipment by providing proper restraints (guide or

directional anchors).

If the load is more because of friction then try to use PTFE/graphite/Mirror polished SS plates to

reduce frictional loads.

In extreme situation expansion joint or cold spring (normally not preferred) can be applied.

Sometimes hot modulus of elasticity can be used to calculate equipment nozzle loads.

Even after all trial and error if it is not possible to reduce the loads within allowable limits then forward

the actual load values (increased by at least 20% if all piping data is not final) to vendor for FEA analysis

and their acceptance.

You might also like

- AIV Screening Per EI GuidelinesDocument26 pagesAIV Screening Per EI GuidelinesChan100% (1)

- Guidelines For Acoustic Induced Vibration (AIV), Flow Induced Vibration (FIV) AnalysisDocument8 pagesGuidelines For Acoustic Induced Vibration (AIV), Flow Induced Vibration (FIV) Analysisgpskumar22No ratings yet

- Stress Analysis of Pump PipingDocument142 pagesStress Analysis of Pump Pipingmakeencv100% (3)

- Load CasesDocument15 pagesLoad CasesVishnu Menon100% (2)

- Nozzle LoadDocument8 pagesNozzle LoadDam VoNo ratings yet

- Calgary 2011 Nozzle Loads PresentationDocument10 pagesCalgary 2011 Nozzle Loads PresentationpexyNo ratings yet

- Sustained Stress Indices (SSI) in The B31.3 2010 EditionDocument9 pagesSustained Stress Indices (SSI) in The B31.3 2010 Editiont_rajith1179100% (2)

- Nozzle StressDocument25 pagesNozzle StressvamsiNo ratings yet

- Accoustic Induced Vibration-1Document6 pagesAccoustic Induced Vibration-1cpsankarNo ratings yet

- Stress Analysis - Guide To Caesar Ii (Ver 4.10) PACKAGE: DOC No.: 29040-PI-UFR-0030 Rev.: R0Document83 pagesStress Analysis - Guide To Caesar Ii (Ver 4.10) PACKAGE: DOC No.: 29040-PI-UFR-0030 Rev.: R0FathyNo ratings yet

- b31.3 Load CasesDocument1 pageb31.3 Load CasesPedro Montes MarinNo ratings yet

- Nozzle Loads - Part 1 - Piping-EngineeringDocument5 pagesNozzle Loads - Part 1 - Piping-EngineeringShaikh Aftab100% (1)

- Piping Stress Analysis For PROCESSDocument6 pagesPiping Stress Analysis For PROCESSFredie Unabia100% (1)

- Inputs Required For FIV & AIV StudyDocument1 pageInputs Required For FIV & AIV StudyRonak MotaNo ratings yet

- CAESARII Assorted TopicsDocument21 pagesCAESARII Assorted TopicsromlibNo ratings yet

- Pip Vessp002-2014Document9 pagesPip Vessp002-2014d-fbuser-93320248No ratings yet

- Improvements in Design and Fitness Evaluation of Above Ground Steel Storage TanksDocument284 pagesImprovements in Design and Fitness Evaluation of Above Ground Steel Storage TanksrodrigoperezsimoneNo ratings yet

- Seismic AnalysisDocument4 pagesSeismic AnalysisAnkithNo ratings yet

- Ligament Pressure Vessel AnalysisDocument8 pagesLigament Pressure Vessel AnalysisAnnie HillNo ratings yet

- Surge Analysis: Mostafa Ajjawi, Jr. Engineer 16230 Mr. Barry Howe, Head of Piping StressDocument17 pagesSurge Analysis: Mostafa Ajjawi, Jr. Engineer 16230 Mr. Barry Howe, Head of Piping StressprashantNo ratings yet

- Multi Layer Pressure VesselsDocument8 pagesMulti Layer Pressure VesselsprivatehomeNo ratings yet

- Orifice Plate Showing VenaDocument6 pagesOrifice Plate Showing VenahugepotatoNo ratings yet

- WRC368Document33 pagesWRC368fahid masoodNo ratings yet

- Tech Brief Pump Curves PDFDocument5 pagesTech Brief Pump Curves PDFThomas KamongNo ratings yet

- Pulsation Suppression Device Design For Reciprocating CompressorDocument9 pagesPulsation Suppression Device Design For Reciprocating CompressorFrancis LinNo ratings yet

- Piping Spring HangersDocument2 pagesPiping Spring HangersyogacruiseNo ratings yet

- Support Arrangement Natural FrequencyDocument3 pagesSupport Arrangement Natural FrequencyrajeevfaNo ratings yet

- B31.3 Process Piping Course - 03 Materials PDFDocument19 pagesB31.3 Process Piping Course - 03 Materials PDFNguyen Anh TungNo ratings yet

- Virtual Anchor Length - KBRDocument22 pagesVirtual Anchor Length - KBRSammar Adhikari100% (2)

- Two Phase FlowDocument4 pagesTwo Phase FlowsindalvaleriNo ratings yet

- Cast - Basket Strainers - 2nd EditionDocument27 pagesCast - Basket Strainers - 2nd EditionmartinnovelNo ratings yet

- Bentley PULS XM Edition: Acoustic Mode ShapesDocument75 pagesBentley PULS XM Edition: Acoustic Mode Shapes聂lNo ratings yet

- Re-Rate Case StudyDocument4 pagesRe-Rate Case StudyA_MosbahNo ratings yet

- WRC 537 Cige Noz B Op 1Document1 pageWRC 537 Cige Noz B Op 1metroroadNo ratings yet

- Treatment of Support Friction in Pipe Stress AnalysisDocument6 pagesTreatment of Support Friction in Pipe Stress Analysissateesh chandNo ratings yet

- PSV Reaction Force - Closed SystemDocument5 pagesPSV Reaction Force - Closed SystemWayne Monnery100% (1)

- Comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2/comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2 PDFDocument13 pagesComparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2/comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2 PDFruponline1No ratings yet

- Causes, Assessment and Reduction of Piping VibrationsDocument12 pagesCauses, Assessment and Reduction of Piping VibrationsGustavo Espinosa MartinezNo ratings yet

- Water Hammer Analysis Using Caesar IIDocument4 pagesWater Hammer Analysis Using Caesar IIramesh100% (1)

- 1Document7 pages1sri9987No ratings yet

- Static Analysis of Slug FlowDocument7 pagesStatic Analysis of Slug FlowGicuNo ratings yet

- Stress Analysis of GRP-GRE-FRP PipingDocument4 pagesStress Analysis of GRP-GRE-FRP PipingHmd MokhtariNo ratings yet

- Maximum Allowable Stress: Mechanical Design of Pressure VesselsDocument17 pagesMaximum Allowable Stress: Mechanical Design of Pressure Vesselsfauzi100% (2)

- Nozzle Loads - Part 2 - Piping-EngineeringDocument3 pagesNozzle Loads - Part 2 - Piping-EngineeringShaikh AftabNo ratings yet

- 10 Dynamic AnalysisDocument113 pages10 Dynamic AnalysisThiên Khánh100% (1)

- Plunger Pump M18Document4 pagesPlunger Pump M18Pipe LopezNo ratings yet

- PIMAPPC Piping Vibration GuidelinesDocument16 pagesPIMAPPC Piping Vibration Guidelinesmika cabello100% (1)

- Acceptable External Nozzle Loads Calculation For Pressure VesseDocument7 pagesAcceptable External Nozzle Loads Calculation For Pressure Vesset_rajith1179No ratings yet

- Nozzle Loads of Equipment and Means For Reducing ThemDocument5 pagesNozzle Loads of Equipment and Means For Reducing ThemamlanfacebookNo ratings yet

- Clarifying Nozzle Load and Piping PDFDocument4 pagesClarifying Nozzle Load and Piping PDFMuhammad ImranNo ratings yet

- PIPING Engineering Interview Questions:-: Isolation, Regulation, Non-Return and Special PurposesDocument21 pagesPIPING Engineering Interview Questions:-: Isolation, Regulation, Non-Return and Special PurposesAdil KhawajaNo ratings yet

- Stress Analysis of Pump PipingDocument5 pagesStress Analysis of Pump PipingSamNo ratings yet

- Spring SelectionDocument12 pagesSpring SelectionNitesh KumarNo ratings yet

- API 521 7 Edition Ballot Item 6.1 New Work Item - Potential ASME Code ViolationsDocument14 pagesAPI 521 7 Edition Ballot Item 6.1 New Work Item - Potential ASME Code ViolationsAyadi_AymanNo ratings yet

- Nozzle Load and PipingDocument5 pagesNozzle Load and PipingJose PradoNo ratings yet

- Design Requirements For Reciprocating CompressorsDocument3 pagesDesign Requirements For Reciprocating Compressorsvsvineesh100% (1)

- Pipes Should Be Properly SupportedDocument3 pagesPipes Should Be Properly SupportedGomathyselviNo ratings yet

- Using The Dynamic Depressuring Utility To Simulate High Pressure Blowdown ScenariosDocument4 pagesUsing The Dynamic Depressuring Utility To Simulate High Pressure Blowdown Scenariosebby1No ratings yet

- Sabp L 006 PDFDocument8 pagesSabp L 006 PDFWNo ratings yet

- Technical Paper #6: Don Faust and Brian Peterson Gartner Refrigeration & Manufacturing, Inc. Plymouth, MinnesotaDocument33 pagesTechnical Paper #6: Don Faust and Brian Peterson Gartner Refrigeration & Manufacturing, Inc. Plymouth, Minnesotapalinox.refrigeracionNo ratings yet

- Factors That Influence Fatigue: - MaterialDocument3 pagesFactors That Influence Fatigue: - Materialaap1No ratings yet

- Thin Walled Pressure VesselsDocument8 pagesThin Walled Pressure Vesselsaap1No ratings yet

- KC - Crack Growth ConditionDocument3 pagesKC - Crack Growth Conditionaap1No ratings yet

- Fundamental Mechanical Properties: FatigueDocument11 pagesFundamental Mechanical Properties: Fatigueaap1No ratings yet

- AWS D1.1 Overview - 1Document7 pagesAWS D1.1 Overview - 1aap1100% (1)

- Pipe Stress and Flexibility AnalysisDocument25 pagesPipe Stress and Flexibility Analysisaap1No ratings yet

- Longitudinal Stress and Hoop StressDocument2 pagesLongitudinal Stress and Hoop Stressaap1100% (2)

- Fatigue AnalysisDocument8 pagesFatigue Analysisaap1No ratings yet

- Solidworks TutorialDocument52 pagesSolidworks TutorialAMar Ridhwan100% (1)

- Stress Analysis - FeaDocument33 pagesStress Analysis - Feaaap1100% (3)

- Introduction Fracture Mechanics 1Document15 pagesIntroduction Fracture Mechanics 1aap1No ratings yet

- Introduction To Finite Element MethodsDocument31 pagesIntroduction To Finite Element Methodsaap1No ratings yet

- Metallic FatigueDocument69 pagesMetallic Fatigueaap1No ratings yet

- Fracture ToughnessDocument20 pagesFracture Toughnessaap1100% (2)

- Failure Mechanisms FatigueDocument12 pagesFailure Mechanisms Fatigueaap1No ratings yet

- 2-D State of StressDocument7 pages2-D State of Stressaap1No ratings yet

- Fracture MechanicsDocument22 pagesFracture Mechanicsaap1No ratings yet

- Stress MohrDocument18 pagesStress Mohraap1No ratings yet

- Mohr's CircleDocument13 pagesMohr's Circleaap1No ratings yet

- Welding Residual StressDocument10 pagesWelding Residual Stressaap1No ratings yet