Professional Documents

Culture Documents

ARL-300 User Manual V22

ARL-300 User Manual V22

Uploaded by

suspekt_no1Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ARL-300 User Manual V22

ARL-300 User Manual V22

Uploaded by

suspekt_no1Copyright:

Available Formats

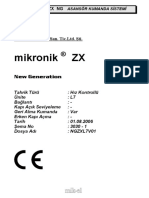

ARL-300

ASANSR KUMANDA KARTI

LIFT CONTROLLER

KULLANICI KILAVUZU

USER MANUAL

TR/EN

www.arkel.com.tr

TRKE

ENGLISH

ARKEL Elektrik Elektronik Ltd. ti.

Yaync Firma

ARKEL Elektrik Elektronik Ticaret Ltd. ti.

erifali Mah. Bayraktar Bulvar ehit Sok. No:32

mraniye stanbul TURKIYE

TEL : (+90 216) 540 67 24

Fax : (+90 216) 540 03 09

E-mail: info@arkel.com.tr

www.arkel.com.tr

Dokman Tarihi

2013

Dokman Srm

V2.2

Donanm Srm

V2.1

Yazlm Srm

V2.22

Bu belge kullanclar iin klavuz olmas amacyla hazrlanmtr. nceden Arkel'in yazl izni alnmakszn, bu belge

iindekilerin tamam veya bir blm herhangi bir biimde yeniden oluturulamaz, kopyalanamaz, oaltlamaz, taklit

edilemez, baka bir yere aktarlamaz, datlamaz, saklanamaz veya yedeklenemez. Arkel, bu belgede tanmlanan

herhangi bir rnde nceden bildiride bulunmakszn deiiklik ve yenilik yapma hakkn sakl tutar.

Arkel, bu klavuzun bilgi ieriinde olabilecek hatalardan ve yanl bilgilerden dolay sorumluluk kabul etmez.

ARKEL

ARL-300

ARKEL Elektrik Elektronik Ltd. ti.

www.arkel.com.tr

NDEKLER

NDEKLER ............................................................................................................................................................... 3

GR ............................................................................................................................................................................... 6

ARL-300 TEKNK ZELLKLER:............................................................................................................................ 7

2. PARAMETRE LSTES........................................................................................................................................... 13

LISAN/LANGUAGE ................................................................................................................................................. 15

ASANSOR TIPI ......................................................................................................................................................... 15

DURAK SAYISI ........................................................................................................................................................ 15

KUMANDA TIPI ....................................................................................................................................................... 15

KABIN CAGRILARI ................................................................................................................................................. 16

KAPI TIPI .................................................................................................................................................................. 16

KAPI KOMUTLARI .................................................................................................................................................. 16

OTO KAPI KATTA ................................................................................................................................................... 16

DURAKTA BEKLEME ............................................................................................................................................. 17

KILIT BEKLEME ...................................................................................................................................................... 17

KAPI ACIK HATASI ................................................................................................................................................. 17

FOTOSEL ZAMANI .................................................................................................................................................. 17

KABIN LAMBASI..................................................................................................................................................... 17

PARK DURAGI ......................................................................................................................................................... 18

PARK ZAMANI......................................................................................................................................................... 18

YANGIN DURAGI .................................................................................................................................................... 18

ITFAIYECI MODU ................................................................................................................................................... 18

YILDIZ YOLVERME ................................................................................................................................................ 18

Y./UCGEN GECIKME .............................................................................................................................................. 18

MOTOR GECIKMESI ............................................................................................................................................... 18

VALF GECIKMESI ................................................................................................................................................... 19

KONTAKTR GECIKME ........................................................................................................................................... 19

KATLAR ARASI MAX ............................................................................................................................................. 19

YAVAS MAX SEYIR ................................................................................................................................................ 19

KAPI ERKEN ACMA ................................................................................................................................................ 19

SEVIYE YENILEME................................................................................................................................................. 19

AKULU INDIRME .................................................................................................................................................... 20

KURTARMA TIPI ..................................................................................................................................................... 20

BINARY/GRAY KOD ............................................................................................................................................... 20

PR ROLE ISLEVI ...................................................................................................................................................... 20

DISPLAY AYARLARI .............................................................................................................................................. 21

FX_SERI A,B,C,.. ...................................................................................................................................................... 22

PT0-PT3 CIKISI ......................................................................................................................................................... 22

GONG CIKISI ............................................................................................................................................................ 22

RST FAZ KONTROL ................................................................................................................................................ 22

HATA KAYITLARI .................................................................................................................................................. 23

HATALARI SIL ......................................................................................................................................................... 23

REVIZYONDA LIMIT .............................................................................................................................................. 23

120 FONKSIYONU ................................................................................................................................................... 23

HARICI EM. ROLESI ................................................................................................................................................ 23

POZISYON RESET ................................................................................................................................................... 24

GRUP KIMLIGI ......................................................................................................................................................... 24

BAKIM SURESI ........................................................................................................................................................ 24

BAKIM SURE SONU ................................................................................................................................................ 24

ARKEL

ARL-300

TRKE

AILI EKRANI ....................................................................................................................................................... 10

ANA EKRAN ............................................................................................................................................................. 10

LCD KONTRAST AYARI......................................................................................................................................... 10

KART ZERNDEN MANUEL HAREKET ............................................................................................................ 10

TULARDAN KAYIT VERMEK ............................................................................................................................. 10

TULARDAN RASGELE KAYIT VERMEK .......................................................................................................... 11

GRUP ALIMA EKRANI ....................................................................................................................................... 11

MENUYE GR ........................................................................................................................................................ 12

MENUDEN IKI ..................................................................................................................................................... 12

ENGLISH

1. LCD EKRAN VE TU TAKIMI ............................................................................................................................... 8

ARKEL Elektrik Elektronik Ltd. ti.

www.arkel.com.tr

ILK DURAK .............................................................................................................................................................. 24

SON DURAK ............................................................................................................................................................. 25

VATMAN CAGRILARI ............................................................................................................................................ 25

TAHLIYE DURAGI .................................................................................................................................................. 25

MAX. KABIN CAGRI ............................................................................................................................................... 25

YON OKLARI ........................................................................................................................................................... 26

KONTAKTOR KONTRL .......................................................................................................................................... 26

A3 VALF KONTROL ................................................................................................................................................ 26

MOTOR FREN IZLEME ........................................................................................................................................... 26

UCM TEST MODU.................................................................................................................................................... 26

SELEKTOR TIPI ....................................................................................................................................................... 26

A3 VALF GECIKMESI ............................................................................................................................................. 27

KURTARMA GECIKME .......................................................................................................................................... 27

A3 VALFI .................................................................................................................................................................. 27

SIFRE ......................................................................................................................................................................... 27

MENUDEN CIKIS ..................................................................................................................................................... 27

ENGLISH

3. ARL-300 HATA KODLARI..................................................................................................................................... 28

4. ARL-300 KUMANDA KARTI ................................................................................................................................. 29

5. FX_SERI KABN SER HABERLEME KARTI ................................................................................................. 30

6. FX_SERI_32 KABN SER HABERLEME VE PANO KAYIT KARTI .......................................................... 31

7. ARL-300 ARJ KARTI ............................................................................................................................................ 32

8. LEVELED KATTA GSTERGE KARTI ............................................................................................................. 33

9. KBK KLEMENS KARTLARI................................................................................................................................. 34

TRKE

10. MANYETK ALTER VE MIKNATISLARIN KURULUMU .......................................................................... 43

10.1. M1 SAYICILI SSTEM N KURULUM ....................................................................................................... 43

10.2. ML1-ML2 SAYICILI SSTEM N KURULUM ........................................................................................... 43

11. ALT VE ST ZORUNLU KESC ALTERLERN BALANTILARI .......................................................... 46

12. KAPI KPRLEME.............................................................................................................................................. 47

12.1. AIK KAPI LE SEVYE YENLEME ............................................................................................................ 47

12.2. ERKEN KAPI AMA ....................................................................................................................................... 47

12.3. KAPI KPRLEME AAMALARI ................................................................................................................ 48

13. GRUP HABERLEME .......................................................................................................................................... 49

13.1. KUMANDA PANOLARI GRUP BALANTILARI ........................................................................................ 49

13.2. GRUP ALIMADA KAT KASETLER BUTON BALANTILARI ............................................................ 49

13.3. GRUP ALIMA AYARLARI......................................................................................................................... 49

14. FZKSEL BOYUTLAR ........................................................................................................................................ 50

15. GVENLK NOTLARI ......................................................................................................................................... 51

ARKEL

ARL-300

www.arkel.com.tr

TRKE

ENGLISH

ARKEL Elektrik Elektronik Ltd. ti.

ARKEL

ARL-300

ARKEL Elektrik Elektronik Ltd. ti.

www.arkel.com.tr

GR

ARL-300 hidrolik ve halatl asansrler iin EN81-1 / 2 standartlarna uygun olarak tasarlanm

tmleik bir kumanda kartdr.

ARL-300 sisteminde sadece birka parametre deiiklii ile asansrnz 1.6 m/s hza kadar, ift

hz, hidrolik veya VVVF (dilili ve dilisiz kumanda), 24 duraa kadar her trl kumanda

sistemine uygun ve 4 asansre kadar grup almal olarak ayarlayabilirsiniz.

Sistem dahili kap kprleme rleleriyle erken kap ama ve kap ak seviye yenileme

yapabilmektedir.

ENGLISH

Sistemde tek otomatik kap iin dahili kontrol giri-klar bulunmaktadr.

Dahili faz sral motor koruma devresi ile ebeke besleme problemleri ve motor scakl kumanda

kart tarafndan kontrol edilir.

Gstergeler iin 7-segment, Gray, terslenmi Gray, Binary, terslenmi Binary kod klar ve katta

k sinyalleri verilebilmektedir.

TRKE

Halatl (dilili veya dilisiz kumanda) ve hidrolik asansrler iin acil durum kurtarma fonksiyonu

mevuttur.

ARKEL

ARL-300

ARKEL Elektrik Elektronik Ltd. ti.

www.arkel.com.tr

ARL-300 TEKNK ZELLKLER:

Kontrol Sinyal Girileri

Kontrol Sinyal klar

0 - +60 C

IP20

<%95

3 x 380V, 50Hz, N

24 5 Vdc

Maks. 400mA 10W, 24VDC iin

En fazla 230Vac

(Hidrolik asansrler iin acil indirmede 24Vdc!)

24 5 Vdc

24 5 Vdc

Ksa devre korumal

2-satir 16-karakter LCD ekran ve 4-tu klavye

Grup alma iin RS-485 seri haberleme

Kabin ile seri tesisat balants iin RS-485 seri haberleme

Son 60 hatann hafzada tutulmas

1 adet programlanabilir giri

1 adet programlanabilir rle ve 4 adet programlanabilir transistr k

Dahili kap kprleme gvenlik devresi

Dahili faz sral motor koruma devresi

Tek otomatik kap iin dahili kontrol giri ve klar

Ksa devre korumal dijital ve sinyal klar

Gstergeler iin menden ayarlanabilir 7-segment, Gray ve Binary kod klar

Hidrolik asansrlerde ARL-SARJ kart destei ile acil indirme

ARKEL

TRKE

260 200 35

ENGLISH

Boyutlar

Boy En Ykseklik (mm)

alma scakl

Koruma snf

Nem

ebeke Kontrol Girileri

Kontrol Beslemesi Gerilimi

G harcamas

Gvenlik Devresi Gerilimi

ARL-300

ARKEL Elektrik Elektronik Ltd. ti.

www.arkel.com.tr

1. LCD EKRAN VE TU TAKIMI

ARL-300 kumanda kartnda 2-satir 16-karakter LCD ekran ve 4-tu klavye bulunmaktadr.

2-satir 16-karakter

LCD ekran

ARL-300 anakart zerindeki butonlarn fonksiyonlar aadaki gibidir:

Ana ekranda

ENGLISH

Ekran deitirme

3 saniye basl tutarak menye giri

3 saniye basl tutarak manel hareket ekranna giri

LCD ekrann kontrast (parlaklk) ayarn arttrma

TRKE

LCD ekrann kontrast (parlaklk) ayarn azaltma

Kayt verme ekrannda

Ekrandan k

3 saniye basl tutarak menye giri

Verilen kayd etkinletirme

Kayt verilecek durak numarasn arttrma

Kayt verilecek durak numarasn azaltma

Rasgele kayt ekrannda

Ekrandan k

3 saniye basl tutarak menye giri

Verilen kayd etkinletirme

lk rastgele kayd verme

Rastgele kayt saysn arttrma

Rastgele kayt saysn azaltma

Menden k ekrannda

Menden k

ARKEL

ARL-300

ARKEL Elektrik Elektronik Ltd. ti.

www.arkel.com.tr

Manel hareket ekrannda

Ekrandan k

3 saniye basl tutarak menye giri

Yn tuu ile birlikte basarak kabini o ynde yksek hzda hareket ettirme

Asansr yukar ynde hareket ettirme

Asansr aa ynde hareket ettirme

Men ierisinde

ENGLISH

Parametre deitirme (ilk parametre ynnde)

Parametre deitirme (menden k ynnde)

Parametre deerini deitirme

Ekranda Menden k yazd srada

Parametre deerini deitirme

TRKE

Display ayarlar ekrannda

Ekrandan k

Durak numarasn seme

Gsterge yazsn seme

Ekrandan k

Ekrana giri

Durak numaras ve gsterge yazsn deitirme

Durak numaras ve gsterge yazsn deitirme

Hata kaytlar ekrannda

Ekrana giri

Hata numarasn arttrma (daha eski hatalar ynnde)

Hata numarasn arttrma (daha yeni hatalar ynnde)

Hatalar sil ekrannda

Ekrana giri

Ekrandan k

Hatalar silmeyi onaylama

ARKEL

ARL-300

ARKEL Elektrik Elektronik Ltd. ti.

www.arkel.com.tr

AILI EKRANI

ARL-300 V1.7x

SERI NO: 36-0298

Sisteme enerji verildiinde LCD ekranda AILI EKRANI olarak

adlandrdmz ekran belirir. Bu ekranda kullanmakta olduunuz

kartn yazlm srm ve seri numaras gsterilmektedir. Ekran iki

saniye bekledikten sonra, ANA EKRAN olarak adlandracamz

grntye geilir.

ANA EKRAN

KAYIT BEKLENIYOR Ana ekranda, kumanda kartnn besleme gerilimi (100) ve asansrn

bulunduu durak numaras gsterilir.

100: 24V DURAK: 1

TRKE

ENGLISH

LCD KONTRAST AYARI

KONTRAST

xxxxxxx

ARL-300 kumanda kartnda LCD ekrann kontrast (parlaklk) ayar tular

yardmyla ayarlanabilmektedir. Ana ekranda iken YUKARI/ASAI

tular kullanlarak kontrast seviyesi arttrlp/azaltlabilir. LCD ekrann

kontrast seviyesi x iaretleri ile temsil edilmektedir. Unutmaynz ki bu

ilem sadece ana ekranda iken yaplabilir nk mende ve dier

ekranlarda YUKARI/AAI butonlar farkl amalar iin

kullanlmaktadr. Ayrca kontrast ayar yapldktan sonra menye bir kez

girilerek yaplan ayarn hafzaya kaydedilmesi gereklidir. Aksi taktirde

kartn enerjisi kesildiinde yaplan kontrast ayar silinmi olacaktr.

KART ZERNDEN MANUEL HAREKET

MANUEL HAREKET

100: 24V DURAK: 1

SA butonu 3 saniye basl tutunuz. Ekranda MANUEL HAREKET

yazs belirecektir. Ardndan YUKARI ve AAI butonlarn

kullanarak asansrnz hareket ettirebilirsiniz. SA buton ile birlikte

yn butonlarna basarsanz kabin yksek hzda hareket edecektir.

Manel hareket modundan kmak iin SOL butonu kullannz.

Elektrik kesilip geldiinde ya da 1 dakika sreyle herhangi bir hareket

butonuna baslmam ise kart kendiliinden bu konumdan kacaktr.

TULARDAN KAYIT VERMEK

KAYIT VERME: 1

AKTIF KAYIT : --

ARKEL

Kayt verme ekranna girebilmek iin ana ekranda iken SOL tua basarak

ilerleyiniz. Bu ekranda iken kayt vermek istediiniz kat

YUKARI/ASAI tularn kullanarak belirledikten sonra SA tua

basarak kayd giriniz. Kayt verilebilecek en yksek kat, asansrn durak

say ile belirlenir. Bu ekrandan kmak iin SOL butonu kullannz.

10

ARL-300

ARKEL Elektrik Elektronik Ltd. ti.

www.arkel.com.tr

TULARDAN RASGELE KAYIT VERMEK

ARL-300 kumanda kart belirlediiniz sayda rastgele kayt oluturarak,

asansr altrabilir. Rastgele kayt ekranna girebilmek iin ana

ekranda iken SOL tua basarak ilerleyiniz. Bu ekranda YUKARI tuuna

basldnda ARL-300 ana kart rastgele bir kayt alr. Alnan bu kayt

st satrda gsterilir. lk rastgele kayt ileminden sonra, vermek

istediiniz kayt saysn YUKARI/ASAI tularn kullanarak

belirleyiniz. Kayt says ekrann alt satrnda gsterilmektedir. Kaytlar

cevaplandka bu say azaltlr. Kaytlar cevaplanrken de kayt saysn

YUKARI/ASAI tuu ile arttrmak/azaltmak mmkndr. Bu say en

ok 99 olarak ayarlanabilmektedir. Ekrandan kmak iin SOL butonu

kullannz.

GRUP ALIMA EKRANI

GRUP DURUMLARI

[A+] B- -- --

Grup alma ekranna girebilmek iin ana ekranda iken SOL tua

basnz. Bu ekranda grup alma ile ilgili bilgiler grlecektir.

Ekranda drt adet panonun grup almadaki durumlar aadaki gibi verilmektedir.

ENGLISH

RASGELE KAYIT: 1

KAYIT SAYISI: --

+, -

: Haberlemesi olan kumanda panosunun grup almaya dahil olup

[]

--

olmadn belirtir. ( - iaretli pano d kaytlara cevap veremez durumdadr.)

: Kontrolc kumanda panosunun kendine ait olan grup kimliini belirtir

: Var olmayan ya da haberleme kurulamayan kumanda panolarn belirtir.

Yukardaki rnek grup alma ekrannda; asansrn dubleks olarak alt, kumanda

panolarnn grup kimliklerinin A ve B olarak tanmland, B panosu ile haberleme

yapldn ancak panonun grup alma dnda olduunu ve kontrolc panonun grup

kimliinin ise A olarak tanmland anlalmaktadr.

ARKEL

11

ARL-300

TRKE

A, B, C, D : Kumanda panolar iin tanmlanan grup kimliklerini belirtir.

ARKEL Elektrik Elektronik Ltd. ti.

www.arkel.com.tr

MENUYE GR

LISAN/LANGUAGE

TURKCE

Menye girebilmek iin SOL butonu 3 saniye basl tutunuz. Eer giri

izni iin herhangi bir ifre tanmlanmam ise (0000: balang ifresi)

ekrana ilk parametre olan LISAN/LANGUAGE yazs kacaktr.

Eer daha nceden bir ifre tanmlanm ise YUKARI ve AAI

butonlarn kullanarak ifrenizi doru biimde giriniz. Ardndan ifreyi

onaylamak iin SA butona basnz. ifreniz doru girilmi ise ilk

parametre ekranda belirecektir. Yanl girilmi ise ekranda GECERSIZ SIFRE uyars belirecek

ve ifre tekrar sorulacaktr. 3 defa hatal ifre girilmesi kartnz blokeye alr. Blokeli kart ancak

puk kodunu kullanarak blokeden karabilirsiniz.

ENGLISH

SIFRE GIRINIZ

0000

Program parametreleri arasnda gei yapmak iin SA ve SOL butonlar, parametre deerlerini

deitirmek iin ise YUKARI ve AAI butonlar kullanlmaktadr.

Yukar ve aa butonlar ile parametre deerini deitirdiiniz anda deiiklik hafzaya

alnacaktr, onaylamak iin ayrca bir tua basmanza gerek yoktur. Ekranda istediiniz parametre

deeri knca sa veya sol buton ile bir sonraki/nceki parametreye direk olarak geebilirsiniz.

Ayarlanan deerlerin hafzaya kalc olarak kayd menden kldnda otomatik olarak

yaplacaktr.

TRKE

MENUDEN IKI

MENUDEN CIKIS

ARKEL

Menden kmak iin SA tua MENUDEN CIKIS ekrann

grnceye kadar basnz. Bu ekranda iken YUKARI tuuna basarak

menden kabilirsiniz.

12

ARL-300

ARKEL Elektrik Elektronik Ltd. ti.

www.arkel.com.tr

2. PARAMETRE LSTES

LISAN/LANGUAGE

ASANSOR TIPI

DURAK SAYISI

KUMANDA TIPI

KABIN CAGRILARI

KAPI TIPI

KAPI KOMUTLARI

OTO KAPI KATTA

DURAKTA BEKLEME

KILIT BEKLEME

KAPI ACIK HATASI

FOTOSEL ZAMANI

KABIN LAMBASI

PARK DURAGI

PARK ZAMANI

YANGIN DURAGI

ITFAIYECI MODU

YILDIZ YOLVERME

Y./UCGEN GECIKME

MOTOR GECIKMESI

VALF GECIKMESI

KONTAKTR GECIKME

KATLAR ARASI MAX

YAVAS MAX SEYIR

KAPI ERKEN ACMA

SEVIYE YENILEME

AKULU INDIRME

KURTARMA TIPI

DISPLAY AYARLARI

FX_SERI A,B,C,..

PT0-PT3 CIKISI

BINARY/GRAY KOD

PR ROLE ISLEVI

GONG CIKISI

RST FAZ KONTROL

HATA KAYITLARI

HATALARI SIL

REVIZYONDA LIMIT

120 FONKSIYONU

POZISYON RESET

HARICI EM. ROLESI

GRUP KIMLIGI

BAKIM SURESI

BAKIM SURE SONU

ILK DURAK

SON DURAK

VATMAN CAGRILARI

TAHLIYE DURAGI

MAX. KABIN CAGRI

YON OKLARI

KONTAKTOR KONTRL

A3 VALF KONTROL

MOTOR FREN IZLEME

ARKEL

(Hidrolik asansrler iin)

(Hidrolik asansrler iin)

(Hidrolik asansrler iin)

(Hidrolik asansrler iin)

(Halatl VVVF asansrler iin)

TRKE

ENGLISH

Aada ARL-300 mensnde yer alan parametreler listelenmitir. Baz parametreler asansr

tahrik tipine gre seilebilir olmaktadr.

(Halatl VVVF ve Hidrolik asansrler iin)

(Halatl VVVF ve Hidrolik asansrler iin)

(Hidrolik asansrler iin)

(Halatl VVVF asansrler iin)

(Hidrolik asansrler iin)

(Hidrolik asansrler iin)

13

ARL-300

ARKEL Elektrik Elektronik Ltd. ti.

UCM TEST MODU

SELEKTOR TIPI

A3VALF GECIKMESI

KURTARMA GECIKME

A3 VALFI

SIFRE

MENUDEN CIKIS

(Hidrolik asansrler iin)

(Hidrolik asansrler iin)

TRKE

ENGLISH

www.arkel.com.tr

ARKEL

14

ARL-300

ARKEL Elektrik Elektronik Ltd. ti.

LISAN/LANGUAGE

www.arkel.com.tr

Bu parametre ile ekrann lisan seimi yaplr.

TRKE: Trke

ENGLISH: ngilizce

NEDERLANDS: Hollandaca

ROMANA: Romence

P: Rusa

DUITS: Almanca

ITALIANO: talyanca

ENGLISH

ARL-300 kumanda kartnda men dilleri iki ayr gruba ayrlmtr. Kart zerinde ayn

anda en fazla 5 farkl dil seimi yaplabilir. Bu dil gruplar unlardr:

1.Grup: Trke, ngilizce, Almanca, Hollandaca ve Rusa

2.Grup: Trke, ngilizce, Almanca, Romence ve talyanca

ASANSOR TIPI

Asansrnzn tahrik tipini bu parametre ile ayarlayabilirsiniz.

asansrler iin bu ayar seilmelidir. Ayrca "KURTARMA TIPI" parametresi sisteme uygun

olarak ayarlanmaldr.

2 HIZLI ASANSOR: ift-hz halatl asansrler iin bu ayar seilmelidir.

DURAK SAYISI

Asansrnzn durak saysn bu parametre ile 24 duraa kadar

ayarlayabilirsiniz.

2-24

KUMANDA TIPI

Asansrnzn kumanda tipini bu parametre ile ayarlayabilirsiniz.

BASIT KUMANDA: Kabin ve kat butonlar paralel balanr. Alnan tek kayt dnda

kayt hafzas tutulmaz.

IC DIS KARISIK: Kabin ve kat butonlar paralel balanr. Kayt hafzas tutulur.

1 BUTON ASAGI: Kabin ve kat butonlar ayr ayr balanr. Kabin kaytlar iki ynde de

toplanr. Kat arlar ise kabin aa doru hareket ederken toplanr.

1 BUTON YUKARI: Kabin ve kat butonlar ayr ayr balanr. Kabin kaytlar iki ynde

de toplanr. Kat arlar ise kabin yukar doru hareket ederken toplanr.

1 BUTON CIFT YON: Kabin ve kat butonlar ayr ayr balanr. Kabin kaytlar ve kat

arlar iki ynde de toplanr.

2 BUTON TOPLAMA: Kabin kaytlar ve katlardaki aa ve yukar butonlar ayr ayr

balanr. Kabin kaytlar ve kat arlar hareket ynne uygun ekilde toplanr.

ARKEL

15

ARL-300

TRKE

HIDROLIK: Hidrolik asansrler iin bu ayar seilmelidir.

HALATLI VVVF: Kademesiz dilili (asenkron makineli) ve dilisiz (senkron makineli)

ARKEL Elektrik Elektronik Ltd. ti.

KABIN CAGRILARI

www.arkel.com.tr

Kumanda kart ile kabin arasndaki balant tipini bu parametre ile

ayarlayabilirsiniz.

ANA KARTA BAGLI: Kumanda kart ile kabindeki tm buton ve alglayclar arasnda

bire bir yani paralel balant yaplacak.

FX SERI-16 BAGLI: Kumanda kart ile kabin buton ve alglayclar arasndaki iletiim

FX-SERI-16 kart zerinden seri haberleme ile yaplacak.

FX SERI-32 BAGLI: Kumanda kart ile kabin buton ve alglayclar arasndaki iletiim

FX-SERI-32 kart zerinden seri haberleme ile yaplacak. 16 durak st sistemlerde seri

kabin tesisat zorunludur ve kumanda panosunda kat arlar iin, revizyon kutusunda

kabin kaytlar iin FX-SERI-32 kart kullanlr.

ENGLISH

16 durak st sistemlerde seri kabin tesisat zorunludur. Kumanda panosunda d

kaytlar, revizyon kutusunda i kaytlar iin FX-SERI-32 kart kullanlmaldr.

KAPI TIPI

Otomatik kap tipini bu parametre yardm ile ayarlayabilirsiniz.

YARI OTOMATK: Asansrde sadece kabin ii gvenlik kaps bulunmaktadr.

TAM OTOMATIK: Asansrde kat ve kabin otomatik kaplar mevcuttur.

TRKE

KAPI KOMUTLARI

Otomatik kaplar iin a-kapa sinyal tipini bu parametre yardm ile

ayarlayabilirsiniz.

SADECE KAPA SNY. : Sadece kapa sinyali var, a sinyali kullanlmyor ise. (Kapa

sinyali var ise kap kapanr, yok ise kap alr). 120 sinyali kesildiinde kapa sinyali

verilmeye devam eder.

KAPA/AC SINYALI: Kapa ve a sinyalleri kullanlyor ise. (Ama sinyali var ise kap

alr. Kapa sinyali var ise kap kapanr. Her iki sinyal de yok ise kap bulunduu

pozisyonu korur). 120 sinyali kesildiinde a ve kapa sinyalleri verilmez.

EN 81-1/2 standartlarna gre acil stop, revizyon ve geri alma konumlarnda otomatik

kap hareketsiz kalmaldr.

OTO KAPI KATTA

Tam otomatik kapl asansrlerde kapnn katta ak veya kapal

beklemesini ayarlayabilirsiniz.

KAPALI BEKLEME: Katta kaplar kapal bekler.

ACIK BEKLEME: Katta kaplar ak bekler. (EN 81-1/2 standartlarna uygun deildir)

Bu parametre EN 81-1/2 standardna uyumluluk iin mutlaka KAPALI BEKLEME

olarak ayarlanmaldr. Eski asansrlerin modernizasyonunda risk oluturmayacak ekilde

yeterli tedbirlerin alnmas veya Avrupa birlii normlarnn geerli olmad lkelerde

kullanlmas durumunda ancak AIK BEKLEME olarak ayarlanabilir.

ARKEL

16

ARL-300

ARKEL Elektrik Elektronik Ltd. ti.

DURAKTA BEKLEME

www.arkel.com.tr

Toplama esnasnda dier kaytlara gitmeden nce durakta bekleme

sresini bu parametreden ayarlayabilirsiniz. [saniye]

0-60 Saniye

Revizyon kutusu seri tesisatl ve oto kapnn A / KAPA buton ular seri karttan

alnm ise DURAKTA BEKLEME sresi uzatlmaldr.

EN81-1 ve EN81-2 standartlarna gre, manel kapl asansrlerde kabin kata

geldikten sonra yeniden harekete gemeden nce en az 2 saniye beklemelidir.

KILIT BEKLEME

Kap kapal sinyali geldikten sonra kilit (140) sinyalinin gelmesi iin

beklenecek maksimum sresi bu parametre ile ayarlanr. [saniye]

10-99 Saniye

ENGLISH

Basit kumandal (toplamasz) asansrlerde bu parametre KABIN LAMBASI sresi

ile ayn tutulmal ve en az 2 saniye olarak ayarlanmaldr.

KAPI ACIK HATASI

Bu parametre ile ayarlanan sre sonunda eer asansrn kaps

kapanmad ise kumanda panosu servis dna geecektir. stenirse bu

fonksiyon iptal edilebilir. [saniye]

IPTAL: Kap ak hatas fonksiyonu devre d braklr.

10-240 Saniye: Kap ak hatasna geme sresidir.

Tam oto kapl panolarda kap ak hata sresi 240 saniye olarak ayarlanmaldr.

FOTOSEL ZAMANI

Kapnn fotosel kesmesi nedeniyle amasndan sonra fotosel

kesmesinin ortadan kalkmasyla birlikte yeniden kapanmak iin

bekleyecei sreyi bu parametre ile ayarlayabilirsiniz. [saniye]

0-60 Saniye

KABIN LAMBASI

Kabin lambas gecikmesini bu parametre ile ayarlayabilirsiniz.

[saniye]

IPTAL: Kabin lambas gecikmesi fonksiyonu devre d braklr.

1-240 Saniye: Kabin lambas gecikmesi sresidir.

EN 81-1/2 standartlar manel kaplarda kabin lambas gecikmesinin devre d

braklmasna izin verilmez.

Basit kumandal (toplamasz) asansrlerde bu parametre DURAKTA BEKLEME

sresi ile ayn tutulmal ve en az 2 saniye olarak ayarlanmaldr.

ARKEL

17

ARL-300

TRKE

Bu sre yarm oto kaplarda 35 saniye, tam oto kaplarda ise 95 saniye olarak

ayarlanmaldr.

ARKEL Elektrik Elektronik Ltd. ti.

PARK DURAGI

www.arkel.com.tr

Asansrn ii bittiinde ayarlanan sre sonunda gitmesini istediiniz

dura bu parametreden ayarlayabilirsiniz

IPTAL: Park dura fonksiyonu devre d braklr.

1-24: Sistemde park dura mevcuttur.

PARK ZAMANI

Park durana gitmeden nce bekleme sresini bu parametre ile

ayarlayabilirsiniz. [saniye]

0-250 Saniye

Yangn duran bu parametre ile ayarlayabilirsiniz. Yangn (YAN)

girii aktif olduunda asansr dorudan tanmlanan kata gider ve

kaplar ak olarak bekler. Yangn sinyalinin kesilmesi ile asansr

normal almasna geri dner.

IPTAL: Sistemde yangn dura tanml deildir.

1-24: Sistemde yangn dura tanmldr.

ITFAIYECI MODU

Asansr, yangn asansr olarak hizmet verecek ise itfaiyeci modu

bu parametre ile aktif edilir.

IPTAL: tfaiyeci modu kullanlmaz.

AKTIF: tfaiyeci modu aktif edilir.

TRKE

ENGLISH

YANGIN DURAGI

tfaiyeci servisi sadece seri kabin tesisatl sistemlerde mmkndr. Kumanda kartnda

seri tesisat varken kullanlmayan 804, K20 ve DTS girileri itfaiyeci modunda aadaki

ekilde balanmaldr:

804: Kabin kasetindeki itfaiyeci anahtar balants iin

K20: Kap ak limiti balants iin

DTS: Kap kapal limiti balants iin

Kap limit kontaklar normalde kapal olmaldr. Kap tam olarak alp-kapandnda

limit sinyalleri kesilmelidir.

YILDIZ YOLVERME

Hidrolik sistemlerde, yukar harekette, kalk srasnda motorun

yldz balantda alma sresini bu parametre ile ayarlayabilirsiniz.

[saniye] [Hidrolik sistemler iin] [Yldz-gen yol verme iin]

0.0-9,9 Saniye

Y./UCGEN GECIKME

Hidrolik sistemlerde, yukar harekette, kalk srasnda motorun

yldz balanty bitirip, gen balantya gemeden nce

bekleyecei sreyi bu parametre ile ayarlayabilirsiniz.

[saniye] [Hidrolik sistemler iin] [Yldz-gen yol verme iin]

0.0-9,9 Saniye

MOTOR GECIKMESI

Hidrolik sistemlerde, yukar harekette, durma sinyali geldikten sonra

motorun almaya devam edecei sreyi bu parametreden

ayarlayabilirsiniz. [saniye] [Hidrolik sistemler iin]

0.0-9,9 Saniye

ARKEL

18

ARL-300

ARKEL Elektrik Elektronik Ltd. ti.

VALF GECIKMESI

www.arkel.com.tr

Hidrolik sistemlerde, durma sinyali geldikten sonra valflarn

almaya devam edecei sreyi bu parametreden ayarlayabilirsiniz.

[saniye] [Hidrolik sistemler iin]

0.0-9,9 Saniye

KONTAKTR GECIKME

Halatl VVVF sistemlerde ana kontaktrn gecikmeli dmesi

istenebilir. Bu gibi durumlarda RP rle knn gecikmesi bu

parametreden ayarlanr. [saniye] [Halatl VVVF sistemler iin]

Kabinin bir kattan dier kata hareketi esnasnda msaade edilen

maksimum seyir sresi bu parametre yardm ile ayarlanr. Eer bu

sre alacak olursa, sistem otomatik olarak kabinin hareketini

durdurur ve bloke olur. [saniye]

5-120 Saniye

EN 81-1/2 standartlarna gre, motor alma zaman am sresi aadaki srelerden

kk olann amayacak ekilde uygun olarak salanmaldr:

a. 45 saniye

b. En uzun seyir mesafesi + 10 saniye

c. En uzun seyir mesafesi 10 saniyeden az ise zaman am sresi en az 20 saniye olmaldr.

YAVAS MAX SEYIR

Asansrn hedef kata vardnda katta durdurucuyu grene kadar

yava hzda hareket edecei maksimum sre bu parametre yardm ile

ayarlanr. Eer bu sre alacak olursa, sistem otomatik olarak kabinin

hareketini durdurur ve bloke olur. [saniye]

5-60 Saniye

KAPI ERKEN ACMA

Kap erken ama fonksiyonunu etkinletirmek iin bu parametre

kullanlr. [Halatl VVVF ve Hidrolik asansrler iin].

IPTAL: Kap erken ama iptal.

AKTIF: Kap erken ama aktif.

Kap erken ama iin kabinin kaplar ak iken hareket etmesine sadece kap ama

blgesi snrlar iinde ve ARL-300 zerindeki kap kprleme devresi kontrol altnda izin

verilmitir. Ayrntl bilgi iin kap kprleme blmne baknz.

SEVIYE YENILEME

Seviye yenilemeyi etkinletirmek iin bu parametre kullanlr. [Halatl

VVVF ve Hidrolik asansrler iin].

IPTAL: Seviye yenileme iptal.

AKTIF: Seviye yenileme aktif.

ARKEL

19

ARL-300

TRKE

KATLAR ARASI MAX

ENGLISH

0.0-9,9 Saniye

ARKEL Elektrik Elektronik Ltd. ti.

www.arkel.com.tr

Seviye yenileme iin kabinin kaplar ak iken hareket etmesine sadece kap ama

blgesi snrlar iinde ve ARL-300 zerindeki kap kprleme devresi kontrol altnda izin

verilmitir. Ayrntl bilgi iin kap kprleme blmne baknz.

AKULU INDIRME

Hidrolik asansrlerde akl indirmeyi etkinletirmek iin bu

parametreyi kullanabilirsiniz. [Hidrolik sistemler iin].

IPTAL: Akl indirme iptal.

AKTIF: Akl indirme aktif.

KURTARMA TIPI

Kademesiz dilili (asenkron makineli) ve dilisiz (senkron makineli)

asansrlerde kurtarma tipi bu parametre ile belirlenir. [Halatl VVVF

sistemler iin]

HARICI VEYA YOK: Dilili (asenkron makineli) asansrler iin bu ayar seilmelidir. Bu

seim, sistemde AKUS-SD ve benzeri bir harici kurtarma nitesi kullanlyor veya sistemde

herhangi bir otomatik kurtarma nitesi bulunmuyor anlamndadr.

FREN BIRAKTIRMA: Fren braktrarak kurtarma dilisiz (senkron makineli) asansrler

iin bu ayar seilmelidir. Fren braktrarak yaplan otomatik kurtarma ileminde (pasif

kurtarma), ARL-300 ana kart mekanik frenleri aarak kabinin kat seviyesine alnmasn

salar. Bu ilem iin ARL-300 kumanda sistemi uygun gte bir UPS ile beslenmelidir.

Hareket yn yk dengesine baldr.

VVVF ILE SUREREK: Bu seenek dilisiz (senkron makineli) asansrlerde, otomatik

kurtarma ilemi VVVF cihaz tarafndan motor srlerek (aktif kurtarma) yaplyor ise

seilmelidir.

TRKE

ENGLISH

Hidrolik asansrlerde arj ARL-SARJ kart tarafndan yaplan 2 adet 12V ak ile acil

indirme yaplr. ARL-300 kart akden alnan 24V ile enerjilendikten sonra, 140B giriine

gelen maks. 24V sinyal ile elektrik kesintisini alglar ve acil indirme rlesini ektirerek acil

indirme valf ile kabini katna kadar indirir.

BINARY/GRAY KOD

LCD ve kayar dijital gstergeler iin ARL-300 ana kart zerindeki

veya FX_SERI kartlar zerindeki Binary veya Gray kod olarak

ayarlanan tm klarn balang deerlerini belirlemek iin bu

parametre kullanlr.

0, 1, 2, 3: Gray/Binary kod klar 0dan saymaya balar. (lk durak iin 0 k verilir)

15, 16, 17, 18: Gray/Binary kod klar 15 den saymaya balar. (lk durak iin 15 k verilir)

PR ROLE ISLEVI

ARL-300 kart zerindeki PR programlanabilir rlenin ilevi bu

parametre ile belirlenir.

GONG CIKISI: Ding Dong k verir. Paralel kabin tesisatnda ding dong k olarak

kullanlr. Kabin tesisat seri olduunda ding dong k FX_SERI kartlar zerindeki DD

kndan alnr.

2. MOTOR KONTROLU: Yksek gl hidrolik sistemlerde seviye yenileme ilemi iin

kullanlan 2. bir motor iin k verir.

ARKEL

20

ARL-300

ARKEL Elektrik Elektronik Ltd. ti.

DISPLAY AYARLARI

www.arkel.com.tr

Her durak iin 7 segment gstergelerde yazlacak kat isimleri veya

katta k sinyalleri bu ekran yardm ile ayarlanr.

Bu ekranda YUKARI butonuna basarak ayarlara giriniz. Ekrann alt satrnda aadaki gibi

bir yaz belirecektir.

Durak numarasn deitirmek iin durak rakam yanp snerken YUKARI-ASAGI

butonlarn kullanarak deitirmek istediiniz duraa geliniz. Daha sonra SA butona

basarak dijital deerinin yanp snmesini salaynz. Tekrar YUKARI-ASAGI butonlarn

kullanarak istediiniz dijital ayarn o durak iin yapnz. stediiniz deeri ayarladktan

sonra ayardan kmak iin tekrar SA butona basnz. Veya baka bir dura ayarlamak iin

SOL butona basp yeniden durak rakamnn yanp snmesini salaynz ve ilemleri

tekrarlaynz.

Aada ARL-300 mensnde 7-segment gstergelerde yazlacak kat isimleri iin

kullanabileceiniz karakterler ve katta klar iin sinyaller listelenmitir:

ENGLISH

DISPLAY AYARLARI

DURAK:1 DISP:0

7-segment

gsterge

Katta k

-9, -8, -7, -6, -5, -4, -3, -2, -1, 0, 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14,

15, 16, 17, 18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29, A, b, C, d, E, F, H,

J, L, n, o, P, u, y, boluk, -, =, 1A, 1b, 2A, 2b

K1, K2, K3, K4, K5, K6, K7, K8, K9, KX

K1: Sadece A ucu k verir

K2: Sadece B ucu k verir

K8: Sadece G2 ucu k verir

K9: Sadece BC ucu k verir

KX: Tm ular k verir

D kasetlerdeki 7-segment gstergeler iin KBK-2 kartndaki A, B, C, D, E, F, G, BC ve

G2 klar kullanlr. 16 durak stnde bu klara ek olarak FX-SERI-32 kart zerindeki

20 k kullanlr. Paralel kabin tesisatl sistemlerde kabin ii 7-segment gstergeler iin

de KBK-2 kartndaki klar kullanlr.

Katta k sinyalleri K1, K2, K8 ve K9 srasyla A, B, G2 ve BC (KBK-2 ve FX-SERI

kartlar zerindeki) klarndan verilmektedir. rnein 1. duraa K1 sinyali atandnda A

kndan 1. durak iin katta sinyali alnr. 2. duraa K2 sinyali atandnda B kndan 2.

Durak iin katta sinyali alnr.

ARKEL

21

ARL-300

TRKE

Gsterge tipi Seilebilecek klar

ARKEL Elektrik Elektronik Ltd. ti.

FX_SERI A,B,C,..

www.arkel.com.tr

Kabin tesisat iin FX_SERI seri haberleme kartlar kullanldnda,

kabin ii gstergeler iin kod k tipi (A, B, C, klarndan

verilen) bu parametre ile ayarlanr.

7 SEGMENT CIKIS: 7 segment kod veya katta k

GRAY KOD CIKIS: Gray kod k

BINARY KOD CIKIS: Binary kod k

TERSLENMIS BINARY: Terslenmi binary kod k

TERSLENMIS GRAY: Terslenmi gray kod k

ENGLISH

Kod k olarak Gray/Binary veya bunlarn terslenmileri seildiinde A, B, C, D ve E

klar srasyla gray/binary kod klarn (M0, M1, M2, M3 ve M4) verecektir. A k

kod klarnn en sa biti, E ise en sol bitidir. E k sadece 16 durak stnde

FX_SERI_32 kart kullanldnda aktiftir.

Katta k sinyalleri iin kod k 7-segment olarak ayarlanmaldr. Katta k sinyalleri

K1, K2, K8 ve K9 srasyla A, B, G2 ve BC ularndan alnr.

PT0-PT3 CIKISI

LCD ve kayar dijital gstergeler iin ARL-300 anakart zerindeki

programlanabilir klarn kod tipini bu parametre ile ayarlayabilirsiniz.

GRAY KOD: Gray kod klar

BINARY KOD: Binary kod klar

TRKE

ARL-300 ana kart zerindeki PT0, PT1, PT2 ve PT3 klar srasyla gray/binary kod

klar (M0, M1, M2, M3) verir. PT0 kod klarnn en sa biti, PT3 ise en sol bitidir.

16 durak st sistemlerde bu parametre FX-SERI-32 kart zerindeki M0, M1, M2, M3, M4

klarnn kod tipini de programlayacaktr. (16 durak st sistemlerde gray/binary kod

klar ARL-300 ana kartndan deil FX-SERI-32 kartndan alnr).

GONG CIKISI

Kabin st gong sinyalinin alma ekli bu parametre ile ayarlanr.

Paralel kabin tesisatl sistemlerde gong k PR programlanabilir rle

kndan alnr. Seri kabin tesisatl sistemlerde gong k FX-SERI

kartlar zerindeki DD kndan alnr.

KAPI ACILIRKEN: Gong sinyali kap alrken verilir.

YAVASA GECERKEN: Gong sinyali asansr yavaa geerken verilir.

DURUNCA: Gong sinyali asansr durunca verilir.

RST FAZ KONTROL

Faz eksiklii ve faz sras kontroln etkinletirmek iin bu

parametreyi kullanabilirsiniz.

IPTAL: RST faz kontrol iptal.

AKTIF: RST faz kontrol aktif.

ARKEL

22

ARL-300

ARKEL Elektrik Elektronik Ltd. ti.

HATA KAYITLARI

www.arkel.com.tr

Asansr alrken oluan tm hatalar bu parametre yardmyla

incelenebilir. Bu ekranda YUKARI butonuna basarak aada grlen

hata listesi ekranna girilir.

HATA NO: 1 H1

H1:KAPI KILIT HA

ARL-300 kumanda kartnda oluan ve hafzada tutulan tm

hatalar bu ekranda rapor edilir.

HATALARI SIL

Hata kaytlarn temizlemek iin bu parametre kullanlr. Bu ekranda

iken nce YUKARI butonuna basarak ardndan hata kaytlarnn

silinmesi ilemini onaylamak iin AAI butonuna basarak silme

ilemi tamamlanr.

REVIZYONDA LIMIT Revizyonda alt-st limit kesicilerin hareket tarzn bu parametre ile

ayarlayabilirsiniz.

ENGLISH

Sistem son 60 hatay saklayacak ekilde tasarlanmtr. Kaytl 60 hata varken yeni bir hata

oluursa en eski (en byk numaral) hata silinir ve yani hata kaydedilir. Bu ekranda hatalar

oluma srasna gre sralanmtr. Ekrann st satrnda hatann listedeki numaras ve hata

kodu yazlmtr. Ekrann alt satrnda ise hata mesaj verilmektedir. Bir sonraki/nceki

hatay grmek iin YUKARI/AAI butonlar kullanlr.

AKUS-SDli panolarda bu parametre KATINA KADAR GIT olarak ayarlanmaldr.

120 FONKSIYONU

120 devresi kesildiinde asansrn hareket tarzn bu parametre ile

ayarlayabilirsiniz.

DUR: 120 devresi kesildiinde asansr duracak, devre tamamlandnda ise asansr

normal almasna devam edecektir.

DUR ve BLOKELE: 120 devresi kesildiinde asansr duracak ve bloke olacaktr.

KAT CAGRI BLOKELE: 120 devresi kesildiinde (yarm otomatik kaplarda kabin

iinden stop butonuna baslnca) kat arlar bloke edilir. Kabin ii kayt verildikten veya

d kap aldktan sonra ancak asansr normal almasna geri dner.

HARICI EM. ROLESI

Hidrolik sisteminizde harici olarak kullanlan bir emniyet rlesi veya

kontaktr varsa, etkinletirmek iin bu parametreyi kullanabilirsiniz.

VAR: Hidrolik sistemde harici emniyet rlesi var.

YOK: Hidrolik sistemde harici emniyet rlesi yok.

Valf blounun kontrol iin elektronik kart kullanan Beringer, GMV-GEV veya

benzeri hidrolik nitelerde harici emniyet rlesi var olarak seilmeli ve balantlar uygun

ekilde yaplmaldr. Bu tarz hidrolik nitelerde valf bobinleri direkt olarak emniyet devresi

zerinden beslenmediinden, valf besleme klar birbirinden bamsz ve seri bal 2

adet kontaktr ile kesilmelidir. Bu kontaktrlerin normalde kapal kontaklar seri olarak

KBK-4 kartndaki PI giriine balanarak kontaktrlerin yapma kontrolnn yaplmas

salanmaldr.

ARKEL

23

ARL-300

TRKE

DIREK DURDUR: Kesiciler kestii anda katna gelmeden asansr durdurulur.

KATINA KADAR GIT: Kesiciler kesse dahi asansr katna kadar gider.

ARKEL Elektrik Elektronik Ltd. ti.

POZISYON RESET

www.arkel.com.tr

Kumanda kart ebeke elektrii kesilse bile son bulunduu pozisyonu

hafzasnda tutacaktr. Fakat baz zel durumlarda asansrn elektrii

yeniden geldiinde bir pozisyon sfrlama istenebilir. Bu durumda

asansr en alt kata 817 kesicisini grene kadar gidecektir. En alt kata

varldnda kat sayc sfrlanr. rnein Akl kurtarma nitelerinin

olduu sistemlerde, bu parametre aktif yaplarak pozisyon sfrlama

salanabilir.

IPTAL: Pozisyon reset iptal.

AKTIF: Pozisyon reset aktif.

TRKE

ENGLISH

GRUP KIMLIGI

Kumanda panosunun grup alma srasndaki grup kimliini bu

parametre yardm ile ayarlayabilirsiniz. Grup kimlikleri A, B, C veya

D olarak ayarlanabilmektedir. Her asansrn kimlii farkl olmaldr.

Ayn mesafedeki kaytlarda ncelik dk grup kimliine sahip olan

asansrdedir.

KONTROLCU PANO A, B, C veya D

BAKIM SURESI

Kartnz alt srece her gn bu parametrenin ayarlanan deeri 1

azalacaktr. rnein 45 gne ayarladnz bu parametre 30 gn sonra

15 deerini gsterir ve 45 gnn sonunda ise 0 deerini alr. Bu

parametrenin 0 deerini almas durumunda asansrn hareket tarz

BAKIM SRE SONU parametresi ile ayarlanr. [gn].

0-255 Gun: 0 ile 255 gn arasnda bir deer girilebilir.

BAKIM SURE SONU Bakm sresi sonunda ARL-300 kumanda kartnn hareket tarzn bu

parametre ile ayarlayabilirsiniz.

CALISMAYA DEVAM: ARL-300 normal almasna devam eder. Herhangi bir uyar ya

da hata vermez.

DUR: ARL-300 kumanda kart almasn durdurur. H22:BAKIM SURESI GECTI

hatas verilir. Asansr normal durumuna getirmek iin ARL-300 mensnde bu

parametrenin yeni bir deere girilmesi gereklidir.

ILK DURAK

Bu parametre sadece grup almada kullanlr. Gruptaki asansrler

arasnda durak fark bulunuyor ise bu parametre ile farkl olan asansr

iin ilk durak ayar yaplr. Bu ayar yaplrken gruptaki asansrlerin

durak saylar menden ayn olarak ayarlanmaldr. rnein 10 durakl

dubleks bir sistemde, A asansr en alt kata hizmet vermiyor ve sadece B

asansr hizmet veriyor ise: Her iki asansr de 10 duraa ayarlanp, A

asansr iin ilk durak ayar EN ALT KAT+1DE olarak

ayarlanmaldr.

EN ALT KATTA: Bu asansr gruptaki en alt kata hizmet veriyor.

EN ALT KAT+1DE: Bu asansr gruptaki en alt katn 1 durak stne hizmet veriyor.

EN ALT KAT+2DE: Bu asansr gruptaki en alt katn 2 durak stne hizmet veriyor.

EN ALT KAT+3DE: Bu asansr gruptaki en alt katn 3 durak stne hizmet veriyor.

ARKEL

24

ARL-300

ARKEL Elektrik Elektronik Ltd. ti.

SON DURAK

www.arkel.com.tr

Bu parametre sadece grup almada kullanlr. Gruptaki asansrler

arasnda durak fark bulunuyor ise bu parametre ile farkl olan asansr

iin son durak ayar yaplr. Bu ayar yaplrken gruptaki asansrlerin

durak saylar menden ayn olarak ayarlanmaldr. rnein 10 durakl

dubleks bir sistemde, A asansr en st kata hizmet vermiyor ve sadece

B asansr hizmet veriyor ise: Her iki asansr de 10 duraa ayarlanp, A

asansr iin son durak ayar EN UST KAT-1DE olarak

ayarlanmaldr.

Asansrn VAT girii aktif edilerek VATman hizmetine alndnda

kaytlar ileme durumu bu parametre ile ayarlanr.

Tek ar: VATman servisinde sadece ilk verilen kayt ileme alnr. Bu kayt

sonlanmadka baka bir kayt alnmaz.

Son ar: VATman servisinde en son verilen kayt ileme alnr.

oklu ar: VATman servisinde var olan tm kaytlar ileme alnr.

TAHLIYE DURAGI

Asansrn tahliye (panik) dura var ise bu parametre ile ayarlanr.

Kabin ierisinden panik butonuna basldnda asansr tm kaytlar

iptal eder. Hareket halindeyse en yakn durakta durur ve kaplar

amadan tahliye durana hareket eder. Duraa vardnda kaplar aar

ve kaplar ak durumda bekler. 30 saniyelik bekleme sonunda asansr

kaplar kapatarak normal almasna geri dner.

IPTAL: Asansrde panik fonksiyonu yok ise tahliye dura iptal edilmelidir.

1-24: Tahliye dura

Panik butonu balants sadece seri kabin tesisatl sistemlerde mmkndr. Kumanda

kartnda seri tesisat varken kullanlmayan 805 girii panik butonu balants iin kullanlr.

MAX. KABIN CAGRI

Bu parametre kabin ierisinden verilebilecek olan maksimum ar

saysn belirler. Bu sayya ulaldktan sonra kabin iinden verilecek

olan kaytlar alnmaz.

LIMIT YOK: Kabin iinden verilecek kaytlar iin bir snr yoktur.

1-15: Kabin iinden verilebilecek maks. kayt saysdr.

Bu parametrenin kabinin alabilecei maksimum yolcu kapasitesine ayarlanmas nerilir.

ARKEL

25

ARL-300

TRKE

VATMAN CAGRILARI

ENGLISH

EN UST KATTA: Bu asansr gruptaki en st kata hizmet veriyor.

EN UST KAT-1DE: Bu asansr gruptaki en st katn 1 durak altna hizmet veriyor.

EN UST KAT-2DE: Bu asansr gruptaki en st katn 2 durak altna hizmet veriyor.

EN ST KAT-3DE: Bu asansr gruptaki en st katn 3 durak altna hizmet veriyor.

ARKEL Elektrik Elektronik Ltd. ti.

YON OKLARI

www.arkel.com.tr

Yn oku sinyallerinin (31 aa yn ve 32 yukar yn) alma ekli bu

parametre ile belirlenir.

HAREKET+TOPLAMA: Yn oku klar, asansr hareket halinde iken hareket ynn,

katta beklerken ise toplama (bir sonraki seyahatin) ynn verir. Basit kumandal

(toplamasz) sistemlerde yn oku klarnn en azndan hareket ynn vermesi iin bu

ayar seilmelidir.

TOPLAMA YONU: Yn oku klar sadece kabin katta beklerken toplama ynn

verir. Asansr hareket halinde iken yn oku klar verilmez.

TRKE

ENGLISH

KONTAKTOR KONTRL

ARL300 Kontaktrlerin yapp yapmadn srekli olarak

denetleyebilir. Eer bu denetim VVVF src gibi baka bir cihaz

tarafndan yaplyorsa denetim kaldrlabilir.

AKTF: ARL300 Kontaktrleri denetler

IPTAL: ARL300 Kontaktrleri denetlemez.

Hidrolik asansrlerde UCM amal eklenen ilave valfin periyodik

olarak kontrol edilmesi gerekir. Bu kontrol syle yaplr. Asansr en

alt kattayken A3 valfi enerjilendirilmeyerek sadece aa valfinin

enerjilendirilmesi salanr. Bu durumda asansrn hareketsiz kalmas beklenir. A3 Valfi tek

bana asansr hareketsiz tutabilmelidir. Eer tutamyor ve asansrde bir hareket oluuyor ise test

ilemi sonunda asansr bloke edilir. [Hidrolik sistemler iin]

A3 VALF KONTROL

AKTF: A3 Valfi test edilir

IPTAL: A3 Valfi test edilmez.

MOTOR FREN IZLEME

Makine freninin dzgn alp almad fren mikro alterleri ile

denetlenmelidir. Eer bu denetleme VVVF src gibi baka bir

cihaz tarafndan yaplyor ise denetlemeye gerek yoktur.

AKTF: Makine freni denetlenir.

IPTAL: Makine freni denetlenmez.

UCM TEST MODU

Kart UCM test durumuna sokar. Bu konuda ki detayl bilgi iin

UCM test dokmanna baknz.

SELEKTOR TIPI

Mknats diziliminin nasl olduunu bildirmek iin kullanr.

ML1 sayc: Sadece ift hzl sistemlerde seilmelidir.

ML1&ML2 Sayc: Normal mknats dizilimi

ML1 & ML2 A3 Sayc: Hassas seviye yenileme mknatslar kullanld durumda seilir.

Seviye yenileme iin seilmesi gereklidir.

ARKEL

26

ARL-300

ARKEL Elektrik Elektronik Ltd. ti.

www.arkel.com.tr

Hidrolik sistemlerde ki A3 valfinin asansr durduktan sonraki

gecikme ayar bu parametre ile ayarlanr [saniye] [Hidrolik sistemler

iin]

A3 VALF GECIKMESI

0.0-9,9 Saniye

KURTARMA GECIKME

Kurtarma ilemine balama gecikmesi bu parametre ile

ayarlanabilir.

Hidrolik sistemler iin A3 valfinin olup olmad bu parametre ile

kontrol edilir. [Hidrolik sistemler iin]

VAR: A3 Valfi bulunmaktadr.

YOK: A3 Valfi bulunmamaktadr.

SIFRE

0000

Menye giri iin herhangi bir ifre verilmemi ise balang ifresi

0000 kabul edilir. Eer ifre girilmek isteniyorsa YUKARI ve AAI

butonlarn kullanarak ifrenizi girilir. Tekrar menye girebilmek iin

girdiiniz ifreyi unutmaynz.

MENUDEN CIKIS

Bu ekranda iken YUKARI tuuna basarak menden kabilirsiniz.

k srasnda tm ayarlanan parametreler kalc olarak hafzaya alnr.

ARKEL

27

ARL-300

TRKE

A3 VALFI

ENGLISH

0.0-9,9 Saniye

ARKEL Elektrik Elektronik Ltd. ti.

www.arkel.com.tr

TRKE

ENGLISH

3. ARL-300 HATA KODLARI

KOD

H1

H2

H3

H4

H5

H6

H7

H8

H9

H10

H11

H12

H13

H14

H15

H16

H17

H18

H19

H20

H21

H22

H23

H24

H25

H26

H27

ARKEL

HATA

KAPI KILIT HATASI. 140 SINYALI YOK.

KATTAN KATA MAX SEYIR SURESI ASILDI.

KAPI UZUN SUREDIR ACIK KALDI.

MAX YAVAS SEYIR SURESI ASILDI.

YUKARI VE ASAGI LIMIT KESICILERIN IKISIDE KESIYOR

ASAGI HAREKET SIRASINDA YUKARI LIMIT KESICI KESTI.

YUKARI HAREKET SIRASINDA ASAGI LIMIT KESICI KESTI.

MOTOR PTC DEVRESI KESTI. MOTOR ASIRI ISI.

SISTEM HATASI.

KONTAKTOR GERIBESLEME HATASI.

ML1 ve ML2 SINYALLERI BIRBIRINE KISA DEVRE.

KAPI KOPRULEME ROLELERI SR2 VE SR3 CEKMEDI.

KAPI KOPRULEME ROLELERI SR2 VEYA SR3 BIRAKMADI.

KAPI KOPRULEME SONLANDIRILMASINA RAGMEN 140 DEVRESI VAR.

RST SEBEKE BESLEME HATASI.

24V (100) BESLEME GERILIMI LIMITIN ALTINDA.

PTC DEVRESI YOK. MOTOR ASIRI ISINDI

VVVF MOTOR SURUCUDEN HATA SINYALI GELIYOR

GRUP KIMLIK CAKISMASI. AYNI KIMLIK KULLANILIYOR.

120 (STOP) DEVRESI YOK. ASANSOR BLOKEYE ALINDI.

HARICI GUVENLIK ROLESI GERI BESLEME HATASI

BAKIM SURESI GECTI

A3 HDU VALFI TEST HATASI

UCM ALGILAMA HATASI

KONTAKTOR GERIBESLEME HATASI

FREN GERIBESLEME HATASI

FREN GERIBESLEME HATASI

28

ARL-300

ARKEL Elektrik Elektronik Ltd. ti.

www.arkel.com.tr

4. ARL-300 KUMANDA KARTI

6

XK2

ENGLISH

12

5V

100

14

XK3

16

ARKEL

13

15

XK1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

11

TRKE

10

17

Tahrik rleleri

Gvenlik devresi ledleri

Kabin lambas rlesi

Lirpomp rlesi

Kap ama-kapama rleleri

Programlanabilir rle

PTC girii ve kap limit girileri

KBK-2 kart balant soketi (20li fleks kablo ile)

Kap kprleme devresi gvenlik rleleri

Kap gvenlik blgesi ledleri (ML1-ML2)

Servis d, megul, aa ve yukar yn sinyal rleleri

Giri sinyal ledleri

Kayt giri ledleri

5V gerilimi ledi (CPU beslemesi)

100 (+24V) gerilimi ledi (Kontrol sinyalleri beslemesi)

KBK-4 kart balant soketi (14l fleks kablo ile)

KBK-2 kart balant soketi (20li fleks kablo ile)

29

ARL-300

ARKEL Elektrik Elektronik Ltd. ti.

www.arkel.com.tr

5. FX_SERI KABN SER HABERLEME KARTI

TRKE

ENGLISH

FX_SERI kart 16 durak ve alt sistemlerde kabin seri haberlemesi iin kullanlmaktadr. ARL-300

kumanda kart ile 2 kablo zerinden seri haberleerek aadaki balantlar iin panodan kabine

ekilecek tesisattan tasarruf salar:

- Kabin kayt ular (401, 402, , 416)

- Kap kapama butonu (DTS) ve kap ama butonu/fotosel/skma konta (K20)

- Dijitaller (A, B, C, , BC, G2)

- Gray/Binary kod klar (M0, M1, M2, M3)

- Katta k sinyalleri (K1, K2, , K9)

- Ar yk (804) ve tam yk (805) sinyalleri

- Gong tetikleme (DD)

- Yn oklar (31, 32)

- Kabin lambas k (2)

- Revizyonda hareket butonlar (500, 501)

FX_SERI kartnda 31 (Aa yn oku) ve 32 (Yukar yn oku) sinyallerinin k gerilimini

ayarlamak iin pin yuvalar bulunmaktadr.

+

-

Jumper + ve orta pine (st pinlere) takldnda sinyal k 100 (+24V)

Jumper - ve orta pine (alt pinlere) takldnda sinyal k 1000 (0V)

olarak ayarlanr.

32 sinyali k ayar

31 sinyali k ayar

FX_SERI kart zerindeki gsterge klarnn (A, B, C, ) kod tipi ARL-300 kumanda kart

mensnden: 7 segment gsterge, katta k, gray kod, terslenmi gray kod, binary kod veya

terslenmi binary kod olarak ayarlanabilir.

FX_SERI kartnn kumanda panosu ile seri balants (S1A-S1B) iin zel yass kablo kullanmaya

gerek yoktur. Bu iki seri tesisat telinin yass kablonun son iki veya ilk ilki teli olmasna zen

gsteriniz. Kabin faz, kap sinyalleri ve pompa gibi yksek gerilim ularnn ise yass kablonun

dier tarafnda kalmasna zen gsteriniz.

Haberleme hatas veya haberleme kopukluu durumunda kart zerindeki krmz hata ledi

yanacaktr.

ARKEL

30

ARL-300

ARKEL Elektrik Elektronik Ltd. ti.

www.arkel.com.tr

6. FX_SERI_32 KABN SER HABERLEME ve PANO KAYIT KARTI

FX_SERI_32 kart 16 durak ve st sistemlerde hem kumanda panosunda kayt girileri iin hem

de revizyon kutusunda kabin seri haberlemesi iin kullanlmaktadr.

Kabin seri haberleme kart olarak kullanldnda FX_SERI kartnn btn fonksiyonlarn yerine

getirir. lave olarak FX-SERI-32 kart zerinde aadaki giri-klar mevcuttur:

- 16 durak stnde kabin kaytlar iin Y17-Y24 kayt ular

- Digitaller iin 20 sinyali k

- 16 durak stnde kabin gstergeleri iin dijitallerin E segmentinden M4 gray/binary kod k

Kart zerindeki A,B,C, segment klar ve M0-M4 kod klar ARL-300 mensnden

programlanabilmektedir.

FX_SERI_32 kartnda, kartn kullanm amacn ayarlamak iin 2 adet jumper bulunmaktadr.

ENGLISH

Kumanda panosunda kat kaytlar iin kullanldnda, katlar iin gray/binary kod klar

FX_SERI_32 kart zerindeki M0-M4 klarndan alnr.

TRKE

J1 jumperi st pinlere takldnda kart revizyon kutusunda i kaytlar

iin, J1 jumperi alt pinlere takldnda kart kumanda panosunda d

kaytlar iin alacaktr.

Yedek jumper

FX_SERI_32 kart alma tipi seimi

FX_SERI_32 kartnda 31 (aa yn oku) ve 32 (Yukar yn oku) sinyallerinin k gerilimi 100

(+24V) olarak sabitlenmitir.

Haberleme hatas veya haberleme kopukluu durumunda kart zerindeki krmz hata ledi

yanacaktr.

5V yanndaki led kabin iin ise hzl, kat iin ise yava yanar.

ARKEL

31

ARL-300

ARKEL Elektrik Elektronik Ltd. ti.

www.arkel.com.tr

TRKE

ENGLISH

7. ARL-300 ARJ KARTI

ARL-300 SARJ kart sadece hidrolik asansrlerde kullanlmaktadr. Hidrolik sistemlerde elektrik

kesintisi durumunda kabini kata getiren acil indirme sisteminin aklerini (2 x 12V/1.2Ah) arj

etmek zere tasarlanmtr. (Elektrik kesintisinde kumanda kart kontrol beslemesi iin ve gvenlik

devreleri ve acil indirme valf beslemesi iin 24Vdc gerekmektedir.)

ARL-300 SARJ kart normal almada ebekeyi kontrol eder. Aklerin arjn yapar ve T1-T2

terminallerine bal olan s sensrlerinin (pano termostat, motor termistr ve ya termostat)

durumuna bal olarak rle konta zerinden kumanda kart PTC giriine uyar sinyali gnderir.

ARKEL

32

ARL-300

ARKEL Elektrik Elektronik Ltd. ti.

www.arkel.com.tr

8. LEVELED KATTA GSTERGE KARTI

Sayma tipi seimi iin jumper:

Katta ledi

ML1-ML2 saycl ise: ML

M1 veya JF saycl ise: 142

Kata geldikten sonra sesli uyar

iin buzzer

ML1-ML2 saycl: ML1 ve ML2

M1 veya JF saycl: 142

LEVELED kart standart olarak hidrolik asansrlerde kullanlmaktadr. Elektrik kesintisi durumunda

dahi asansrn katnda olup olmad bilgisi KATTA ledi araclyla gsterilir. Ayrca elektrik

kesintisi olduktan sonra (100-1000 kesildiinde) katta bilgisi geldii anda zerindeki buzzer ile bir

sre sesli uyar verir. Katta bilgisinin farkl yerlerde (pano dnda) gsterilebilmesi iin led k

(12V/1W) bulunmaktadr.

LEVELED kartna balanacak mknats alterlerin (SML1-SML2 veya SJF) elektrik kesintisinde

dahi sinyal gnderebilmeleri iin 24V kesildiinde ak zerinden (12V) beslenecek ekilde

balanmas gereklidir. Bu balant iin seyir mknatslarnn ortak ucu REVBA revizyon kartnda

MLO klemensinden alnmaldr.

ARKEL

33

ARL-300

TRKE

Mknats alter girileri:

Ak balants (BAT+) revizyon

kutusu aksnden (12V) alnmaldr.

ENGLISH

L+ ve L- katta lambas k

(12V/1W)

ARKEL Elektrik Elektronik Ltd. ti.

www.arkel.com.tr

9. KBK KLEMENS KARTLARI

KBK-2

ARL-300 kumanda kart ile birlikte kullanlan balant kartdr.

1

TRKE

ENGLISH

XK2

1

2

3

XK3

ARL-300 kart balant soketi (20li fleks kablo ile)

ARL-300 kart balant soketi (20li fleks kablo ile)

31, 32, 02 ve 12 sinyallerinin k belirleme jumperi (KBK-2 rumuzlar ksmnda jumper

ayar anlatlmtr)

KBK-4

ARL-300 kumanda kart ile birlikte kullanlan balant kartdr.

XK1

1

2

ARKEL

ARL-300 kart balant soketi (14l fleks kablo ile)

Geri alma el terminali var/yok jumperi (KBK-4 rumuzlar ksmnda jumper ayar

anlatlmtr)

34

ARL-300

ARKEL Elektrik Elektronik Ltd. ti.

www.arkel.com.tr

KBK-5

ARL-300 kumanda panolarnda emniyet devresi balantlar iin kullanlan balant kartdr.

1

2

Geri alma el terminali balant soketleri

Emniyet devresi ledleri

ENGLISH

1

2

KBK-6

TRKE

ARL-300 kumanda panolarnda revizyon kutusu ierisinde emniyet devresi balantlar iin

kullanlan balant kartdr.

ARKEL

Revizyon el terminali balant soketleri

35

ARL-300

ARKEL Elektrik Elektronik Ltd. ti.

www.arkel.com.tr

ENGLISH

ARL-300 Kumanda Kart zerindeki Ortak Rumuzlar:

L1

L2

L3

N

1

2

LO

LA

K3

K5

K15

10A

120

130

140A

140B

10B

SF1

TRKE

SF2

ML1

ML2

141

142

PT0

PT1

PT2

PT3

KRC

S2A-S2B

S1A-S1B

100

1000

PTC

K19

K16

ebeke Besleme

ebeke Ntr

Kabin Beslemesi Girii

Kabin Lambas Beslemesi

Kap Ama Mknats Rle Kontak Orta

Kap Ama Mknats Rle Kontak A

Kap Kapa Sinyali

Kap A Sinyali

Kap A/Kapa Sinyal Orta

Gvenlik Devresi Ntr Dn

Stop Devresi

Kap Fi Kontak Devresi

Maks. 230Vac

Kap Kilit Devresi

Kap Kilit Devresi (Hidrolik veya AKUS-SD Kurtarcl

Maks. 28Vdc

Sistemlerde Acil Kurtarma Girii)

Kontaktrlerin Ntr k

Kap Kprleme Devresi Girii

(120 devresi)

Sadece VVVF veya hidrolik sistemler iin kap

erken ama veya seviye yenileme istendiinde.

Kap Kprleme Devresi Girii

(140 devresi)

ML1 veya M1

Manyetik alter girileridir. Sinyal balantlar asansrn

sinyali

tahrik tipine gre deiir. ift hzl sistemlerde M1 ve 142

ML2 sinyali

kullanlr. Hidrolik ve VVVF sistemlerde ML1, ML2, 141 ve

141 sinyali

142 kullanlr.

142 sinyali

Programlanabilir Transistor k (M0: Gray/Binary Kod k)

Menden Gray

Programlanabilir Transistor k (M1: Gray/Binary Kod k)

veya Binary kod

Programlanabilir Transistor k (M2: Gray/Binary Kod k)

olarak ayarlanr.

Programlanabilir Transistor k (M3: Gray/Binary Kod k)

Ana Kontaktrlerin Geri besleme Girii. 100 sinyali ana kontaktrlerin normalde

kapal kontaklarndan seri geirilerek bu girie balanmaldr.

Grup Kumanda Haberleme Ular

Kabin Seri Haberleme Ular (FX_SERI kartlar ile)

Kontrol Devreleri Beslemesi (+24Vdc)

Kontrol Devreleri Beslemesi (0V)

Motor Termistr & Pano Termostat & Ya Termostat (Hidrolik) & Fren Direnci

Termostat (VVVF). Sinyal olduu srece

Kap Kapama Limiti

Kap limitlerinin ARL-300 kart tarafndan

Sinyali

kullanlmad kaplarda (monofaze ve trifaze kaplarn

Kap Ama Limiti Sinyali haricindekilerde) bu giriler 100 klemensine

kprlenmelidir.

PR

PRA

XK1

XK2

XK3

ARKEL

Programlanabilir Rle Kontak Orta Menden gong k veya harici emniyet

Programlanabilir Rle Kontak A rlesi olarak programlanr.

KBK-4 kart balant soketi (14l fleks kablo ile)

KBK-2 kart balant soketi (20li fleks kablo ile)

KBK-2 kart balant soketi (20li fleks kablo ile)

36

ARL-300

ARKEL Elektrik Elektronik Ltd. ti.

www.arkel.com.tr

Tahrik Tipine Gre ARL-300 Kart Rle klar:

ift Hzl Asansrler in Rle klar :

V11

VA

VB, VC

VD

RU

11

KU1, KU2, KH Kontaktrleri Besleme Gerilimi

Yukar Yn Kontaktr (KU2)

Yksek Hz Kontaktr (KH)

Aa Yn Kontaktr (KU1)

Dk Hz Kontaktr (KF)

Dk Hz Kontaktr (KF) Besleme Gerilimi

Hidrolik Asansrler in Rle klar :

ARKEL

ENGLISH

Valf Besleme Gerilimi

Yukar Yava Valf

Yukar Hzl Valf

Aa Hzl Valf

Aa Yava Valf

Acil ndirme Valf Beslemesi Orta

Acil ndirme Valf Beslemesi A

ebeke Kontaktr Beslemesi Orta

ebeke Kontaktr Beslemesi A

Yukar Kontaktr

gen Kontaktr

Yldz Kontaktr

Kontaktr Besleme Gerilimi

TRKE

V11

VA

VB

VC

VD

AV1

AV2

RE1

RE2

RU

RD

RS

11

37

ARL-300

ARKEL Elektrik Elektronik Ltd. ti.

www.arkel.com.tr

VVVF Asansrler in Rle klar (*):

Dilili Tahrik

(Asenkron Makine)

V11

VA

VB, VC

VD

AV1

ENGLISH

AV2

RE1

RE2

RU

TRKE

11

Dilisiz Tahrik (Senkron Makine)

Fren atrarak pasif

Motor srerek aktif

kurtarma

kurtarma

VVVF Sinyalleri Besleme VVVF Sinyalleri Besleme

VVVF Sinyalleri

Gerilimi

Gerilimi

Besleme Gerilimi

Yukar Yn Sinyali

Yukar Yn Sinyali

Yukar Yn Sinyali

Yksek Hz Sinyali

Yksek Hz Sinyali

Yksek Hz Sinyali

Aa Yn Sinyali

Aa Yn Sinyali

Aa Yn Sinyali

Dk Hz Sinyali Orta

Otomatik Kurtarma Sinyal

Akl Kurtarma

Orta

Kontaktr Beslemesi

Orta

Dk Hz Sinyali (**)

Otomatik Kurtarma Sinyal

Akl Kurtarma

k

Kontaktr Besleme

Gerilimi

Revizyon Hz Rlesi Orta Revizyon Hz Rlesi Orta ebeke Kontaktr

Beslemesi Orta

Revizyon Hz Rlesi A Revizyon Hz Rlesi A

ebeke Kontaktr

(***)

Beslemesi Gerilimi

Ana Kontaktrler (KPA,

Ana Kontaktrler (KPA,

Ana Kontaktrler (KPA,

KPB)

KPB)

KPB)

Ana Kontaktrlerin (KPA, Ana Kontaktrlerin (KPA,

Ana Kontaktrlerin

KPB) Besleme Gerilimi

KPB) Besleme Gerilimi

(KPA, KPB) Besleme

Gerilimi

* : VVVF sistemler iin asenkron/senkron tahrik tipi ayar ARL-300 mensndeki KURTARMA

TIPI parametresi ile belirlenir.

** : ADrive motor srcs kullanlan dilisiz tahrikli sistemlerde dk hz sinyali yukar ve

aa yn klarndan birer diyotla paralel olarak verilmelidir.

*** : Motor srerek aktif kurtarmal sistemlerde revizyon hz sinyali 869EK terminalinden (KBK-4

kart zerindeki) ektirilecek bir rlenin normalde kapal kontandan verilmelidir.

ARKEL

38

ARL-300

ARKEL Elektrik Elektronik Ltd. ti.

www.arkel.com.tr

501

YAN

DEP

DTS

K20

804

805

VAT

817

818

PI

869EK

Revizyon Anahtar (Revizyon Kutusundan)

Paralel tesisatta

Revizyon Aa Hareket Butonu

Seri tesisatta

Kayt iptal butonu girii

(Buton orta 869 sinyalinden alnmaldr.)

Paralel tesisatta

Revizyon Yukar Hareket Butonu

Yangn hbar Konta

Deprem hbar Konta

Paralel tesisatta

Kap Kapama Butonu

Seri tesisatta

tfaiyeci modu aktif ise kap kapal limiti balants

Paralel tesisatta

Kap Ama Butonu & Kap Skma Konta & Fotosel

Konta

Seri tesisatta

tfaiyeci modu aktif ise kap ak limiti balants

Paralel tesisatta

Ar Yk Konta

Seri tesisatta

tfaiyeci modu aktif ise kabin kasetindeki itfaiyeci anahtar

balants

Paralel tesisatta

Tam Yk Konta

Seri tesisatta

Tahliye dura seilmi ise panik butonu balants

Vatman Anahtar

Alt Zorunlu Kesici Manyetik alter

st Zorunlu Kesici Manyetik alter

VVVF sistemlerde

VVVF cihaz hata sinyali girii

Hidrolik sistemlerde Harici emniyet rlesi var olarak seili ise harici

kontaktrlerin geri besleme sinyali girii

Revizyon Anahtar (Kumanda Kartna)

EK* kullanlmyor ise (Jumper taklr)

EK* kullanlyor ise (Jumper taklmaz)

ekil-1: KBK4 kartnda bulunan 2li jumper balants

EK: Geri Alma El Terminali

ARKEL

39

ARL-300

TRKE

869

500

ENGLISH

KBK-4 Kart zerindeki Rumuzlar:

ARKEL Elektrik Elektronik Ltd. ti.

www.arkel.com.tr

ENGLISH

KBK-2 Kart zerindeki Rumuzlar:

190

Kullanlmaz

A-G2

X1-X16

02

12

31

32

S1A-S1B

S2A-S2B

ARL-300 kart basit kumanda iin 190 d kumanda mtereki k

vermemektedir. Bu amala 12 (megul sinyali) kndan bir rle ektirilmesi ve

rlenin normalde kapal kontandan 190 sinyali verilmesi tavsiye edilir. Ayrca

DURAKTA BEKLEME ve KABIN LAMBASI parametreleri doru ekilde

ayarlanmaldr.

7-Segment Gsterge klar

/ D Kumanda Kayt Girileri

Servis D Lambalar

Megul Lambalar

Aa Yn Oku Lambalar

Yukar Yn Oku Lambalar

Kabin Seri (FX_SERI) Haberleme Ular

Grup Kumanda Haberleme Ular

31, 32, 02 ve 12 sinyal klar 100 ise:

31, 32, 02 ve 12 sinyal klar 1000 ise:

TRKE

ekil-2: KBK2 kartnda bulunan 3li jumper balants

ARKEL

40

ARL-300

ARKEL Elektrik Elektronik Ltd. ti.

www.arkel.com.tr

Revizyon Anahtar (Kumanda Panosu 869 Terminalinden)

Geri Alma Anahtar (Kumanda Kartna)

Geri Alma Butonlar Beslemesi

Geri Alma Aa Hareket Butonu

Geri Alma Yukar Hareket Butonu

XHT1-A

XHT1-B

Geri Alma El Terminali Konnektr (5-pin)

Geri Alma El Terminali Konnektr (5-pin)

110

10

10A

120

130

135

140

Gvenlik Devreleri Beslemesi Faz k (220Vac)

Gvenlik Devreleri Beslemesi Ntr k

Gvenlik Devresi Ntr Dn

Stop Devresi Dn

Kat Kaplar Fi Kontak Dn

Kat Kaplar Kilit Kontak Dn

Kabin Kaps Fi Kontak Dn (Gvenlik Devresi Faz Nihayi Dn)

110-110A

110A-110B

110B-110C

110C-110D

110D-110E

110E-110F

110F-111

Kuyu Dibi Acil Stop Butonu

Kuyu Kapa Konta

Gevek Halat Konta

Hz Reglatr Kasnak Gergi Konta

Yedek (Patlak Hortum Konta)

Yedek (Ar Basn Konta)

Yedek

SS1

SS2

SS3

SS4

SS5

SS6

SS7

(Geri Alma Acil Stop Butonu : SS8 )

112-113

113-114

114-115

115-116

116-118

Hz Reglatr Konta

Kabin Tamponu Konta

Kar Arlk Tamponu Konta

st Limit Kesici Konta

Alt Limit Kesici Konta

120-130

130-135

Kat Kaplar Fi Kontak Devresi

Kat Kaplar Kilit Kontak Devresi

(Tam otomatik kat kaplarnda 130 terminali 135 terminaline kprlenmelidir.)

118

119A

119B

120

135

140

SS9

SS10

SS11

SS12

SS13

Kabin Gvenlik Devresi Terminalleri

(Yass Kablo ile Revizyon Kutusundaki KBK-6 Balant Kartna)

Balantlar iin kumanda panosu emalarnn 5. sayfasna baknz.

ARKEL

41

ARL-300

TRKE

869

869EK

HTE

500

501

ENGLISH

KBK-5 Balant Kart zerindeki Rumuzlar:

ARKEL Elektrik Elektronik Ltd. ti.

www.arkel.com.tr

TRKE

ENGLISH

KBK-6 Balant Kart zerindeki Rumuzlar:

869

500

501

100

Revizyon Anahtar

Revizyon Aa Hareket Butonu

Revizyon Yukar Hareket Butonu

Revizyon Sinyalleri Beslemesi (+24Vdc)

XHT2-A

XHT2-B

Revizyon El Terminali Konnektr (5-pin)