Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

9 viewsISO General Purpose Metric Threads

ISO General Purpose Metric Threads

Uploaded by

huachuliuIt provide basic knowledge of ISO general purpose metric threads

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Asme B1.9-1973 (2017)Document38 pagesAsme B1.9-1973 (2017)vijay pawar100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Handbook Prototyp Threading UsDocument124 pagesHandbook Prototyp Threading UsRobotNo ratings yet

- Hexalobular (6 Lobe) Socket Flat Countersunk Head Screws: Article# d1 d2 Max. K Max. T Max. A LDocument3 pagesHexalobular (6 Lobe) Socket Flat Countersunk Head Screws: Article# d1 d2 Max. K Max. T Max. A LNewschrisNo ratings yet

- Catalog EIGHTDocument55 pagesCatalog EIGHTThăng Phạm ĐìnhNo ratings yet

- AMP Profile RevI-1Document16 pagesAMP Profile RevI-1andhika kharsimaNo ratings yet

- Lexington Platform Bed - Full: Instructions For The SKU# 6222-LX-FDocument2 pagesLexington Platform Bed - Full: Instructions For The SKU# 6222-LX-FMNo ratings yet

- Camworks 2.5-Axis Milling: For Pocketing, Contouring, and DrillingDocument2 pagesCamworks 2.5-Axis Milling: For Pocketing, Contouring, and DrillingAxel DominiqueNo ratings yet

- MONOMATICDocument7 pagesMONOMATICArthur KAZARAUNo ratings yet

- Tolerances - Unless Noted: Notice:: 700 West 21St Street P.O. Box 20 Yankton, South Dakota 57078Document1 pageTolerances - Unless Noted: Notice:: 700 West 21St Street P.O. Box 20 Yankton, South Dakota 57078RubenNo ratings yet

- PRINCIPLES OF MACHINE WORK and ADVANCED MACHINE WORK PDFDocument584 pagesPRINCIPLES OF MACHINE WORK and ADVANCED MACHINE WORK PDFgotti45100% (2)

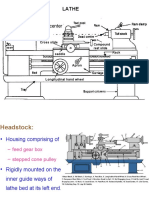

- Basic Machine Tools: Nikunj PatelDocument23 pagesBasic Machine Tools: Nikunj PatelIshan Patel100% (1)

- Cutting Internal Screw ThreadsDocument5 pagesCutting Internal Screw ThreadsAlfred KuwodzaNo ratings yet

- Line Instl-Bleed Air, Fr79-80, Z171 Figure 12A CSN Page 12A - 0 OCT.01/04Document2 pagesLine Instl-Bleed Air, Fr79-80, Z171 Figure 12A CSN Page 12A - 0 OCT.01/04alanNo ratings yet

- Exhibitors in EMMA 2012Document19 pagesExhibitors in EMMA 2012kinner3No ratings yet

- Acme Thread General Purpose - Class 2G: Reference PWM Drawing PC50563, Rev. 5Document1 pageAcme Thread General Purpose - Class 2G: Reference PWM Drawing PC50563, Rev. 5metroroadNo ratings yet

- Miscellaneous PDFDocument18 pagesMiscellaneous PDFFederico GuillenNo ratings yet

- BSP Threaded EN1092 DIN2566 FlangeDocument4 pagesBSP Threaded EN1092 DIN2566 FlangeChowKC03No ratings yet

- Din en Iso 898-99Document32 pagesDin en Iso 898-99Trek PhotosNo ratings yet

- Husky 1025 PCDocument15 pagesHusky 1025 PCeliasgtNo ratings yet

- Metric Fine Thread Profile-1Document7 pagesMetric Fine Thread Profile-1sultanrandhawaNo ratings yet

- Metric Thread Size and Tolerance CalculatorDocument6 pagesMetric Thread Size and Tolerance Calculatorsales100% (1)

- Spec 2012-09 A00Document45 pagesSpec 2012-09 A00DiegoNo ratings yet

- LatheClass1 3dupDocument20 pagesLatheClass1 3dupomkardashetwarNo ratings yet

- Ceiling SpecsDocument2 pagesCeiling SpecsKurt Darryl SabelloNo ratings yet

- Fed-Std-H28-14a-1983+notice 2019Document12 pagesFed-Std-H28-14a-1983+notice 2019Anthony WeaverNo ratings yet

- Catalogul Pieselor de Schimb Spare Parts Catalogue Каталог запчастейDocument89 pagesCatalogul Pieselor de Schimb Spare Parts Catalogue Каталог запчастейС/Х ЗапчастиNo ratings yet

- Threads - and - Threaded - Joints - Mechanical - Engineering - DrawingDocument24 pagesThreads - and - Threaded - Joints - Mechanical - Engineering - DrawingAdiman Abdul JabarNo ratings yet

- Asme B1.8Document42 pagesAsme B1.8jithinjose86No ratings yet

- (Student) T2 PScrewDocument10 pages(Student) T2 PScrewZAMEER AKRAM ABDUL WAHABNo ratings yet

- BN - 3803 Hexalobular Socket Countersunk Flat Head Screws Fully ThreadedDocument2 pagesBN - 3803 Hexalobular Socket Countersunk Flat Head Screws Fully ThreadedMSD ENGRNo ratings yet

ISO General Purpose Metric Threads

ISO General Purpose Metric Threads

Uploaded by

huachuliu0 ratings0% found this document useful (0 votes)

9 views8 pagesIt provide basic knowledge of ISO general purpose metric threads

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentIt provide basic knowledge of ISO general purpose metric threads

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

9 views8 pagesISO General Purpose Metric Threads

ISO General Purpose Metric Threads

Uploaded by

huachuliuIt provide basic knowledge of ISO general purpose metric threads

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 8

Za]

ISO GENERAL PURPOSE METRIC THREADS-COMPONENT

4,0 | Basic major diameter of the workpiece thread feaue ana: wanie

= — Toancos usc ona -#90965/1

21 | asic minor diameter of tho itemal workpiece thread Base DrersoreWreces 18 4218

42, Dz | Basic pitch diameter of the workpiece thread

Basic minor diameter of external thread

Fundamental deviation of the external thread

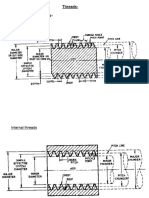

" e —————————— BASIC PROFILE AND DIMENSIONS

1 | Fundamental deviation of the internal thread

‘m | Distance between the middle ot the tolerance e

zones Tp ofthe thread ring gauge and T gp of the re

GO check plug

| Pin

4 | Height ofthe triangle ofthe thread profile Tv

Tep | Tolerance for the pitch diameter of GO and NOT GO

dead check plug, wear heck plugs and ee

seta S|

ERs cect al 6] a

Ta Tolerance for the major diameter of the workpiece

exeral esd 3

0,=D-2x3 H=0-06495p

Td» | Tolerance forthe pitch diameter of the workpiece danas iad -18REp

external thread &

: 0\=D-2x5 =D 10805

TD, | Tolerance for the minor diameter of the workpiece 5

ira head dy =d-2% 5 H=a~ 108289

= H = 0866025 xp

TD | Tolerance forthe pitch diameter ofthe workpiece

internal thread

ToL | Tlome tre pich dame ct CO'and NOT. | ESerrony OF Tol ERANCE WiTH RESPECT

thread pl

read plug gauges - - TO ZERO LINE (BASIC SIZE)

Tr | Tolerance for the pitch diameter of GO and NOT GO

Y (NUT THREAD)

thread ring gauges

0 (BASIC size)

Wao | Average amount available for the permissible wear

of GO thread plug gauge and GO thread ring gauge

5S

a

Wie | Average amount available fr the permissible wear

‘of the NOT GO thread plug gauge and NOT GO

thread ring gauge

ZpL_| Distance between the midcle of the tolerance zone =

Tpt of the GO thread plug gauge and the lower limit

ofthe workpiece thread Yy (BOLT THREAD)

== aol 8

Zn _| Distance between the middle of he tolerance zone

Tp ofthe GO thread ing gauge andthe upper limit ee

of the workpiece thread ei

SEenow ron ETC THREAD GAUGES: 10

BAKE!

DESIGNATION: 11 SHALL CONSIST OF A SIZE DESIGNATION AND

TOLERANCE CLASS DESIGNATION.

SIZE DESIGNATION: Sizz OF A THREAD SHALL BE DESIGNATED

BY THE LETTER M FOLLOWED BY THE DIAMETER AND THE PITCH, THE

‘TWO SEPERATED BY THE SIGN x, WHERE THERE IS NO INDICATION OF

PITCH IT SHALL IMPLY COARSE PITCH. eg: MBxt., M10

TOLERANCE CLASS DESIGNATION:

eg:

CODE LETTER FOR

ISO METRIC THREAD

THREAD SIZE

(MAJOR DIAMETER x PITCH)

TOLERANCE CLASS

FOR PITCH DIAMETER

TOLERANCE CLASS FOR

THE CREST DIAMETER,

-59 69

Mw 20x2 6H

TOLERANCE CLASS FOR PITCH DIAMETER

AND CREST DIAMETER WHEN BOTH

TOLERANCE CLASSES ARE THE SAME

A FIT BETWEEN THREADED PARTS IS INDICATED BY THE NUT THREAD

‘TOLERANCE CLASS FOLLOWED BY THE BOLT THREAD TOLERANCE

CLASS, SEPARATED BY A STROKE. eg: M6- GH/6g. M4 -H/Sg69

forme here p = pitch

fig = +18 + np) Elf es = Fundamental deviations for

By =o rut and boft teas

eg = ~ (50 + Hp) Except tor p< 048 mm eee)

ey = — (18 + tg)

FUNDAMENTAL DEVIATIONS FOR

NUT THREADS AND BOLT THREADS

Fundamental deviation

prc | Nut thread | Bolt thread

A 2.01 ah, ds

a] e 8 h

er | ev | eo | e | e

wm [am | pm | oem | um

o | +7] o Sram

a2 | +a | 0 Zi} o

oa | two =| 6

as | +9 | 0 =e |e

oe | 3] 0 Z| o

as | 320 | 0 »| 0

os | +m} o | -w|-2] 0

o | 3a] 0 | =| -2] 0

a | sz] a | -%|-2/ 0

ov | +2] 0 | -s|]-2] 0

a | 3%] 0 | =| -% | 0

5 +e | 0 | =| -| 0

1 [+2] o | -|-2] 0 |

is | sa | 0 | -@| <2] o

i |sa| io | in| -a| 0

2 +e | 0 7 °

as | ie] o o| 2 | 6

3 +e | oo | 8] -a| 0

as | +s] 0 | -9|-s] 0

* te | o | | -0| 0

as | tes | 0 | -wo| “6 | 0

5 +n} o|-w]-n|]

ss | s%| 0 |-w|-m| 0

6 to] o | in| so] 0

NUT THREADS WITH TOLERANCE POSITION G

1

BOLT THREADS WITH TOLERANCE POSITIONS

me pte

fut

nae reser

Ss

NUT THREADS WITH TOLERANCE POSITION H

eg

"

TOLERANCES FOR NORMAL THREAD ENGAGEMENT

‘RECOMMENDED TOLERANCE CLASSES FOR BOLTS

RECOMMENDED TOLERANCE CLASSES FOR NUTS

OLA |, TaN Leia TOLERANCE TOLERANCE TOLERANCE POSITION | TOLERANCE POSITION

cum | posmion | postion | posmion

i 7 UALTY 6 4

FINE rs Fe #4

eon os (a) & vweoun fs icy

coarse oI CORRE 73 7H

PITCH DIAMETER TOLERANCES FOR BOLT THREADS, (T¢2)

Pitch diameter tolerance for bolt threads for

grade (6) = Tay (6) = 90xp-* X d meant

‘TOLERANCE GRADE

PITCH DIAMETER TOLERANCES FOR NUT THREADS.,(7 2}

Pitch diameter tolerance for nut threads

(Tp,) are obtained from the Td, (6) values

‘according to the following table

Where Tq, is expressed in micrometers.

P = pitch in mm.

a geometrical mean value of the

mean diameter range limits in mm.

DIAMETER RANGE TABLE

BASIC MAJOR DIAMETER ‘a 4 ean

‘OVER UPTO & INCLUDING|

098 14 wa

14 28 1.980

2a 56 3.960

56 a2 7920

2 22a 15.839

224 45 31.749

4 90 3.040

0 180 27279

180 355 252.784

TOLERANCES FOR MAJOR DIAMETER OF BOLT THREAD (Tq)

Tq (6) = 1804p? - 318

“ ve

TOLERANCE GRADE

a 6 3

083 Ty (6) Tg (6) 16 Ta (8)

TOLERANCE GRADE

3 4 5 6

4 5 ‘ 7 8

05 79,16) | 08374, (6) | 0873 (8)| Ts, (6)

085 Ta )] 106. (6)| 13270 16)] 1249 (6) | axes)

7 8 °

125 Tag(6) | 18 Tap (6) 2 Tap (6) TOLERANCES FOR MINOR DIAMETER OF NUT THREAD(Tp,)

2

TOLERANCE GRADE

4 5 6 7 8

08 7p, (6)

1p, (8) | 1257p, (6)| 18 7p, (6)

088 Tp, (6)

FORMULA FOR Tp, TOLERANCE FOR GRADE (5)

a) Pitches 0.2 to 0.8 mm

Tp; (6) = 433 p - 190 p22

») Pitch 1 mm and coarser

Tp, (6) = 230p7

LENGTH OF THREAD ENGAGEMENT

‘The length of thread engagement (length of thread in operation)

is divided into three groups as Short (8), Nermal(N) and Long (t),

Hthe length of head engagement is unknown

(@s inthe manufacture of standard bolts), qroup N is recommended,

For each pitch within a certain dlameter range, ‘o*has

been set equal othe smallest clameter inthis range.

Length of tread engagement N min = 2.24 xp xd°*

Nmax= 670xp xd"

‘Where N.p (pitch, are in mm,

DIMENSIONS OF ISO METRIC THREADS : COMPONENTS

NTE ievsions INTERNAL THREADS EXTERNAL THREADS

‘ARE IN mm, 6H 69

7

homval pron [MARE] PrCHO wmon waiono mono |unono

s 7 ‘MIN: MIN MAX MIN, MAX MAX MIN, MAX ‘MIN MAX

71] eas | 1000] 0806 | oaea | aves | aves | 1000 | osc | osse | aves | 0729

02 | i000 | osm | 20 | ores | omar | 1000 | os | oar | osee | ove

“a 0.25 1.100 0938 0994 0829 0885, 1.100 1.033, 0.938 0.885 0.829

a2 | 1100 | oar | toc | oases | ost | 1100 | 1048 | ogra | ose | oaes

=12 | 025 | 1200 | 1038 | 108 | ose | ges | 1200 | 1103 | 1092 | o9es | ooze

02 | 1200 iio | oes | ost | 1200 | ite | tom | to22 | ses |

“1a | 03 | +400 1205 | 1075 | 1x42 1400 | 1305 | 1205 | 1149 | 107s

02 | +400 1320 | ire | 1201 | 4400 | tae | ta | 1220 | tse

16 | 038 | 1600 rasa] 1221) tsar | tse | 1406 | 1351 | 120 | 1202

a2 | 1600 tse | 1303 | iaea | t60_| 1527 | 1450 | aoa | 1266

te | 02s | 1800 1.658 rset | a7e1| 1896) 1s] tao | 1402

02 | 1800 1786 tess | 1780 | ter | 1850 | te00 | 1500

2 | 04 | 2000 1880 tere | 1961 | ras azar | tes | 1548

: 025 | 2000 92 isco | toe | isi | 1920 | see | azn

22 | 04s | 2200 2003 f iis) 1838 | 2180 | 2080 | 188 | 1817 | 1683

| 02s | 2200 aire | 1900 2oce | are | 2115 | 2020 | ts64 | s911

28 | oas | 2500 2208 | eo | et | 2450 | 2280 | 2160 | en | 1989

oas_| 2500 zase | arr, az | 2as | 2306 | 2ase | aro | 2s0e

3 | 05 | 3000 277s | 2459 | 2508 | 2900 | 2a | 2655 | 2580 | 2409

| 035 | 3000 zaca | 2ect_| arr | 2001 | 2506 | 27sa | cear | 2ove

as [os | asco | ano | a222 | 2050 | 3010 | 347 | aas« | 000 | coos | 2220

oss | ss0o | sem | 3363 | ase | szer| aor | sas | ase | ster | Stoo

@ | 07 | 4000 | ass | asea | aos | oace | asm | aes | asco | asa | azzo

_| 05 | 4000 | sors | 375 | 34a | 3500 | asco | ase | 3655 | 3500 | 3430

as | 07s | 4500} «ora | aia | e688 | save | aa7e | aaze | aoc) coor | aes

05 | 4500 | ais | az | 399 | so | asco | aaa | as | 4030 | 00

5 | 08 | 5000 | 4480 | 260s | atze | ace | agr6 | ages | ase | as | «110

as | sooo | sav | a7 | 4450 | 500 | asc | 4am | cess | ase0 |

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Asme B1.9-1973 (2017)Document38 pagesAsme B1.9-1973 (2017)vijay pawar100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Handbook Prototyp Threading UsDocument124 pagesHandbook Prototyp Threading UsRobotNo ratings yet

- Hexalobular (6 Lobe) Socket Flat Countersunk Head Screws: Article# d1 d2 Max. K Max. T Max. A LDocument3 pagesHexalobular (6 Lobe) Socket Flat Countersunk Head Screws: Article# d1 d2 Max. K Max. T Max. A LNewschrisNo ratings yet

- Catalog EIGHTDocument55 pagesCatalog EIGHTThăng Phạm ĐìnhNo ratings yet

- AMP Profile RevI-1Document16 pagesAMP Profile RevI-1andhika kharsimaNo ratings yet

- Lexington Platform Bed - Full: Instructions For The SKU# 6222-LX-FDocument2 pagesLexington Platform Bed - Full: Instructions For The SKU# 6222-LX-FMNo ratings yet

- Camworks 2.5-Axis Milling: For Pocketing, Contouring, and DrillingDocument2 pagesCamworks 2.5-Axis Milling: For Pocketing, Contouring, and DrillingAxel DominiqueNo ratings yet

- MONOMATICDocument7 pagesMONOMATICArthur KAZARAUNo ratings yet

- Tolerances - Unless Noted: Notice:: 700 West 21St Street P.O. Box 20 Yankton, South Dakota 57078Document1 pageTolerances - Unless Noted: Notice:: 700 West 21St Street P.O. Box 20 Yankton, South Dakota 57078RubenNo ratings yet

- PRINCIPLES OF MACHINE WORK and ADVANCED MACHINE WORK PDFDocument584 pagesPRINCIPLES OF MACHINE WORK and ADVANCED MACHINE WORK PDFgotti45100% (2)

- Basic Machine Tools: Nikunj PatelDocument23 pagesBasic Machine Tools: Nikunj PatelIshan Patel100% (1)

- Cutting Internal Screw ThreadsDocument5 pagesCutting Internal Screw ThreadsAlfred KuwodzaNo ratings yet

- Line Instl-Bleed Air, Fr79-80, Z171 Figure 12A CSN Page 12A - 0 OCT.01/04Document2 pagesLine Instl-Bleed Air, Fr79-80, Z171 Figure 12A CSN Page 12A - 0 OCT.01/04alanNo ratings yet

- Exhibitors in EMMA 2012Document19 pagesExhibitors in EMMA 2012kinner3No ratings yet

- Acme Thread General Purpose - Class 2G: Reference PWM Drawing PC50563, Rev. 5Document1 pageAcme Thread General Purpose - Class 2G: Reference PWM Drawing PC50563, Rev. 5metroroadNo ratings yet

- Miscellaneous PDFDocument18 pagesMiscellaneous PDFFederico GuillenNo ratings yet

- BSP Threaded EN1092 DIN2566 FlangeDocument4 pagesBSP Threaded EN1092 DIN2566 FlangeChowKC03No ratings yet

- Din en Iso 898-99Document32 pagesDin en Iso 898-99Trek PhotosNo ratings yet

- Husky 1025 PCDocument15 pagesHusky 1025 PCeliasgtNo ratings yet

- Metric Fine Thread Profile-1Document7 pagesMetric Fine Thread Profile-1sultanrandhawaNo ratings yet

- Metric Thread Size and Tolerance CalculatorDocument6 pagesMetric Thread Size and Tolerance Calculatorsales100% (1)

- Spec 2012-09 A00Document45 pagesSpec 2012-09 A00DiegoNo ratings yet

- LatheClass1 3dupDocument20 pagesLatheClass1 3dupomkardashetwarNo ratings yet

- Ceiling SpecsDocument2 pagesCeiling SpecsKurt Darryl SabelloNo ratings yet

- Fed-Std-H28-14a-1983+notice 2019Document12 pagesFed-Std-H28-14a-1983+notice 2019Anthony WeaverNo ratings yet

- Catalogul Pieselor de Schimb Spare Parts Catalogue Каталог запчастейDocument89 pagesCatalogul Pieselor de Schimb Spare Parts Catalogue Каталог запчастейС/Х ЗапчастиNo ratings yet

- Threads - and - Threaded - Joints - Mechanical - Engineering - DrawingDocument24 pagesThreads - and - Threaded - Joints - Mechanical - Engineering - DrawingAdiman Abdul JabarNo ratings yet

- Asme B1.8Document42 pagesAsme B1.8jithinjose86No ratings yet

- (Student) T2 PScrewDocument10 pages(Student) T2 PScrewZAMEER AKRAM ABDUL WAHABNo ratings yet

- BN - 3803 Hexalobular Socket Countersunk Flat Head Screws Fully ThreadedDocument2 pagesBN - 3803 Hexalobular Socket Countersunk Flat Head Screws Fully ThreadedMSD ENGRNo ratings yet