Professional Documents

Culture Documents

Ahu Bsria Final Report

Ahu Bsria Final Report

Uploaded by

razali131266Copyright:

Available Formats

You might also like

- BG49 Commissioning Air SystemsDocument83 pagesBG49 Commissioning Air SystemsFinlay100% (2)

- BG11 2010 Commissioning Job BookDocument97 pagesBG11 2010 Commissioning Job BookFinlay0% (1)

- BG 71 2017 Building Services ReportsDocument37 pagesBG 71 2017 Building Services ReportsFinlayNo ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- BSRIA 18th Nov MM Animated Build Background Hidden (003) JSSDocument45 pagesBSRIA 18th Nov MM Animated Build Background Hidden (003) JSSMohamed Imran100% (1)

- Heating and Ventilating Contractors' AssociationDocument4 pagesHeating and Ventilating Contractors' Associationsshoeburrahman0% (2)

- Bsria-Blue-Book-2019 (Sample) PDFDocument24 pagesBsria-Blue-Book-2019 (Sample) PDFFUCKU0% (1)

- Typical Medical Equip Heat GainDocument1 pageTypical Medical Equip Heat GainMostafa AlaahobaNo ratings yet

- TN19 2001 (AirDocument15 pagesTN19 2001 (AirmichaelmangaaNo ratings yet

- Commissioning Job Book - A Framework For Managing The Commissioning Process - SampleDocument12 pagesCommissioning Job Book - A Framework For Managing The Commissioning Process - SampleibrahimsirpiNo ratings yet

- DG251 14 Electrical ServicesDocument3 pagesDG251 14 Electrical Servicesnirmalb21No ratings yet

- Pre-Commission Cleaning of Pipework Systems (Superseded) - SampleDocument9 pagesPre-Commission Cleaning of Pipework Systems (Superseded) - Samplesiva8784No ratings yet

- CP13 - 1999 MV and AC in BuildingDocument56 pagesCP13 - 1999 MV and AC in Buildingbozow bozowlNo ratings yet

- CTV PRC007M en - 09152015Document40 pagesCTV PRC007M en - 09152015razali131266100% (1)

- ASHRAE-191 Public Draft ReviewDocument33 pagesASHRAE-191 Public Draft ReviewMustafa MogriNo ratings yet

- Technical Guide: Understanding The Principles of Dpcvs & Picvs in Dynamic BalancingDocument76 pagesTechnical Guide: Understanding The Principles of Dpcvs & Picvs in Dynamic BalancingSalaheddine Zantout100% (1)

- Electric Duct HeatersDocument13 pagesElectric Duct HeatersKhizerNo ratings yet

- Saudi Arabia Ahu World Market For Air Conditioning 2014 (Sample)Document36 pagesSaudi Arabia Ahu World Market For Air Conditioning 2014 (Sample)nadarasanNo ratings yet

- Belimo Smoke ControlDocument35 pagesBelimo Smoke ControlNenad Mutavdzic100% (1)

- Axial AXBDocument20 pagesAxial AXBhoseyliauNo ratings yet

- Commissioning Process For Buildings and SystemsDocument51 pagesCommissioning Process For Buildings and Systemsanmella100% (1)

- BSRIA Unsterstand Acoustic Performance DataDocument28 pagesBSRIA Unsterstand Acoustic Performance DataMick Parson100% (2)

- Water Treatment For Closed Heating and Cooling Systems: A Bsria GuideDocument22 pagesWater Treatment For Closed Heating and Cooling Systems: A Bsria GuidecarrspaintsNo ratings yet

- Operating and Maintenance Manuals - Solution - EdocumentsDocument3 pagesOperating and Maintenance Manuals - Solution - EdocumentsneluNo ratings yet

- Moisture Load CalculationDocument2 pagesMoisture Load CalculationNguyễn Anh TuấnNo ratings yet

- Ashrae ChartDocument1 pageAshrae ChartSMBEAUTYNo ratings yet

- BESA TR 40 - Technical Report 40 A Guide To Good Practice For Local Exhaust VentilationDocument64 pagesBESA TR 40 - Technical Report 40 A Guide To Good Practice For Local Exhaust VentilationSophie-Louise Mercedes100% (1)

- Im j1 Personnel Cooling Load Estimation 2014Document40 pagesIm j1 Personnel Cooling Load Estimation 2014Melvin SanchezNo ratings yet

- Air BalancingDocument4 pagesAir BalancingMohammed Javid HassanNo ratings yet

- ASHRAE PD On Environmental Tobacco SmokeDocument15 pagesASHRAE PD On Environmental Tobacco Smokepal_stephen100% (1)

- CIBSE Commissioning Code B 2002 BoilersDocument39 pagesCIBSE Commissioning Code B 2002 BoilersPeter Gardner0% (1)

- 1 Air System Balancing 2023 0823Document27 pages1 Air System Balancing 2023 082319020674sNo ratings yet

- FCUs Vs VRFDocument37 pagesFCUs Vs VRFMario B. Dalu100% (1)

- CIBSE CHW DebateDocument48 pagesCIBSE CHW Debateamith_km100% (1)

- BSRIA 2007 - Controls For End UsersDocument28 pagesBSRIA 2007 - Controls For End UsersRuiNo ratings yet

- Ashrae Qatar Presentation - 23 March 19Document97 pagesAshrae Qatar Presentation - 23 March 19Jose Luis Alvarez GonzalvesNo ratings yet

- DDC Controls Part 1 Pnwd-Sa-8834Document92 pagesDDC Controls Part 1 Pnwd-Sa-8834185412No ratings yet

- 2014 1984 Chart and CodesDocument2 pages2014 1984 Chart and Codesnubaz0% (1)

- AHRI Standard 551-591 SI 2015 Add1 Oct 17 PDFDocument127 pagesAHRI Standard 551-591 SI 2015 Add1 Oct 17 PDFNitesh SinghNo ratings yet

- MVAC SpecificationDocument185 pagesMVAC Specificationhdung0375% (4)

- Commissioning Training Manual TemplateDocument12 pagesCommissioning Training Manual TemplateHuseyin Sengul100% (1)

- VRF VS Chiller: Technical ManagerDocument38 pagesVRF VS Chiller: Technical ManagerJhon Lewis Pino100% (2)

- VAV Fundamentals ASHRAEDocument24 pagesVAV Fundamentals ASHRAEheartbreakkid132No ratings yet

- ASHRAE-Guideline 5-2001 Smoke ManagementDocument15 pagesASHRAE-Guideline 5-2001 Smoke ManagementKhesraw KhawarNo ratings yet

- VAV System Air BalancingDocument3 pagesVAV System Air BalancingShoukat Ali ShaikhNo ratings yet

- Ashrae Green Guide PDFDocument16 pagesAshrae Green Guide PDFsriwahyunimarzukiNo ratings yet

- Cibse TM30Document38 pagesCibse TM30DanZel DanNo ratings yet

- ANSI-ASHRAE Addendum To ASHRAE-34 - 2019 - C - 20191118Document8 pagesANSI-ASHRAE Addendum To ASHRAE-34 - 2019 - C - 20191118Sergio Motta GarciaNo ratings yet

- BSRIA A-Z ListDocument14 pagesBSRIA A-Z ListJOSEPH APPIAHNo ratings yet

- Consultant Queries - Chilled Water PumpDocument6 pagesConsultant Queries - Chilled Water PumpMohammad Abdul KhadeerNo ratings yet

- Article - The Good Ventilation of Switchgear and Transformer Rooms 18dec2015 PDFDocument8 pagesArticle - The Good Ventilation of Switchgear and Transformer Rooms 18dec2015 PDFphilipyongNo ratings yet

- 2023 Training ProgrammeDocument11 pages2023 Training ProgrammeFernando CabreraNo ratings yet

- NEBBinar ASHRAE 202 PDFDocument42 pagesNEBBinar ASHRAE 202 PDFGustavo ChavesNo ratings yet

- Drain Pipe Work of Indoor UnitDocument24 pagesDrain Pipe Work of Indoor UnitMiguel AbuegNo ratings yet

- All About AHUsDocument24 pagesAll About AHUsrahulNo ratings yet

- Computer Based Operating and Maintenance Manuals Options and Procurement Guidance Withdrawn (Sample)Document7 pagesComputer Based Operating and Maintenance Manuals Options and Procurement Guidance Withdrawn (Sample)STEVEN DELAHUNTY100% (1)

- Refrigeration & Air Conditioning Lab (Mey-303) Experiment No. 3 Aim: To Evaluate The Performance of Domestic Air ConditionerDocument9 pagesRefrigeration & Air Conditioning Lab (Mey-303) Experiment No. 3 Aim: To Evaluate The Performance of Domestic Air ConditionerIshwarjit SinghNo ratings yet

- An Investigation of Air Conditioning System Diagnosis: January 2020Document11 pagesAn Investigation of Air Conditioning System Diagnosis: January 2020mrrizauNo ratings yet

- 1.1test MethodologyDocument14 pages1.1test MethodologyjvfcvNo ratings yet

- Is 13687 1993Document15 pagesIs 13687 1993ADIPESHNo ratings yet

- Installation and Operating InstructionsDocument12 pagesInstallation and Operating Instructionsrazali131266No ratings yet

- Hvac Factsheet Cleaning Coils 09 13Document3 pagesHvac Factsheet Cleaning Coils 09 13razali131266No ratings yet

- CRV 2.0 2007ym-2012ymDocument1 pageCRV 2.0 2007ym-2012ymrazali131266No ratings yet

- Energy Auditor Checklist A. Building Envelope: Does This Problem Exist? Recomme Nded N/ADocument24 pagesEnergy Auditor Checklist A. Building Envelope: Does This Problem Exist? Recomme Nded N/Arazali131266No ratings yet

- CTV PRC007M en - 09152015Document40 pagesCTV PRC007M en - 09152015razali131266100% (1)

- Industrial - Pricing & Tariff - Tenaga Nasional BerhadDocument3 pagesIndustrial - Pricing & Tariff - Tenaga Nasional Berhadrazali131266No ratings yet

- 50 - Indust Water Pumping PDFDocument62 pages50 - Indust Water Pumping PDFrazali131266No ratings yet

- CLCH-PRC022-En - 092013 - Performance Air Handler CatalogDocument216 pagesCLCH-PRC022-En - 092013 - Performance Air Handler Catalograzali131266No ratings yet

- EEMs To Consider 2011-09-15Document12 pagesEEMs To Consider 2011-09-15razali131266No ratings yet

- Esco Final 29april2013Document2 pagesEsco Final 29april2013razali131266No ratings yet

- Survey of The Green Energy Industry 2011Document15 pagesSurvey of The Green Energy Industry 2011razali131266No ratings yet

- How To Select The Right Replacement or Retrofit Coil For Your ApplicationDocument8 pagesHow To Select The Right Replacement or Retrofit Coil For Your Applicationrazali131266No ratings yet

- Pump EE by ThermodynamicsDocument21 pagesPump EE by Thermodynamicsrazali131266No ratings yet

Ahu Bsria Final Report

Ahu Bsria Final Report

Uploaded by

razali131266Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ahu Bsria Final Report

Ahu Bsria Final Report

Uploaded by

razali131266Copyright:

Available Formats

Air handling unit

performance tests

Final Report 53830/1

Carried out for

Air Handlers Northern Ltd

By Calum Maclean

15 November 2010

Air handling unit

performance tests

Carried out for:

Air Handlers Northern Ltd

Bute Street

Weaste

Salford

Lancashire

M50 1DU

Contract:

Final Report 53830/1

Date:

15 November 2010

Issued by:

BSRIA Limited

Old Bracknell Lane West,

Bracknell,

Berkshire RG12 7AH UK

Telephone: +44 (0)1344 465600

Fax:

+44 (0)1344 465626

E: bsria@bsria.co.uk W: www.bsria.co.uk

Compiled by:

Approved by:

Name: Calum Maclean

Name: Greg King BSc MSc M.InstR

Title:

Title:

Senior Research Engineer

Group Manager

MicroClimate & Test

This report must not be reproduced except in full without the written approval of an executive director of BSRIA. It is only

intended to be used within the context described in the text.

BSRIA

Page 3 of 11

Final Report 53830/1

AIR HANDLING UNIT PERFORMANCE TESTS

CONTENTS

CONTENTS

1

INTRODUCTION........................................................................................................................... 5

INSTRUMENTATION.................................................................................................................... 5

2.1

2.2

2.3

2.4

Temperature and humidity ..................................................................................................5

Air flowrates ........................................................................................................................5

Electrical and thermal loads ...............................................................................................5

Calibration...........................................................................................................................5

UNIT DESCRIPTION .................................................................................................................... 6

TEST PROCEDURE ..................................................................................................................... 6

4.1

4.2

Test setup ...........................................................................................................................6

Test conditions....................................................................................................................7

TEST RESULTS ........................................................................................................................... 8

OBSERVATIONS AND CONCLUSIONS.................................................................................... 11

TABLES

Table 1

Table 2

Table 3

Table 4

Table 5

Table 6

Table 7

Target test conditions ............................................................................................................. 7

Test 1 Cooling 1 .................................................................................................................. 8

Test 2 Cooling 2 .................................................................................................................. 8

Test 3 Heating 1 .................................................................................................................. 9

Test 4 Heating 2 .................................................................................................................. 9

Test 5 Heating 3 ................................................................................................................ 10

Test 6 Heating 4 ................................................................................................................ 10

FIGURES

Figure 1 Test setup ............................................................................................................................... 6

BSRIA

Page 4 of 11

Final Report 53830/1

AIR HANDLING UNIT PERFORMANCE TESTS

INTRODUCTION

INTRODUCTION

BSRIA was contacted by Air Handlers Northern Ltd to test an air handling unit (AHU). The unit

consisted of a combined air supply and extract system. The tests were conducted during March and

April 2010. A range of tests was conducted for a range of outside air conditions including summer,

winter and mid-season.

The tests were conducted to determine the capacity and the energy used by the unit during the range of

conditions tested.

The construction of the test facility, the instrumentation used, the data collected, analysis and the

derived conclusions are presented in this report.

INSTRUMENTATION

2.1

TEMPERATURE AND HUMIDITY

Two types of sensors were used to measure temperature during the test, platinum resistance

thermometers (PRTs) and combined Vaisala temperature and relative humidity (RH) sensors.

2.2

AIR FLOWRATES

Before the testing took place, pressure drop against flow rate curves were taken for the supply and

extract coils within the unit. The pressure drop and flowrate were measured using a Wilson flowgrid,

fitted to the extract side of the AHU, and a set of micro-manometers. The airflow rates were recorded

during the testing by measuring the pressure drop across the coils.

2.3

ELECTRICAL AND THERMAL LOADS

Power consumption measurements were conducted on the AHUs using two Yokogawa power meters

during the tests. One Yokogawa power meter was measuring the total power into the AHU and the

second Yokogawa was measuring the compressor power only.

2.4

CALIBRATION

All equipment significant to measurements is regularly serviced and maintained according to the

manufacturers instruction and is regularly calibrated in accordance with the BSRIA quality

requirements.

BSRIA

Page 5 of 11

Final Report 53830/1

AIR HANDLING UNIT PERFORMANCE TESTS

UNIT DESCRIPTION

UNIT DESCRIPTION

The AHU comprised of a single unit with:

1.

2.

3.

4.

5.

6.

Air supply section

Air extract section

Compressor and corresponding coil system

Thermal wheel for energy recovery

Inverter driven fans

Control system

The air supplied to the building is conditioned using a combination of a thermal wheel and a coil

supplied from a compressor to provide cooling or heating as required. The compressor capacity was

variable over the range of 10% to 100% in both cooling and heating modes.

The thermal wheel is switched off during the cooling tests via the units control system.

TEST PROCEDURE

4.1

TEST SETUP

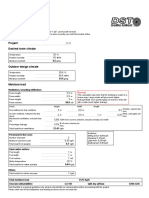

The test setup is shown in Figure 1 below:

Figure 1 Test setup

The black Xs show the placement of the humidity and temperature probes and consist of four probes

each. The pressure drop across the supply and extract coils was measured during the testing to allow a

measure of the air volume flowrate. The air volume flowrate against pressure drop curves for the two

coils were recorded prior to the tests by use of a Wilson flow grid.

Combined %RH and temperature probe placements:

A.

B.

C.

D.

Outside air supply

Air onto supply coil temperature

Air off supply coil and air to building

Air return from building

BSRIA

Page 6 of 11

Final Report 53830/1

AIR HANDLING UNIT PERFORMANCE TESTS

TEST PROCEDURE

The tests were conducted at the settings requested by the client, to simulate a range of conditions

including summer, winter and mid season.

The test data was recorded at 1 minute intervals and averaged over the test period when completed.

The air was supplied to the AHU at the required condition by use of a range of equipment depending

on the condition required. The supply conditions were held constant throughout the test period.

4.2

TEST CONDITIONS

Test description

Air on temperature

Air supply to

building

temperature

Air return from

building

temperature

Airflow volume

Target test conditions

Test number

Table 1

Units

m3.s-1

Cooling 1

24.5

20.0

26.0

1.0

Cooling 2

30.0

20.0

26.0

1.0

Heating 1

1.0

20.0

20.0

1.0

Heating 2

4.0

20.0

20.0

1.0

Heating 3

8.0

20.0

20.0

1.0

Heating 4

0.0

26.0

20.0

0.8

BSRIA

Page 7 of 11

Final Report 53830/1

AIR HANDLING UNIT PERFORMANCE TESTS

5

Table 2

TEST RESULTS

Test 1 Cooling 1

Date of test

Start time of test

Length of test

HP Low (gauge)

HP High (gauge)

LP Low (gauge)

LP High (gauge)

Compressor percentage

Power to compressor

Compressor power high

Compressor power low

Fresh air temp

Air onto coil temp

Air off coil temp

Air return temp

29-Apr-10

14:48:30

30.0

12.9

14.0

5.2

7.0

36.0

1.20

2.72

0.48

24.5

24.2

20.2

26.2

Minutes

Bar

Bar

Bar

Bar

%

kW

kW

kW

C

C

C

C

Air supply volume

1.00

ms-1

Air extract volume

Cooling over coil

Cooling over supply unit

Supply fan setting

Extract fan setting

0.97

4.91

5.3

32.6

32.5

ms-1

kW

kW

Hz

Hz

Table 3

Test 2 Cooling 2

Date of test

Start time of test

Length of test

HP Low (gauge)

HP High (gauge)

LP Low (gauge)

LP High (gauge)

Compressor percentage

Power to compressor

Compressor power high

Compressor power low

Fresh air temp

29-Apr-10

16:26:30

30.0

17.6

17.6

5.3

5.3

100.0

3.00

3.05

1.58

30.2

Minutes

Bar

Bar

Bar

Bar

%

kW

kW

kW

C

Air onto coil temp

Air off coil temp

Air return temp

30.1

20.0

26.3

C

C

C

Air supply volume

0.99

ms-1

Air extract volume

Cooling over coil

Cooling over supply unit

Supply fan setting

Extract fan setting

1.03

12.27

12.4

32.7

32.6

ms-1

kW

kW

Hz

Hz

BSRIA

TEST RESULTS

Page 8 of 11

Final Report 53830/1

AIR HANDLING UNIT PERFORMANCE TESTS

Table 4

Test 3 Heating 1

Date of test

Start time of test

Length of test

HP Low (gauge)

HP High (gauge)

LP Low (gauge)

LP High (gauge)

Compressor percentage

Power to compressor

Compressor power high

Compressor power low

Fresh air temp

Air onto coil temp

Air off coil temp

Air return temp

30-Apr-10

9:50:00

30.0

10.1

12.0

3.6

4.3

55.0

1.33

2.23

0.46

0.8

15.1

20.0

20.4

Minutes

Bar

Bar

Bar

Bar

%

kW

kW

kW

C

C

C

C

Air supply volume

1.03

ms-1

Air extract volume

Heating over coil

Heating over supply unit

Supply fan setting

Extract fan setting

0.99

6.18

24.3

32.7

32.6

ms-1

kW

kW

Hz

Hz

Table 5

Test 4 Heating 2

Date of test

Start time of test

Length of test

HP Low (gauge)

HP High (gauge)

LP Low (gauge)

LP High (gauge)

Compressor percentage

Power to compressor

Compressor power high

Compressor power low

30-Apr-10

11:02:30

30.0

10.0

11.8

3.9

4.7

43.0

1.14

2.21

0.48

Minutes

Bar

Bar

Bar

Bar

%

kW

kW

kW

Fresh air temp

Air onto coil temp

Air off coil temp

Air return temp

3.5

16.1

20.0

20.4

C

C

C

C

Air supply volume

1.02

ms-1

Air extract volume

Heating over coil

Heating over supply unit

Supply fan setting

Extract fan setting

1.01

4.93

20.7

32.7

32.6

ms-1

kW

kW

Hz

Hz

BSRIA

TEST RESULTS

Page 9 of 11

Final Report 53830/1

AIR HANDLING UNIT PERFORMANCE TESTS

Table 6

Test 5 Heating 3

Date of test

30-Apr-10

Start time of test

Length of test

HP Low (gauge)

HP High (gauge)

LP Low (gauge)

LP High (gauge)

Compressor percentage

Power to compressor

Compressor power high

Compressor power low

Fresh air temp

Air onto coil temp

Air off coil temp

Air return temp

12:40:00

30.0

9.8

11.4

4.4

5.3

30.0

0.93

2.21

0.48

8.2

17.3

20.0

19.9

Minutes

Bar

Bar

Bar

Bar

%

kW

kW

kW

C

C

C

C

Air supply volume

0.99

ms-1

Air extract volume

Heating over coil

Heating over supply unit

Supply fan setting

Extract fan setting

1.03

3.34

14.5

32.7

32.6

ms-1

kW

kW

Hz

Hz

Table 7

Test 6 Heating 4

Date of test

Start time of test

Length of test

HP Low (gauge)

HP High (gauge)

LP Low (gauge)

LP High (gauge)

Compressor percentage

Power to compressor

Compressor power high

30-Apr-10

15:23:00

30.0

13.8

13.8

2.9

2.9

100.0

2.43

2.46

Compressor power low

Fresh air temp

Air onto coil temp

Air off coil temp

Air return temp

2.41

-0.3

15.0

25.6

20.7

kW

C

C

C

C

Air supply volume

0.81

ms-1

Air extract volume

Heating over coil

Heating over supply unit

Supply fan setting

Extract fan setting

0.77

10.63

25.9

27.4

27.9

ms-1

kW

kW

Hz

Hz

BSRIA

TEST RESULTS

Minutes

Bar

Bar

Bar

Bar

%

kW

kW

Page 10 of 11

Final Report 53830/1

AIR HANDLING UNIT PERFORMANCE TESTS

OBSERVATIONS AND CONCLUSIONS

OBSERVATIONS AND CONCLUSIONS

A range of tests were completed on the air handling unit at the requested conditions of the client to

simulate summer, mid season and winter conditions.

Tests 1 to 5 show that the unit was able to provide the conditioned air at the requested temperature, of

20C, from an ambient temperature of between 1C and 30C at a volume flowrate of 1.0 m3.s-1.

During the heating tests the thermal wheel was on for heat recovery from the extract air from the

simulated building. The thermal wheel was inactive during the two cooling tests.

Test 6 shows that the unit can provide 0.8 m3.s-1 of conditioned air at 26C to a building at a fresh air

inlet temperature of 0C. The test was conducted to check the winter heating capacity at maximum

compressor duty.

BSRIA

Page 11 of 11

Final Report 53830/1

You might also like

- BG49 Commissioning Air SystemsDocument83 pagesBG49 Commissioning Air SystemsFinlay100% (2)

- BG11 2010 Commissioning Job BookDocument97 pagesBG11 2010 Commissioning Job BookFinlay0% (1)

- BG 71 2017 Building Services ReportsDocument37 pagesBG 71 2017 Building Services ReportsFinlayNo ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- BSRIA 18th Nov MM Animated Build Background Hidden (003) JSSDocument45 pagesBSRIA 18th Nov MM Animated Build Background Hidden (003) JSSMohamed Imran100% (1)

- Heating and Ventilating Contractors' AssociationDocument4 pagesHeating and Ventilating Contractors' Associationsshoeburrahman0% (2)

- Bsria-Blue-Book-2019 (Sample) PDFDocument24 pagesBsria-Blue-Book-2019 (Sample) PDFFUCKU0% (1)

- Typical Medical Equip Heat GainDocument1 pageTypical Medical Equip Heat GainMostafa AlaahobaNo ratings yet

- TN19 2001 (AirDocument15 pagesTN19 2001 (AirmichaelmangaaNo ratings yet

- Commissioning Job Book - A Framework For Managing The Commissioning Process - SampleDocument12 pagesCommissioning Job Book - A Framework For Managing The Commissioning Process - SampleibrahimsirpiNo ratings yet

- DG251 14 Electrical ServicesDocument3 pagesDG251 14 Electrical Servicesnirmalb21No ratings yet

- Pre-Commission Cleaning of Pipework Systems (Superseded) - SampleDocument9 pagesPre-Commission Cleaning of Pipework Systems (Superseded) - Samplesiva8784No ratings yet

- CP13 - 1999 MV and AC in BuildingDocument56 pagesCP13 - 1999 MV and AC in Buildingbozow bozowlNo ratings yet

- CTV PRC007M en - 09152015Document40 pagesCTV PRC007M en - 09152015razali131266100% (1)

- ASHRAE-191 Public Draft ReviewDocument33 pagesASHRAE-191 Public Draft ReviewMustafa MogriNo ratings yet

- Technical Guide: Understanding The Principles of Dpcvs & Picvs in Dynamic BalancingDocument76 pagesTechnical Guide: Understanding The Principles of Dpcvs & Picvs in Dynamic BalancingSalaheddine Zantout100% (1)

- Electric Duct HeatersDocument13 pagesElectric Duct HeatersKhizerNo ratings yet

- Saudi Arabia Ahu World Market For Air Conditioning 2014 (Sample)Document36 pagesSaudi Arabia Ahu World Market For Air Conditioning 2014 (Sample)nadarasanNo ratings yet

- Belimo Smoke ControlDocument35 pagesBelimo Smoke ControlNenad Mutavdzic100% (1)

- Axial AXBDocument20 pagesAxial AXBhoseyliauNo ratings yet

- Commissioning Process For Buildings and SystemsDocument51 pagesCommissioning Process For Buildings and Systemsanmella100% (1)

- BSRIA Unsterstand Acoustic Performance DataDocument28 pagesBSRIA Unsterstand Acoustic Performance DataMick Parson100% (2)

- Water Treatment For Closed Heating and Cooling Systems: A Bsria GuideDocument22 pagesWater Treatment For Closed Heating and Cooling Systems: A Bsria GuidecarrspaintsNo ratings yet

- Operating and Maintenance Manuals - Solution - EdocumentsDocument3 pagesOperating and Maintenance Manuals - Solution - EdocumentsneluNo ratings yet

- Moisture Load CalculationDocument2 pagesMoisture Load CalculationNguyễn Anh TuấnNo ratings yet

- Ashrae ChartDocument1 pageAshrae ChartSMBEAUTYNo ratings yet

- BESA TR 40 - Technical Report 40 A Guide To Good Practice For Local Exhaust VentilationDocument64 pagesBESA TR 40 - Technical Report 40 A Guide To Good Practice For Local Exhaust VentilationSophie-Louise Mercedes100% (1)

- Im j1 Personnel Cooling Load Estimation 2014Document40 pagesIm j1 Personnel Cooling Load Estimation 2014Melvin SanchezNo ratings yet

- Air BalancingDocument4 pagesAir BalancingMohammed Javid HassanNo ratings yet

- ASHRAE PD On Environmental Tobacco SmokeDocument15 pagesASHRAE PD On Environmental Tobacco Smokepal_stephen100% (1)

- CIBSE Commissioning Code B 2002 BoilersDocument39 pagesCIBSE Commissioning Code B 2002 BoilersPeter Gardner0% (1)

- 1 Air System Balancing 2023 0823Document27 pages1 Air System Balancing 2023 082319020674sNo ratings yet

- FCUs Vs VRFDocument37 pagesFCUs Vs VRFMario B. Dalu100% (1)

- CIBSE CHW DebateDocument48 pagesCIBSE CHW Debateamith_km100% (1)

- BSRIA 2007 - Controls For End UsersDocument28 pagesBSRIA 2007 - Controls For End UsersRuiNo ratings yet

- Ashrae Qatar Presentation - 23 March 19Document97 pagesAshrae Qatar Presentation - 23 March 19Jose Luis Alvarez GonzalvesNo ratings yet

- DDC Controls Part 1 Pnwd-Sa-8834Document92 pagesDDC Controls Part 1 Pnwd-Sa-8834185412No ratings yet

- 2014 1984 Chart and CodesDocument2 pages2014 1984 Chart and Codesnubaz0% (1)

- AHRI Standard 551-591 SI 2015 Add1 Oct 17 PDFDocument127 pagesAHRI Standard 551-591 SI 2015 Add1 Oct 17 PDFNitesh SinghNo ratings yet

- MVAC SpecificationDocument185 pagesMVAC Specificationhdung0375% (4)

- Commissioning Training Manual TemplateDocument12 pagesCommissioning Training Manual TemplateHuseyin Sengul100% (1)

- VRF VS Chiller: Technical ManagerDocument38 pagesVRF VS Chiller: Technical ManagerJhon Lewis Pino100% (2)

- VAV Fundamentals ASHRAEDocument24 pagesVAV Fundamentals ASHRAEheartbreakkid132No ratings yet

- ASHRAE-Guideline 5-2001 Smoke ManagementDocument15 pagesASHRAE-Guideline 5-2001 Smoke ManagementKhesraw KhawarNo ratings yet

- VAV System Air BalancingDocument3 pagesVAV System Air BalancingShoukat Ali ShaikhNo ratings yet

- Ashrae Green Guide PDFDocument16 pagesAshrae Green Guide PDFsriwahyunimarzukiNo ratings yet

- Cibse TM30Document38 pagesCibse TM30DanZel DanNo ratings yet

- ANSI-ASHRAE Addendum To ASHRAE-34 - 2019 - C - 20191118Document8 pagesANSI-ASHRAE Addendum To ASHRAE-34 - 2019 - C - 20191118Sergio Motta GarciaNo ratings yet

- BSRIA A-Z ListDocument14 pagesBSRIA A-Z ListJOSEPH APPIAHNo ratings yet

- Consultant Queries - Chilled Water PumpDocument6 pagesConsultant Queries - Chilled Water PumpMohammad Abdul KhadeerNo ratings yet

- Article - The Good Ventilation of Switchgear and Transformer Rooms 18dec2015 PDFDocument8 pagesArticle - The Good Ventilation of Switchgear and Transformer Rooms 18dec2015 PDFphilipyongNo ratings yet

- 2023 Training ProgrammeDocument11 pages2023 Training ProgrammeFernando CabreraNo ratings yet

- NEBBinar ASHRAE 202 PDFDocument42 pagesNEBBinar ASHRAE 202 PDFGustavo ChavesNo ratings yet

- Drain Pipe Work of Indoor UnitDocument24 pagesDrain Pipe Work of Indoor UnitMiguel AbuegNo ratings yet

- All About AHUsDocument24 pagesAll About AHUsrahulNo ratings yet

- Computer Based Operating and Maintenance Manuals Options and Procurement Guidance Withdrawn (Sample)Document7 pagesComputer Based Operating and Maintenance Manuals Options and Procurement Guidance Withdrawn (Sample)STEVEN DELAHUNTY100% (1)

- Refrigeration & Air Conditioning Lab (Mey-303) Experiment No. 3 Aim: To Evaluate The Performance of Domestic Air ConditionerDocument9 pagesRefrigeration & Air Conditioning Lab (Mey-303) Experiment No. 3 Aim: To Evaluate The Performance of Domestic Air ConditionerIshwarjit SinghNo ratings yet

- An Investigation of Air Conditioning System Diagnosis: January 2020Document11 pagesAn Investigation of Air Conditioning System Diagnosis: January 2020mrrizauNo ratings yet

- 1.1test MethodologyDocument14 pages1.1test MethodologyjvfcvNo ratings yet

- Is 13687 1993Document15 pagesIs 13687 1993ADIPESHNo ratings yet

- Installation and Operating InstructionsDocument12 pagesInstallation and Operating Instructionsrazali131266No ratings yet

- Hvac Factsheet Cleaning Coils 09 13Document3 pagesHvac Factsheet Cleaning Coils 09 13razali131266No ratings yet

- CRV 2.0 2007ym-2012ymDocument1 pageCRV 2.0 2007ym-2012ymrazali131266No ratings yet

- Energy Auditor Checklist A. Building Envelope: Does This Problem Exist? Recomme Nded N/ADocument24 pagesEnergy Auditor Checklist A. Building Envelope: Does This Problem Exist? Recomme Nded N/Arazali131266No ratings yet

- CTV PRC007M en - 09152015Document40 pagesCTV PRC007M en - 09152015razali131266100% (1)

- Industrial - Pricing & Tariff - Tenaga Nasional BerhadDocument3 pagesIndustrial - Pricing & Tariff - Tenaga Nasional Berhadrazali131266No ratings yet

- 50 - Indust Water Pumping PDFDocument62 pages50 - Indust Water Pumping PDFrazali131266No ratings yet

- CLCH-PRC022-En - 092013 - Performance Air Handler CatalogDocument216 pagesCLCH-PRC022-En - 092013 - Performance Air Handler Catalograzali131266No ratings yet

- EEMs To Consider 2011-09-15Document12 pagesEEMs To Consider 2011-09-15razali131266No ratings yet

- Esco Final 29april2013Document2 pagesEsco Final 29april2013razali131266No ratings yet

- Survey of The Green Energy Industry 2011Document15 pagesSurvey of The Green Energy Industry 2011razali131266No ratings yet

- How To Select The Right Replacement or Retrofit Coil For Your ApplicationDocument8 pagesHow To Select The Right Replacement or Retrofit Coil For Your Applicationrazali131266No ratings yet

- Pump EE by ThermodynamicsDocument21 pagesPump EE by Thermodynamicsrazali131266No ratings yet