Professional Documents

Culture Documents

Weld Neck Flange Design

Weld Neck Flange Design

Uploaded by

Kamlesh LuharCopyright:

Available Formats

You might also like

- Common Law TrustDocument17 pagesCommon Law TrustTrey Sells97% (71)

- CES Wrong Answer Summary 1e18da38 A505 48c1 b100 8cddd2b264e7Document4 pagesCES Wrong Answer Summary 1e18da38 A505 48c1 b100 8cddd2b264e7Sridharan Narasingan75% (4)

- Module 1 (Database Management in Construction)Document42 pagesModule 1 (Database Management in Construction)MARTHIE JASELLYN LOPENANo ratings yet

- Padeye Design CheekDocument1 pagePadeye Design CheekPawan ShettyNo ratings yet

- Saddle Calc PD5500Document6 pagesSaddle Calc PD5500Vamsi SNo ratings yet

- Data Industri JabodetabekDocument669 pagesData Industri JabodetabekBudy Nugraha88% (25)

- FL Violation Point and Statute ReferenceDocument27 pagesFL Violation Point and Statute ReferenceJenniferRaePittsNo ratings yet

- Anchor Flange CalcDocument4 pagesAnchor Flange CalcPriyam KmNo ratings yet

- Branch Calculation Table: XXX XXXDocument4 pagesBranch Calculation Table: XXX XXXmaz100% (1)

- Buckling Check: Material DataDocument28 pagesBuckling Check: Material Datading liuNo ratings yet

- Body Flange .PVDB FlangeDocument1 pageBody Flange .PVDB FlangeAnonymous aBg51lbe18No ratings yet

- Calcs 4Document19 pagesCalcs 4Syariful Maliki NejstaršíNo ratings yet

- Torispherical Cone With KnuckleDocument2 pagesTorispherical Cone With KnuckleSajal KulshresthaNo ratings yet

- Pipeline Virtual Anchor Length Calculations: VariablesDocument3 pagesPipeline Virtual Anchor Length Calculations: Variablesromvos8469No ratings yet

- Flange DesignDocument6 pagesFlange DesignAKSHAY BHATKARNo ratings yet

- Local Buckling Analysis Based On DNV-OS-F101 2000Document4 pagesLocal Buckling Analysis Based On DNV-OS-F101 2000shervinyNo ratings yet

- Anchor FlangeDocument8 pagesAnchor FlangeHanda Bin AdiNo ratings yet

- Simple Pipeline Sizing - Rev JMVDocument42 pagesSimple Pipeline Sizing - Rev JMVJMVNo ratings yet

- Barabanki Stability AnalysisDocument2 pagesBarabanki Stability AnalysisAnonymous sfkedkymNo ratings yet

- Spreaer Beam&Lifting Line Beam p3Document2 pagesSpreaer Beam&Lifting Line Beam p3Sabrang LorNo ratings yet

- Combined Load TowerDocument21 pagesCombined Load TowerHusin SaputraNo ratings yet

- Attachment - 1 Document No. 081113B-CL-303-R0 Permissible Elastic Bend Limit Calculation (48in Hassyan Gas Pipeline Location Class 4)Document4 pagesAttachment - 1 Document No. 081113B-CL-303-R0 Permissible Elastic Bend Limit Calculation (48in Hassyan Gas Pipeline Location Class 4)ISRAEL PORTILLONo ratings yet

- Trunnion Calcualtion SheetDocument22 pagesTrunnion Calcualtion SheetAbhijit50% (2)

- Synechron: Customer Name Date Created byDocument1 pageSynechron: Customer Name Date Created byneelNo ratings yet

- Trunnion 6 TonDocument3 pagesTrunnion 6 TonEngr Khurram Jaan RamayNo ratings yet

- A Spreadsheet Program For The Calculation of Piping Systems and The Selection of Pumps PDFDocument12 pagesA Spreadsheet Program For The Calculation of Piping Systems and The Selection of Pumps PDFtebo8teboNo ratings yet

- News Letter For Expansion Bellow PDFDocument4 pagesNews Letter For Expansion Bellow PDFAsma Khan100% (1)

- Input:: Note de Calcul Calculation NoteDocument4 pagesInput:: Note de Calcul Calculation NotekardujorgeNo ratings yet

- Skirt Support TrialDocument11 pagesSkirt Support TrialAbhishek Nag50% (2)

- Wid Stiffener Welding CalculationDocument2 pagesWid Stiffener Welding CalculationrichardchiamNo ratings yet

- Blind Plate or Manhole Cover DesignDocument2 pagesBlind Plate or Manhole Cover DesignHarish Kumar MahavarNo ratings yet

- Burst DiscDocument6 pagesBurst DiscMa AlNo ratings yet

- Beams On Elastic FoundationsDocument3 pagesBeams On Elastic FoundationsIgnatius SamrajNo ratings yet

- Tubesheet Calculation: Step 1Document2 pagesTubesheet Calculation: Step 1Bintang LazuardiNo ratings yet

- Earth Pressure CalcDocument3 pagesEarth Pressure Calcsuman_civilNo ratings yet

- CP Design OD (In) OD (MM) Length Area (m2)Document1 pageCP Design OD (In) OD (MM) Length Area (m2)mtuanlatoi9704No ratings yet

- Chapter 11 - Section DesignDocument8 pagesChapter 11 - Section DesignDavid SinambelaNo ratings yet

- 도로교 설계기준 (2010) PDFDocument593 pages도로교 설계기준 (2010) PDFpooh7039No ratings yet

- Surge ForceDocument2 pagesSurge ForceJ A S JASNo ratings yet

- API 650 RF Pad Calculation PDFDocument1 pageAPI 650 RF Pad Calculation PDFBimal DeyNo ratings yet

- WTG FDN Design Steps1Document9 pagesWTG FDN Design Steps1Ramachandran Sundararaman100% (1)

- Design of Buried Pipeline Block AnchorDocument2 pagesDesign of Buried Pipeline Block Anchoragung_gpeNo ratings yet

- Mathcad - Case-1 (40 Od) InstallDocument4 pagesMathcad - Case-1 (40 Od) InstallAdvisNo ratings yet

- C17058 XXXXXXXX FPSO Carioca MV30: Lthe Offshore Engineering Nozzle Evaluation SheetDocument3 pagesC17058 XXXXXXXX FPSO Carioca MV30: Lthe Offshore Engineering Nozzle Evaluation SheetJ A S JAS100% (1)

- Skid Calculation Sheet: Reference: Pressure Vessel Handbook, Eugene F. Megyesy MaterialDocument8 pagesSkid Calculation Sheet: Reference: Pressure Vessel Handbook, Eugene F. Megyesy MaterialAzharyanto FadhliNo ratings yet

- Weight Calculation For SR Forging: Vessel Tag No. V-102A G Shell Thickness 62 MMDocument6 pagesWeight Calculation For SR Forging: Vessel Tag No. V-102A G Shell Thickness 62 MMduazo2009No ratings yet

- Astm D3294 PtefDocument6 pagesAstm D3294 PtefIsabella RomeroNo ratings yet

- Spreaer Beam&Lifting Line Beam p5Document2 pagesSpreaer Beam&Lifting Line Beam p5Sabrang LorNo ratings yet

- Weld Capacity of Eccentric Connection Based On AISC 360-05: The Connection Design Is AdequateDocument9 pagesWeld Capacity of Eccentric Connection Based On AISC 360-05: The Connection Design Is Adequatechristian abogadoNo ratings yet

- API 650 Pipe Column DesignDocument4 pagesAPI 650 Pipe Column DesignJoselito CalagosNo ratings yet

- Design-Calculations For Pipelines (Onshore)Document19 pagesDesign-Calculations For Pipelines (Onshore)George100% (1)

- Unit weight (γ), angle of friction (ø) and allowable bearing pressure for different soil typesDocument5 pagesUnit weight (γ), angle of friction (ø) and allowable bearing pressure for different soil typesSuraj PantNo ratings yet

- Pipe Line CalculationDocument14 pagesPipe Line Calculationsamirbendre1No ratings yet

- Calculo de Brida Segun ASMEDocument29 pagesCalculo de Brida Segun ASMEakarcz6731No ratings yet

- PE Liner Pulling Force Calculations - ADSDocument1 pagePE Liner Pulling Force Calculations - ADSbcsmurthyNo ratings yet

- Mathcad - Sandy SoilDocument1 pageMathcad - Sandy SoillsatchithananthanNo ratings yet

- PVElite RefDocument6 pagesPVElite RefakhilNo ratings yet

- PV Elite ResultDocument239 pagesPV Elite ResultChaitanya Sai TNo ratings yet

- Offcom Completa - v.01Document7 pagesOffcom Completa - v.01Argonauta_navegadorNo ratings yet

- ANZ-DS-E-5016 HV Surge DiverterDocument17 pagesANZ-DS-E-5016 HV Surge Divertermika cabelloNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolssierroNo ratings yet

- Structural Calculation of Protection SlabDocument2 pagesStructural Calculation of Protection Slabjoe pilarizaNo ratings yet

- BlindDocument3 pagesBlindSajal KulshresthaNo ratings yet

- Sample8 DrawingDocument1 pageSample8 DrawingRam Kumar NNo ratings yet

- Sluice Valve ChampersDocument34 pagesSluice Valve ChampersWessam NourNo ratings yet

- Flange Calculation ASMEVIII-Custom WNRF (Alternate Check)Document11 pagesFlange Calculation ASMEVIII-Custom WNRF (Alternate Check)Kashif Kazi100% (1)

- Nozzle Design - Codeware-Compress FAQsDocument9 pagesNozzle Design - Codeware-Compress FAQsKashif KaziNo ratings yet

- UT of Pressure Vessel Construction WeldsDocument30 pagesUT of Pressure Vessel Construction WeldsKashif KaziNo ratings yet

- Spence SRVsDocument132 pagesSpence SRVsKashif KaziNo ratings yet

- T109 Maxiprofile KlingerDocument5 pagesT109 Maxiprofile KlingerKashif KaziNo ratings yet

- VocabulariesDocument1 pageVocabulariesKashif KaziNo ratings yet

- Inf Luence of Tip Clearance On The Flow Field and Aerodynamic Performance of The Centrif Ugal ImpellerDocument6 pagesInf Luence of Tip Clearance On The Flow Field and Aerodynamic Performance of The Centrif Ugal Impellerarm coreNo ratings yet

- BGT-FS1 Metal Wind Speed Sensor ManualDocument3 pagesBGT-FS1 Metal Wind Speed Sensor ManualJojoNo ratings yet

- RXDC - My RayDocument2 pagesRXDC - My RayMedical DXBNo ratings yet

- Topic F BenlacDocument5 pagesTopic F BenlacJho MalditahNo ratings yet

- Jurnal Hubungan Dukungan Keluarga Terhadap Kualitas Hidup Pasien StrokeDocument5 pagesJurnal Hubungan Dukungan Keluarga Terhadap Kualitas Hidup Pasien StrokeNadia UlfaNo ratings yet

- FX2N-16DNET Devicenet User ManualDocument126 pagesFX2N-16DNET Devicenet User ManualNguyen QuanNo ratings yet

- Annexure - Common Loan Application Form With Formats I, II and III-EnglishDocument12 pagesAnnexure - Common Loan Application Form With Formats I, II and III-EnglishPratyush DasNo ratings yet

- Shock 2022 SeminarDocument17 pagesShock 2022 Seminarrosie100% (2)

- Oracle Assignment 1Document14 pagesOracle Assignment 1Yogesh Kulkarni100% (1)

- Scott Cooley Lyric and Chord Songbook Volume OneDocument272 pagesScott Cooley Lyric and Chord Songbook Volume OneScott CooleyNo ratings yet

- Textbook Biscuit Cookie and Cracker Production Process Production and Packaging Equipment Second Edition Iain Davidson Ebook All Chapter PDFDocument54 pagesTextbook Biscuit Cookie and Cracker Production Process Production and Packaging Equipment Second Edition Iain Davidson Ebook All Chapter PDFmartin.hughes511100% (21)

- Priyanka - 50300 16 130Document4 pagesPriyanka - 50300 16 130Aravind GopaganiNo ratings yet

- Guarantee LetterDocument1 pageGuarantee LetterWizcarmelo ParcellanoNo ratings yet

- Special Continuous Probability DistributionsDocument11 pagesSpecial Continuous Probability DistributionsnofacejackNo ratings yet

- Governing KwuDocument21 pagesGoverning KwuVishal Kumar Laddha100% (4)

- Illegal Gold Mines in The PhilippinesDocument2 pagesIllegal Gold Mines in The PhilippinesMaricar RamirezNo ratings yet

- Pokemon Resolute Version Full Walkthrough PDFDocument3 pagesPokemon Resolute Version Full Walkthrough PDFsildora cedrik markNo ratings yet

- 230/33Kv Bole Lemi Substation Calculation Note - Protection Relay Setting - 230Kv Bus Bar & Bus CouplerDocument29 pages230/33Kv Bole Lemi Substation Calculation Note - Protection Relay Setting - 230Kv Bus Bar & Bus CouplerDebebe TsedekeNo ratings yet

- BDA PresentationsDocument26 pagesBDA PresentationsTejaswiniNo ratings yet

- Circuits Virtual LabDocument2 pagesCircuits Virtual LabPaula GómezNo ratings yet

- Comprehensive Plan For Lee CountyDocument9 pagesComprehensive Plan For Lee County3798chuckNo ratings yet

- Print DigestsDocument42 pagesPrint DigestsMirellaNo ratings yet

- Caption Text Tgas Bhs InggrisDocument6 pagesCaption Text Tgas Bhs InggrisPangbaterek PekaryaNo ratings yet

- Lesson 13 Changes That Cause Harmful and Useful To The EnvironmentDocument29 pagesLesson 13 Changes That Cause Harmful and Useful To The EnvironmentEmily Conde100% (3)

Weld Neck Flange Design

Weld Neck Flange Design

Uploaded by

Kamlesh LuharCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Weld Neck Flange Design

Weld Neck Flange Design

Uploaded by

Kamlesh LuharCopyright:

Available Formats

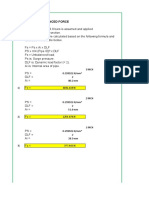

WELD NECK FLANGE DESIGN RAISED FACE

Design Conditions

Design Pressure psi

Design Temperature F

Pipe Wall Thk

Gasket and Bolting Calculations

1000

150

0.5

Pipe OD

Bolt Circle

X

A

Outside Diameter of Flange

Bolting

23.1

Nominal Pipe

0.125

0.25

0.375

0.5

0.75

1

1.25

1.5

2

2.5

3

3.5

4

5

6

8

Pipe OD

0.405

0.54

0.675

0.84

1.05

1.315

1.66

1.9

2.375

2.875

3.5

4

4.5

5.563

6.625

8.625

563469.352729717

10

10.75

549438.71

12

12.75

14

14

16

16

404489.0610 Am

1.5000 G = outside diameter of contact face - 2 x b, in

Ab

22600 Hp

202244.53

23300 H

25000 W m1

Design Temp Sb

Atm Temp

347194.17

0.5000

10000.0000

2.5000

21.9775

21.0253

W gasket seating

W m1 operating load

549438.71

Gasket

Width

Check

(Raised Face ONLY); Nm = AbSa / (2 * y * PI * G)

25000

Sa

Load

0.4372

Lever Arm

Moment

HD

176714.59

hD

3.2500

MD

574322.4071

18

18

HG = H p

202244.53

hG

1.3624

MG

275532.3736

20

20

170479.59

hT

2.8687

MT

HT

Gasket Seating

2.2500

2.1250

y from UA-49.1

m from UA-49.1

Condition

Operating

3.0000

0.6124

15.0000

R

go

Corrosion Allowance

0

bo from Table UA-49.2 1(a) or 1(b)

Design Temp Sfo

Flange

Atm Temp Sfa

Allowable Stress

N=

b=

B=

g1

Facing Details

19.5

27

16

6.5

3

20

1.155

600

Hub Diameter Beginning at Chamfer

Length Through the Hub

Thickness of Flange

Number of Bolts

Area at Root of (1) Bolt

Flange Rating

Flange Material

Bolting Material

Gasket Details

Hg = W

Allowable Stress

1.5 * Sfo

33900 SH

563469.352729717

hg

1.3624

Stress CalculationOperating Conditions (Use M)

489052.4451

24

24

Mo

1338907.2257

30

30

Mo

767655.114518318

Shape Constants

19061.4668

K=A/B

1.8000

h / ho

1.1867

12867.6554

1.5843

0.6300

Sfo

22600 SR

22600 ST

10099.4086

1.8929

0.0400

Sfo

22600

15964.5611

3.4742

1.6000

3.8177

1.5 * Sfa

10928.7875

Sfa

34950 SH

23300 SR

U

g1 / go

f

e = F / ho

ho = B * go

2.7386

Sfa

23300 ST

5790.4405

Sfa

23300

9153.1936

Sfo

3.141592654

From Table UA-49.1 and UA-49.2

16

23.75

OD Large End of Hub

PI

Stress CalculationGasket Seating (Use M)

7377.5997

4.5000

d = U / V * ho * go * go

Other Stress Formula Factors

t of flange assumed or actual

1.6901

1.9202

1.0668

0.4132

1.4800

Means from UA-51.2

Means from UA-51.3

0.2300

Means from UA-51.6

65.3457

0.347826087

M

M

89260.4817

51177.0076

Gasket Dimensions

Inner Diameter

Sealing Element

of Outer Diameter of

Sealing Element

16.25

22.25

You might also like

- Common Law TrustDocument17 pagesCommon Law TrustTrey Sells97% (71)

- CES Wrong Answer Summary 1e18da38 A505 48c1 b100 8cddd2b264e7Document4 pagesCES Wrong Answer Summary 1e18da38 A505 48c1 b100 8cddd2b264e7Sridharan Narasingan75% (4)

- Module 1 (Database Management in Construction)Document42 pagesModule 1 (Database Management in Construction)MARTHIE JASELLYN LOPENANo ratings yet

- Padeye Design CheekDocument1 pagePadeye Design CheekPawan ShettyNo ratings yet

- Saddle Calc PD5500Document6 pagesSaddle Calc PD5500Vamsi SNo ratings yet

- Data Industri JabodetabekDocument669 pagesData Industri JabodetabekBudy Nugraha88% (25)

- FL Violation Point and Statute ReferenceDocument27 pagesFL Violation Point and Statute ReferenceJenniferRaePittsNo ratings yet

- Anchor Flange CalcDocument4 pagesAnchor Flange CalcPriyam KmNo ratings yet

- Branch Calculation Table: XXX XXXDocument4 pagesBranch Calculation Table: XXX XXXmaz100% (1)

- Buckling Check: Material DataDocument28 pagesBuckling Check: Material Datading liuNo ratings yet

- Body Flange .PVDB FlangeDocument1 pageBody Flange .PVDB FlangeAnonymous aBg51lbe18No ratings yet

- Calcs 4Document19 pagesCalcs 4Syariful Maliki NejstaršíNo ratings yet

- Torispherical Cone With KnuckleDocument2 pagesTorispherical Cone With KnuckleSajal KulshresthaNo ratings yet

- Pipeline Virtual Anchor Length Calculations: VariablesDocument3 pagesPipeline Virtual Anchor Length Calculations: Variablesromvos8469No ratings yet

- Flange DesignDocument6 pagesFlange DesignAKSHAY BHATKARNo ratings yet

- Local Buckling Analysis Based On DNV-OS-F101 2000Document4 pagesLocal Buckling Analysis Based On DNV-OS-F101 2000shervinyNo ratings yet

- Anchor FlangeDocument8 pagesAnchor FlangeHanda Bin AdiNo ratings yet

- Simple Pipeline Sizing - Rev JMVDocument42 pagesSimple Pipeline Sizing - Rev JMVJMVNo ratings yet

- Barabanki Stability AnalysisDocument2 pagesBarabanki Stability AnalysisAnonymous sfkedkymNo ratings yet

- Spreaer Beam&Lifting Line Beam p3Document2 pagesSpreaer Beam&Lifting Line Beam p3Sabrang LorNo ratings yet

- Combined Load TowerDocument21 pagesCombined Load TowerHusin SaputraNo ratings yet

- Attachment - 1 Document No. 081113B-CL-303-R0 Permissible Elastic Bend Limit Calculation (48in Hassyan Gas Pipeline Location Class 4)Document4 pagesAttachment - 1 Document No. 081113B-CL-303-R0 Permissible Elastic Bend Limit Calculation (48in Hassyan Gas Pipeline Location Class 4)ISRAEL PORTILLONo ratings yet

- Trunnion Calcualtion SheetDocument22 pagesTrunnion Calcualtion SheetAbhijit50% (2)

- Synechron: Customer Name Date Created byDocument1 pageSynechron: Customer Name Date Created byneelNo ratings yet

- Trunnion 6 TonDocument3 pagesTrunnion 6 TonEngr Khurram Jaan RamayNo ratings yet

- A Spreadsheet Program For The Calculation of Piping Systems and The Selection of Pumps PDFDocument12 pagesA Spreadsheet Program For The Calculation of Piping Systems and The Selection of Pumps PDFtebo8teboNo ratings yet

- News Letter For Expansion Bellow PDFDocument4 pagesNews Letter For Expansion Bellow PDFAsma Khan100% (1)

- Input:: Note de Calcul Calculation NoteDocument4 pagesInput:: Note de Calcul Calculation NotekardujorgeNo ratings yet

- Skirt Support TrialDocument11 pagesSkirt Support TrialAbhishek Nag50% (2)

- Wid Stiffener Welding CalculationDocument2 pagesWid Stiffener Welding CalculationrichardchiamNo ratings yet

- Blind Plate or Manhole Cover DesignDocument2 pagesBlind Plate or Manhole Cover DesignHarish Kumar MahavarNo ratings yet

- Burst DiscDocument6 pagesBurst DiscMa AlNo ratings yet

- Beams On Elastic FoundationsDocument3 pagesBeams On Elastic FoundationsIgnatius SamrajNo ratings yet

- Tubesheet Calculation: Step 1Document2 pagesTubesheet Calculation: Step 1Bintang LazuardiNo ratings yet

- Earth Pressure CalcDocument3 pagesEarth Pressure Calcsuman_civilNo ratings yet

- CP Design OD (In) OD (MM) Length Area (m2)Document1 pageCP Design OD (In) OD (MM) Length Area (m2)mtuanlatoi9704No ratings yet

- Chapter 11 - Section DesignDocument8 pagesChapter 11 - Section DesignDavid SinambelaNo ratings yet

- 도로교 설계기준 (2010) PDFDocument593 pages도로교 설계기준 (2010) PDFpooh7039No ratings yet

- Surge ForceDocument2 pagesSurge ForceJ A S JASNo ratings yet

- API 650 RF Pad Calculation PDFDocument1 pageAPI 650 RF Pad Calculation PDFBimal DeyNo ratings yet

- WTG FDN Design Steps1Document9 pagesWTG FDN Design Steps1Ramachandran Sundararaman100% (1)

- Design of Buried Pipeline Block AnchorDocument2 pagesDesign of Buried Pipeline Block Anchoragung_gpeNo ratings yet

- Mathcad - Case-1 (40 Od) InstallDocument4 pagesMathcad - Case-1 (40 Od) InstallAdvisNo ratings yet

- C17058 XXXXXXXX FPSO Carioca MV30: Lthe Offshore Engineering Nozzle Evaluation SheetDocument3 pagesC17058 XXXXXXXX FPSO Carioca MV30: Lthe Offshore Engineering Nozzle Evaluation SheetJ A S JAS100% (1)

- Skid Calculation Sheet: Reference: Pressure Vessel Handbook, Eugene F. Megyesy MaterialDocument8 pagesSkid Calculation Sheet: Reference: Pressure Vessel Handbook, Eugene F. Megyesy MaterialAzharyanto FadhliNo ratings yet

- Weight Calculation For SR Forging: Vessel Tag No. V-102A G Shell Thickness 62 MMDocument6 pagesWeight Calculation For SR Forging: Vessel Tag No. V-102A G Shell Thickness 62 MMduazo2009No ratings yet

- Astm D3294 PtefDocument6 pagesAstm D3294 PtefIsabella RomeroNo ratings yet

- Spreaer Beam&Lifting Line Beam p5Document2 pagesSpreaer Beam&Lifting Line Beam p5Sabrang LorNo ratings yet

- Weld Capacity of Eccentric Connection Based On AISC 360-05: The Connection Design Is AdequateDocument9 pagesWeld Capacity of Eccentric Connection Based On AISC 360-05: The Connection Design Is Adequatechristian abogadoNo ratings yet

- API 650 Pipe Column DesignDocument4 pagesAPI 650 Pipe Column DesignJoselito CalagosNo ratings yet

- Design-Calculations For Pipelines (Onshore)Document19 pagesDesign-Calculations For Pipelines (Onshore)George100% (1)

- Unit weight (γ), angle of friction (ø) and allowable bearing pressure for different soil typesDocument5 pagesUnit weight (γ), angle of friction (ø) and allowable bearing pressure for different soil typesSuraj PantNo ratings yet

- Pipe Line CalculationDocument14 pagesPipe Line Calculationsamirbendre1No ratings yet

- Calculo de Brida Segun ASMEDocument29 pagesCalculo de Brida Segun ASMEakarcz6731No ratings yet

- PE Liner Pulling Force Calculations - ADSDocument1 pagePE Liner Pulling Force Calculations - ADSbcsmurthyNo ratings yet

- Mathcad - Sandy SoilDocument1 pageMathcad - Sandy SoillsatchithananthanNo ratings yet

- PVElite RefDocument6 pagesPVElite RefakhilNo ratings yet

- PV Elite ResultDocument239 pagesPV Elite ResultChaitanya Sai TNo ratings yet

- Offcom Completa - v.01Document7 pagesOffcom Completa - v.01Argonauta_navegadorNo ratings yet

- ANZ-DS-E-5016 HV Surge DiverterDocument17 pagesANZ-DS-E-5016 HV Surge Divertermika cabelloNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolssierroNo ratings yet

- Structural Calculation of Protection SlabDocument2 pagesStructural Calculation of Protection Slabjoe pilarizaNo ratings yet

- BlindDocument3 pagesBlindSajal KulshresthaNo ratings yet

- Sample8 DrawingDocument1 pageSample8 DrawingRam Kumar NNo ratings yet

- Sluice Valve ChampersDocument34 pagesSluice Valve ChampersWessam NourNo ratings yet

- Flange Calculation ASMEVIII-Custom WNRF (Alternate Check)Document11 pagesFlange Calculation ASMEVIII-Custom WNRF (Alternate Check)Kashif Kazi100% (1)

- Nozzle Design - Codeware-Compress FAQsDocument9 pagesNozzle Design - Codeware-Compress FAQsKashif KaziNo ratings yet

- UT of Pressure Vessel Construction WeldsDocument30 pagesUT of Pressure Vessel Construction WeldsKashif KaziNo ratings yet

- Spence SRVsDocument132 pagesSpence SRVsKashif KaziNo ratings yet

- T109 Maxiprofile KlingerDocument5 pagesT109 Maxiprofile KlingerKashif KaziNo ratings yet

- VocabulariesDocument1 pageVocabulariesKashif KaziNo ratings yet

- Inf Luence of Tip Clearance On The Flow Field and Aerodynamic Performance of The Centrif Ugal ImpellerDocument6 pagesInf Luence of Tip Clearance On The Flow Field and Aerodynamic Performance of The Centrif Ugal Impellerarm coreNo ratings yet

- BGT-FS1 Metal Wind Speed Sensor ManualDocument3 pagesBGT-FS1 Metal Wind Speed Sensor ManualJojoNo ratings yet

- RXDC - My RayDocument2 pagesRXDC - My RayMedical DXBNo ratings yet

- Topic F BenlacDocument5 pagesTopic F BenlacJho MalditahNo ratings yet

- Jurnal Hubungan Dukungan Keluarga Terhadap Kualitas Hidup Pasien StrokeDocument5 pagesJurnal Hubungan Dukungan Keluarga Terhadap Kualitas Hidup Pasien StrokeNadia UlfaNo ratings yet

- FX2N-16DNET Devicenet User ManualDocument126 pagesFX2N-16DNET Devicenet User ManualNguyen QuanNo ratings yet

- Annexure - Common Loan Application Form With Formats I, II and III-EnglishDocument12 pagesAnnexure - Common Loan Application Form With Formats I, II and III-EnglishPratyush DasNo ratings yet

- Shock 2022 SeminarDocument17 pagesShock 2022 Seminarrosie100% (2)

- Oracle Assignment 1Document14 pagesOracle Assignment 1Yogesh Kulkarni100% (1)

- Scott Cooley Lyric and Chord Songbook Volume OneDocument272 pagesScott Cooley Lyric and Chord Songbook Volume OneScott CooleyNo ratings yet

- Textbook Biscuit Cookie and Cracker Production Process Production and Packaging Equipment Second Edition Iain Davidson Ebook All Chapter PDFDocument54 pagesTextbook Biscuit Cookie and Cracker Production Process Production and Packaging Equipment Second Edition Iain Davidson Ebook All Chapter PDFmartin.hughes511100% (21)

- Priyanka - 50300 16 130Document4 pagesPriyanka - 50300 16 130Aravind GopaganiNo ratings yet

- Guarantee LetterDocument1 pageGuarantee LetterWizcarmelo ParcellanoNo ratings yet

- Special Continuous Probability DistributionsDocument11 pagesSpecial Continuous Probability DistributionsnofacejackNo ratings yet

- Governing KwuDocument21 pagesGoverning KwuVishal Kumar Laddha100% (4)

- Illegal Gold Mines in The PhilippinesDocument2 pagesIllegal Gold Mines in The PhilippinesMaricar RamirezNo ratings yet

- Pokemon Resolute Version Full Walkthrough PDFDocument3 pagesPokemon Resolute Version Full Walkthrough PDFsildora cedrik markNo ratings yet

- 230/33Kv Bole Lemi Substation Calculation Note - Protection Relay Setting - 230Kv Bus Bar & Bus CouplerDocument29 pages230/33Kv Bole Lemi Substation Calculation Note - Protection Relay Setting - 230Kv Bus Bar & Bus CouplerDebebe TsedekeNo ratings yet

- BDA PresentationsDocument26 pagesBDA PresentationsTejaswiniNo ratings yet

- Circuits Virtual LabDocument2 pagesCircuits Virtual LabPaula GómezNo ratings yet

- Comprehensive Plan For Lee CountyDocument9 pagesComprehensive Plan For Lee County3798chuckNo ratings yet

- Print DigestsDocument42 pagesPrint DigestsMirellaNo ratings yet

- Caption Text Tgas Bhs InggrisDocument6 pagesCaption Text Tgas Bhs InggrisPangbaterek PekaryaNo ratings yet

- Lesson 13 Changes That Cause Harmful and Useful To The EnvironmentDocument29 pagesLesson 13 Changes That Cause Harmful and Useful To The EnvironmentEmily Conde100% (3)