Professional Documents

Culture Documents

Oil Refi Ning Example.: The Feed Conditions Are

Oil Refi Ning Example.: The Feed Conditions Are

Uploaded by

Azad QaderCopyright:

Available Formats

You might also like

- Exp 15Document7 pagesExp 15Ishan GuptaNo ratings yet

- Distillation Aspen HysysDocument66 pagesDistillation Aspen HysysCzarina MasicatNo ratings yet

- Tutorial 2 QuestionDocument2 pagesTutorial 2 QuestionMohammed Amer100% (1)

- Ammonia Process DescriptionDocument51 pagesAmmonia Process DescriptionSaad Khan89% (9)

- Oil Refining Example DataDocument5 pagesOil Refining Example Datamsz_2003No ratings yet

- Páginas DesdeSeparation Process Principles (Seader & Henley, 2006) - SEGUNDA-EDICIONDocument1 pagePáginas DesdeSeparation Process Principles (Seader & Henley, 2006) - SEGUNDA-EDICIONAlanAlcazar100% (1)

- Total Base Number (TBN) in Used Motor Oil: Titration Application Note H-064Document3 pagesTotal Base Number (TBN) in Used Motor Oil: Titration Application Note H-064ahmetNo ratings yet

- Crude Oil DistillationDocument34 pagesCrude Oil Distillationfathi100% (2)

- Ethylene ProductionDocument7 pagesEthylene Productionaiman naim100% (1)

- Refinery All Lectures PDFDocument64 pagesRefinery All Lectures PDFHelin HassanNo ratings yet

- Crue Distillation Process (1) .EditedDocument16 pagesCrue Distillation Process (1) .EditedEdunjobi TundeNo ratings yet

- Energy Saving in Steam Systems.Document34 pagesEnergy Saving in Steam Systems.babis1980No ratings yet

- PDH - Plant-Case-Study-When-Linda-TripsDocument6 pagesPDH - Plant-Case-Study-When-Linda-TripsosamaNo ratings yet

- DistillaryDocument12 pagesDistillarysreejaNo ratings yet

- Deisel Hydrotreating UnitDocument9 pagesDeisel Hydrotreating UnitRittu Paul100% (1)

- The Function of Steam Boiler Is To Transfer Heat Produced by Burning of Fuel, To The Water and Thus To Produce Steam. Requirement of SteamDocument5 pagesThe Function of Steam Boiler Is To Transfer Heat Produced by Burning of Fuel, To The Water and Thus To Produce Steam. Requirement of SteamSaurabh AryaNo ratings yet

- Question Paper For RACDocument2 pagesQuestion Paper For RACSDvidyaNo ratings yet

- KilnLine OperationDocument32 pagesKilnLine Operationbreakthrough198889% (9)

- Interview Q and Ans FOR THARMAL POWER PLANTDocument15 pagesInterview Q and Ans FOR THARMAL POWER PLANTRajkumar Prasad100% (2)

- Procesos InglesDocument4 pagesProcesos InglesMarcoDulongJaraNo ratings yet

- Tutorial 2 QuestionDocument2 pagesTutorial 2 QuestionderianzacharyNo ratings yet

- Refrigeration and Air Conditioning QPDocument2 pagesRefrigeration and Air Conditioning QPAndrea DouglasNo ratings yet

- Unit 3 Overview of CDU and VDUDocument38 pagesUnit 3 Overview of CDU and VDU22 shantanu kapadnisNo ratings yet

- Distillation Exp.Document5 pagesDistillation Exp.Ibrahim DewaliNo ratings yet

- Thermal Behaviour of Transformers With Natural Oil Convection CoolingDocument4 pagesThermal Behaviour of Transformers With Natural Oil Convection CoolingConstantin DorinelNo ratings yet

- Cement Kilns-Chlorine Impact On ProcessDocument27 pagesCement Kilns-Chlorine Impact On Processmuhaisen2009100% (5)

- Methanol SynthesisDocument21 pagesMethanol SynthesisAnonymous cenxRyKU5No ratings yet

- Energy ProblemsDocument7 pagesEnergy ProblemsprpunkskaterNo ratings yet

- Boiler ReferenceDocument29 pagesBoiler ReferencetagolimotNo ratings yet

- ATD AssignmentDocument2 pagesATD AssignmentsamarthgkNo ratings yet

- Process and Plant For Distillation of Methanol. Description Technical FieldDocument19 pagesProcess and Plant For Distillation of Methanol. Description Technical FieldDr.AhmedNo ratings yet

- Presentation On CDCP Boilers - NEWDocument145 pagesPresentation On CDCP Boilers - NEWmohanivar77100% (4)

- Amine Processing Unit DEADocument9 pagesAmine Processing Unit DEAFlorin Daniel AnghelNo ratings yet

- Boiler Efficiency: Heat Input Is Pulverised Coal Heat Output Is Superheated SteamDocument17 pagesBoiler Efficiency: Heat Input Is Pulverised Coal Heat Output Is Superheated SteamHumayun Rashid KhanNo ratings yet

- Boiler Ratings: 'From and At' RatingDocument4 pagesBoiler Ratings: 'From and At' RatingsenaNo ratings yet

- SWS GPSA Engineering Data Book 12th EdDocument3 pagesSWS GPSA Engineering Data Book 12th Edfaisalmurad67% (3)

- Thermal CrackingDocument24 pagesThermal Crackingzubi0585No ratings yet

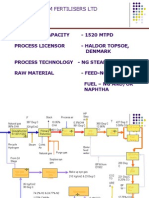

- Ammonia Plant: Kribhco Shyam Fertilisers LTDDocument51 pagesAmmonia Plant: Kribhco Shyam Fertilisers LTDSabeeh Faruqui100% (1)

- Problems in DesalinationDocument5 pagesProblems in DesalinationAbdelrahman AboudNo ratings yet

- Crude Oil Refining (Crude Oil DistillationDocument12 pagesCrude Oil Refining (Crude Oil Distillationشيبوب shaibobNo ratings yet

- Project Report PDFDocument7 pagesProject Report PDFImran Sajid ShahidNo ratings yet

- Hysys Workbook Part-1: By: Eng. Ahmed DeyabDocument23 pagesHysys Workbook Part-1: By: Eng. Ahmed Deyabahmed atwaNo ratings yet

- Assignment 4 (7332)Document8 pagesAssignment 4 (7332)Musa KaleemNo ratings yet

- Boiler EfficiencyDocument32 pagesBoiler Efficiencyइंजी. महेन्द्र प्रताप सिंह100% (2)

- Floating Production TechnologyDocument19 pagesFloating Production TechnologyHtin Lin AungNo ratings yet

- ITK-233-6 - Power Production & RefrigerationDocument30 pagesITK-233-6 - Power Production & RefrigerationAndy Noven KrisdiantoNo ratings yet

- Ash Handling System Design For The Power Plant: 1.0 Boiler Data: Description ParametersDocument4 pagesAsh Handling System Design For The Power Plant: 1.0 Boiler Data: Description ParametersvesselNo ratings yet

- حلول هوم ورك L.C5Document6 pagesحلول هوم ورك L.C5Abdulsalam SNo ratings yet

- Threlkeld 5 AnswersDocument11 pagesThrelkeld 5 AnswersJaycob Clavel100% (2)

- D86 and TBPDocument27 pagesD86 and TBPJulio Cesar Fernadez Estela0% (1)

- Calculation of Boiler EfficiencyDocument14 pagesCalculation of Boiler EfficiencyBharat Choksi100% (1)

- Actual Vapor Compression Refrigeration Cycle ProblemsDocument3 pagesActual Vapor Compression Refrigeration Cycle ProblemsFAISAL RAHIMNo ratings yet

- Luyben 2012Document7 pagesLuyben 2012JAN JERICHO MENTOYNo ratings yet

- Cap 04Document3 pagesCap 04Jorge PozoNo ratings yet

- Fuels Liq Manufacture of Metallurgical Coke: Beehive Oven Otto Hoffmann OvenDocument51 pagesFuels Liq Manufacture of Metallurgical Coke: Beehive Oven Otto Hoffmann OvenAgnivesh Sharma0% (3)

- Aluminum Silicates. (Zeolite)Document9 pagesAluminum Silicates. (Zeolite)MarNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

Oil Refi Ning Example.: The Feed Conditions Are

Oil Refi Ning Example.: The Feed Conditions Are

Uploaded by

Azad QaderOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oil Refi Ning Example.: The Feed Conditions Are

Oil Refi Ning Example.: The Feed Conditions Are

Uploaded by

Azad QaderCopyright:

Available Formats

Oil refi ning example.

A pre-heated crude needs to be fractionate to produce the following

product:

1.

2.

3.

4.

5.

Naphtha: produced from top 3-phase condenser.

Kerosene: produced from reboiler side stripper.

Diesel fuel: produced from steam side stripper.

Gas oil: produced from steam side stripper.

Residue: produced from the bottom.

The feed conditions

are :

Temp. = 450 of

Press. = 5.171 bar

Liq. Vol. flow rate = 100,000 bbl/day

The oil will be heated in the furnace to 650 o f, and then feed to the towe

r that

have (29 tray + partial condenser).

The feed enter the tower at stage 28, and a steam stream enters at the

bottom.

TBP Distillation Assay

The oil has the following laboratory assay

data:

o

Liquid Volume Percent Distilled Temperature ( f) Molecular weight

Steam Streams Information

0.0

80.0

10.0

AGO steam

50.0

349.0

150

430.0

50

527.0

635.0 50

282.0 2500

751.0

350.0

255.0

Pressure

(psia)

Temp. ( f)

20.0

Bottom steam

30.0

Diesel steam

40.0

68.0

Mass flow

119.0

(lb/hr)

150.0

7500

182.0

3000

225.0

375

300

300

Light Ends Liquid Volume Percent

60.0

i-Butane

0.19

Pump around915.0

specifications 456.0

n-Butane

0.11 Duty

And

the

other

operationReturn

conditions

are

listed belo 585.0

80.0

1095.0

Pump

Drawn

Circulation

w:

around90.0 stage

rate(bbl/day) 713.0

i-Pentane stage 1277.0

0.37 (BTU/hr)

PA_1

2

1

50,000

0.46 - 55e6

98.0 n-Pentane

1410.0

838.0

Liq. Vol. % distilled

API Gravity

PA_2

17

16

30,000

-3.5e7

70.0

PA_3

13.0 22

21

Viscosity Assay

33.0

57.0

Liquid Volume

Percent Distilled

74.0

10.0

91.0

30.0

30,000

63.28

Viscosity (cP) 100

0.20

0.75

-3.5e7

54.86

o

45.91

Viscosity (cP) 210

38.21

0.10

26.01

0.30

50.0

4.20

0.80

70.0

39.00

7.50

90.0

600.00

122.30

Bulk Crude Properties

MW

API Gravity

300.00

48.75

Initial estimated values

o

Temperature ( f)

* The Kerosene reboiler duty = 7.5 x 106 BTU/hr.

Condenser

100

Condenser press. drop

Top stage

Bottom

stage

stripper

Type

Pressure (psia)

19.7

250

700

Draw stage

32.7 stage

Return

Kerosene

Reboiled

Diesel

Steam

17

16

AGO

steam

22

21

The products requirement*:

1.

2.

3.

4.

Naphtha: 20,000 bbl/day

Kerosene: 13,000 bbl/day

Diesel fuel: 17,000 bbl/day

AGO: 5,000 bbl/day

You might also like

- Exp 15Document7 pagesExp 15Ishan GuptaNo ratings yet

- Distillation Aspen HysysDocument66 pagesDistillation Aspen HysysCzarina MasicatNo ratings yet

- Tutorial 2 QuestionDocument2 pagesTutorial 2 QuestionMohammed Amer100% (1)

- Ammonia Process DescriptionDocument51 pagesAmmonia Process DescriptionSaad Khan89% (9)

- Oil Refining Example DataDocument5 pagesOil Refining Example Datamsz_2003No ratings yet

- Páginas DesdeSeparation Process Principles (Seader & Henley, 2006) - SEGUNDA-EDICIONDocument1 pagePáginas DesdeSeparation Process Principles (Seader & Henley, 2006) - SEGUNDA-EDICIONAlanAlcazar100% (1)

- Total Base Number (TBN) in Used Motor Oil: Titration Application Note H-064Document3 pagesTotal Base Number (TBN) in Used Motor Oil: Titration Application Note H-064ahmetNo ratings yet

- Crude Oil DistillationDocument34 pagesCrude Oil Distillationfathi100% (2)

- Ethylene ProductionDocument7 pagesEthylene Productionaiman naim100% (1)

- Refinery All Lectures PDFDocument64 pagesRefinery All Lectures PDFHelin HassanNo ratings yet

- Crue Distillation Process (1) .EditedDocument16 pagesCrue Distillation Process (1) .EditedEdunjobi TundeNo ratings yet

- Energy Saving in Steam Systems.Document34 pagesEnergy Saving in Steam Systems.babis1980No ratings yet

- PDH - Plant-Case-Study-When-Linda-TripsDocument6 pagesPDH - Plant-Case-Study-When-Linda-TripsosamaNo ratings yet

- DistillaryDocument12 pagesDistillarysreejaNo ratings yet

- Deisel Hydrotreating UnitDocument9 pagesDeisel Hydrotreating UnitRittu Paul100% (1)

- The Function of Steam Boiler Is To Transfer Heat Produced by Burning of Fuel, To The Water and Thus To Produce Steam. Requirement of SteamDocument5 pagesThe Function of Steam Boiler Is To Transfer Heat Produced by Burning of Fuel, To The Water and Thus To Produce Steam. Requirement of SteamSaurabh AryaNo ratings yet

- Question Paper For RACDocument2 pagesQuestion Paper For RACSDvidyaNo ratings yet

- KilnLine OperationDocument32 pagesKilnLine Operationbreakthrough198889% (9)

- Interview Q and Ans FOR THARMAL POWER PLANTDocument15 pagesInterview Q and Ans FOR THARMAL POWER PLANTRajkumar Prasad100% (2)

- Procesos InglesDocument4 pagesProcesos InglesMarcoDulongJaraNo ratings yet

- Tutorial 2 QuestionDocument2 pagesTutorial 2 QuestionderianzacharyNo ratings yet

- Refrigeration and Air Conditioning QPDocument2 pagesRefrigeration and Air Conditioning QPAndrea DouglasNo ratings yet

- Unit 3 Overview of CDU and VDUDocument38 pagesUnit 3 Overview of CDU and VDU22 shantanu kapadnisNo ratings yet

- Distillation Exp.Document5 pagesDistillation Exp.Ibrahim DewaliNo ratings yet

- Thermal Behaviour of Transformers With Natural Oil Convection CoolingDocument4 pagesThermal Behaviour of Transformers With Natural Oil Convection CoolingConstantin DorinelNo ratings yet

- Cement Kilns-Chlorine Impact On ProcessDocument27 pagesCement Kilns-Chlorine Impact On Processmuhaisen2009100% (5)

- Methanol SynthesisDocument21 pagesMethanol SynthesisAnonymous cenxRyKU5No ratings yet

- Energy ProblemsDocument7 pagesEnergy ProblemsprpunkskaterNo ratings yet

- Boiler ReferenceDocument29 pagesBoiler ReferencetagolimotNo ratings yet

- ATD AssignmentDocument2 pagesATD AssignmentsamarthgkNo ratings yet

- Process and Plant For Distillation of Methanol. Description Technical FieldDocument19 pagesProcess and Plant For Distillation of Methanol. Description Technical FieldDr.AhmedNo ratings yet

- Presentation On CDCP Boilers - NEWDocument145 pagesPresentation On CDCP Boilers - NEWmohanivar77100% (4)

- Amine Processing Unit DEADocument9 pagesAmine Processing Unit DEAFlorin Daniel AnghelNo ratings yet

- Boiler Efficiency: Heat Input Is Pulverised Coal Heat Output Is Superheated SteamDocument17 pagesBoiler Efficiency: Heat Input Is Pulverised Coal Heat Output Is Superheated SteamHumayun Rashid KhanNo ratings yet

- Boiler Ratings: 'From and At' RatingDocument4 pagesBoiler Ratings: 'From and At' RatingsenaNo ratings yet

- SWS GPSA Engineering Data Book 12th EdDocument3 pagesSWS GPSA Engineering Data Book 12th Edfaisalmurad67% (3)

- Thermal CrackingDocument24 pagesThermal Crackingzubi0585No ratings yet

- Ammonia Plant: Kribhco Shyam Fertilisers LTDDocument51 pagesAmmonia Plant: Kribhco Shyam Fertilisers LTDSabeeh Faruqui100% (1)

- Problems in DesalinationDocument5 pagesProblems in DesalinationAbdelrahman AboudNo ratings yet

- Crude Oil Refining (Crude Oil DistillationDocument12 pagesCrude Oil Refining (Crude Oil Distillationشيبوب shaibobNo ratings yet

- Project Report PDFDocument7 pagesProject Report PDFImran Sajid ShahidNo ratings yet

- Hysys Workbook Part-1: By: Eng. Ahmed DeyabDocument23 pagesHysys Workbook Part-1: By: Eng. Ahmed Deyabahmed atwaNo ratings yet

- Assignment 4 (7332)Document8 pagesAssignment 4 (7332)Musa KaleemNo ratings yet

- Boiler EfficiencyDocument32 pagesBoiler Efficiencyइंजी. महेन्द्र प्रताप सिंह100% (2)

- Floating Production TechnologyDocument19 pagesFloating Production TechnologyHtin Lin AungNo ratings yet

- ITK-233-6 - Power Production & RefrigerationDocument30 pagesITK-233-6 - Power Production & RefrigerationAndy Noven KrisdiantoNo ratings yet

- Ash Handling System Design For The Power Plant: 1.0 Boiler Data: Description ParametersDocument4 pagesAsh Handling System Design For The Power Plant: 1.0 Boiler Data: Description ParametersvesselNo ratings yet

- حلول هوم ورك L.C5Document6 pagesحلول هوم ورك L.C5Abdulsalam SNo ratings yet

- Threlkeld 5 AnswersDocument11 pagesThrelkeld 5 AnswersJaycob Clavel100% (2)

- D86 and TBPDocument27 pagesD86 and TBPJulio Cesar Fernadez Estela0% (1)

- Calculation of Boiler EfficiencyDocument14 pagesCalculation of Boiler EfficiencyBharat Choksi100% (1)

- Actual Vapor Compression Refrigeration Cycle ProblemsDocument3 pagesActual Vapor Compression Refrigeration Cycle ProblemsFAISAL RAHIMNo ratings yet

- Luyben 2012Document7 pagesLuyben 2012JAN JERICHO MENTOYNo ratings yet

- Cap 04Document3 pagesCap 04Jorge PozoNo ratings yet

- Fuels Liq Manufacture of Metallurgical Coke: Beehive Oven Otto Hoffmann OvenDocument51 pagesFuels Liq Manufacture of Metallurgical Coke: Beehive Oven Otto Hoffmann OvenAgnivesh Sharma0% (3)

- Aluminum Silicates. (Zeolite)Document9 pagesAluminum Silicates. (Zeolite)MarNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet