Professional Documents

Culture Documents

Me 565 Advanced Fea Spring 03 Final Project, Do Not Discuss With Anyone!

Me 565 Advanced Fea Spring 03 Final Project, Do Not Discuss With Anyone!

Uploaded by

sujaydsouza19870 ratings0% found this document useful (0 votes)

20 views1 pageThis document provides instructions for a final project analyzing the end-cap of a bolted steel cylindrical pressure vessel using finite element analysis. Students are asked to model the vessel, apply appropriate loads and boundary conditions, and analyze the results to determine if the gasket seal requirement is satisfied and examine any other critical areas of the design. The report should include details of the discretization method, number of elements, boundary conditions, solution methods, and results and conclusions.

Original Description:

Final

Original Title

Final Exam

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides instructions for a final project analyzing the end-cap of a bolted steel cylindrical pressure vessel using finite element analysis. Students are asked to model the vessel, apply appropriate loads and boundary conditions, and analyze the results to determine if the gasket seal requirement is satisfied and examine any other critical areas of the design. The report should include details of the discretization method, number of elements, boundary conditions, solution methods, and results and conclusions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

20 views1 pageMe 565 Advanced Fea Spring 03 Final Project, Do Not Discuss With Anyone!

Me 565 Advanced Fea Spring 03 Final Project, Do Not Discuss With Anyone!

Uploaded by

sujaydsouza1987This document provides instructions for a final project analyzing the end-cap of a bolted steel cylindrical pressure vessel using finite element analysis. Students are asked to model the vessel, apply appropriate loads and boundary conditions, and analyze the results to determine if the gasket seal requirement is satisfied and examine any other critical areas of the design. The report should include details of the discretization method, number of elements, boundary conditions, solution methods, and results and conclusions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

ME 565 Advanced FEA

Spring 03

Final project, do not discuss with anyone!

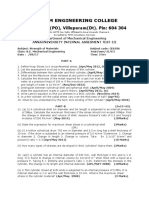

The figure illustrates the end-cap of a bolted steel cylindrical pressure vessel. There are ten 1-in.

diameter bolts preloaded so as to produce gasket sealing. The required preload should produce an

average gasket compressive stress of 10.8 kpsi. The pressure vessel is then subjected to the

internal pressure of 3500 Psi. Assume the copper-asbestos gasket has a modulus of elasticity of

E = 13.5103 psi. The design requirement is is to able to maintain the gasket seal. For that to

happen, the average gasket compressive stress should be at least 2.5 times the internal pressure.

Is this requirement satisfied for the given design? Are there any other critical areas in the design

which must be closely examined?

Follow the following guidelines when submitting your report:

1) What discretization method did you select (element type and formulation)? And why?

2) How many elements (of each type) were used? Describe, or clearly illustrate the element

distribution.

3) What Boundary conditions (loads, restraints) were employed? What approximations were

considered?

4) What method(s) of solution were employed?

5) Describe all relevant results, and how you arrived at the stated conclusions.

You might also like

- How To Design Roof Purlins - A Solved Example - Structville...Document23 pagesHow To Design Roof Purlins - A Solved Example - Structville...Charles Vladimir SolvaskyNo ratings yet

- Somqpit 3Document3 pagesSomqpit 3Anbu SelvanNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Theoretical Design GallettiDocument8 pagesTheoretical Design GallettiAnonymous 0GmaK60SNo ratings yet

- Static and Buckling Analysis of Concrete Spherical Shells: Ivana MekjavićDocument7 pagesStatic and Buckling Analysis of Concrete Spherical Shells: Ivana Mekjavićbkp2112No ratings yet

- Analysis of Simple StressesDocument39 pagesAnalysis of Simple StressesEduCartNo ratings yet

- Structural Analysis of Concrete Spherical Shells: MEKJAVIC, I (Vana)Document2 pagesStructural Analysis of Concrete Spherical Shells: MEKJAVIC, I (Vana)Iver LopezNo ratings yet

- TRN Simulation Question AnswersDocument4 pagesTRN Simulation Question AnswersCristhian Stefano Falchi PosadaNo ratings yet

- Composite ImplantDocument21 pagesComposite ImplantAlessandro Forestieri100% (1)

- Harmonic Analysis of Flex Seal of Rocket NozzleDocument14 pagesHarmonic Analysis of Flex Seal of Rocket NozzlemadhumamayyaNo ratings yet

- Design of Eccentrically Connected Cleat Plates in CompressionDocument10 pagesDesign of Eccentrically Connected Cleat Plates in CompressionPinoScribdNo ratings yet

- Design and Analysis of Bushed Pin Flexible Coupling: April 2017Document9 pagesDesign and Analysis of Bushed Pin Flexible Coupling: April 2017DOLSON BUTTI204008No ratings yet

- Extended AbstractDocument11 pagesExtended AbstractMuhammad SaimNo ratings yet

- SUMMER 2010 Coventry University Faculty of Engineering and ComputingDocument4 pagesSUMMER 2010 Coventry University Faculty of Engineering and ComputingVinay GowdaNo ratings yet

- MECH0007 Fundamentals of Materials Materials Characterisation Lab Pro-Forma Answer SheetDocument13 pagesMECH0007 Fundamentals of Materials Materials Characterisation Lab Pro-Forma Answer SheetFrank LiNo ratings yet

- Taller 3 - Propiedades MecánicasDocument2 pagesTaller 3 - Propiedades MecánicasJuan Pablo Rinc�n Ru�zNo ratings yet

- ANSYS BOLT Proceedings-63-00010-V4Document9 pagesANSYS BOLT Proceedings-63-00010-V4ricardovomNo ratings yet

- Functioning of Flange Joints Findings From Full Scale Experiments and Fem AnalysisDocument10 pagesFunctioning of Flange Joints Findings From Full Scale Experiments and Fem AnalysisSpecial Sicim ProcessesNo ratings yet

- 2002 Int Ansys ConfDocument10 pages2002 Int Ansys ConfjowarNo ratings yet

- ProblemDocument3 pagesProblemHaldor8No ratings yet

- Finite Element Analysis of Large Diameter Concrete Spherical Shell Domes - Hani Aziz AmeenDocument16 pagesFinite Element Analysis of Large Diameter Concrete Spherical Shell Domes - Hani Aziz AmeenHani Aziz AmeenNo ratings yet

- Ce010 601 Design of Steel Structures Ce PDFDocument5 pagesCe010 601 Design of Steel Structures Ce PDFPrakash rubanNo ratings yet

- Belt Conveyor Pulley Design - Why The Failures - Terry KingDocument11 pagesBelt Conveyor Pulley Design - Why The Failures - Terry KingJakesNo ratings yet

- Impact Analysis of A Concrete Storage ContainerDocument21 pagesImpact Analysis of A Concrete Storage ContainerD.c. PhamNo ratings yet

- Figure 1 Below Shows A Built-Up Beam Made of A36 Steel With FDocument3 pagesFigure 1 Below Shows A Built-Up Beam Made of A36 Steel With FMerwin Andrew UyNo ratings yet

- Compressive Strength Assessment of Concrete Structures From Small Core by Point Load TestDocument8 pagesCompressive Strength Assessment of Concrete Structures From Small Core by Point Load Testzacoeb_a1669No ratings yet

- MDPE Final TutorialDocument4 pagesMDPE Final Tutoriallata sinsinwarNo ratings yet

- BAE 417 Exam 1 - Fall 2006 - 2Document7 pagesBAE 417 Exam 1 - Fall 2006 - 2Youssef FekryNo ratings yet

- Fin DesignDocument12 pagesFin DesignMuraleedharanNo ratings yet

- Machine Design I Nme 501 Eme501Document3 pagesMachine Design I Nme 501 Eme501himanshujaiswal04596No ratings yet

- Shot Crete 2005Document5 pagesShot Crete 2005Anonymous UebIaD8A8CNo ratings yet

- 322 F22 PS9 - UpdatedDocument4 pages322 F22 PS9 - UpdatedlokeshNo ratings yet

- Tutorial Fastener Sesi Mac 2020Document4 pagesTutorial Fastener Sesi Mac 2020ilya danisyahNo ratings yet

- A General Design Approach For Post Tensioned Timber SubassembliesDocument17 pagesA General Design Approach For Post Tensioned Timber Subassemblies陈飞No ratings yet

- The Ultimate Strength and Stiffness of Modern Roof Systems With Hat-Shaped PurlinsDocument9 pagesThe Ultimate Strength and Stiffness of Modern Roof Systems With Hat-Shaped PurlinsMatias GaitanNo ratings yet

- Diagonal Ribs Increase Torsional Rigidity: by Robert L. WeckmanDocument3 pagesDiagonal Ribs Increase Torsional Rigidity: by Robert L. WeckmanKamesh Aru DNo ratings yet

- Timur Choban KhidirJCSgDocument8 pagesTimur Choban KhidirJCSgyash sanwareNo ratings yet

- Design and Analysis of Bushed Pin Flexible Coupling: April 2017Document8 pagesDesign and Analysis of Bushed Pin Flexible Coupling: April 2017Koushik NaganNo ratings yet

- FASTENERSDocument34 pagesFASTENERSEmreNo ratings yet

- PDH Post Tensioned Concrete Design PDFDocument8 pagesPDH Post Tensioned Concrete Design PDFJorge Mallea HooperNo ratings yet

- DME Question Bank - 3171917Document4 pagesDME Question Bank - 3171917fgyjnsv786No ratings yet

- Coursework Structural Integrity 2017feedbackDocument10 pagesCoursework Structural Integrity 2017feedbackCarlosNo ratings yet

- Literature ReviewDocument8 pagesLiterature ReviewAkhil RajagopalNo ratings yet

- HW8Document2 pagesHW8winter_snow714No ratings yet

- Saragoca VAZ SIMOES 2003+Document6 pagesSaragoca VAZ SIMOES 2003+jaimemontNo ratings yet

- Che f412 Midsem Test PedDocument2 pagesChe f412 Midsem Test PedPratik ChavanNo ratings yet

- Snap Fit DesignDocument4 pagesSnap Fit DesignJagadish_kNo ratings yet

- Answer All The Questions (5 X 2 10)Document10 pagesAnswer All The Questions (5 X 2 10)Robinson PrabuNo ratings yet

- Stress and Design Analysis of Triple Reduction Gearbox CasingDocument6 pagesStress and Design Analysis of Triple Reduction Gearbox CasingdilipNo ratings yet

- QUIZ (Each Question Carries 2 Marks, 5x2 10 Marks)Document1 pageQUIZ (Each Question Carries 2 Marks, 5x2 10 Marks)sutha_me20098282No ratings yet

- Estimating The Compressive Strength of Drilled Concrete Cores by Point Load TestingDocument6 pagesEstimating The Compressive Strength of Drilled Concrete Cores by Point Load TestingAchfas ZacoebNo ratings yet

- Moment End ConnectionsDocument8 pagesMoment End ConnectionsEfrainz TorresNo ratings yet

- Performance of Structural Insulated Panel With Fibre Cement Skins Subject To Windborne Debris Impact: Numerical StudyDocument8 pagesPerformance of Structural Insulated Panel With Fibre Cement Skins Subject To Windborne Debris Impact: Numerical StudyWilly SusantoNo ratings yet

- ISE386 Assignment 2 Solution - FinalDocument4 pagesISE386 Assignment 2 Solution - Final吳心100% (1)

- Fea Analysis of Pressure Vessel Withdifferent Type of End ConnectionsDocument5 pagesFea Analysis of Pressure Vessel Withdifferent Type of End ConnectionsFilip StojkovskiNo ratings yet

- Cable Profile For Box Girder DesignDocument2 pagesCable Profile For Box Girder DesignPunithan PunithanNo ratings yet

- Department of Civil Engineering CIVL2201 Structural MechanicsDocument8 pagesDepartment of Civil Engineering CIVL2201 Structural Mechanicssky willaNo ratings yet

- Analysis of The Integrity of A Single Stud Assembly With Externally Corroded NutsDocument19 pagesAnalysis of The Integrity of A Single Stud Assembly With Externally Corroded NutsrandyooiscribdNo ratings yet

- A Practical Design Guide For Welded Connections Analysis and Design of Welded ConnectionsDocument22 pagesA Practical Design Guide For Welded Connections Analysis and Design of Welded ConnectionsMukhtar HadiNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Handout 3 TMR4305 Lecture 13 09 2007Document5 pagesHandout 3 TMR4305 Lecture 13 09 2007sujaydsouza1987No ratings yet

- ReadmeDocument1 pageReadmesujaydsouza1987No ratings yet

- Initial Stress DefinitionDocument6 pagesInitial Stress Definitionsujaydsouza1987No ratings yet

- 2007 Paper 11 Question 3Document1 page2007 Paper 11 Question 3sujaydsouza1987No ratings yet

- Project 1Document1 pageProject 1sujaydsouza1987No ratings yet

- 2007 Paper 3 Question 4Document1 page2007 Paper 3 Question 4sujaydsouza1987No ratings yet

- ME 565 Advanced Finite Element Analysis, Spring Term 2003: Geometric Nonlinearity Assignment, Due Date: May 2Document1 pageME 565 Advanced Finite Element Analysis, Spring Term 2003: Geometric Nonlinearity Assignment, Due Date: May 2sujaydsouza1987No ratings yet

- Hw2 Benchmark Z BeamDocument7 pagesHw2 Benchmark Z Beamsujaydsouza1987No ratings yet

- Non-Linear Load Balancing: Workshop 9Document18 pagesNon-Linear Load Balancing: Workshop 9sujaydsouza1987No ratings yet

- Antler JointDocument1 pageAntler Jointsujaydsouza1987No ratings yet

- Plates and Shells Assignment, Due Date: April 12: ME 565 Advanced Finite Element Analysis, Spring Term 2003Document1 pagePlates and Shells Assignment, Due Date: April 12: ME 565 Advanced Finite Element Analysis, Spring Term 2003sujaydsouza1987No ratings yet

- Tattoo Designs & Symbols: Tribal TattoosDocument7 pagesTattoo Designs & Symbols: Tribal Tattoossujaydsouza1987100% (1)

- Intern's Project List:: Project: 2 Units in MKSDocument2 pagesIntern's Project List:: Project: 2 Units in MKSsujaydsouza1987No ratings yet

- Optimization of Car Rim Using OptiStructDocument6 pagesOptimization of Car Rim Using OptiStructsujaydsouza1987No ratings yet