Professional Documents

Culture Documents

Chapter 1: Gas Assisted Injection Molding 15

Chapter 1: Gas Assisted Injection Molding 15

Uploaded by

shilton19890 ratings0% found this document useful (0 votes)

7 views4 pagesvjhjkhjkkjk

Original Title

0791X_toc

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentvjhjkhjkkjk

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

7 views4 pagesChapter 1: Gas Assisted Injection Molding 15

Chapter 1: Gas Assisted Injection Molding 15

Uploaded by

shilton1989vjhjkhjkkjk

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 4

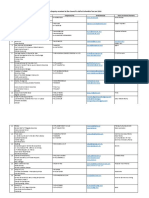

Table of Contents

Preface

Helmut Potente and Hans-Peter Heim

One-shot Manufacturing: What is Possible with New Molding Technologies

James F. Stevenson

v

1

Chapter 1: Gas Assisted Injection Molding

15

Gas Assist Injection Molding. The North American Legacy

Jack Avery

Flow Directions in the Gas Assisted Injection Molding Technology

Young Soo Soh and Chan Hong Chung

Gas-assisted Injection Molding: Influence of Processing Conditions and

Material Properties

Kurt W Koelling and Ronald C Kaminski

Cover Part as an Application Example for Gas-assisted Injection Molded Parts

Michael Hansen

Molded Part Design for the Gas Injection Technique

H. Potente and H.-P. Heim

Design Optimization of Gas Channels for an Air Cleaner Assembly Using

CAE Simulations

D.M. Gao, A. Garcia-Rejon, G. Salloum and D. Baylis

The Occurrence of Fiber Exposure in Gas Assist Injection Molded Nylon

Composites

Shih-Jung Liu and Jer-Haur Chang

Saving Costs and Time by Means of Gas-assisted Powder Injection Molding

Christian Hopmann, Walter Michaeli

Gas-assisted Reaction Injection Molding (GRIM): Application of the Gas

Injection Technology to the Manufacturing of Hollow Polyurethane Parts

I. Kleba, E. Haberstroh

15

27

35

43

51

57

65

73

79

Chapter 2: Thin Wall Molding

89

Thin Wall Processing of Engineering Resins: Issues and Answers

Larry Cosma

89

ii

Table of Contents

Effects of Processing Conditions and Material Models on the Injection

Pressure and Flow Length in Thinwall Parts

A. J. Poslinski

10 Common Pitfalls in Thin-Wall Plastic Part Design

Timothy A. Palmer

Flow Instabilities in Thin-wall Injection Molding of Thermoplastic Polyurethane

Christian D. Smialek, Christopher L. Simpson

Pressure Loss in Thin Wall Moldings

John W. Bozzelli, Jim Cardinal, and Bill Fierens

Integrating Thin Wall Molders Needs into Polymer Manufacturing

W. G. Todd, H. K. Williams, D. L. Wise

Thinning Injection Molded Computer Walls

Lee Hornberger and Ken Lown

Chapter 3: Molding Micro Parts and Micro Structures

99

107

113

121

127

133

143

Transcription of Small Surface Structures in Injection Molding an Experimental

Study

143

Uffe R. Arl, Erik M. Kjr

Injection Molding of Sub- m Grating Optical Elements

149

R. Wimberger-Friedl

Process Analysis and Injection Molding of Microstructures

157

Alrun Spennemann and Walter Michaeli

Simualtion of the Micro Injection Molding Process

163

Oliver Kemmann, Lutz Weber, Ccile Jeggy, Olivier Magotte, and

Franois Dupret

Chapter 4: Manufacturing of Composites

Melt Compression Molding (MCM) a One-shot Process for In-mold Lamination

and Compression Molding by Melt Strip Deposition

Georg H. Kuhlmann

In-mold Lamination Back Compression Molding

Thomas Huber

Analysis and Characterization of Flow Channels during Manufacturing of

Composites by Resin Transfer Molding

R. V. Mohan, K. K. Tamma, S. Bickerton, S. G. Advani and D. R. Shires

Optimization of Channel Design in VARTM Processing

Roopesh Mathur, Suresh G. Advani and Bruce K. Fink

171

171

187

193

209

Table of Contents

Injection Compression Molding. A Low Pressure Process for Manufacturing

Textile-Covered Mouldings

Carsten Brockmann, Walter Michaeli

Kurz-Hastings Inmold Decoration

Roy Bomberger

Chapter 5: Improving Material Properties

High Impact Strength Reinforced Polyester Engineering Resins for Automotive

Applications

Mengshi Lu, Kevin Manning, Suzanne Nelsen, and Steve Leyrer

Control of Internal Stresses in Injection Molded Parts Through the Use of

Vibrational Molding, RHEOMOLDINGSM, Technology

Akihisa Kikuchi, Marc Galop, Harold L. Brown, and Alexander Bubel

Experimental Determination of Optimized Vibration-assisted Injection Molding

Processing Parameters for Atactic Polystyrene

Alan M. Tom, Akihisa Kikuchi, and John P. Coulter

Vibrated Gas Assist Molding: Its Benefits in Injection Molding

J.P. Ibar

Chapter 6: Mold Making and Plasticisation

iii

215

223

229

229

237

245

253

259

Advances in Stack Molding Technology

259

Vincent Travaglini and Henry Rozema

Advanced Valve Gate Technology for Use in Specialty Injection Molding

267

John Blundy, David Reitan, and Jack Steele

In-mold Labeling for High Speed, Thin Wall Injection Molding

273

Gary Fong

Advances in Fusible Core Technique

281

E. Schmachtenberg and O. Schrder

Processing Glass-filled Polyethylene on a Twin-screw Injection Molding

Extruder

287

David Bigio, Rajath Mudalamane, Yue Huang and Saeid Zerafati

Injection Molding by Direct Compounding

295

Bernd Klotz

Improvement of the Molded Part Quality: Optimization of the Plastification Unit 301

S. Boelinger and W. Michaeli

iv

Table of Contents

Non-return Valve with Distributive and Dispersive Mixing Capability

Chris Rauwendaal

307

Index

313

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Final Report MEFB213Document15 pagesFinal Report MEFB213Syafiq Fauzi50% (4)

- Analytic Solutions For Tapered Column Buckling PDFDocument6 pagesAnalytic Solutions For Tapered Column Buckling PDFshilton1989No ratings yet

- RPM To Linear Velocity Calculator - EndMemoDocument1 pageRPM To Linear Velocity Calculator - EndMemoshilton1989No ratings yet

- STEP Files - ProcedureDocument1 pageSTEP Files - Procedureshilton1989No ratings yet

- 1Document9 pages1shilton1989No ratings yet

- Goyen HardwareDocument3 pagesGoyen Hardwareshilton1989No ratings yet

- Preface: John Moalli Menlo Park. CaliforniaDocument1 pagePreface: John Moalli Menlo Park. Californiashilton1989No ratings yet

- OF Of: of P. P. 2091, An of P. On On ofDocument5 pagesOF Of: of P. P. 2091, An of P. On On ofshilton1989No ratings yet

- T A B L E 23O.-Characterlstlcs A Number of Plastics'6Document2 pagesT A B L E 23O.-Characterlstlcs A Number of Plastics'6shilton1989No ratings yet

- Document Change Notice DCN Number 5070: Old Revision New Revision Logistics Review (Y/N)Document1 pageDocument Change Notice DCN Number 5070: Old Revision New Revision Logistics Review (Y/N)shilton1989No ratings yet

- Document Change Notice DCN Number 5098: Old Revision New Revision Logistics Review (Y/N)Document1 pageDocument Change Notice DCN Number 5098: Old Revision New Revision Logistics Review (Y/N)shilton1989No ratings yet

- Heep 103Document5 pagesHeep 103pk2varmaNo ratings yet

- Chapter 3 HydrotreatingDocument15 pagesChapter 3 HydrotreatingAbdul QayyumNo ratings yet

- ColumbiaDocument2 pagesColumbiaN Inbasagaran100% (2)

- Heat Exchanger Selection GuideDocument2 pagesHeat Exchanger Selection GuiderodrigoperezsimoneNo ratings yet

- Castings, Austenitic-Ferritic (Duplex) Stainless Steel, For Pressure-Containing PartsDocument3 pagesCastings, Austenitic-Ferritic (Duplex) Stainless Steel, For Pressure-Containing Partscarlos100% (1)

- Chart PracticesDocument12 pagesChart PracticesSamrat ChawlaNo ratings yet

- Cemtec A1Document2 pagesCemtec A1pravi3434No ratings yet

- DMA BrochureDocument20 pagesDMA BrochurelongttNo ratings yet

- GG25 PDFDocument2 pagesGG25 PDFGeorge_Wabag_2014No ratings yet

- ISO 8501-Pictorial Clasiification Standard For Surface CleanlinessDocument29 pagesISO 8501-Pictorial Clasiification Standard For Surface CleanlinessabhibmaneNo ratings yet

- Relationship Between Microstructure and Mechanical Properties of Silicon Nitride CeramicsDocument8 pagesRelationship Between Microstructure and Mechanical Properties of Silicon Nitride CeramicsAmy RobinsonNo ratings yet

- Heat Treatment BasicsDocument17 pagesHeat Treatment BasicsvasanthiNo ratings yet

- IncinerationDocument30 pagesIncinerationOMSAIRAMANo ratings yet

- Giz2012 en Comparison of Eu GMP Guidelines With Who Guidelines PDFDocument70 pagesGiz2012 en Comparison of Eu GMP Guidelines With Who Guidelines PDFMr ThanhNo ratings yet

- Domestic Production and Foreign Trade The American Capital Position Re-ExaminedDocument23 pagesDomestic Production and Foreign Trade The American Capital Position Re-ExaminedKevin Mcdonald100% (2)

- Macsteel VRN Product Catalogue 2021Document48 pagesMacsteel VRN Product Catalogue 2021Joshua Hobson100% (1)

- Deindustrialization in IndiaDocument3 pagesDeindustrialization in IndiaAshwini RaiNo ratings yet

- Bata Shoe Company (Bangladesh) Ltd.Document6 pagesBata Shoe Company (Bangladesh) Ltd.Vurdalack666No ratings yet

- 27390644Document75 pages27390644LabroufiAbdelouahedNo ratings yet

- Sika PDS - E - CPAC 20601 PDFDocument2 pagesSika PDS - E - CPAC 20601 PDFlwin_oo2435No ratings yet

- d14 3-d14 3m-2005PVDocument8 pagesd14 3-d14 3m-2005PVweldingchileNo ratings yet

- Iyer, Ananth V Introduction To The Four Cs of Supply Chain Management Chain Structure, Competition, Capacity and Coordination PDFDocument162 pagesIyer, Ananth V Introduction To The Four Cs of Supply Chain Management Chain Structure, Competition, Capacity and Coordination PDFYoslen MartinezNo ratings yet

- Refractory in IndiaDocument5 pagesRefractory in IndiaEM EZNo ratings yet

- BFW AiravatDocument4 pagesBFW Airavatyraju88No ratings yet

- Statement of Purpose Surge Iit KanpurDocument1 pageStatement of Purpose Surge Iit KanpurVaibhav Gupta100% (1)

- Advanced Granulation Technology: Presented by Department of Pharmaceutics Faculty of Pharmacy Sri Ramachandra UniversityDocument24 pagesAdvanced Granulation Technology: Presented by Department of Pharmaceutics Faculty of Pharmacy Sri Ramachandra UniversityAleeya rizviNo ratings yet

- E6010Document3 pagesE6010Anonymous oUoJ4A8xNo ratings yet

- Building Code Australia ComplianceDocument24 pagesBuilding Code Australia ComplianceLampard ChenNo ratings yet

- Polymers For Electronic ComponentsDocument116 pagesPolymers For Electronic ComponentsTheodoros NiklanovitsNo ratings yet