Professional Documents

Culture Documents

Analysis of Archimedes Screw Design Parameters

Analysis of Archimedes Screw Design Parameters

Uploaded by

HeriSaputraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Analysis of Archimedes Screw Design Parameters

Analysis of Archimedes Screw Design Parameters

Uploaded by

HeriSaputraCopyright:

Available Formats

An Analysis of Archimedes Screw Design Parameters and their

Influence on Dispensing Quality for Electronics Assembly Applications.

By

Daryl Santos and Sunil Chhabra

State University of New York at Binghamton

Binghamton, NY - 13902

Tel: (607) 777-4769; Fax: (607) 777-4094; Email: santos@binghamton.edu

And

Douglass Dixon, Wendy Cummings, Sergio Porcari and Steven Rocco Marongelli

Universal Instruments Corporation

Binghamton, NY - 13902

Tel: (607) 779-4630; Fax: (607) 779-7212; Email: dixond@uic.com

ABSTRACT

Dispensing any fluid material onto a mixed technology printed circuit board (PCB) substrate has two basic

requirements: applying the material to the exact location required, and dispensing a dot of exact volume.

Due to the decreasing pad sizes, and the typical density required in the material pattern, these are major

challenges [3]. There are two basic types of dispensing mechanisms that are used for practical production:

the Archimedes Metering Valve (AMV) and the Positive Displacement Pump [5]. The performance of the

Archimedes Screw in the AMV depends a great deal on screw design and operating conditions. The

principle geometric variables of the Archimedes Screw are the channel depths, i.e., the radial distance

between the cylinder surface and root diameter of the screw, the pitch of the screw, the type of threads and

the number of channels through which the material can flow. The dimensions of the nozzle, such as the

nozzle ID and stand off height, and the rheological properties of the material also influence the parameters

required for a consistent dot. Dispensing with an AMV is based on the laws of momentum, fluid dynamics,

energy, and mass transport. The amount of material dispensed depends upon the pitch of threads, depth of

cut, type of thread, length of screw, the number of starts, and angle of rotation of the screw. The quantity

of material dispensed increases with an increase in depth of cut, decrease in pitch, increase in encoder

counts, and increasing the number of channels. This paper studies the effect of different geometric

variables of the screw, and the screw-nozzle combination that optimizes the quantity of material dispensed

without affecting dot consistency.

INTRODUCTION

An Archimedes pump utilizes a threaded screw

to turn the material down a cylinder. The

material is pumped forward by the relative

movement of the screw in the cylinder. The

transporting mechanism is similar to a nut held

in a wrench with the screw rotating in the nut.

Normally, the screw advances in the nut, but

when the screw is physically prevented from

advancing, as in the case of the Archimedes

screw, the nut will slide in the wrench. A motor

through a gearbox turns the screw, but a circular

ring on the head of the screw prevents it from

being pushed out of the cylinder. The movement

of the screw within the cylinder causes a

pressure rise along the length of the screw.

When the material reaches the nozzle, it

experiences a change in area, and as a result, it

undergoes pressure variation. The nozzle offers

resistance to the flow of material, termed as

Back-Pressure.

The force with which the

material dispensed is resultant of the pressure

difference between the pump and the nozzle. As

a result, it is extremely important to understand

the screw parameters, the screw-nozzle

combination and the operating conditions that

maximize production.

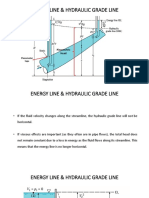

SCREW DESIGN PARAMETERS

1.

Pitch of Threads ( t ) :

This (see Figure 1) is defined as the distance

between two consecutive threads [1]. A high

value of pitch, i.e., small value of thread/inch,

passes along the channels of the screw, it

undergoes a pressure variation.

Since the

cartridge is a constant volume chamber, and as

the amount of material fed increases, the

pressure of the material within the cartridge

rises. A very high-pressure rise within the

cartridge could cause separation of flux and

solder metal spheres. Hence, there is a limit to

the length of the screw that causes sufficient

pressure build-up and minimizes separation.

Figure 1 Screw design parameters

reduces the effective surface area of contact.

This reduced surface area of contact causes a

reduction in pressure build-up as compared to a

screw with a greater number of threads/inch. A

high pitch causes excessive material to be fed

between the threads than the nozzle can handle

and, hence, increase the Back-Pressure. This, in

turn, reduces the amount of material dispensed as

it counteracts the pressure developed to dispense

it.

()

2. Depth of Cut h = Dmajor Droot

2:

4. Number of Starts :

The number of starts determines the number of

channels through which the material can flow in

the cartridge. With an increase in the number of

starts, a greater quantity of material flows into

the cartridge. This increases the pressure of the

material in the cartridge and consequently

increases the volume dispensed. A multi-start

thread also provides more channels for the

material to leave the screw and also increases the

volume dispensed.

OPERATING CONDITIONS

3. Type of Thread :

Apart from the screw design parameters, the

operating conditions also play an equally

important role in the quantity and quality of the

dispensed dot. The material parameters, such as

viscosity, thixotropic property, metal content and

solder powder size, influence the flow behavior.

Viscosity is defined as the property of a fluid by

virtue of which it offers resistance to the

movement of one layer of fluid over an adjacent

layer. There is a low and high threshold value

for the viscosity of the solder paste. A high

value of viscosity (> 400 Kcps) will offer a high

resistance to flow affecting the quality of the

dispensed dot [6]. Moreover, if the material has

a very low viscosity, it will tend to flow freely,

thus causing it to drool.

Solder paste is a mixture of solder metal spheres,

flux, and additives. The density of the solder

metal is about 8 times the density of flux [5].

This density difference between solder metal and

flux causes them to separate at high shearing

forces. Square threads have sharper edges as

compared to angled threads such as the British

Standard Whitworth. The square threads can

possibly cause excessive shearing of solder paste

and, hence, increase separation.

The relationship between the nozzle ID and

particle size is also an important aspect for

successful dispensing. Too large a particle size

through a fine nozzle ID will cause it to clog. A

rule of thumb suggests that the nozzle ID should

be 8 times larger than the solder paste particle

size to avoid clogging [5]. With a decrease in

nozzle ID the flow area for the material

decreases, increasing the Back-Pressure and thus

decreasing the flow rate.

3. Length of Screw :

The length of screw influences the pressure

buildup and distribution. As the solder paste

The following is the test plan developed to

understand the effect of the above-mentioned

parameters on the flow rate of the material.

The amount of material dispensed is directly

proportional to the depth of cut, up to a certain

point, depending upon the nozzle ID. For a

given nozzle ID there is an optimum value for

the depth of cut to minimize Back-Pressure.

Any increase in the depth of cut beyond this

point causes the flux in the solder paste to act as

a lubricant, therefore causing slippage between

the screw and the solder paste. This reduces the

pressure build-up in the cartridge. Hence, to

maximize the amount of material dispensed

through a nozzle, it is necessary to determine the

optimum depth of cut of a screw.

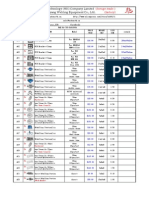

To analyze the effect of the above-mentioned

parameters, eight screws with variation in the

depth of cut, and number of starts were designed.

For the first four screws, the depth of cut is

increased keeping the same number of starts (see

Table 1). For the next four screws, the number

of starts is doubled with the same values of depth

of cut. The pitch of the screws is constant.

Table 1 Variation in dimensions of the screws

Code Number Depth of

of Starts cut (mils)

1 Single

10

2 Single

15

3 Single

20

4 Single

30

5 Double

10

6 Double

15

7 Double

20

8 Double

30

Equipment:

The experiment was conducted on an

Archimedes Metering Valve mounted on a XYZ

table (Universal Instrument Model GDM

4716A).

Experiment Design:

The motion control is obtained through a servo

system using an encoder disc. The encoder

counts on the disc control the angle of rotation of

the screw. The machine is programmed to

dispense from 500 to 5000 encoder counts in

steps of 500 encoder counts. A value of 12800

encoder counts corresponds to one complete

rotation of the screw. The solder paste was

dispensed onto a substrate at each step and

weighed. The procedure was repeated 5 times

for each step.

The experiment was first

conducted for unrestricted flow (without any

nozzle) and then for restricted flow using a

nozzle of 16, 20 and 24 mil ID. The air pressure

is kept constant at 15psi to maintain a steady

flow of solder paste from the syringe to the

cartridge.

Material:

The solder paste used for the study was

63Sn37Pb, Type III with a metal load of 85%

(w/w) and viscosity 400Kcps using a Brookfield

viscometer at 25o C.

RESULTS

1. Effect of Depth of Cut:

For unrestricted flow, (i.e. without a nozzle) the

weight of solder paste dispensed increases with

an increase in the depth of cut and angle of

rotation; Figure 2 validates the conjecture. In

performing the same type of experiment with a

16-mil nozzle ID, interesting results are obtained

(see Figure 3). While Screw #2 and Screw #3

performed differently under unrestricted flow,

Figure 3 indicates that, with this restriction, an

increase in depth of cut does not significantly

increase the quantity of dispensed solder paste.

This trend seems to also be manifested in the

comparison of Screws #6 and #7. Another

Weight of solder paste dispensed in grams

TEST PLAN

0.01500

#8

#4

#7

#6

0.01000

#3

#5

#2

0.00500

#1

0.00000

500 1000 1500 2000 2500 3000 3500 4000 4500 5000

Encoder Counts

Figure 2 Effect of depth of cut on weight of

solder paste dispensed for unrestricted flow

interesting result concerns the comparison

between Screws #6, #7, and #8 (the double start

screws) in Figure 3. Since Screw #8 has the

largest depth of cut, one may expect that it would

dispense the largest quantity of solder paste.

While this is evidenced for unrestricted flow, it

is not the case with a 16-mil nozzle restriction.

In fact, Screw #8 at the higher encoder counts

dispensed a smaller quantity of solder paste than

Screws #6 and #7. Screw #8 has the maximum

depth of cut, but dispenses comparatively less

than Screw #6 and Screw #7.

Hence, the quantity of material dispensed by a

double threaded screw is greater than a single

0.00450

#6

0.00350

0.00300

#8

0.00300

#5

0.00250

#3

#7

#2

0.00200

#4

#1

0.00150

0.00100

0.00050

0.00000

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

Encoder Counts

Weight of Solder Paste Dispensed

grams

Weight of Solder Paste Dispensed

grams

0.00400

#5

0.00250

0.00200

#1

0.00150

0.00100

0.00050

0.00000

0

Figure No 3 Effect of depth of cut on weight of

solder paste dispensed with a 16-mil ID nozzle.

This inadequate build-up of pressure can be

attributed to the slippage between the screw and

the material. The above graph indicates the

following: increasing the depth of cut need not

necessarily increase the dispensed volume.

Hence, with reducing nozzle ID it is important to

determine the depth of cut that maximizes

dispense rate.

2. Effect of Number of Starts:

The number of starts determines the distance

moved by the material in one rotation of the

screw.

0.00400

Weight of solder paste dispensed

grams

#5

0.00350

0.00300

0.00250

#1

0.00200

0.00150

0.00100

0.00050

0.00000

0

1000

2000

3000

4000

5000

6000

Encoder Counts

Figure 4 Effect of number of starts on weight of

solder paste dispensed for a 20-mil ID nozzle.

For a single threaded screw, the distance moved

by the material in one rotation is equal to the

pitch of the screw; whereas, for a double

threaded screw, the distance moved by the

material in one rotation is twice the pitch.

1000

2000

3000

4000

5000

6000

Encoder Counts

Figure 5 Effect of number of starts on weight of

solder paste dispensed for a 16-mil ID nozzle.

threaded screw for the same amount of turn.

This is also observed during experimentation.

Increasing the number of starts increased the

flow rate of the solder paste. For example,

Figure 4 and 5 show the increase in the quantity

of solder paste dispensed for a 16-mil and a 20mil ID nozzle using Screw #1 and Screw #5.

Similar results are obtained in comparing the

other pairs of single vs. double start screw.

3. Effect of Nozzle ID:

A nozzle is specified in terms of its standoff and

inner diameter (ID). The nozzle ID determines

the size of the dispensed dot. As the solder paste

flows from the cartridge into the nozzle, it

undergoes a change in flow area, resulting in

pressure change. A high-pressure variation

could result in separation of the flux and the

solder balls. With a decrease in nozzle ID, the

resistance to flow also increases, thus increasing

the Back-Pressure. If the screw feeds more

material than the nozzle can handle, excessive

build-up of Back-Pressure occurs, causing

slippage between the screw and the material.

This slippage results in inadequate pressure

build-up for dispensing. This is possibly due to

the separation between the flux and the solder

balls, where the flux acts as a lubricant,

preventing surface contact of the solder metal

spheres with the screw surface.

For given dimensions of the screw and material

properties, the Back-Pressure increases with a

decrease in nozzle ID. Due to this increase in

% Reduction in weight of solder paste

dispensed

Back-Pressure, the quantity of solder paste

dispensed decreases.

100

90

80

70

60

50

40

30

20

10

0

500

It is also concluded that the Back-Pressure

increases with a decrease in nozzle ID and

increase in encoder counts. Hence, for a given

nozzle ID, it is necessary to determine the

amount of rotation of a screw so that the pressure

developed to dispense is greater than the BackPressure. Any further increase in rotation could

result in a marginally reduced quantity of solder

paste dispensed and increased separation.

16-mil ID

20-mil ID

1500

2500

3500

depth of cut. For a 16-mil ID nozzle, Screw #6

and Screw #7 dispensed more than Screw #8.

Also, increasing the depth of cut from 16-mils to

20-mils did not result in an increase in the

quantity of dispensed material.

4500

Encoder Counts

Figure 6 Effect of nozzle ID on the quantity of

the solder paste dispensed using Screw #1.

Experimentation with a 16-mil and 20-mil ID

nozzle (see Figure 6) indicates that the

percentage reduction is constant for different

amounts of rotation of the screw.

The

percentage reduction is a relative difference

calculation 1 . A similar effect is observed with

the remaining seven screws indicating that the

Back-Pressure increases with a decrease in

nozzle ID and an increase in encoder counts to

keep the percentage reduction constant.

FUTURE WORK

Apart from studying the effect of different nozzle

ID size, the number of starts, and the depth of cut

on the volume dispensed, it would also be

interesting to see the effect of different pitch

values, the different types of threads and

variation in the length of screw. The experiment

was studied using a solder paste with 85% metal

loading. A variation in the metal loading of the

solder paste could significantly result in the

change of volume dispensed and hence the

Screw-Nozzle combination that optimizes

dispensing.

REFERENCES

1.

CONCLUSION

The effect of different geometric variables of the

Archimedes Screw and nozzle ID on the quantity

of material dispensed were studied. In order to

achieve the maximum flow rate, it is necessary to

determine the depth of cut, the number of starts,

and the screw-nozzle combination. It was noted

that the quantity of dispensed material increases

with an increase in encoder counts, but after a

certain point for a high depth of cut, the quantity

of material dispensed decreases for a reduced

nozzle ID. This indicates that there is an optimal

screw-nozzle combination that maximizes

production rate. In general, increasing the

number of starts or the channels for the material

to flow increased the quantity of material

dispensed. The nozzle ID sets the limit to the

1

Percentage Reduction = (W g - W r) / W r

Where

W g = Weight of solder paste with unrestricted

flow.

W r = Weight of solder paste with restricted flow.

2.

3.

4.

5.

6.

Spotts, M. F., Design of Machine Elements

6th Edition, Prentice-Hall, Inc., Englewood

Cliffs, New Jersey, 1985.

Dixon, D., Archimedes Pumps, Universal

Instruments Corporation, 1996.

Engel, J., Solder Paste Dispensing On

Micro-Hybrid Substrates for SurfaceMount

Applications, Hybrid Circuit Technology,

July 1991.

Tadmore, Z. and Klein, I., Engineering

Principles of Plasticating Extrusion, Van

Nostrand Reinhold Company, New York,

1970.

Dixon, D. et al., Practical Issues Concerning

Dispensing End Effectors, Universal

Instruments Corporation, 1996.

Lee, N. C. et al., Achieving Ultra-Fine Dot

Solder

Paste

Dispensing,

Indium

Corporation of America, 1998.

You might also like

- Ipc 7527Document3 pagesIpc 7527ram dhuke100% (1)

- IPC J-STD-004C en 2022 Requirements For Soldering FluxesDocument16 pagesIPC J-STD-004C en 2022 Requirements For Soldering Fluxescdming0% (2)

- BAHIR DAR UNIVERSITY - Design of Centrifugal Pump AbDocument30 pagesBAHIR DAR UNIVERSITY - Design of Centrifugal Pump AbADEFRIS BELACHEWNo ratings yet

- PDF IIHR402Document61 pagesPDF IIHR402Sanjib MazumderNo ratings yet

- Experiment 1 and 2Document6 pagesExperiment 1 and 2haudeitbaNo ratings yet

- Influence of Air Knife Wiping On Coating Thickness inDocument9 pagesInfluence of Air Knife Wiping On Coating Thickness inTrilok Chand GuptaNo ratings yet

- Surface Mount TechnologyDocument138 pagesSurface Mount Technologynksharma44100% (2)

- JEDEC Solderability 22B102EDocument26 pagesJEDEC Solderability 22B102EAlex Garcia100% (1)

- Screw PumpDocument12 pagesScrew Pumpemilliomud100% (1)

- Hydrodynamic ScrewsDocument8 pagesHydrodynamic Screwsarrester97No ratings yet

- Pressure Surge Damage in PipelineDocument16 pagesPressure Surge Damage in PipelinebbmokshNo ratings yet

- Impeller Materials FlygtDocument4 pagesImpeller Materials FlygtrenatocamaramNo ratings yet

- Bell and Gossett Sump DesignDocument8 pagesBell and Gossett Sump DesignVelpandian ManiNo ratings yet

- Water Hammer Sound Celerity Equation Surge in Pipe Water Hammer Variable-Waves SpeedDocument8 pagesWater Hammer Sound Celerity Equation Surge in Pipe Water Hammer Variable-Waves SpeedmanojmoryeNo ratings yet

- Flygt PDFDocument40 pagesFlygt PDFjesusNo ratings yet

- IIT-Intake and Exhaust Manifold DesignDocument28 pagesIIT-Intake and Exhaust Manifold DesignVasudev GuptaNo ratings yet

- Francis ReportDocument24 pagesFrancis Reportantukara100% (3)

- Flow Measurement ManualDocument10 pagesFlow Measurement ManualSHANKARNo ratings yet

- Characteristic Curves of Pumps and TurbinesDocument7 pagesCharacteristic Curves of Pumps and Turbinessonabrar10No ratings yet

- Pump Selection A Real ExampleDocument6 pagesPump Selection A Real ExampleBassam AmirNo ratings yet

- Lecture 2. Types of Machine DrawingDocument19 pagesLecture 2. Types of Machine DrawingaddisudagneNo ratings yet

- The Power of Wear RingsDocument18 pagesThe Power of Wear RingsVinh Do ThanhNo ratings yet

- (Carl Schaschke) Fluid Mechanics Worked ExamplesDocument164 pages(Carl Schaschke) Fluid Mechanics Worked Examplesrok100% (1)

- Lift CalculationDocument3 pagesLift CalculationHussain JiffryNo ratings yet

- Flygt Vertical Column FAS VersionDocument8 pagesFlygt Vertical Column FAS VersioncomedyboNo ratings yet

- Water Hammer: KSB Know-How, Volume 1Document34 pagesWater Hammer: KSB Know-How, Volume 1ashumishra007No ratings yet

- Closed Conduit Flow ExptDocument99 pagesClosed Conduit Flow ExptStephanie Anne FortinNo ratings yet

- Free VortexDocument3 pagesFree VortexVrushiket Patil67% (3)

- Orifice & free jet flow: Z P ρg V Z P ρg VDocument4 pagesOrifice & free jet flow: Z P ρg V Z P ρg VEsra BelhajNo ratings yet

- Penstocks Catalogue PDFDocument19 pagesPenstocks Catalogue PDFAhmed AbuoelnagaNo ratings yet

- Trashrack 2021 ManualDocument10 pagesTrashrack 2021 ManualomerscheenNo ratings yet

- Hydraulics Lab ManualDocument12 pagesHydraulics Lab ManualArman OlaNo ratings yet

- Waterman Tilting Weir GatesDocument3 pagesWaterman Tilting Weir Gatessandaldm100% (1)

- Manning's Roughness Coefficient (N)Document11 pagesManning's Roughness Coefficient (N)Khurram MumtazNo ratings yet

- KT Penstock PDFDocument24 pagesKT Penstock PDFKmi GutierrezNo ratings yet

- Notch and WeirsDocument33 pagesNotch and WeirsAbdur RashidNo ratings yet

- Factory Performance Testing of Vertical Turbine PumpsDocument3 pagesFactory Performance Testing of Vertical Turbine PumpsSrećko BlaževićNo ratings yet

- Is 4622 2003Document27 pagesIs 4622 2003Apurba Haldar100% (1)

- Guidelines For Selection of Turbines, Preliminary Dimensioning and Layout of Surface Hydroelectric Power HousesDocument17 pagesGuidelines For Selection of Turbines, Preliminary Dimensioning and Layout of Surface Hydroelectric Power HousessubasratnaNo ratings yet

- Bombas Sumergibles KSBDocument92 pagesBombas Sumergibles KSBArturPNo ratings yet

- HTTP WWW Mathalino Com Reviewer Fluid Mechanics and Hydraulics Energy and HeadDocument13 pagesHTTP WWW Mathalino Com Reviewer Fluid Mechanics and Hydraulics Energy and HeadYel Carla Sovill100% (3)

- Unit V: - TurbinesDocument56 pagesUnit V: - TurbinesparthibankNo ratings yet

- L .2 Hydraulic PumpDocument45 pagesL .2 Hydraulic PumpMentsnot GetuNo ratings yet

- (726847550) Exp 6 Head Loss Due To Pipe Fitting 2012Document6 pages(726847550) Exp 6 Head Loss Due To Pipe Fitting 2012Nirvenesh CaspianNo ratings yet

- Pipe FrictionDocument4 pagesPipe FrictionShubham ChauhanNo ratings yet

- Hydro-Mechanical EquipmentDocument160 pagesHydro-Mechanical EquipmentSteve MadrigalNo ratings yet

- PumpDocument33 pagesPumppramodtryNo ratings yet

- 1 - Hydro Power PlantsDocument54 pages1 - Hydro Power Plantsraghurmi100% (1)

- Pump Sump-Design General PrinciplesDocument14 pagesPump Sump-Design General Principlesspnatu0% (1)

- Centifugal PumpDocument8 pagesCentifugal PumpTinaaTinyNo ratings yet

- Water Hammer ArticleDocument14 pagesWater Hammer ArticleayoungaNo ratings yet

- Energy Line & Hydraulic Grade Line: Piezometric HeadDocument19 pagesEnergy Line & Hydraulic Grade Line: Piezometric HeadMaryam Arif100% (1)

- Pump LectureDocument22 pagesPump LectureRafie MohammedNo ratings yet

- Centrifugal PumpDocument11 pagesCentrifugal PumpJamie Shane DemosthenousNo ratings yet

- Well Design PDFDocument29 pagesWell Design PDFPratul ChoudhuryNo ratings yet

- Pump Intake DesignDocument52 pagesPump Intake DesignAnonymous CMS3dL1T75% (4)

- Lift TrafficDocument32 pagesLift TrafficMatthew WongNo ratings yet

- Permeability TestDocument10 pagesPermeability TestIsa MuellerNo ratings yet

- Pumps Training Very BasicDocument38 pagesPumps Training Very Basicprashant mishraNo ratings yet

- Net Positive Suction Head for Rotodynamic Pumps: A Reference GuideFrom EverandNet Positive Suction Head for Rotodynamic Pumps: A Reference GuideRating: 5 out of 5 stars5/5 (1)

- Wire Surface Roughness As Possible Criteria For Evaluation of Dies WearDocument6 pagesWire Surface Roughness As Possible Criteria For Evaluation of Dies WearNguyen Thanh TrungNo ratings yet

- Solder Paste LiteratureDocument1 pageSolder Paste LiteraturescmeswarNo ratings yet

- Downloaded From Manuals Search EngineDocument44 pagesDownloaded From Manuals Search Enginemilton arenaNo ratings yet

- Infineon An 1035 ApplicationNotes v29 01 enDocument44 pagesInfineon An 1035 ApplicationNotes v29 01 enLeonard GržetićNo ratings yet

- RMA-223 User GuideDocument2 pagesRMA-223 User Guidemarc_2ice@yahoo.comNo ratings yet

- ICS R490说明书(ENGLISH) PDFDocument14 pagesICS R490说明书(ENGLISH) PDFFurqonudin SejahteraNo ratings yet

- PIHR Book PDFDocument163 pagesPIHR Book PDFRanjitha BNo ratings yet

- IPC HDBK 001SDocument7 pagesIPC HDBK 001SKauã MartinsNo ratings yet

- A DMAIC Approach To Printed Circuit Board Quality Improvement-1Document9 pagesA DMAIC Approach To Printed Circuit Board Quality Improvement-1rogers4759No ratings yet

- TN0018 Technical Note: Linear Accelerometers in LGA Package Surface Mounting GuidelinesDocument15 pagesTN0018 Technical Note: Linear Accelerometers in LGA Package Surface Mounting Guidelinesthanggimme.phanNo ratings yet

- IPC-TM-650: IPC Test Method ManualDocument30 pagesIPC-TM-650: IPC Test Method ManualQUALITY LABORATORYNo ratings yet

- Material Data Sheet NC 259 Sn100c Solder Paste Rev 1Document3 pagesMaterial Data Sheet NC 259 Sn100c Solder Paste Rev 1vkmsNo ratings yet

- Pf-Emco#218-63p Rev.bDocument6 pagesPf-Emco#218-63p Rev.bPhung Cam VanNo ratings yet

- R276 Solder Paste: Dispensable No-Clean Solder Paste For Leaded and Lead-Free AlloysDocument2 pagesR276 Solder Paste: Dispensable No-Clean Solder Paste For Leaded and Lead-Free AlloysChoice OrganoNo ratings yet

- M705-GRN360-MZ: High-Reliability, High-Preheat Resistance Lead-Free Solder PasteDocument12 pagesM705-GRN360-MZ: High-Reliability, High-Preheat Resistance Lead-Free Solder PasteAlejandro Hernandez de DiosNo ratings yet

- CDS-Solder PasteDocument2 pagesCDS-Solder PasteSaul SolisNo ratings yet

- Surface Mounting TechnlogyDocument161 pagesSurface Mounting Technlogyhariharasankar100% (2)

- Solder Paste Printing ProcessDocument8 pagesSolder Paste Printing ProcessShooting StarNo ratings yet

- The Effect of Rotating Atomizer Geometry On The SaDocument7 pagesThe Effect of Rotating Atomizer Geometry On The SamazaherramazaniNo ratings yet

- Three-Dimensional CFD Simulation of The Stencil Printingperformance of Solder PasteDocument9 pagesThree-Dimensional CFD Simulation of The Stencil Printingperformance of Solder PastecocozhouNo ratings yet

- Pin-in-Paste Stencil Design SpreadsheetDocument4 pagesPin-in-Paste Stencil Design Spreadsheetsmtdrkd100% (1)

- Can Nano Coatings Really Improve Stencil PerformanceDocument56 pagesCan Nano Coatings Really Improve Stencil Performanceachref jebaliNo ratings yet

- LY201503-2 BGA Accessories PricelistDocument5 pagesLY201503-2 BGA Accessories PricelistNebojsaKocicNo ratings yet

- Indium10.8hf Pbfree Solder Paste 99040 A4 r9Document2 pagesIndium10.8hf Pbfree Solder Paste 99040 A4 r9rigoberto solNo ratings yet

- FmeaDocument5 pagesFmeaBuiTrungNo ratings yet

- Philips hts3520Document64 pagesPhilips hts3520gabriel6276No ratings yet